ASTM F2620-20ae2

(Practice)Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings

SIGNIFICANCE AND USE

4.1 The procedures described in Sections 7 – 9 are primarily intended for (but not limited to) field joining of polyethylene (PE) pipe and fittings, using suitable equipment and appropriate environmental control procedures. When properly implemented, strong pressure/leak-tight joints are produced. When these joints are destructively tested, the failure occurs outside the fusion joined area.

4.2 Melt characteristics, average molecular weight and molecular weight distribution are influential factors in establishing suitable fusion parameters; therefore, consider the manufacturer’s instructions in the use or development of a specific fusion procedure. See Annex A1.

4.3 The socket fusion, butt fusion, and saddle fusion procedures in this practice are suitable for joining PE gas pipe and fittings, PE water pipe and fittings, and PE general purpose pipes and fittings made to PE product specifications from organizations such as ASTM, AWWA, API, and ISO that are used in pressure, low pressure and non-pressure applications. For gas applications, qualification of the procedure by testing joints made using the procedure in accordance with regulations from the authority having jurisdiction are required.

SCOPE

1.1 This practice describes procedures for making joints with polyethylene (PE) pipe and fittings by means of heat fusion joining in, but not limited to, a field environment. Other suitable heat fusion joining procedures are available from various sources including pipe and fitting manufacturers. This practice does not purport to address all possible heat fusion joining procedures, or to preclude the use of qualified procedures developed by other parties that have been proved to produce reliable heat fusion joints.

1.2 The parameters and procedures are applicable only to joining polyethylene pipe and fittings of related polymer chemistry. They are intended for PE fuel gas pipe in accordance with Specification D2513 and PE potable water, sewer and industrial pipe manufactured in accordance with Specification F714, Specification D3035, and AWWA C901 and C906. Consult with the pipe manufacturers to make sure they approve this procedure for the pipe to be joined (see Appendix X1).

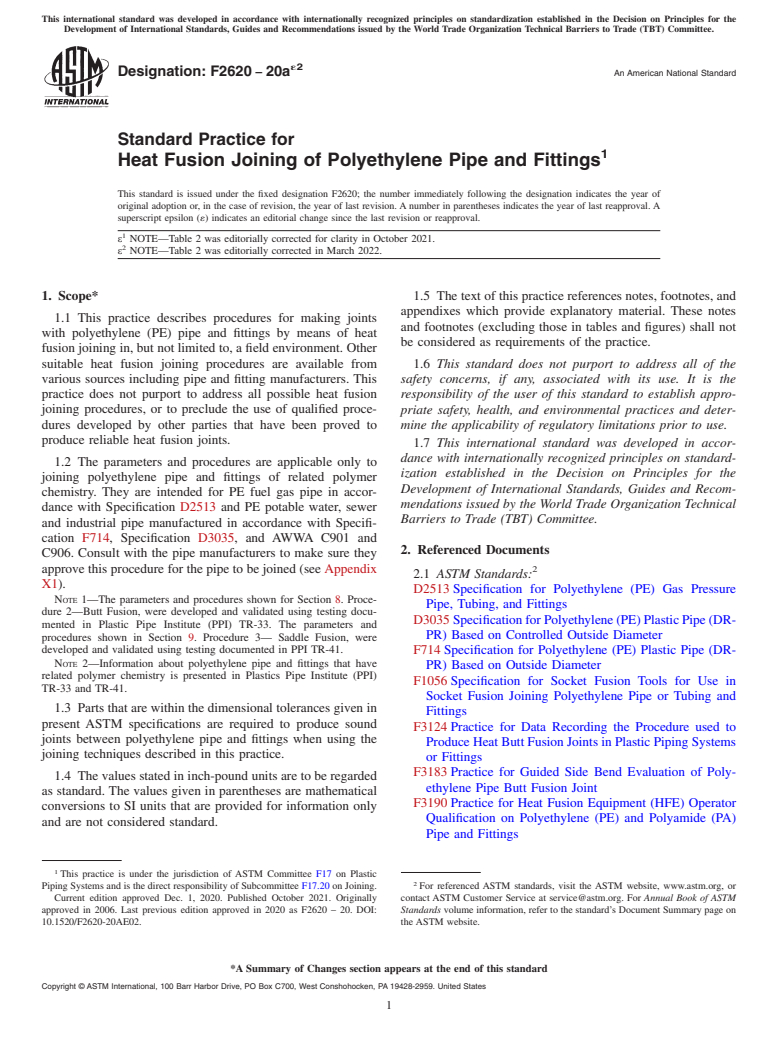

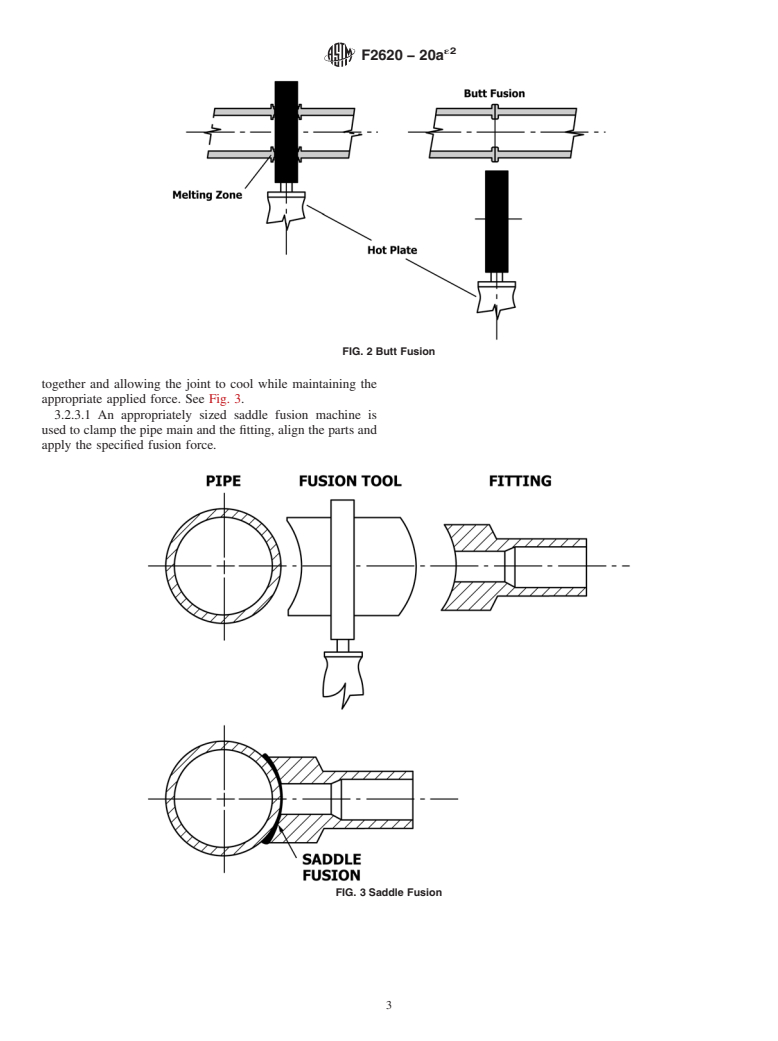

Note 1: The parameters and procedures shown for Section 8. Procedure 2—Butt Fusion, were developed and validated using testing documented in Plastic Pipe Institute (PPI) TR-33. The parameters and procedures shown in Section 9. Procedure 3— Saddle Fusion, were developed and validated using testing documented in PPI TR-41.

Note 2: Information about polyethylene pipe and fittings that have related polymer chemistry is presented in Plastics Pipe Institute (PPI) TR-33 and TR-41.

1.3 Parts that are within the dimensional tolerances given in present ASTM specifications are required to produce sound joints between polyethylene pipe and fittings when using the joining techniques described in this practice.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this practice references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade O...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´2

Designation: F2620 − 20a An American National Standard

Standard Practice for

1

Heat Fusion Joining of Polyethylene Pipe and Fittings

This standard is issued under the fixed designation F2620; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 2 was editorially corrected for clarity in October 2021.

2

ε NOTE—Table 2 was editorially corrected in March 2022.

1. Scope* 1.5 The text of this practice references notes, footnotes, and

appendixes which provide explanatory material. These notes

1.1 This practice describes procedures for making joints

and footnotes (excluding those in tables and figures) shall not

with polyethylene (PE) pipe and fittings by means of heat

be considered as requirements of the practice.

fusion joining in, but not limited to, a field environment. Other

suitable heat fusion joining procedures are available from 1.6 This standard does not purport to address all of the

various sources including pipe and fitting manufacturers. This safety concerns, if any, associated with its use. It is the

practice does not purport to address all possible heat fusion responsibility of the user of this standard to establish appro-

joining procedures, or to preclude the use of qualified proce- priate safety, health, and environmental practices and deter-

dures developed by other parties that have been proved to

mine the applicability of regulatory limitations prior to use.

produce reliable heat fusion joints.

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.2 The parameters and procedures are applicable only to

ization established in the Decision on Principles for the

joining polyethylene pipe and fittings of related polymer

Development of International Standards, Guides and Recom-

chemistry. They are intended for PE fuel gas pipe in accor-

mendations issued by the World Trade Organization Technical

dance with Specification D2513 and PE potable water, sewer

Barriers to Trade (TBT) Committee.

and industrial pipe manufactured in accordance with Specifi-

cation F714, Specification D3035, and AWWA C901 and

2. Referenced Documents

C906. Consult with the pipe manufacturers to make sure they

approve this procedure for the pipe to be joined (see Appendix 2

2.1 ASTM Standards:

X1).

D2513 Specification for Polyethylene (PE) Gas Pressure

NOTE 1—The parameters and procedures shown for Section 8. Proce-

Pipe, Tubing, and Fittings

dure 2—Butt Fusion, were developed and validated using testing docu-

D3035 SpecificationforPolyethylene(PE)PlasticPipe(DR-

mented in Plastic Pipe Institute (PPI) TR-33. The parameters and

PR) Based on Controlled Outside Diameter

procedures shown in Section 9. Procedure 3— Saddle Fusion, were

developed and validated using testing documented in PPI TR-41.

F714 Specification for Polyethylene (PE) Plastic Pipe (DR-

NOTE 2—Information about polyethylene pipe and fittings that have

PR) Based on Outside Diameter

related polymer chemistry is presented in Plastics Pipe Institute (PPI)

F1056 Specification for Socket Fusion Tools for Use in

TR-33 and TR-41.

Socket Fusion Joining Polyethylene Pipe or Tubing and

1.3 Parts that are within the dimensional tolerances given in

Fittings

present ASTM specifications are required to produce sound

F3124 Practice for Data Recording the Procedure used to

joints between polyethylene pipe and fittings when using the

Produce Heat Butt Fusion Joints in Plastic Piping Systems

joining techniques described in this practice.

or Fittings

F3183 Practice for Guided Side Bend Evaluation of Poly-

1.4 The values stated in inch-pound units are to be regarded

ethylene Pipe Butt Fusion Joint

as standard. The values given in parentheses are mathematical

F3190 Practice for Heat Fusion Equipment (HFE) Operator

conversions to SI units that are provided for information only

Qualification on Polyethylene (PE) and Polyamide (PA)

and are not considered standard.

Pipe and Fittings

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2020. Published October 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2006. Last previous edition approved in 2020 as F2620 – 20. DOI: Standards volume information, refer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.