ASTM D545-08

(Test Method)Standard Test Methods for Preformed Expansion Joint Fillers for Concrete Construction (Nonextruding and Resilient Types)

Standard Test Methods for Preformed Expansion Joint Fillers for Concrete Construction (Nonextruding and Resilient Types)

SIGNIFICANCE AND USE

The compression resistance perpendicular to the faces, the resistance to the extrusion during compression, and the ability to recover after release of the load are indicative of a joint filler's ability to fill continuously a concrete expansion joint and thereby prevent damage that might otherwise occur during thermal expansion. The asphalt content is a measure of the fiber-type joint filler's durability and life expectancy. In the case of cork-type fillers, the resistance to water absorption and resistance to boiling hydrochloric acid are relative measures of durability and life expectancy.

SCOPE

1.1 These test methods cover the physical properties associated with preformed expansion joint fillers. The test methods include:

PropertySection Expansion in Boiling Water7.1 Recovery and Compression7.2 Extrusion7.3 Boiling in Hydrochloric Acid7.4 Asphalt Content7.5 Water Absorption7.6 Density7.7

Note 1—Specific test methods are applicable only to certain types of joint fillers, as stated herein.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D545 − 08

StandardTest Methods for

Preformed Expansion Joint Fillers for Concrete

1

Construction (Nonextruding and Resilient Types)

This standard is issued under the fixed designation D545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 These test methods cover the physical properties asso-

E691Practice for Conducting an Interlaboratory Study to

ciated with preformed expansion joint fillers.The test methods

Determine the Precision of a Test Method

include:

Property Section

3. Significance and Use

Expansion in Boiling Water 7.1

Recovery and Compression 7.2

3.1 The compression resistance perpendicular to the faces,

Extrusion 7.3

Boiling in Hydrochloric Acid 7.4

the resistance to the extrusion during compression, and the

Asphalt Content 7.5

ability to recover after release of the load are indicative of a

Water Absorption 7.6

joint filler’s ability to fill continuously a concrete expansion

Density 7.7

joint and thereby prevent damage that might otherwise occur

NOTE 1—Specific test methods are applicable only to certain types of

during thermal expansion. The asphalt content is a measure of

joint fillers, as stated herein.

thefiber-typejointfiller’sdurabilityandlifeexpectancy.Inthe

1.2 The values stated in inch-pound units are to be regarded

case of cork-type fillers, the resistance to water absorption and

as standard. The values given in parentheses are mathematical

resistance to boiling hydrochloric acid are relative measures of

conversions to SI units that are provided for information only

durability and life expectancy.

and are not considered standard.

1.3 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 Balance, for weighing joint fillers capable of weighing

responsibility of the user of this standard to consult and

test specimens within 0.01 g.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4.2 Mechanical Convection Oven, capable of maintaining

220 6 5.0°F (104 6 3°C).

2. Referenced Documents

4.3 Desiccator, of sufficient size to accommodate the test

2

2.1 ASTM Standards:

specimens.

D147Methods of Testing Bituminous Mastics (Withdrawn

3

4.4 Vernier Caliper, for measuring length and width of

1984)

specimens with accuracy within 60.01 in. (0.25 mm).

D1037Test Methods for Evaluating Properties of Wood-

Base Fiber and Particle Panel Materials

4.5 Dial Micrometer, or other measuring device, graduated

to read in 0.001-in. (0.02-mm) units.

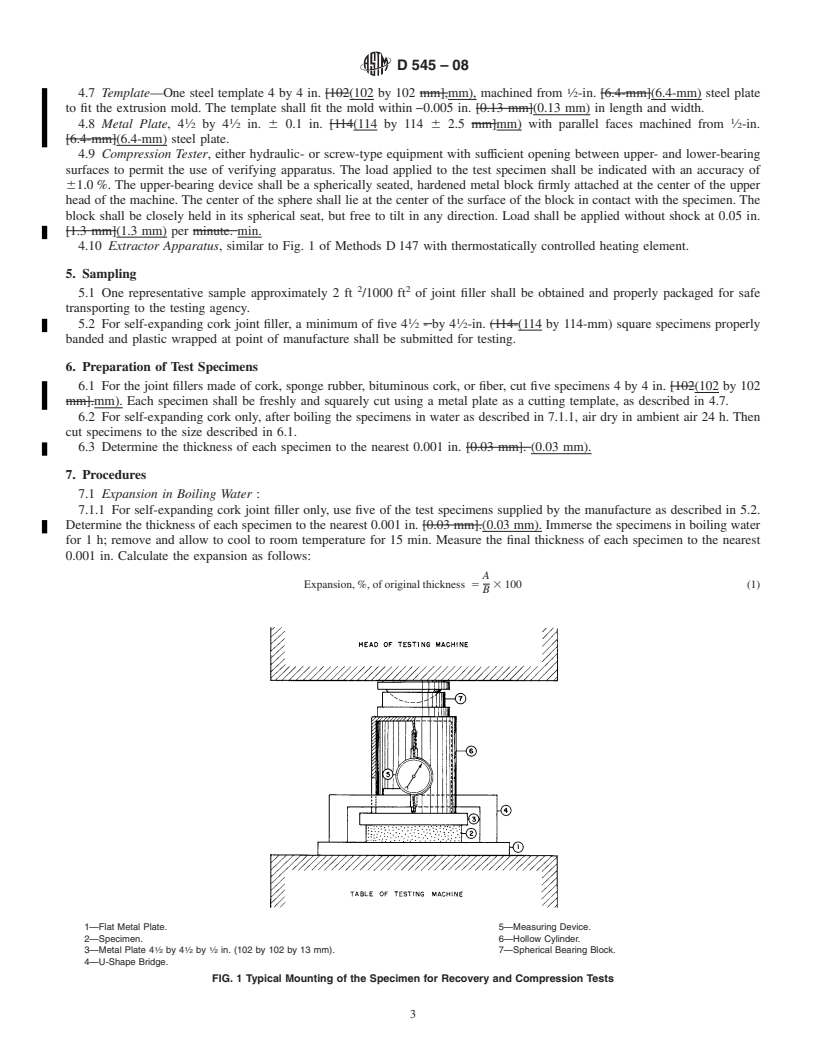

4.6 Extrusion Mold—Three-sided steel mold to confine

1

These methods are under the jurisdiction of ASTM Committee D04 on Road

lateral movement of specimens under compression to one side

and Paving Materials and are the direct responsibility of Subcommittee D04.34 on

Preformed Joint Fillers, Sealers and Sealing Systems.

only. Interior dimensions shall be 4 by 4 in. (102 by 102 mm)

Current edition approved July 1, 2008. Published August 2008. Originally

with permissible variations in length and width of 60.015 in.

approved in 1939. Last previous edition approved in 2005 as D545–99(2005).

(0.38 mm). Mold sides shall be of such height as to extend at

DOI: 10.1520/D0545-08.

2

least 0.5 in. (13 mm) above the test specimens.Atypical mold

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

can be made from a steel base ⁄2by4by4 6 0.015 in. (13 by

Standards volume information, refer to the standard’s Document Summary page on

1

102 by 102 6 0.3 mm) and three bolted steel side plates ⁄4 in.

the ASTM website.

1

3

(6.35 mm) thick, extending approximately 1 ⁄2 in. (38 mm)

The last approved version of this historical standard is referenced on

www.astm.org. above the base plate, thus forming a three-sided open-top box.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D545 − 08

4.7 Template—One steel template 4 by 4 in. (102 by 102 6. Preparation of Test Specimens

1

mm), machined from ⁄2-in. (6.4-mm) steel plate to fit the

6.1 For the joint fillers made of cork, sponge rubber,

extrusion mold. The template shall fit the mold within−0.005

bituminouscork,orfiber,cutfivespecimens4by4in.(102by

in. (0.13 mm) in length and width.

102 mm). Each specimen shall

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D545–99 (Reapproved 2005) Designation:D545–08

Standard Test Methods for

Preformed Expansion Joint Fillers for Concrete

1

Construction (Nonextruding and Resilient Types)

This standard is issued under the fixed designation D545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thesetestmethodscoverthephysicalpropertiesassociatedwithpreformedexpansionjointfillers.Thetestmethodsinclude:

Property Section

Asphalt content 7.5 Expan-

sion in

Boiling Wa-

ter

Boiling in hydrochloric acid 7.4 Recov-

ery and

Compres-

sion

Compression 7.2 Extru-

sion

Density 7.7 Boiling

in Hydro-

chloric Acid

Expansion in boiling water 7.1 Asphalt

Content

Extrusion 7.3 Water

Absorption

Recovery 7.2

Water absorption 7.6Density

1.2The values stated in inch-pound are to be regarded as standard.

NOTE 1—Specific test methods are applicable only to certain types of joint fillers, as stated herein.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D147MethodsofTestingBituminousMastics,Grouts,andLikeMixtures Discontinued1985;MethodsofTestingBituminous

Mastics

D1037Test Methods for Evaluating the Properties of Wood-Base Fiber and Particle Panel Materials Test Methods for

Evaluating Properties of Wood-Base Fiber and Particle Panel Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Significance and Use

3.1 The compression resistance perpendicular to the faces, the resistance to the extrusion during compression, and the ability

1

ThesemethodsareunderthejurisdictionofASTMCommitteeD04onRoadandPavingMaterialsandarethedirectresponsibilityofSubcommitteeD04.34onPreformed

Joint Fillers, Sealers,Sealers and Sealing Systems.Systems.

Current edition approved July 15, 2005.1, 2008. Published August 2005.2008. Originally approved in 1939. Last previous edition approved in 19992005as

D545–99(2005).

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D545–08

torecoverafterreleaseoftheloadareindicativeofajointfiller’sabilitytofillcontinuouslyaconcreteexpansionjointandthereby

prevent damage that might otherwise occur during thermal expansion. The asphalt content is a measure of the fiber-type joint

filler’s durability and life expectancy. In the case of cork-type fillers, the resistance to water absorption and resistance to boiling

hydrochloric acid are relative measures of durability and life expectancy.

4. Apparatus

4.1 Balance, for weighing joint fillers capable of weighing test specimens within 0.01 g.

4.2 Mechanical Convection Oven , capable of maintaining 220 6 5.0°F [104(104 6 3°C]. 3°C).

4.3 Desiccator, of sufficient size to accommodate the test specimens.

4.4 Vernier Caliper, for measuring length and width of specimens with accuracy within 60.01 in. [0.25 mm]. (0.25 mm).

4.5 Dial Micrometer, or other measuring device, graduated to read in 0.001-in. [0.02-mm](0.02-mm) units.

4.6 Extrusion Mold— Three-sided steel mold to confine lateral movement of specimens under compression to one side only.

Interior dimensions shall be 4 by 4 in. [102(102 by 102 mm]mm) with permissible variations in length and width of 60.015 in.

[0.38 mm].(0.38 mm). Mold sides shall be of such height as to extend at least 0.5 in. [13 mm](13 mm) above the test specimens.

1

A typical mold can be made from a steel base ⁄2by4by4 6 0.015 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.