ASTM D233-13(2022)

(Test Method)Standard Test Methods of Sampling and Testing Turpentine

Standard Test Methods of Sampling and Testing Turpentine

SIGNIFICANCE AND USE

3.1 The test procedures described in this standard were developed when the chief use for turpentine was as a solvent. Currently however, the chief use for turpentine (and pinenes) is as raw materials for the production of resins and synthetic organic chemicals. Thus the chemical composition of turpentines and pinenes is extremely important and tests, in addition to the ones described in these test methods, are required in order to fully characterize turpentines and pinenes. The most widely used technique for determining the chemical composition of turpentines (and pinenes) is gas chromatography (see Test Methods D6387).

SCOPE

1.1 These test methods cover procedures for sampling and testing turpentine, as defined by the Code of Federal Regulations and Terminology D804. These test methods are also used for the sampling and testing of pinenes, the major components of most turpentines.

1.2 These test methods primarily measure the physical rather than the chemical properties of turpentines and pinenes. As turpentines and pinenes are currently used chiefly as chemical raw materials for the production of resins and synthetic organic chemicals, chemical composition is also very important. Consequently, testing the chemical composition of turpentines and pinenes by gas chromatography has displaced these test methods to a large extent. (See for example Test Methods D6387.)

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

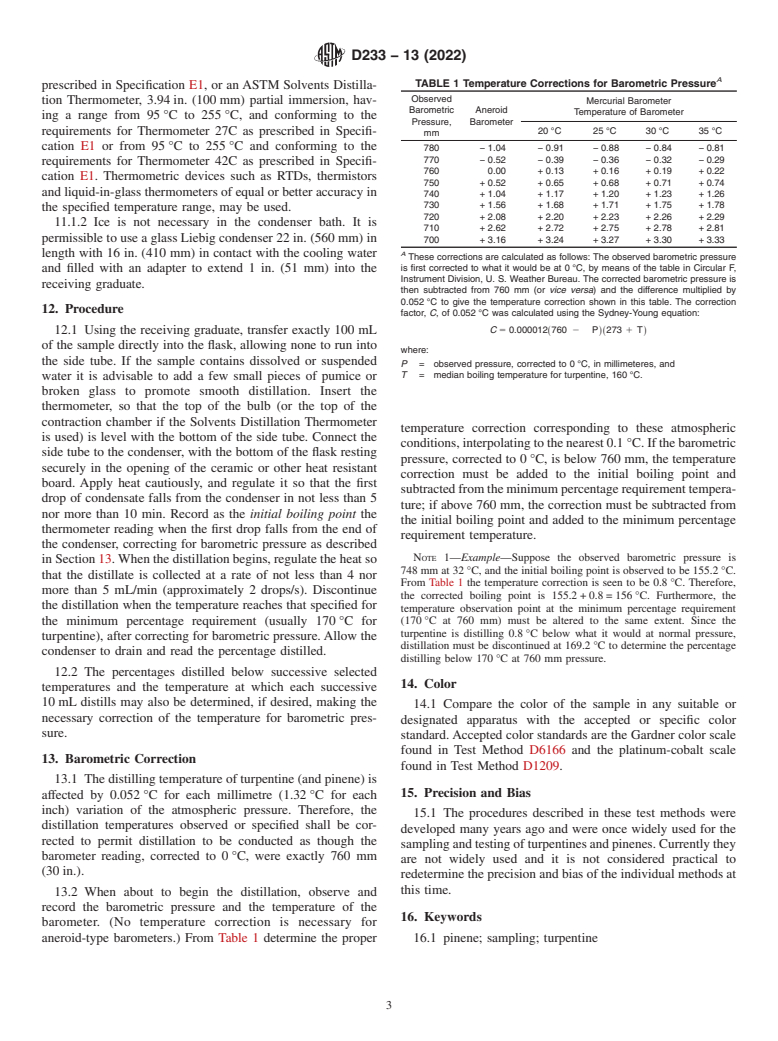

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D233 − 13 (Reapproved 2022)

Standard Test Methods of

Sampling and Testing Turpentine

This standard is issued under the fixed designation D233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover procedures for sampling and

D86 Test Method for Distillation of Petroleum Products and

testing turpentine, as defined by the Code of Federal Regula-

Liquid Fuels at Atmospheric Pressure

tions and Terminology D804. These test methods are also used

D270 Methods of Sampling Petroleum and Petroleum Prod-

for the sampling and testing of pinenes, the major components

ucts (Withdrawn 1984)

of most turpentines.

D804 Terminology Relating to Pine Chemicals, Including

1.2 These test methods primarily measure the physical

Tall Oil and Related Products

rather than the chemical properties of turpentines and pinenes.

D1193 Specification for Reagent Water

As turpentines and pinenes are currently used chiefly as

D1209 Test Method for Color of Clear Liquids (Platinum-

chemical raw materials for the production of resins and

Cobalt Scale)

synthetic organic chemicals, chemical composition is also very

D6166 Test Method for Color of Pine Chemicals and Re-

important. Consequently, testing the chemical composition of

lated Products (Instrumental Determination of Gardner

turpentines and pinenes by gas chromatography has displaced

Color)

these test methods to a large extent. (See for example Test

D6387 Test Methods for Composition of Turpentine and

Methods D6387.)

Related Terpene Products by Capillary Gas Chromatogra-

1.3 The values stated in inch-pound units are to be regarded phy

E1 Specification for ASTM Liquid-in-Glass Thermometers

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 2.2 Other Document:

Code of Federal Regulations, Title 7, Part 160 Regulations

and are not considered standard.

and Standards for Naval Stores, 1999

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Significance and Use

responsibility of the user of this standard to establish appro-

3.1 The test procedures described in this standard were

priate safety, health, and environmental practices and deter-

developed when the chief use for turpentine was as a solvent.

mine the applicability of regulatory limitations prior to use.

Currentlyhowever,thechiefuseforturpentine(andpinenes)is

1.5 This international standard was developed in accor-

as raw materials for the production of resins and synthetic

dance with internationally recognized principles on standard-

organic chemicals. Thus the chemical composition of turpen-

ization established in the Decision on Principles for the

tines and pinenes is extremely important and tests, in addition

Development of International Standards, Guides and Recom-

to the ones described in these test methods, are required in

mendations issued by the World Trade Organization Technical

order to fully characterize turpentines and pinenes. The most

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

These test methods are under the jurisdiction of ASTM Committee D01 on Standards volume information, refer to the standard’s Document Summary page on

Paint and Related Coatings, Materials, and Applications and are the direct the ASTM website.

responsibility of Subcommittee D01.34 on Pine Chemicals and Hydrocarbon The last approved version of this historical standard is referenced on

Resins. www.astm.org.

Current edition approved Dec. 1, 2022. Published December 2022. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

approved in 1926. Last previous edition approved in 2017 as D233 – 13 (2017). 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

DOI: 10 .1520/D0233-13R22. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D233 − 13 (2022)

widely used technique for determining the chemical composi- DETECTION AND REMOVAL OF SEPARATED

tion of turpentines (and pinenes) is gas chromatography (see WATER

Test Methods D6387).

6. Procedure

6.1 Draw a portion by means of a glass or metal container

4. Purity of Reagents

with a removable stopper or top, or with a “thief,” from the

4.1 Reagent grade chemicals shall be used in all tests.

lowest part of the container, or by opening the bottom valve of

Unless otherwise indicated, it is intended that all reagents shall

the perfectly level tank car. If water is found in this sample,

conform to the specifications of the Committee on Analytical

draw it all out, record the quantity, and deduct it from the total

Reagents of the American Chemical Society, where such

volume of liquid delivered.

specifications are available. Other grades may be used, pro-

APPEARANCE

vided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

7. Procedure

the determination.

7.1 Examine a portion of the sample after agitation to

4.2 Unless otherwise indicated, references to water shall be

determine whether its appearance conforms to specifications.

understood to mean reagent water conforming to Specification

ODOR

D1193.

8. Procedure

SAMPLING

8.1 Compare the odor of the sample with an agreed-upon

5. Sampling water-free reference sample kept in the dark in a completely

filled, well-stoppered bottle. In the absence of such a sample,

5.1 The method of sampling specified in 5.2 or 5.3 shall be

compare with samples of known purity similarly preserved.

used, according to the special conditions that apply.

SPECIFIC GRAVITY

5.2 From Loaded Tank Car or Other Large Vessel—The

compositesampletakenshallbenotlessthan ⁄2gal(1.9L)and

9. Procedure

should consist of small samples of not more than 1 qt (0.9 L)

9.1 Determine the specific gravity at 15.6/15.6 °C by any

each, taken from near the top and bottom by means of a metal

convenient method having a precision of 0.0005. Determina-

or glass container with removable stopper or top. This device,

tions made at any other temperature using apparatus standard-

attached to a suitable pole, shall be lowered to the desired

ized at 15.6 °C shall be corrected by adding to or subtracting

depth, the stopper or top removed, and the container allowed to

fromtheobservedreading0.00082foreachdegreeCelsiusthat

fill. If a sample from close to the bottom of a tank shows a

the temperature of the liquid is above or below 15.6 °C. If the

decided difference in color or appearance from samples taken

determination is made with apparatus calibrated for a tempera-

at other depths, an extra bottom sample shall be taken and

ture other than 15.6 °C, the observed reading shall first be

examined separately from the composite sample. In such case,

calculated to density at the temperature of observation, then

the composite sample shall not include any portion of such

converted to density at 15.6 °C by applying the above factor,

bottom sampling.

and finally converted to specific gravity by dividing the

calculated density by 0.999 (the density of water at 15.6 °C).

5.3 From Barrels and Drums—At least 5 % of the packages

in any shipment shall be represented in the sample. The

REFRACTIVE INDEX

purchaser may increase the percentage of packages to be

sampled at his direction, and it is recommended that every 10. Procedure

package be sampled in the case of expensive terpene hydro-

10.1 Determine the refractive index with an accurate

carbons that are bought in small quantity. A portion shall be

instrument, at 20 °C if possible. If determined at any other

withdrawn from about the center of each package sampled by

temperature,correctthereadingobtainedto20 °Cbyaddingor

means of a “thief” or other sampling device. The composite

subtrac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.