ASTM D365-01(2005)

(Guide)Standard Guide for Soluble Nitrocellulose Base Solutions

Standard Guide for Soluble Nitrocellulose Base Solutions

SIGNIFICANCE AND USE

Since the desired specifications and compositions of soluble nitrocellulose base solutions vary greatly, these methods are used to establish whether limits that shall be as agreed upon between the producer and the user have been met.

SCOPE

1.1 These test methods cover the testing of soluble nitrocellulose base solutions that are made by dispersing various kinds and concentrations of soluble nitrocellulose (cellulose nitrate) in various solvent mixtures.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D365–01(Reapproved2005)

Standard Guide for

Soluble Nitrocellulose Base Solutions

This standard is issued under the fixed designation D365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope CONSISTENCY (VISCOSITY)

1.1 This guide covers the testing of soluble nitrocellulose

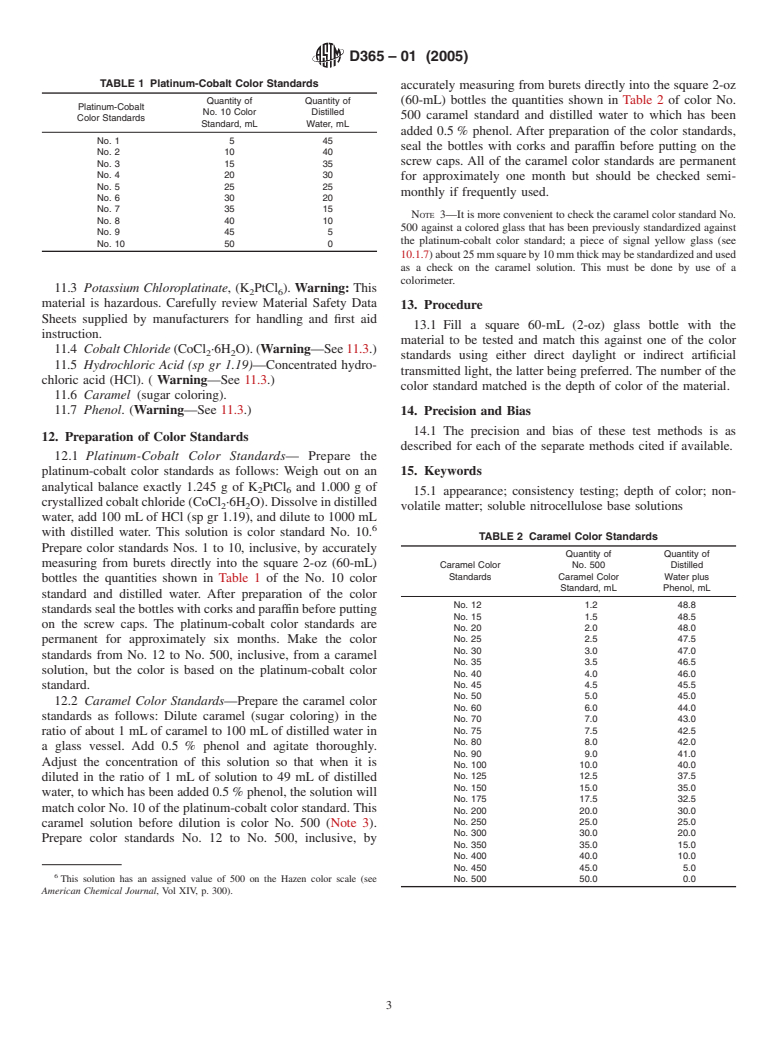

5. Consistency Tests

base solutions that are made by dispersing various kinds and

5.1 For Consistencies from 3 to 500 s—Determine the

concentrations of soluble nitrocellulose (cellulose nitrate) in

consistency by falling-ball consistency test described in Test

various solvent mixtures.

Methods D301 for those solutions having a consistency from 3

1.2 The values stated in SI units are to be regarded as the

to 500 s when tested in that apparatus.

standard. The values given in parentheses are for information

5.2 For Consistencies Less than 3 s—Determine the con-

only.

sistency by Test Method D1200 for those solutions having a

1.3 This standard does not purport to address all of the

consistency of less than 3 s when tested in the falling-ball

safety concerns, if any, associated with its use. It is the

apparatus referred to in 5.1.

responsibility of the user of this standard to establish appro-

5.3 For Consistencies over 500 s—Determine the consis-

priate safety and health practices and determine the applica-

tency using the apparatus and procedure described in Sections

bility of regulatory limitations prior to use. For specific hazard

6 and 7 for those solutions having a consistency greater than

statements see Section 11.

500 s when tested in the falling-ball apparatus referred to in

2. Referenced Documents 5.1.

2.1 ASTM Standards:

6. Apparatus

D301 Test Methods for Soluble Cellulose Nitrate

6.1 The consistency test apparatus, shown in Fig. 1, shall

D333 Guide for Clear and Pigmented Lacquers

consist of the following:

D1193 Specification for Reagent Water

6.1.1 Glass Tube (preferably heat-resistant glass), 50 6

D1200 Test Method for Viscosity by Ford Viscosity Cup

1.5 mm (2 6 ⁄32 in.) in inside diameter and 255 mm (10 in.)

E300 Practice for Sampling Industrial Chemicals

in length, with marks 177 61mm(5 6 ⁄16 in.) apart, the

3. Significance and Use upper one being 75 mm (3 in.) from the top of the tube.

3.1 Since the desired specifications and compositions of

NOTE 1—The steel ball can be removed (in order to leave the same

soluble nitrocellulose base solutions vary greatly, these meth- material in the tube for a check run) by removing the lower stopper.

However, a small air bubble is usually introduced in this way. It is

ods are used to establish whether limits that shall be as agreed

preferable to invert the tube, removing the guide to get the ball out. It is

upon between the producer and the user have been met.

often necessary to put a few drops of solvent in the guide lip to loosen it

from the tube on account of the solution drying at the edge of the tube.

4. Sampling

When the latter method is used for removing the ball, a larger bubble

4.1 Select the sampling method from those listed in Practice

traverses the tube than when the former method is used, but a large bubble

E300.

movessufficientlyfast,eveninaveryviscoussolution,toescapeatthetop

in a few minutes, whereas small bubbles take hours to escape.

6.1.2 Steel Ball, 15.88 6 0.02 mm (0.625 6 0.001 in.) in

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

diameter, and weighing 16.536 6 0.10 g.

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.55 on Factory Applied Coatings on Preformed Products.

6.1.3 Aluminum Guide Cone of light gage aluminum (ap-

Current edition approved May 15, 2005. Published August 2005. Originally

proximately 0.5 mm (0.02 in.) in thickness) as shown in Fig. 1.

approved in 1933. Last previous edition approved in 2001 as D365 – 01. DOI:

The orifice of the guide cone shall be 22 mm ( ⁄8 in.) in

10.1520/D0365-01R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or diameter, the conical portion 25 mm (1 in.) in height, the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Borosilicate glass is satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D365–01 (2005)

NONVOLATILE MATTER

8. Procedure

8.1 Determine the percent of nonvolatile matter in accor-

dance with the procedure described in the Nonvolatile Matter

section of Test Methods D333.

APPEARANCE OF SOLUTION

9. Procedure

9.1 Compare the appearance of the soluble nitrocellulose

base solution with a reference standard agreed upon between

the purchaser and the seller (both the reference standard and

sample solutions shall be thoroughly agitated before making

observations) in similar bottles for turbidity, hair, grain, and

insoluble matter.

DEPTH OF COLOR

10. Apparatus

FIG. 1 Apparatus for Consistency (Viscosity) Test of Solutions

Having Consistencies over 500 s

10.1 The apparatus used for the preparation of the color

standards and for the depth of color determinations shall

consist of the following:

10.1.1 Light—Source of transmitted light.

cylindrical portion 12.7 mm ( ⁄2 in.) in height, and the outside

diameter shall be slightly under 50 mm (2 in.) so as to fit

NOTE 2—Not absolutely necessary but will increase accuracy and be

snugly into the viscosity tube.

more convenient.

6.1.4 Stoppers, made preferably of rubber and covered with

10.1.2 Bottles,threedozen60m(2-ozL)screw-cap,square,

tin foil.

glass.

10.1.3 Flasks, several, 1-L, volumetric.

7. Procedure

10.1.4 Burets, two, 50-mL.

7.1 Fill the tube in any convenient manner whereby bubbles 10.1.5 Analytical Balance.

do not form and no appreciable amount of solvent is lost. One

10.1.6 ColorimeterDubosq colorimeter (see Note 2).

method is to immerse the lower end of the open tube in the 10.1.7 Color Glass—Yellow glass about 25 mm square and

solution and to apply suction at the upper end of the tube. In

10 mm thick.

this manner the tube can be filled in from 5 to 10 s without the

introduction of air bubbles or an appreciable loss of solvent. 11. Reagents and Materials

Close the bottom of the tube with a stopper covered with tin

11.1 Purity of Reagents—Reagent grade chemicals shall be

foil. Push the aluminum guide cone slowly into the top of the

used in all tests. Unless otherwise indicated, it is intended that

tubeandinsertastoppercoveredwithtinfoilintothetopofthe

all reagents shall conform to the specifications of the Commit-

guide.

tee onAnalytical Reagents of theAmerican Chemical Society,

7.2 Bring the tube and its contents to a temperature of 25 6

where such specifications are available. Other grades may be

0.1°C by placing in a suitable bath. Allow at least 30 min for

used, provided it is first ascertained that the reagent is of

the solution to reach temperature equilibrium. For accurate

sufficiently high purity to permit its use without lessening the

measurements keep the tube during the determina

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.