ASTM B797-20

(Test Method)Standard Test Method for Surface Finger-Oxide Penetration Depth and Presence of Interparticle Oxide Networks in Powder Forged (PF) Steel Parts

Standard Test Method for Surface Finger-Oxide Penetration Depth and Presence of Interparticle Oxide Networks in Powder Forged (PF) Steel Parts

SIGNIFICANCE AND USE

5.1 The presence of surface finger-oxide penetration and interparticle oxide networks are two of the properties used to evaluate powder forged steel parts for proper processing. Maximum acceptable depths of penetration of surface finger-oxide penetration and acceptable concentrations of subsurface interparticle oxide networks depend on the component and its service environment.

5.2 Results of tests may be used to qualify parts for shipment.

SCOPE

1.1 This test method covers a metallographic method for determining the maximum depth of surface finger-oxide penetration and the concentration of subsurface interparticle oxide networks in critical areas of powder forged steel parts.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B797 −20

Standard Test Method for

Surface Finger-Oxide Penetration Depth and Presence of

Interparticle Oxide Networks in Powder Forged (PF) Steel

1

Parts

This standard is issued under the fixed designation B797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 surface finger-oxides, n—surface finger-oxides are

surface oxides that follow prior particle boundaries into a

1.1 This test method covers a metallographic method for

powderforgedpartfromthesurfaceandcannotberemovedby

determining the maximum depth of surface finger-oxide pen-

physical means such as rotary tumbling; examples of surface

etration and the concentration of subsurface interparticle oxide

finger-oxides are shown in Fig. 1.

networks in critical areas of powder forged steel parts.

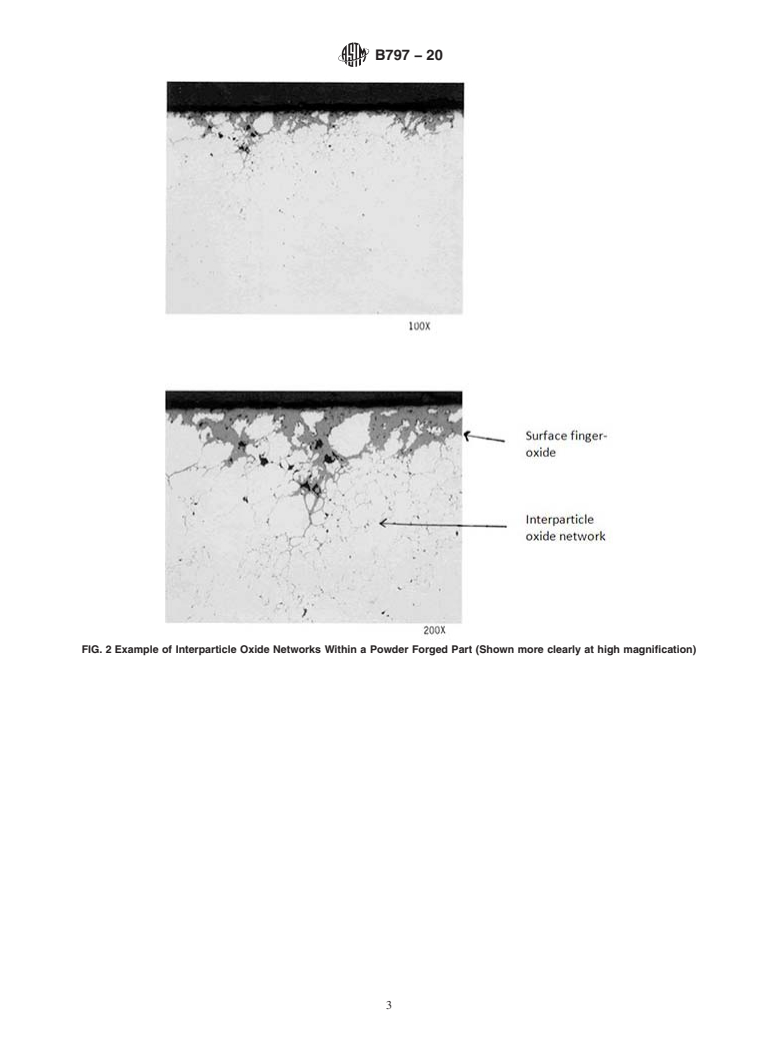

3.1.2 interparticle oxide networks, n—interparticle oxide

1.2 Units—The values stated in SI units are to be regarded

networks are continuous or discontinuous oxides that follow

asstandard.Nootherunitsofmeasurementareincludedinthis

prior particle boundaries in powder forged parts; examples of

standard.

interparticle oxide networks are shown in Fig. 2.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 A section representing both surface and subsurface

priate safety, health, and environmental practices and deter-

regionsofacriticalareaiscutfromthepowderforgedpartand

mine the applicability of regulatory limitations prior to use.

mounted for metallographic grinding and polishing.

1.4 This international standard was developed in accor-

4.2 For surface finger-oxide penetration, the polished and

dance with internationally recognized principles on standard-

unetched sample is examined microscopically at a magnifica-

ization established in the Decision on Principles for the

tion of 400 to 500×. The maximum depth of penetration of

Development of International Standards, Guides and Recom-

surface finger-oxides is measured.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.3 For interparticle oxide network concentration, the pol-

ished and unetched sample is examined microscopically at a

2. Referenced Documents

magnification of 200 to 500× to determine the presence of

2

2.1 ASTM Standards: interparticle oxide networks.

E3Guide for Preparation of Metallographic Specimens

E177Practice for Use of the Terms Precision and Bias in 5. Significance and Use

ASTM Test Methods

5.1 The presence of surface finger-oxide penetration and

E691Practice for Conducting an Interlaboratory Study to

interparticle oxide networks are two of the properties used to

Determine the Precision of a Test Method

evaluate powder forged steel parts for proper processing.

Maximum acceptable depths of penetration of surface finger-

3. Terminology

oxide penetration and acceptable concentrations of subsurface

3.1 Definitions of Terms Specific to This Standard: interparticle oxide networks depend on the component and its

service environment.

5.2 Results of tests may be used to qualify parts for

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal

shipment.

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.11 on Near Full Density Powder Metallurgy Materials.

Current edition approved Oct. 1, 2020. Published October 2020. Originally 6. Apparatus

approved in 1988. Last previous edition approved in 2015 as B797–15. DOI:

6.1 Equipment for the metallographic preparation of test

10.1520/B0797-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or specimens.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 A metallographic microscope permitting observation

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and measurement up to a magnification of 500×.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B797−20

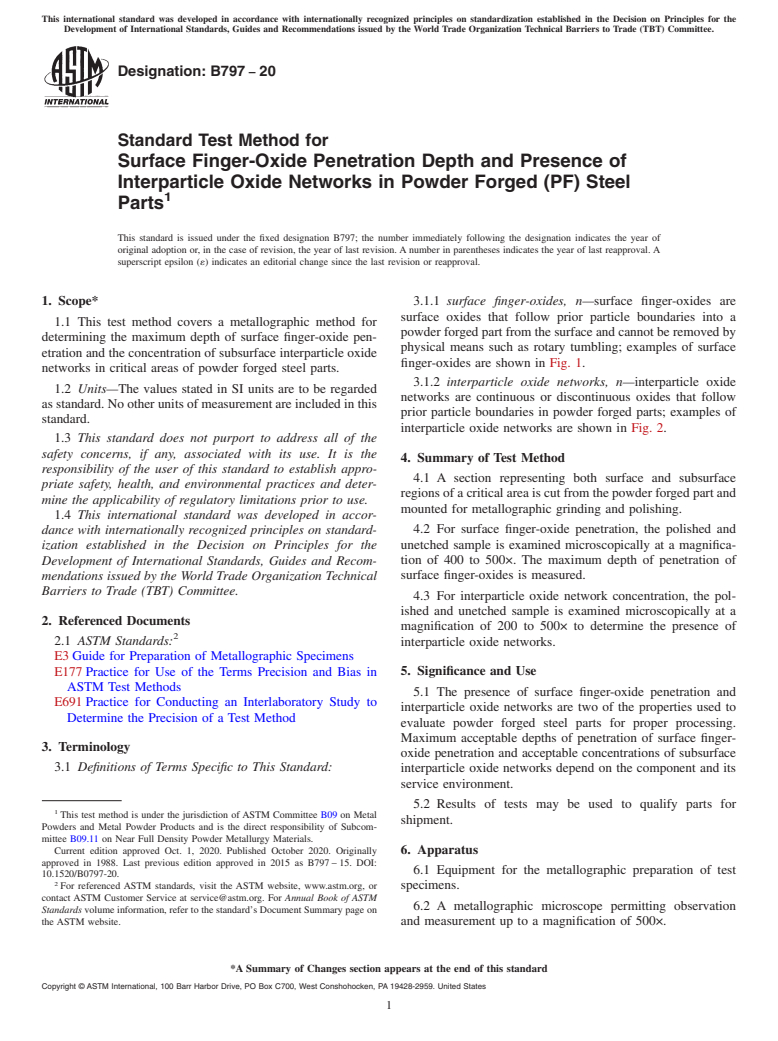

FIG. 1Example of Surface Finger-Oxide Penetration Extending Inward from the Powder Forged Part Surface (Shown more clearly at

highmagnification)

2

---------------------- Page: 2 --------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B797 − 15 B797 − 20

Standard Test Method for

Surface Finger-Oxide Penetration Depth and Presence of

Interparticle Oxide Networks in Powder Forged (PF) Steel

1

Parts

This standard is issued under the fixed designation B797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a metallographic method for determining the maximum depth of surface finger-oxide penetration and

the concentration of subsurface interparticle oxide networks in critical areas of powder forged steel parts.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced DocumentDocuments

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

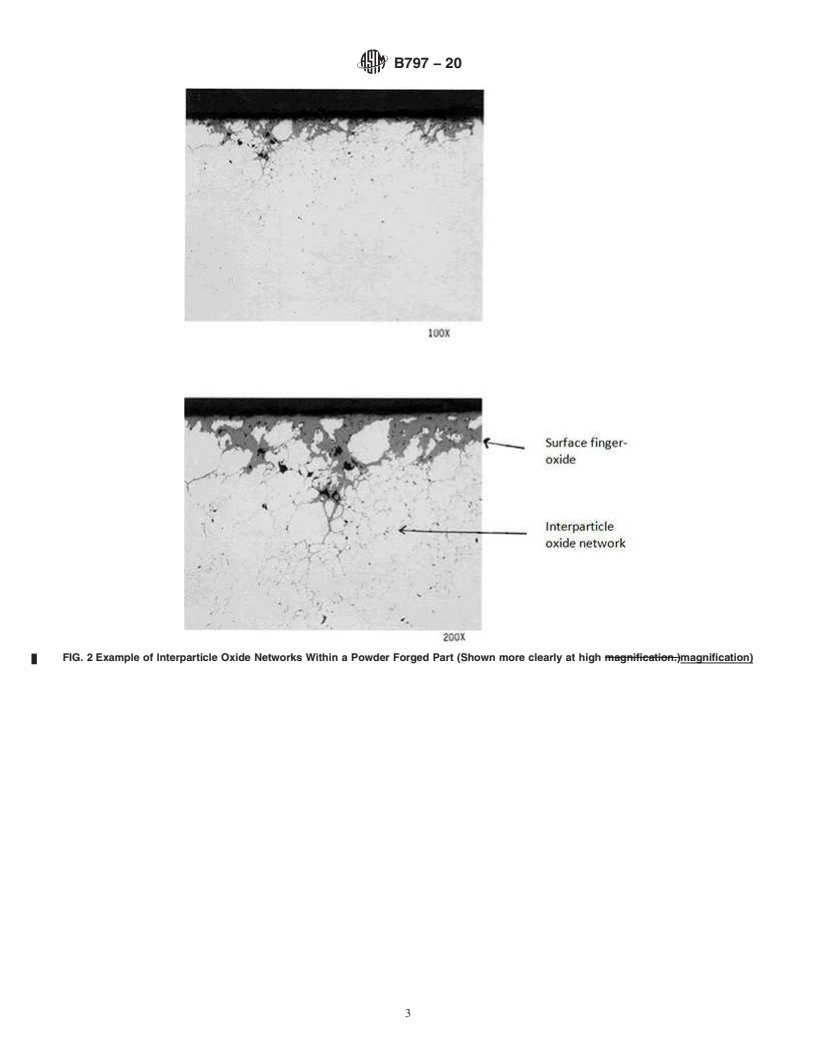

3.1.1 surface finger-oxides—finger-oxides, n—surface finger-oxides are surface oxides that follow prior particle boundaries into

a powder forged part from the surface and cannot be removed by physical means such as rotary tumbling. Examplestumbling;

examples of surface finger-oxides are shown in Fig. 1.

3.1.2 interparticle oxide networks—networks, n—interparticle oxide networks are continuous or discontinuous oxides that follow

prior particle boundaries in powder forged parts. Examplesparts; examples of interparticle oxide networks are shown in Fig. 2.

1

This test method is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee B09.11

on Near Full Density Powder Metallurgy Materials.

Current edition approved Oct. 1, 2015Oct. 1, 2020. Published November 2015October 2020. Originally approved in 1988. Last previous edition approved in 20072015

as B797 – 93B797 – 15.(2007). DOI: 10.1520/B0797-15.10.1520/B0797-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B797 − 20

FIG. 1 Example of Surface Finger-Oxide Penetration Extending Inward from the Powder Forged Part Surface (Shown more clearly at

high magnification.)magnification)

2

---------------------- Page: 2 ----------------------

B797 − 20

FIG. 2 Example of Interparticle Oxide Networks Within a Powder Forged Part (Shown more clearly at high magnification.)magnification)

3

---------------------- Page: 3 ----------------------

B797 − 20

4. Summary of Test Method

4.1 A section representing both surface and subsurface regions of a critical area is cut from the powder forged part and mounted

for metallographic grinding and polishing.

4.2 For surface finger-oxide penetration, the polished and unetched sample is examined microscopically at a magnification of 400

to 500×. The maximum depth of penetration of surface finger-oxides is measured.

4.3 For interparticle oxide network concentration, the polished and unetched sample is examined microscopically at a

magnification of 200 to 500× to determine the presence of interparticle oxide networks.

5. Significance and Use

5.1 The presence of surface finger-oxide penetration and interparticle oxide networks are two of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.