ASTM D5249-10(2021)

(Specification)Standard Specification for Backer Material for Use with Cold- and Hot-Applied Joint Sealants in Portland Cement Concrete and Asphalt Joints

Standard Specification for Backer Material for Use with Cold- and Hot-Applied Joint Sealants in Portland Cement Concrete and Asphalt Joints

ABSTRACT

This specification covers backer material, either in rod or strip form, for use with cold- and hot-applied joint sealant in portland-cement concrete or asphalt-pavement joints. Sealant backer material is available in three types: Type I, Type II, and Type III, and serves one or more of the following purposes: (1) limits the amount and depth of sealant applied to a joint, (2) acts as a barrier interface to prevent backside adhesion (bondbreaker), and (3) provides a form to assist the sealant in developing a shape factor. The material shall be easily compressed and installed in the joint reservoir and shall be heat resistant when used with hot-applied sealants. Physical properties of the material shall conform to the specified requirements for (1) density, (2) tensile strength, (3) water absorption, (3) compression deflection force, (4) compression recovery, (5) heat resistance, and (6) maximum shrinkage. The test specimen, test procedure, apparatus, and calculations for the physical properties enumerated are detailed.

SCOPE

1.1 This specification covers backer material for cold- and hot-applied joint sealant for use in portland cement concrete or asphalt pavement joints.

1.2 This specification establishes basic requirements for sealant backer material, either in rod or strip form, that can withstand the temperature of hot- or cold-applied sealants without excessive deformation.

1.3 Sealant backer material serves one or more of the following purposes:

1.3.1 Limits the amount and depth of sealant applied to a joint,

1.3.2 Acts as a barrier interface to prevent backside adhesion (bond breaker), and

1.3.3 Provides a form to assist the sealant in developing a shape factor.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information purposes only.

1.5 The following safety hazards caveat pertains only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5249 −10 (Reapproved 2021)

Standard Specification for

Backer Material for Use with Cold- and Hot-Applied Joint

Sealants in Portland Cement Concrete and Asphalt Joints

This standard is issued under the fixed designation D5249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers backer material for cold- and

C670 Practice for Preparing Precision and Bias Statements

hot-applied joint sealant for use in portland cement concrete or

for Test Methods for Construction Materials

asphalt pavement joints.

C1016 Test Method for Determination of Water Absorption

1.2 This specification establishes basic requirements for

of Sealant Backing (Joint Filler) Material

sealant backer material, either in rod or strip form, that can

C1253 Test Method for Determining the Outgassing Poten-

withstand the temperature of hot- or cold-applied sealants

tial of Sealant Backing

without excessive deformation.

D545 Test Methods for Preformed Expansion Joint Fillers

for Concrete Construction (Nonextruding and Resilient

1.3 Sealant backer material serves one or more of the

Types)

following purposes:

D1622 Test Method for Apparent Density of Rigid Cellular

1.3.1 Limits the amount and depth of sealant applied to a

Plastics

joint,

D1623 Test Method for Tensile and Tensile Adhesion Prop-

1.3.2 Acts as a barrier interface to prevent backside adhe-

erties of Rigid Cellular Plastics

sion (bond breaker), and

D5535 Terminology Relating to Formed-in-Place Sealants

1.3.3 Provides a form to assist the sealant in developing a

for Joints and Cracks in Pavements (Withdrawn 2009)

shape factor. E1 Specification for ASTM Liquid-in-Glass Thermometers

E220 Test Method for Calibration of Thermocouples By

1.4 The values stated in inch-pound units are to be regarded

Comparison Techniques

as the standard. The values in parentheses are for information

purposes only.

3. Terminology

1.5 The following safety hazards caveat pertains only to the

3.1 For definitions, refer to Terminology D5535.

test methods described in this specification. This standard does

not purport to address all of the safety concerns, if any, 4. Classification

associated with its use. It is the responsibility of the user of this

4.1 Sealant backer material is available in three types:

standard to establish appropriate safety, health, and environ-

4.1.1 Type 1, shall be round rods of various diameters

mental practices and determine the applicability of regulatory

intended for use with cold- and hot-applied sealants.

limitations prior to use.

4.1.2 Type 2, shall be sheets or strips of various thicknesses,

1.6 This international standard was developed in accor-

laminated or skived by the manufacturer but capable of being

dance with internationally recognized principles on standard-

field laminated and used with cold- and hot-applied sealants.

ization established in the Decision on Principles for the

4.1.3 Type 3, shall be round rods of various diameters

Development of International Standards, Guides and Recom-

limited for use with cold-applied sealants.

mendations issued by the World Trade Organization Technical

4.2 Type 1 and Type 3 rod materials are intended for use

Barriers to Trade (TBT) Committee.

primarily where there is a reservoir, either already existing or

1 2

This specification is under the jurisdiction of ASTM Committee D04 on Road For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Paving Materials and is the direct responsibility of Subcommittee D04.33 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Formed In-Place Sealants for Joints and Cracks in Pavements. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2021. Published May 2021. Originally the ASTM website.

approved in 1992. Last previous edition approved in 2016 as D5249 – 10 (2016). The last approved version of this historical standard is referenced on

DOI: 10.1520/D5249-10R21. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5249−10 (2021)

formed, such as a contraction joint, where the rod will limit the where:

sealant depth and prevent the sealant from bonding to the

WA = water absorption by volume, %,

bottom of the joint reservoir (bond breaker) thus eliminating

W = weightofwaterabsorbedfromtestsmadeaccordingto

bottom-side adhesion.

Test Methods D545,g,and

t = thickness of 4 in. by 4 in. specimen, inches.

4.3 Type 2 strip material is intended primarily for use where

there is an opening the full depth of the pavement, such as an 9.1.2 For the purposes of this calculation,1gof water

expansionjointforwhichitisdesirabletohaveafillermaterial

occupies 0.061 in. at test conditions.

completely fill the opening and prevent or minimize the

9.2 Density—Tests for density of Types 1 and 3 materials

accumulation of water or incompressible materials below the

shallbemadeinaccordancewithTestMethodD1622.Testsfor

sealant.

density of Type 2 material shall be made in accordance with

Test Methods D545.

5. Ordering Information

9.3 Tensile Strength—Tests for tensile strength of Types 1

5.1 Types1,2,and3backermaterialareavailableinarange

and 3 materials shall be made in accordance with Test Method

of sizes, lengths, and diameters; they are available on reels, in

D1623.

coils, or in straight lengths. Consult the manufacturer for

9.4 Compression Deflection and Recovery—Type 2 material

information on how to order.

shall be tested in accordance withTest Methods D545.Types 1

5.2 Backer material must be ordered by diameter or size in

and3materialsshallbetestedinaccordancewiththefollowing

relation to the joint opening, usually 25 to 35 % larger than the

procedure.

joint width.

9.4.1 Significance and Use—This test method covers a

procedure for measuring the force necessary to compress the

6. Materials

backer material, and the percentage recovery of original

6.1 Sealant backer material shall be easily compressed and

dimensions after removal of the compression load.

installed in the joint reservoir. This material shall be heat

9.4.2 Apparatus:

resistant when used with hot-applied sealants.

9.4.2.1 An apparatus shall be provided having a flat com-

pression plate larger than the specimen to be tested, connected

7. Physical Properties

to a force measuring device, and mounted in such a manner

7.1 Physical properties of the sealant backer material shall

that the specimen can be deflected (compressed) at a speed of

conform to the requirements of Table 1.

0.5 to 2 in./min. The apparatus shall be arranged to support the

specimen on a level horizontal plate. The apparatus shall be

8. Workmanship, Finish, and Appearance

capable of measuring the distance between the movable plate

8.1 The product shall be clean and free of scale or foreign

and the stationary plate.

matter, oil, or water which could wipe off on a joint sidewall

9.4.2.2 Calipers, capable of measuring 0.001 in.

and interfere with the proper cure or adhesion of the sealant.

9.4.3 Test Specimens:

9.4.3.1 Test specimens shall be 6 6 0.125 in. lengths of the

9. Test Methods

backer material.

9.1 Water Absorption—Tests for water absorption of the

9.4.3.2 Each test requires a minimum effective area of

Types 1 and 3 backing material shall be made in accordance

3.0 in. . When the effective area of a single length is less than

withTestMethodC1016,ProcedureB.Type2materialshallbe

3 in. , multiple lengths shall be used in a single test. When

tested in accordance with Test Methods D545.

rod-shaped backer material is less than ⁄4 in. in diameter,

9.1.1 For Type 2 material:

multiple lengths are required for each test (see Table 2).

9.4.4 Number of Test Specimens—Test three specimens for

W 3100

WA 5 (1)

each sample. The values reported shall be the mean of those

262t

observed.

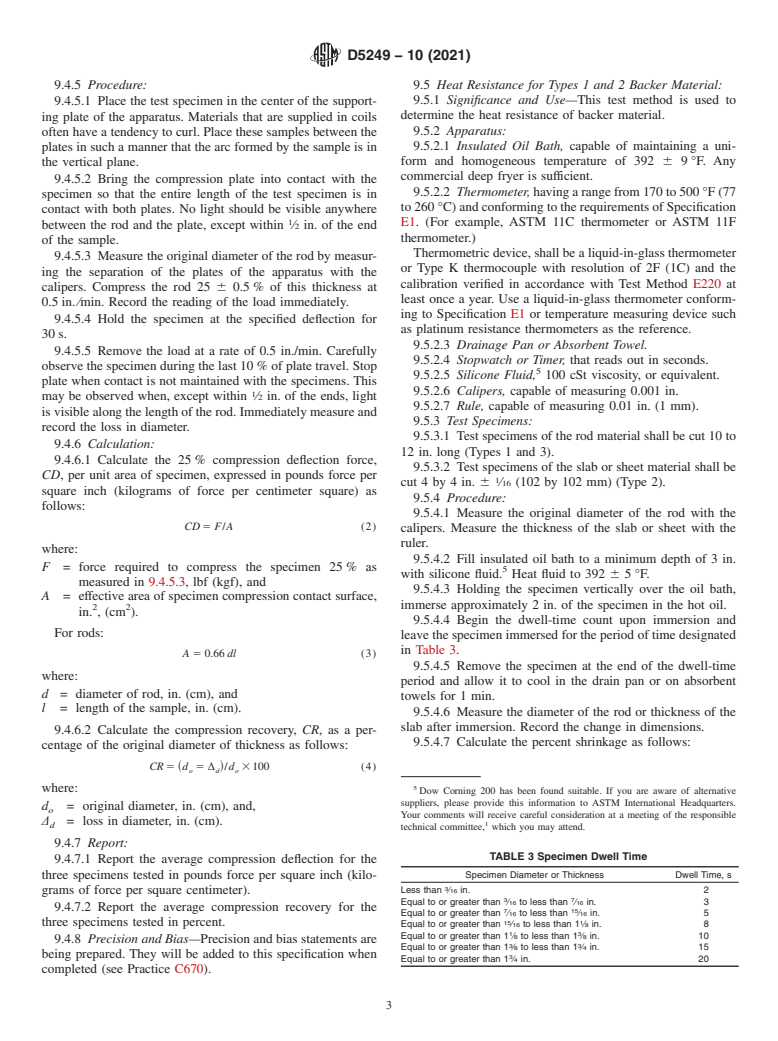

TABLE 1 Physical Property Requirements BrownandSharpModel579-1orequivalenthasbeenfoundsuitable.Ifyouare

aware of alternative suppliers, please provide this information to ASTM Interna-

Property Type 1 Type 2 Type 3

tional Headquarters.Your comments will receive careful consideration at a meeting

3 3

Density, lb/ft (kg/m ), max 6 (96.1) 4 (64.1) 6 (96.1)

of the responsible technical committee, which you may attend.

Tensile strength, psi (kgf/cm ), 20 (1.41) N/A 20 (1.41)

min

Water absorption, by volume, 0.5 0.5 0.5 TABLE 2 Multiple Specimen Requirements for Rod-Shaped

%, max

Backer Materials for Compression Recovery Testing

25 % Compression deflection 15 (1.06) 15 (1.06) 15 (1.06)

2 Specimens Required for Each

force, psi (kgf/cm ), max

Rod Diameter

Test

Compression recovery, %, min 90 90 90

Heat resistance, °F 392 ± 5 392± 5 N/A ⁄4 in. or larger 1

3 5

°C 200 ± 2.8 200 ± 2.8 N/A ⁄8 to ⁄8 in. 2

Maximum shrinkage, % 10 % 10 % N/A < ⁄8 in. 3

D5249−10 (2021)

9.4.5 Procedure: 9.5 Heat Resistance for Types

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.