ASTM C670-10

(Practice)Standard Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

Standard Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

ABSTRACT

This practice provides guidance in preparing precision and bias statements for ASTM test methods pertaining to construction materials. Test method shall conform to the maximum acceptable range of individual measurements. In order to be valid the indexes of precision to be included in the precision statement as guides for the operator must be based on estimates of the precision of the test method obtained from a statistically designed inter-laboratory series of tests. This series of tests must involve a sufficient number of laboratories, materials, and replicate measurements so that the results obtained provide reliable estimates of the true precision characteristic of the test method. The procedures described in this practice are based on the assumption that the proper estimates of precision have already been obtained. In any test method, tolerances are placed on the accuracy of measuring equipment. All tests made with a given set of equipment which has an error within the permitted tolerance will produce results with a small consistent bias, but that bias is not inherent in the test method and is not included in the bias statement for the test method. There are two conditions which permit the bias of a test method to be estimated: a standard reference sample of known value has been tested by the test method, and the test method has been applied to a sample which has been compounded in such a manner that the true value of the property being measured is known, such as may be the case, for example, in a test for cement content of concrete.

SCOPE

1.1 This practice supplements Practice E177, in order to provide guidance in preparing precision and bias statements for ASTM test methods pertaining to certain construction materials (Note 1). Recommended forms for precision and bias statements are included. A discussion of the purpose and significance of these statements for the users of those test methods is also provided.

Note 1—Although under the jurisdiction of Committee C09, this practice was developed jointly by Committees C01, D04, and C09, and has been endorsed by all three committees. It has subsequently been adopted for use by Committee D18.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C670 − 10

StandardPractice for

Preparing Precision and Bias Statements for Test Methods

1

for Construction Materials

This standard is issued under the fixed designation C670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* limit” (abbreviated (1s)) is used in Practice E177 to denote the

estimateofthestandarddeviationorsigmathatischaracteristic

1.1 This practice supplements Practice E177, in order to

of the total statistical population. The one-sigma limit is an

provideguidanceinpreparingprecisionandbiasstatementsfor

indication of the variability (as measured by the deviations

ASTM test methods pertaining to certain construction materi-

above and below the average) of a large group of individual

als (Note 1). Recommended forms for precision and bias

test results obtained under similar conditions.

statements are included. A discussion of the purpose and

3.2.1 single-operator one-sigma limit—the one-sigma limit

significance of these statements for the users of those test

for single-operator precision is a quantitative estimate of the

methods is also provided.

variability of a large group of individual test results when the

NOTE 1—Although under the jurisdiction of Committee C09, this

testshavebeenmadeonthesamematerialbyasingleoperator

practice was developed jointly by Committees C01, D04, and C09, and

using the same apparatus in the same laboratory over a

has been endorsed by all three committees. It has subsequently been

relatively short period of time. This statistic is the basic one

adopted for use by Committee D18.

usedtocalculatethesingle-operatorindexofprecisiongivenin

2. Referenced Documents

the precision statement for guidance of the operator.

2

3.2.2 multilaboratory one-sigma limit—the one-sigma limit

2.1 ASTM Standards:

for multilaboratory precision is a quantitative estimate of the

C109/C109MTest Method for Compressive Strength of

variability of a large group of individual test results when each

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

testhasbeenmadeinadifferentlaboratoryandeveryefforthas

Specimens)

been made to make the test portions of the material as nearly

C802Practice for Conducting an Interlaboratory Test Pro-

identical as possible. Under normal circumstances the esti-

gram to Determine the Precision of Test Methods for

mates of one-sigma limit for multilaboratory precision are

Construction Materials

larger than those for single-operator precision, because differ-

E177Practice for Use of the Terms Precision and Bias in

entoperatorsanddifferentapparatusarebeingusedindifferent

ASTM Test Methods

laboratories for which the environment may be different.

3. Terminology 3.2.3 one-sigma limit in percent (1s%)—in some cases the

coefficient of variation is used in place of the standard

3.1 Definitions of Terms Specific to This Standard:

deviation as the fundamental statistic. This statistic is termed

3.2 one-sigma limit (1s)—the fundamental statistic underly-

the“one-sigmalimitinpercent”(abbreviated(1s%))andisthe

ing all indexes of precision is the standard deviation of the

appropriate standard deviation (1s) divided by the average of

population of measurements characteristic of the test method

the measurements and expressed as a percent. When it is

when the latter is applied under specifically prescribed condi-

appropriatetouse(1s%)inplaceof(1s)isdiscussedinSection

tions (a given system of causes). The terminology “one-sigma

6.

3.3 Acceptable Range of Results:

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

3.3.1 acceptable difference between two results—the “dif-

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.94

ference two-sigma limit (d2s)” or “difference two-sigma limit

on Evaluation of Data (Joint C09 and C01).

in percent (d2s%),” as defined in Practice E177, has been

Current edition approved Oct. 1, 2010. Published November 2010. Originally

selectedastheappropriateindexofprecisioninmostprecision

approved in 1971. Last previous edition approved in 2003 as C670-03. DOI:

10.1520/C0670-10.

statements. These indexes indicate a maximum acceptable

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

difference between two results obtained on test portions of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

same material under the applicable system of causes described

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in 4.1.1 and 4.1.

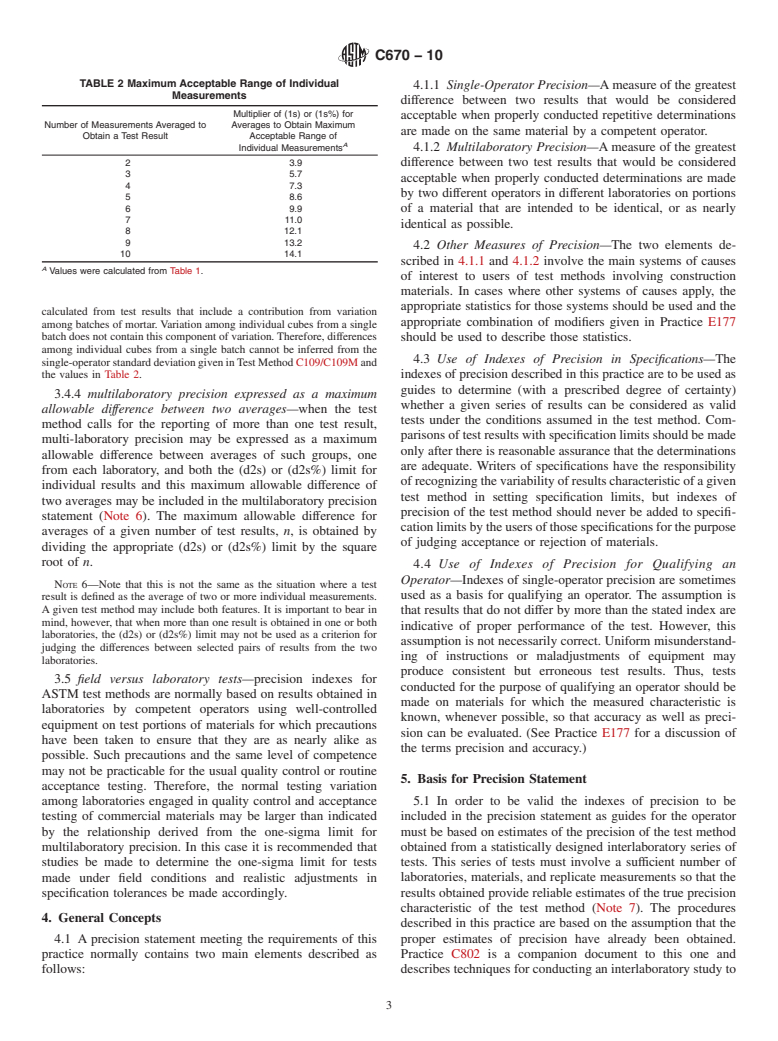

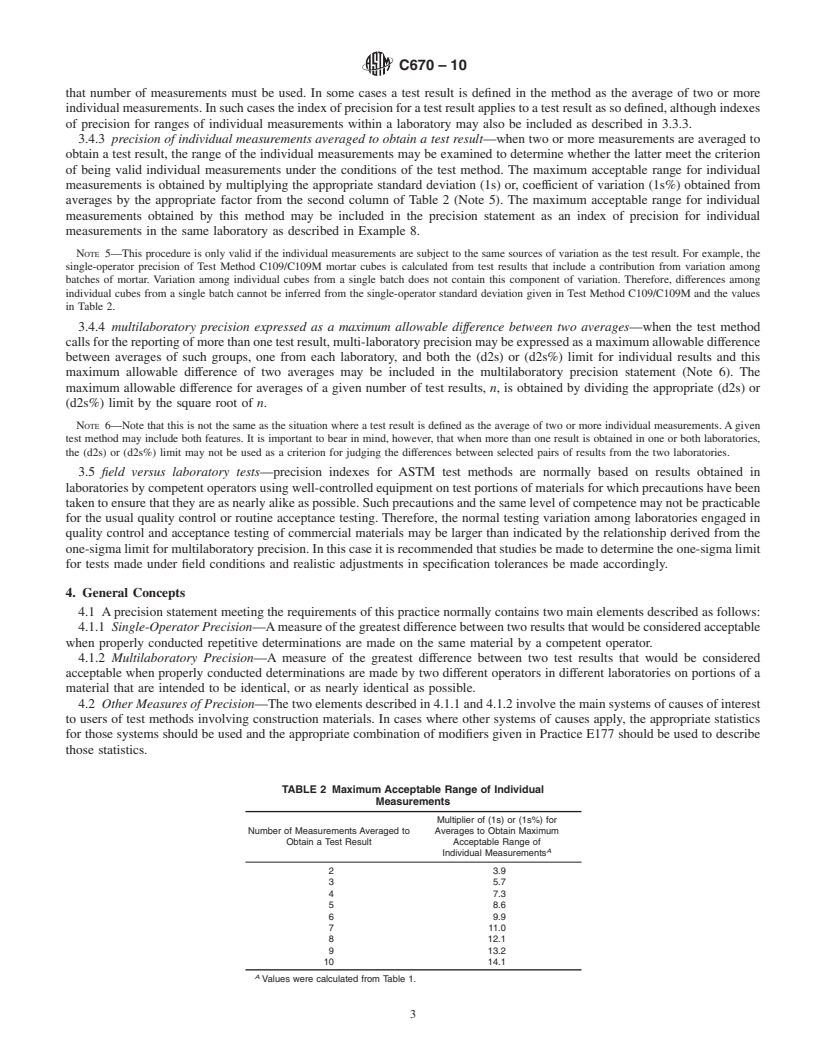

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C670–03 Designation:C670–10

Standard Practice for

Preparing Precision and Bias Statements for Test Methods

1

for Construction Materials

This standard is issued under the fixed designation C670; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 ThispracticesupplementsPracticeE177,inordertoprovideguidanceinpreparingprecisionandbiasstatementsforASTM

test methods pertaining to certain construction materials (Note 1). Recommended forms for precision and bias statements are

included. A discussion of the purpose and significance of these statements for the users of those test methods is also provided.

NOTE 1—AlthoughunderthejurisdictionofCommitteeC-9,C09,thispracticewasdevelopedjointlybyCommitteesC-1,D-4,C01,D04,andC-9,C09,

and has been endorsed by all three committees. It has subsequently been adopted for use by Committee D-18. D18.

2. Referenced Documents

2

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C802 Practice for Conducting an Interlaboratory Test Program to Determine the Precision of Test Methods for Construction

Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.2 one-sigma limit (1s)—the fundamental statistic underlying all indexes of precision is the standard deviation of the

population of measurements characteristic of the test method when the latter is applied under specifically prescribed conditions (a

given system of causes). The terminology “one-sigma limit” (abbreviated (1s)) is used in Practice E177 to denote the estimate of

the standard deviation or sigma that is characteristic of the total statistical population. The one-sigma limit is an indication of the

variability (as measured by the deviations above and below the average) of a large group of individual test results obtained under

similar conditions.

3.2.1 single-operator one-sigma limit—the one-sigma limit for single-operator precision is a quantitative estimate of the

variabilityofalargegroupofindividualtestresultswhenthetestshavebeenmadeonthesamematerialbyasingleoperatorusing

the same apparatus in the same laboratory over a relatively short period of time. This statistic is the basic one used to calculate

the single-operator index of precision given in the precision statement for guidance of the operator.

3.2.2 multilaboratory one-sigma limit—the one-sigma limit for multilaboratory precision is a quantitative estimate of the

variability of a large group of individual test results when each test has been made in a different laboratory and every effort has

been made to make the test portions of the material as nearly identical as possible. Under normal circumstances the estimates of

one-sigma limit for multilaboratory precision are larger than those for single-operator precision, because different operators and

different apparatus are being used in different laboratories for which the environment may be different.

3.2.3 one-sigma limit in percent (1s%)—in some cases the coefficient of variation is used in place of the standard deviation as

the fundamental statistic. This statistic is termed the “one-sigma limit in percent” (abbreviated (1s%)) and is the appropriate

standarddeviation(1s)dividedbytheaverageofthemeasurementsandexpressedasapercent.Whenitisappropriatetouse(1s%)

in place of (1s) is discussed in Section 6.

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee C09.94 on

Evaluation of Data.

Current edition approved Jan. 10, 2003. Published March 2003. Originally approved in 1971. Last previous edition approved in 1996 as C670-96. DOI:

10.1520/C0670-03.on Evaluation of Data (Joint C09 and C01).

Current edition approved Oct. 1, 2010. Published November 2010. Originally approved in 1971. Last previous edition approved in 2003 as C670-03. DOI:

10.1520/C0670-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.