ASTM D7874-13(2022)

(Guide)Standard Guide for Applying Failure Mode and Effect Analysis (FMEA) to In-Service Lubricant Testing

Standard Guide for Applying Failure Mode and Effect Analysis (FMEA) to In-Service Lubricant Testing

SIGNIFICANCE AND USE

5.1 This guide is intended as a guideline for fluid analysis programs and serves as an initial justification for selecting fluid tests and sampling frequencies. Plant operating experience along with the review and benchmarking of similar applications is required to ensure that lessons learned are implemented.

5.2 Selection of proper fluid tests for assessing in-service component condition may have both safety and economic implications. Some failure modes may cause component disintegration, increasing the safety hazard. Thus, any fluid test that can predict such conditions should be included in the condition-monitoring program. Conversely, to maintain a sustainable and successful fluid-monitoring program, the scope of the fluid tests and their frequency should be carefully balanced between the associated risks versus expected program cost savings and benefits.

5.3 The failure modes monitored may be similar from one application to the next, but the risk and consequences of failure may differ.

5.4 This analysis can be used to determine which in-service lubricant analysis tests would be of highest value and which would be ineffective for the failure modes of interest. This information can also be used to determine the best monitoring strategy for a suite of failure modes and how often assessment is needed to manage the risk of failure.

SCOPE

1.1 This guide describes a methodology to select tests to be used for in-service lubricant analysis. The selection of fluid tests for monitoring failure mode progression in industrial applications applies the principles of failure mode and effect analysis (FMEA).

1.2 Although typical FMEA addresses all possible product failure modes, the focus of this guide is not intended to address failures that have a very high probability of unsafe operation as these should immediately be addressed by other means.

1.3 This guide is limited to components selected for condition-monitoring programs by providing a methodology to choose fluid tests associated with specific failure modes for the purpose of identifying their earliest developing stage and monitoring fault progression. The scope of this guide is also focused on those failure modes and their consequences that can effectively be detected and monitored by fluid analysis techniques.

1.4 This guide pertains to a process to be used to ensure an appropriate amount of condition monitoring is performed with the objective of improving equipment reliability, reducing maintenance costs, and enhancing fluid analysis monitoring of industrial machinery. This guide can also be used to select the monitoring frequencies needed to make the failure determinations and provide an assessment of the strengths and weaknesses of a current condition-monitoring program.

1.5 This guide does not eliminate the programmatic requirements for appropriate assembly, operational, and maintenance practices.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7874 − 13 (Reapproved 2022)

Standard Guide for

Applying Failure Mode and Effect Analysis (FMEA) to In-

Service Lubricant Testing

This standard is issued under the fixed designation D7874; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This guide describes a methodology to select tests to be

ization established in the Decision on Principles for the

used for in-service lubricant analysis. The selection of fluid

Development of International Standards, Guides and Recom-

tests for monitoring failure mode progression in industrial

mendations issued by the World Trade Organization Technical

applications applies the principles of failure mode and effect

Barriers to Trade (TBT) Committee.

analysis (FMEA).

1.2 Although typical FMEA addresses all possible product

2. Referenced Documents

failure modes, the focus of this guide is not intended to address

2.1 ASTM Standards:

failures that have a very high probability of unsafe operation as

D7684 Guide for Microscopic Characterization of Particles

these should immediately be addressed by other means.

from In-Service Lubricants

1.3 This guide is limited to components selected for

D7720 Guide for Statistically Evaluating Measurand Alarm

condition-monitoring programs by providing a methodology to

Limits when Using Oil Analysis to Monitor Equipment

choose fluid tests associated with specific failure modes for the

and Oil for Fitness and Contamination

purpose of identifying their earliest developing stage and

2.2 IEC Standard:

monitoring fault progression. The scope of this guide is also

IEC 60812 Analysis Techniques for System Reliability—

focusedonthosefailuremodesandtheirconsequencesthatcan

ProcedureforFailureModeandEffectsAnalysis(FMEA),

effectively be detected and monitored by fluid analysis tech-

niques.

1.4 This guide pertains to a process to be used to ensure an 3. Terminology

appropriate amount of condition monitoring is performed with

3.1 Definitions:

the objective of improving equipment reliability, reducing

3.1.1 cause(s) of failure, n—underlying source(s) for each

maintenance costs, and enhancing fluid analysis monitoring of

potential failure mode that can be identified and described by

industrial machinery. This guide can also be used to select the

analytical testing.

monitoring frequencies needed to make the failure determina-

3.1.2 component incipient failure, n—moment a component

tions and provide an assessment of the strengths and weak-

begins to deteriorate or undergo changes that will eventually

nesses of a current condition-monitoring program.

lead to the loss of its design function.

1.5 This guide does not eliminate the programmatic require-

3.1.2.1 Discussion—This moment may not be easily detect-

ments for appropriate assembly, operational, and maintenance

ablebecauseofsensitivitylimitationsofmonitoringinstrumen-

practices.

tation or a lack of measurable change in performance charac-

1.6 This standard does not purport to address all of the teristics or both.

safety concerns, if any, associated with its use. It is the

3.1.3 criticality number, C, n—product of the severity (S)

responsibility of the user of this standard to establish appro-

and occurrence (O) numbers for a given failure mode’s causes

priate safety, health, and environmental practices and deter-

and effects.

mine the applicability of regulatory limitations prior to use.

3.1.4 design function, n—function or task that the system or

component should perform.

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.96.04 on Guidelines for In-Services Lubricants Analysis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2022. Published October 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2018 as D7874 – 13 (2018). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7874-13R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7874 − 13 (2022)

3.1.5 detection ability number, D, n—ranking number that 3.1.15 severity number, S, n—ranking number that describes

describes the ability of a specific fluid test to successfully the seriousness of the consequences of each failure mode’s

detect a failure mode’s causes or effects. A scale is used to causes and effects on potential injury, component or equipment

grade detection ability numbers; see an example in 6.4.7. damage, and system availability.

3.1.15.1 Discussion—A scale is used to grade severity

3.1.6 effect(s) of failure, n—potential outcome(s) of each

numbers. See an example in 6.3.1.

failure mode on the system or component.

3.1.7 failure-developing period, FDP, n—period from com-

4. Summary of Guide

ponent’s incipient failure to functional failure.

4.1 This guide is designed to aid the user to optimize their

3.1.8 failure mode, n—physical description of the manner in

condition-monitoring program.

which a failure occurs.

4.2 Failure mode and effect analysis (FMEA) is applied by

3.1.9 failure mode and effect analysis, FMEA, n—analytical

the user of this guide to those machines selected in their

approach to determine and address methodically all possible

condition-monitoring program based on their significance to

system or component failure modes and their associated causes

production and safety. The user of this guide determines the

and effects on system performance.

possible failure modes for each machine and applies FMEA

3.1.9.1 Discussion—This approach can be used to evaluate

separately for each failure mode. A severity number (S)is

designs and track risk-reducing improvements to equipment

assigned for each failure mode’s causes and effects.

reliability.

4.3 The user of this guide then determines how frequently

3.1.10 failure modes, effects, and criticality analysis,

the failure mode’s causes or effects are likely to occur based on

FMECA, n—extension to FMEAthat involves ranking the risk

past operating experience under similar applications for a

associated with failure modes to allow prioritization and

predetermined time period. An occurrence number (O)is

selection of an appropriate maintenance strategy.

assigned for each failure mode’s causes and effects.

3.1.10.1 Discussion—A metric-describing criticality is de-

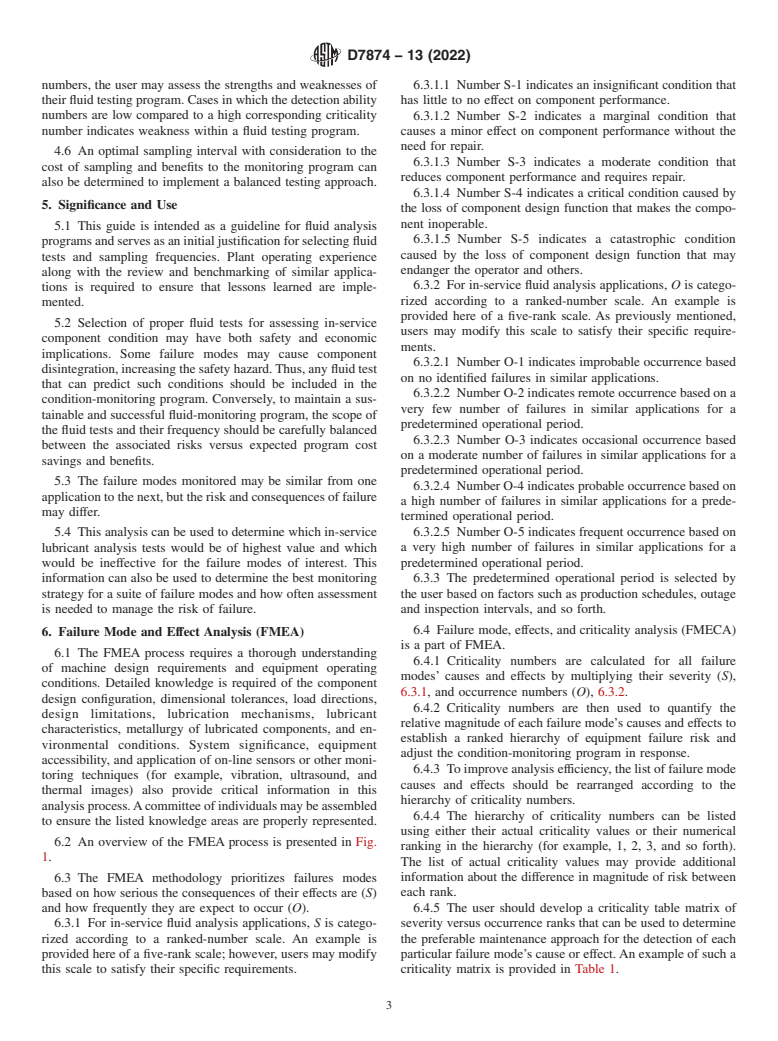

4.4 The severity and occurrence numbers are constant for

termined by the product of a severity number (S) and its

each failure mode’s specific cause or effect. Calculating the

occurrence number (O) for each given failure mode’s causes

product of the severity and occurrence numbers (criticality

and effects.

number) for all failure modes’ causes and effects allows the

3.1.11 functional failure, n—inability of the component or

user to establish a ranked hierarchy of the risk associated with

system to perform its required design function.

equipment failure.Atable matrix of severity versus occurrence

3.1.12 occurrence number, O, n—ranking number that de-

ranks can then be used to allow the user to determine whether

scribes the probability of occurrence of a failure mode’s causes

a given failure mode’s cause or effect is tolerable and requires

and effects over a predetermined period of time based on past

periodic inspection, fluid testing, or design modification (for

operating experience in similar applications; see an example in

example, Table 1).This is used to justify the need for testing of

6.3.2.

specific failure modes’ causes or effects within a predictive

3.1.13 P-F curve, n—illustration of component failure pro- maintenance program.

gression (component condition versus time) from incipient

4.5 For those failure modes’ causes and effects that require

failure to functional failure (F).

fluid testing, several test methods should be considered. A

3.1.14 P-F interval, n—period from the point in time in detection ability number (D) is determined by the user for each

which a change in performance characteristics or condition can test method based on the test’s ability to detect the failure

first be detected (P) to the point in time in which functional mode’s causes and effects. By comparing the ranking of

failure (F) will occur as illustrated on a P-F curve. criticality numbers with their corresponding detection ability

TABLE 1 Criticality Matrix

Severity Number

Occurrence S-1 S-2 S-3 S-4 S-5

Number Insignificant Marginal Moderate Critical Catastrophic

O-1 Tolerable Tolerable Periodic Periodic Testing

Improbable Inspection Inspection

O-2 Tolerable Periodic Periodic Testing Testing

Remote Inspection Inspection

O-3 Periodic Periodic Testing Testing Testing

Occasional Inspection Inspection

O-4 Periodic Testing Testing Testing Design

Probable Inspection Modification

O-5 Testing Testing Testing Design Design

Frequent Modification Modification

D7874 − 13 (2022)

numbers, the user may assess the strengths and weaknesses of 6.3.1.1 Number S-1 indicates an insignificant condition that

their fluid testing program. Cases in which the detection ability has little to no effect on component performance.

numbers are low compared to a high corresponding criticality

6.3.1.2 Number S-2 indicates a marginal condition that

number indicates weakness within a fluid testing program. causes a minor effect on component performance without the

need for repair.

4.6 An optimal sampling interval with consideration to the

6.3.1.3 Number S-3 indicates a moderate condition that

cost of sampling and benefits to the monitoring program can

reduces component performance and requires repair.

also be determined to implement a balanced testing approach.

6.3.1.4 Number S-4 indicates a critical condition caused by

5. Significance and Use

the loss of component design function that makes the compo-

nent inoperable.

5.1 This guide is intended as a guideline for fluid analysis

6.3.1.5 Number S-5 indicates a catastrophic condition

programsandservesasaninitialjustificationforselectingfluid

caused by the loss of component design function that may

tests and sampling frequencies. Plant operating experience

endanger the operator and others.

along with the review and benchmarking of similar applica-

6.3.2 For in-service fluid analysis applications, O is catego-

tions is required to ensure that lessons learned are imple-

rized according to a ranked-number scale. An example is

mented.

provided here of a five-rank scale. As previously mentioned,

5.2 Selection of proper fluid tests for assessing in-service

users may modify this scale to satisfy their specific require-

component condition may have both safety and economic

ments.

implications. Some failure modes may cause component

6.3.2.1 Number O-1 indicates improbable occurrence based

disintegration, increasing the safety hazard.Thus, any fluid test

on no identified failures in similar applications.

that can predict such conditions should be included in the

6.3.2.2 Number O-2 indicates remote occurrence based on a

condition-monitoring program. Conversely, to maintain a sus-

very few number of failures in similar applications for a

tainable and successful fluid-monitoring program, the scope of

predetermined operational period.

the fluid tests and their frequency should be carefully balanced

6.3.2.3 Number O-3 indicates occasional occurrence based

between the associated risks versus expected program cost

on a moderate number of failures in similar applications for a

savings and benefits.

predetermined operational period.

5.3 The failure modes monitored may be similar from one

6.3.2.4 Number O-4 indicates probable occurrence based on

application to the next, but the risk and consequences of failure

a high number of failures in similar applications for a prede-

may differ.

termined operational period.

5.4 This analysis can be used to determine which in-service 6.3.2.5 Number O-5 indicates frequent occurrence based on

lubricant analysis tests would be of highest value and which a very high number of failures in similar applications for a

would be ineffective for the failure modes of interest. This predetermined operational period.

information can also be used to determine the best monitoring 6.3.3 The predetermined operational period is selected by

strategy for a suite of failure modes and how often assessment the user based on factors such as production schedules, outage

is needed to manage the risk of failure. and inspection intervals, and so forth.

6.4 Failure mode, effects, and criticality analysis (FMECA)

6. Failure Mode and Effect Analysis (FMEA)

is a part of FMEA.

6.1 The FMEA process requires a thorough understanding

6.4.1 Criticality numbers are calculated for all failure

of machine design requirements and equipment operating

modes’ causes and effects by multiplying their severity (S),

conditions. Detailed knowledge is required of the component

6.3.1, and occurrence numbers (O), 6.3.2.

design configuration, dimensional tolerances, load directions,

6.4.2 Criticality numbers are then used to quantify the

design limitations, lubrication mechanisms, lubricant

relative magnitude of each failure mode’s causes and effects to

characteristics, metallurgy of lubricated components, and en-

establish a ranked hierarchy of equipment failure risk and

vironmental conditions. System significance, equipment

adjust the condition-monitoring program in response.

accessibility, and application of on-line sensors or other moni-

6.4.3 To improve analysis efficiency, the list of failure mode

toring techniques (for example, vibration, ultrasound, and

causes and effects should be rearranged according to the

thermal images) also provide critical information in this

hierarchy of criticality numbers.

analysisprocess.Acommitteeofindividualsmaybeassembled

6.4.4 The hierarchy of criticality numbers can be listed

to ensure the listed knowledge areas are properly represented.

using either their actual criticality values or their numerical

6.2 An overview of the FMEA process is presented in Fig.

ranking in the hierarchy (for example, 1, 2, 3, and so forth).

1.

The list of actual criticality values may

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.