ASTM D5853-11

(Test Method)Standard Test Method for Pour Point of Crude Oils

Standard Test Method for Pour Point of Crude Oils

SIGNIFICANCE AND USE

The pour point of a crude oil is an index of the lowest temperature of handleability for certain applications.

This is the only pour point method specifically designed for crude oils.

The maximum and minimum pour point temperatures provide a temperature window where a crude oil, depending on its thermal history, might appear in the liquid as well as the solid state.

The test method can be used to supplement other measurements of cold flow behavior. It is especially useful for the screening of the effect of wax interaction modifiers on the flow behavior of crude oils.

SCOPE

1.1 This test method covers two procedures for the determination of the pour point temperatures of crude oils down to −36°C. Procedure A provides a measure of the maximum (upper) pour point temperature and is described in 9.1. Procedure B provides a measure of the minimum (lower) pour point temperature and is described in 9.2.

1.2 The use of this test method is limited to use for crude oils. Pour point temperatures of other petroleum products can be determined by Test Method D97.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5853 − 11

Designation: 441/99

Standard Test Method for

1

Pour Point of Crude Oils

This standard is issued under the fixed designation D5853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers two procedures for the deter- 2.1 ASTM Standards:

D97Test Method for Pour Point of Petroleum Products

mination of the pour point temperatures of crude oils down to

−36°C. Procedure A provides a measure of the maximum D130Test Method for Corrosiveness to Copper from Petro-

leum Products by Copper Strip Test

(upper) pour point temperature and is described in 9.1. Proce-

dure B provides a measure of the minimum (lower) pour point D323TestMethodforVaporPressureofPetroleumProducts

(Reid Method)

temperature and is described in 9.2.

D4057Practice for Manual Sampling of Petroleum and

1.2 The use of this test method is limited to use for crude

Petroleum Products

oils. Pour point temperatures of other petroleum products can

D4177Practice for Automatic Sampling of Petroleum and

be determined by Test Method D97.

Petroleum Products

1.3 The values stated in SI units are to be regarded as

E1Specification for ASTM Liquid-in-Glass Thermometers

standard. No other units of measurement are included in this

E77Test Method for Inspection and Verification of Ther-

standard.

mometers

1.4 WARNING—Mercury has been designated by many

3. Terminology

regulatory agencies as a hazardous material that can cause

3.1 Definitions of Terms Specific to This Standard:

central nervous system, kidney and liver damage. Mercury, or

3.1.1 maximum (upper) pour point, n—the pour point ob-

its vapor, may be hazardous to health and corrosive to

tained after the test specimen has been subjected to a pre-

materials.Cautionshouldbetakenwhenhandlingmercuryand

scribed treatment designed to enhance gelation of wax crystals

mercury containing products. See the applicable product Ma-

and solidification of the test specimen.

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi-

3.1.2 minimum (lower) pour point, n—the pour point ob-

tional information. Users should be aware that selling mercury tained after the test specimen has been subjected to a pre-

and/or mercury containing products into your state or country scribed treatment designed to delay gelation of wax crystals

may be prohibited by law. and solidification of the test specimen.

1.5 This standard does not purport to address all of the 3.1.3 pour point, n—thelowesttemperatureatwhichmove-

safety concerns, if any, associated with its use. It is the ment of the test specimen is observed under the conditions of

responsibility of the user of this standard to establish appro- the test.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use. For specific hazard

4.1 Afterpreliminaryheating,thetestspecimeniscooledat

statements, see Section 7.

a specified rate and examined at intervals of 3°C for flow

characteristics. The lowest temperature at which movement of

the test specimen is observed is recorded as the pour point.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.07 on Flow Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1995. Last previous edition approved in 2009 as D5853–09. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D5853-11. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5853 − 11

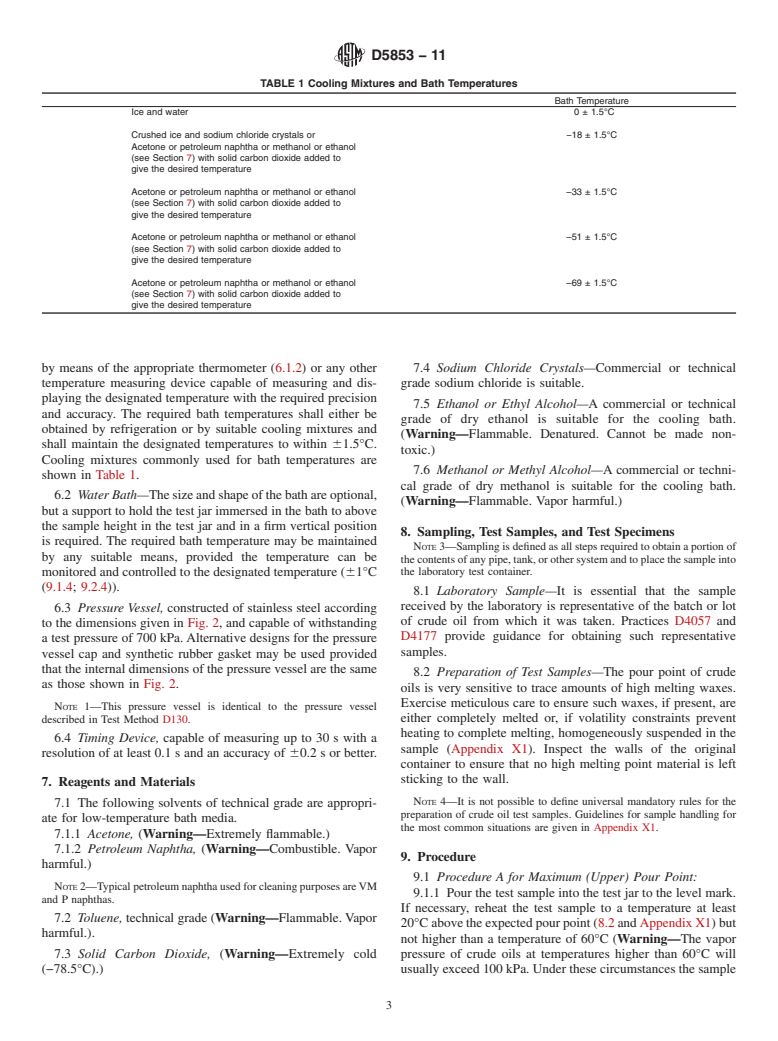

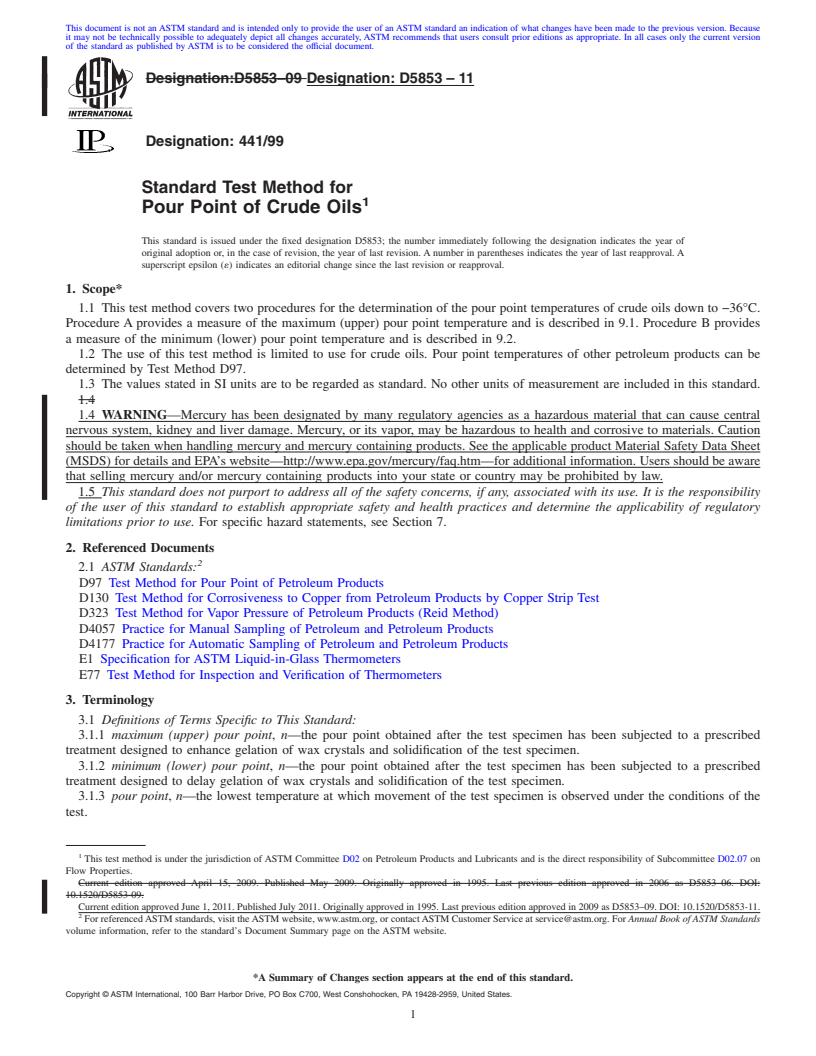

NOTE 1—All dimensions are stated in millimetres.

FIG. 1 Apparatus for Pour Point Test

5. Significance and Use

Thermometer

Number

Thermometer Temperature Range

5.1 The pour point of a crude oil is an index of the lowest

ASTM IP

temperature of handleability for certain applications.

High cloud and pour −38 to +50°C 5C 1C

5.2 Thisistheonlypourpointmethodspecificallydesigned

Low cloud and pour −80 to +20°C 6C 2C

Melting point +32 to +127°C 61C 63C

for crude oils.

6.1.2.1 Since separation of liquid column thermometers

5.3 The maximum and minimum pour point temperatures

occasionally

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5853–09 Designation:D5853–11

Designation: 441/99

Standard Test Method for

1

Pour Point of Crude Oils

This standard is issued under the fixed designation D5853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers two procedures for the determination of the pour point temperatures of crude oils down to −36°C.

Procedure A provides a measure of the maximum (upper) pour point temperature and is described in 9.1. Procedure B provides

a measure of the minimum (lower) pour point temperature and is described in 9.2.

1.2 The use of this test method is limited to use for crude oils. Pour point temperatures of other petroleum products can be

determined by Test Method D97.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4

1.4 WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

E77 Test Method for Inspection and Verification of Thermometers

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 maximum (upper) pour point, n—the pour point obtained after the test specimen has been subjected to a prescribed

treatment designed to enhance gelation of wax crystals and solidification of the test specimen.

3.1.2 minimum (lower) pour point, n—the pour point obtained after the test specimen has been subjected to a prescribed

treatment designed to delay gelation of wax crystals and solidification of the test specimen.

3.1.3 pour point, n—the lowest temperature at which movement of the test specimen is observed under the conditions of the

test.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.07 on

Flow Properties.

Current edition approved April 15, 2009. Published May 2009. Originally approved in 1995. Last previous edition approved in 2006 as D5853–06. DOI:

10.1520/D5853-09.

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapprovedin1995.Lastpreviouseditionapprovedin2009asD5853–09.DOI:10.1520/D5853-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5853–11

4. Summary of Test Method

4.1 After preliminary heating, the test specimen is cooled at a specified rate and examined at intervals of 3°C for flow

characteristics. The lowest temperature at which movement of the test specimen is observed is recorded as the pour point.

5. Significance and Use

5.1 The pour point of a crude oil is an index of the lowest temperature of handleability for certain applications.

5.2 This is the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.