ASTM D6773-22

(Test Method)Standard Test Method for Bulk Solids Using Schulze Ring Shear Tester

Standard Test Method for Bulk Solids Using Schulze Ring Shear Tester

SIGNIFICANCE AND USE

5.1 Reliable, controlled flow of bulk solids from bins and hoppers is essential in almost every industrial facility. Unfortunately, flow stoppages due to arching and ratholing are common. Additional problems include uncontrolled flow (flooding) of powders, segregation of particle mixtures, usable capacity which is significantly less than design capacity, caking and spoilage of bulk solids in stagnant zones, and structural failures.

5.2 By measuring the flow properties of bulk solids, and designing bins and hoppers based on these flow properties, most flow problems can be prevented or eliminated (1).3

5.3 For bulk solids with a significant percentage of particles (typically, one third or more) finer than about 6 mm (1/4 in.), the unconfined yield strength is governed by the fines (−6 mm fraction). For such bulk solids, strength and wall friction tests may be performed on the fine fraction only.

Note 1: The quality of the result produced by this standard is dependent on the competence of personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself ensure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors. Practice D3740 was developed for agencies engaged in the testing or inspection (or both) of soil and rock. As such it is not totally applicable to agencies performing this standard. However, users of this standard should recognize that the framework of Practice D3740 is appropriate for evaluating the quality of an agency performing this standard. Currently there is no known qualifying national authority that inspects agencies that perform this standard.

SCOPE

1.1 This test method covers the apparatus and procedures for measuring the unconfined yield strength of bulk solids during both continuous flow and after storage at rest. In addition, measurements of internal friction, bulk density, and wall friction on various wall surfaces are included.

1.2 This test method covers operation of the manually-controlled Schulze Ring Shear Tester. An automated version of this tester is also available. Its method of testing bulk solids is similar in principle to that described in this test method.

1.3 The most common use of this information is in the design of storage bins and hoppers to prevent flow stoppages due to arching and ratholing, including the slope and smoothness of hopper walls to provide mass flow. Parameters for structural design of such equipment may also be derived from this data. Another application is the measurement of the flowability of bulk solids, for example, for comparison of different products or optimization.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.4.1 The procedures used to specify how data are collected/recorded or calculated in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives: and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measure are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the respons...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6773 − 22

Standard Test Method for

1

Bulk Solids Using Schulze Ring Shear Tester

This standard is issued under the fixed designation D6773; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

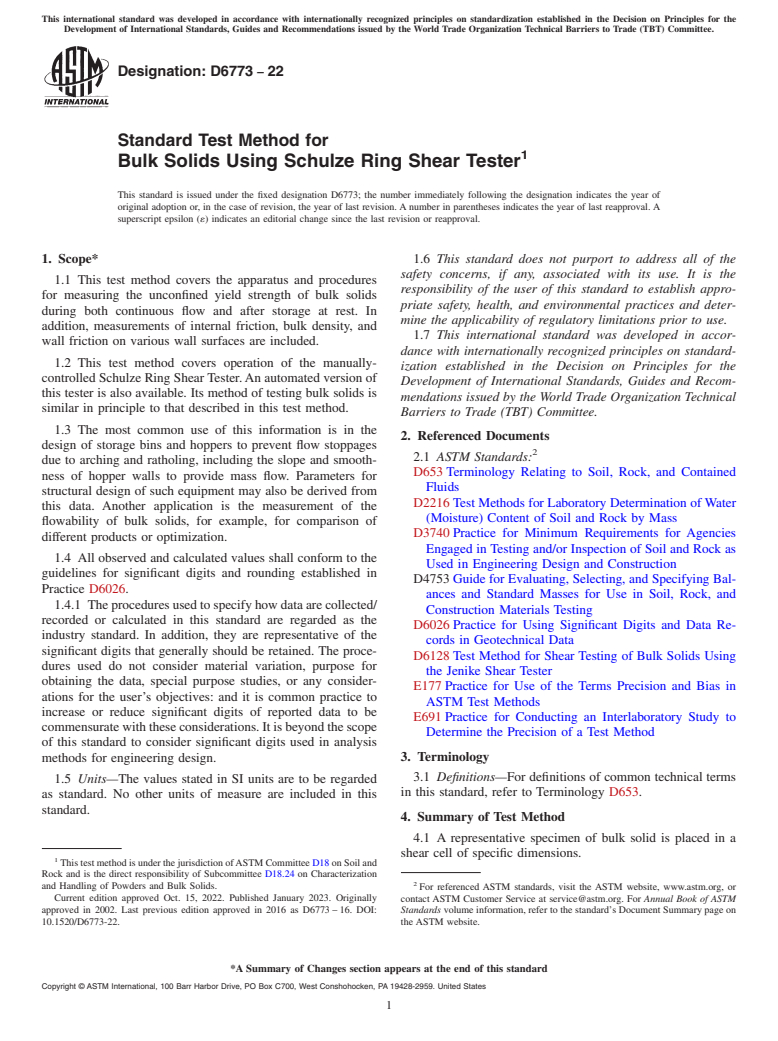

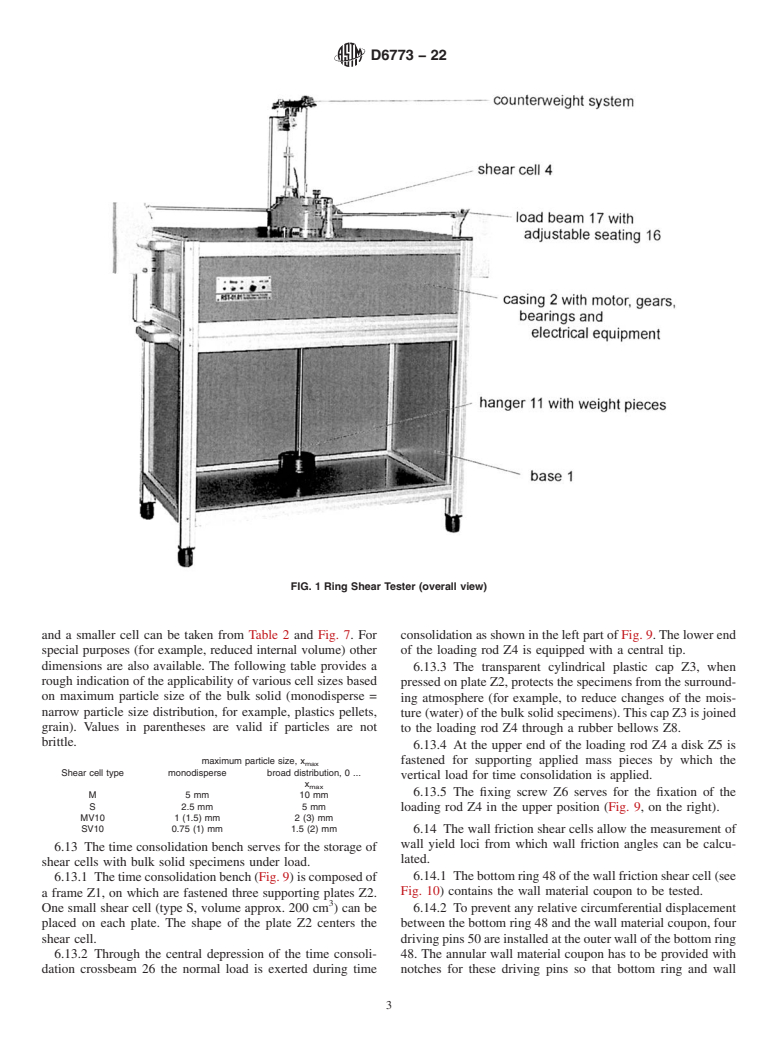

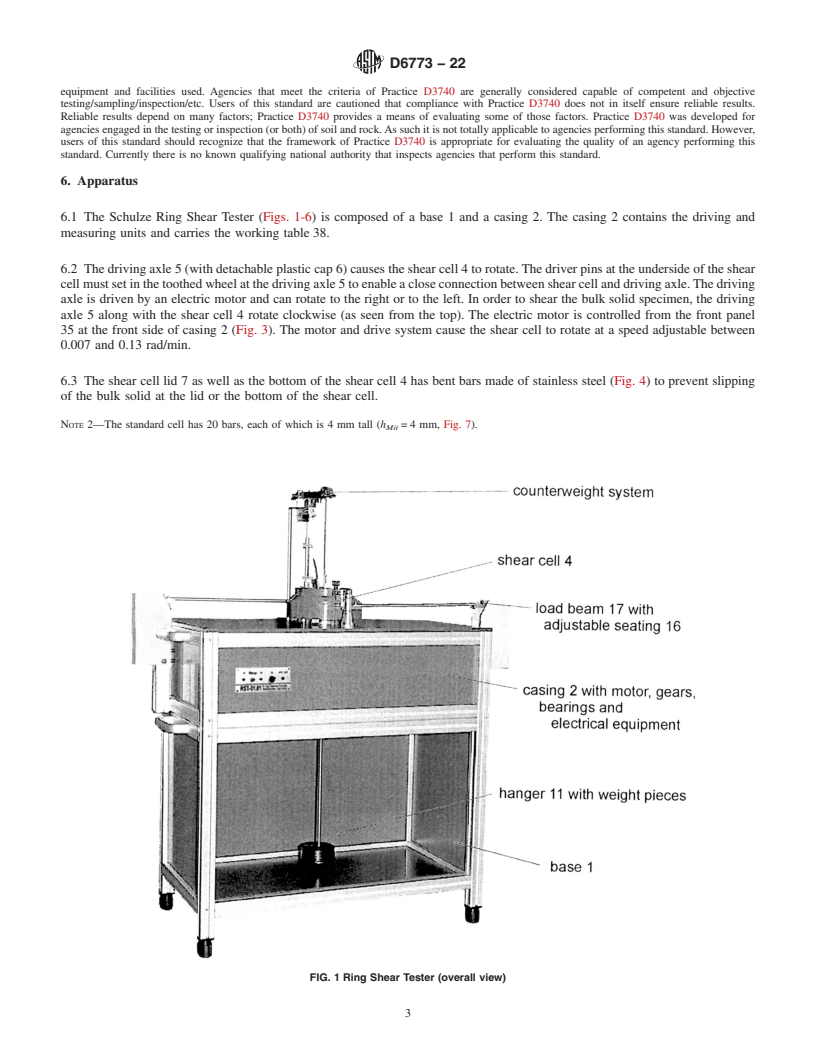

1. Scope* 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the apparatus and procedures

responsibility of the user of this standard to establish appro-

for measuring the unconfined yield strength of bulk solids

priate safety, health, and environmental practices and deter-

during both continuous flow and after storage at rest. In

mine the applicability of regulatory limitations prior to use.

addition, measurements of internal friction, bulk density, and

1.7 This international standard was developed in accor-

wall friction on various wall surfaces are included.

dance with internationally recognized principles on standard-

1.2 This test method covers operation of the manually-

ization established in the Decision on Principles for the

controlledSchulzeRingShearTester.Anautomatedversionof

Development of International Standards, Guides and Recom-

this tester is also available. Its method of testing bulk solids is

mendations issued by the World Trade Organization Technical

similar in principle to that described in this test method.

Barriers to Trade (TBT) Committee.

1.3 The most common use of this information is in the

2. Referenced Documents

design of storage bins and hoppers to prevent flow stoppages

2

2.1 ASTM Standards:

due to arching and ratholing, including the slope and smooth-

D653Terminology Relating to Soil, Rock, and Contained

ness of hopper walls to provide mass flow. Parameters for

Fluids

structural design of such equipment may also be derived from

D2216Test Methods for Laboratory Determination ofWater

this data. Another application is the measurement of the

(Moisture) Content of Soil and Rock by Mass

flowability of bulk solids, for example, for comparison of

D3740Practice for Minimum Requirements for Agencies

different products or optimization.

Engaged in Testing and/or Inspection of Soil and Rock as

1.4 All observed and calculated values shall conform to the

Used in Engineering Design and Construction

guidelines for significant digits and rounding established in

D4753Guide for Evaluating, Selecting, and Specifying Bal-

Practice D6026.

ances and Standard Masses for Use in Soil, Rock, and

1.4.1 Theproceduresusedtospecifyhowdataarecollected/

Construction Materials Testing

recorded or calculated in this standard are regarded as the

D6026Practice for Using Significant Digits and Data Re-

industry standard. In addition, they are representative of the

cords in Geotechnical Data

significant digits that generally should be retained. The proce-

D6128Test Method for Shear Testing of Bulk Solids Using

dures used do not consider material variation, purpose for

the Jenike Shear Tester

obtaining the data, special purpose studies, or any consider-

E177Practice for Use of the Terms Precision and Bias in

ations for the user’s objectives: and it is common practice to

ASTM Test Methods

increase or reduce significant digits of reported data to be

E691Practice for Conducting an Interlaboratory Study to

commensuratewiththeseconsiderations.Itisbeyondthescope

Determine the Precision of a Test Method

of this standard to consider significant digits used in analysis

methods for engineering design. 3. Terminology

3.1 Definitions—For definitions of common technical terms

1.5 Units—The values stated in SI units are to be regarded

in this standard, refer to Terminology D653.

as standard. No other units of measure are included in this

standard.

4. Summary of Test Method

4.1 A representative specimen of bulk solid is placed in a

shear cell of specific dimensions.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

2

and Handling of Powders and Bulk Solids. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 15, 2022. Published January 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2016 as D6773–16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6773-22. the ASTM website.

*A Summary of Changes section appears at

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6773 − 16 D6773 − 22

Standard Test Method for

1

Bulk Solids Using Schulze Ring Shear Tester

This standard is issued under the fixed designation D6773; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the apparatus and procedures for measuring the unconfined yield strength of bulk solids during both

continuous flow and after storage at rest. In addition, measurements of internal friction, bulk density, and wall friction on various

wall surfaces are included.

1.2 This test method covers operation of the manually-controlled Schulze Ring Shear Tester. An automated version of this tester

is also available. Its method of testing bulk solids is similar in principle to that described in this test method.

1.3 The most common use of this information is in the design of storage bins and hoppers to prevent flow stoppages due to arching

and ratholing, including the slope and smoothness of hopper walls to provide mass flow. Parameters for structural design of such

equipment may also be derived from this data. Another application is the measurement of the flowability of bulk solids, for

example, for comparison of different products or optimization.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice

D6026.

1.4.1 The procedures used to specify how data are collected/recorded or calculated in this standard are regarded as the industry

standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not

consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives:

and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations.

It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measure are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.24 on Characterization and

Handling of Powders and Bulk Solids.

Current edition approved Feb. 1, 2016Oct. 15, 2022. Published March 2016January 2023. Originally approved in 2002. Last previous edition approved in 20082016 as

D6773 – 08.D6773 – 16. DOI: 10.1520/D6773-16.10.1520/D6773-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6773 − 22

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D2216 Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D4753 Guide for Evaluating, Selecting, and Specifying Balances and Standard Masses for Use in Soil, Rock, and Construction

Materials Testing

D6026 Practice for Using Significant Digits and Data Records in Geotechnical Data

D6128 Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Tester

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—For commo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.