ASTM F2390-21

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Content

Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Content

ABSTRACT

This specification covers the basic requirements and corresponding test methods for poly(vinyl chloride) (PVC) plastic drain, waste, and vent (DWV) pipes and fittings that contain a uniform blend of virgin PVC compound and post-industrial recycle material. When evaluated by the test procedures provided herein, the pipes and fittings shall conform to specified values of the following requirements: dimensions; pipe stiffness, deflection load, lower confidence limit, and flattening resistance; crush resistance; impact resistance; hydrostatic burst resistance; and solvent cement.

SCOPE

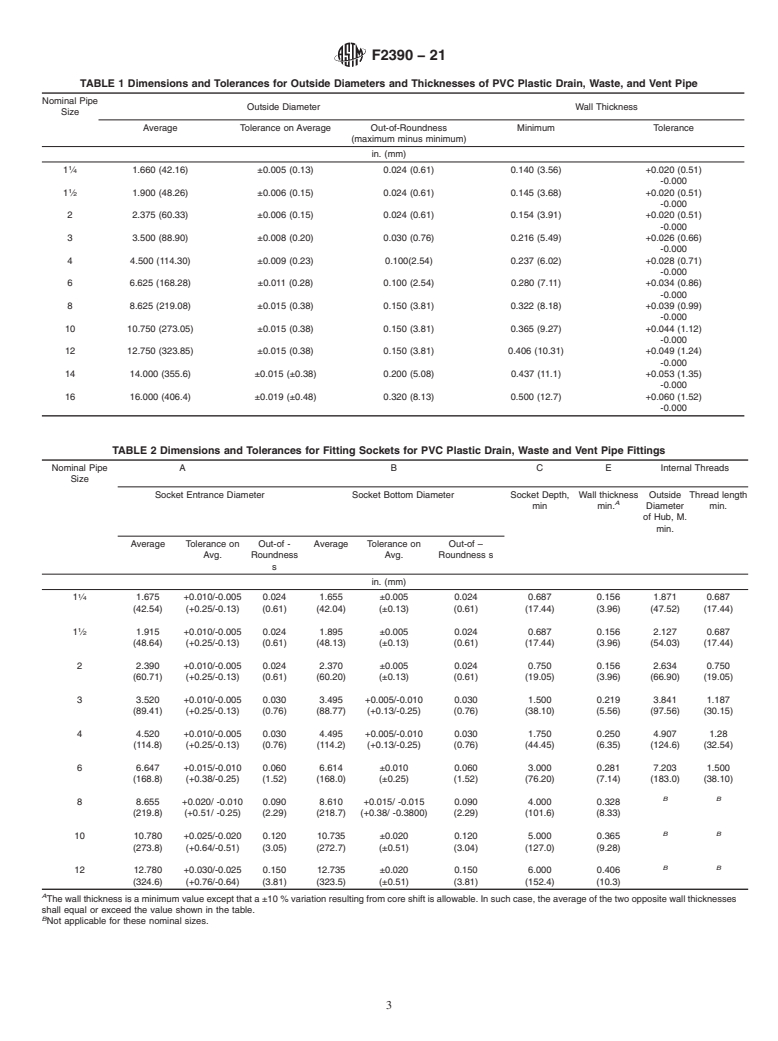

1.1 This specification covers requirements and test methods for materials, dimensions and tolerances, pipe stiffness, crush resistance, impact resistance, hydrostatic burst resistance, and solvent cement for poly(vinyl chloride) plastic drain, waste, and vent (DWV) pipe and fittings.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should a system fail for any reason.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2390 −21 An American National Standard

Standard Specification for

Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent

(DWV) Pipe and Fittings Having Post-Industrial Recycle

1

Content

This standard is issued under the fixed designation F2390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers requirements and test methods 2.1 ASTM Standards:

for materials, dimensions and tolerances, pipe stiffness, crush D618 Practice for Conditioning Plastics for Testing

resistance, impact resistance, hydrostatic burst resistance, and D1599 Test Method for Resistance to Short-Time Hydraulic

solvent cement for poly(vinyl chloride) plastic drain, waste, Pressure of Plastic Pipe, Tubing, and Fittings

and vent (DWV) pipe and fittings. D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.2 The values stated in inch-pound units are to be regarded

D1784 Classification System and Basis for Specification for

as standard. The values given in parentheses are mathematical

Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlo-

conversions to SI units that are provided for information only

rinated Poly(Vinyl Chloride) (CPVC) Compounds

and are not considered standard.

D2122 Test Method for Determining Dimensions of Ther-

1.3 Thetextofthisspecificationreferencesnotes,footnotes,

moplastic Pipe and Fittings

and appendixes which provide explanatory material. These

D2412 Test Method for Determination of External Loading

notesandfootnotes(excludingthoseintablesandfigures)shall

Characteristics of Plastic Pipe by Parallel-Plate Loading

not be considered as requirements of the specification.

D2444 Practice for Determination of the Impact Resistance

1.4 The following safety hazards caveat pertains only to the of Thermoplastic Pipe and Fittings by Means of a Tup

test methods portion, Section 7, of this specification. This

(Falling Weight)

standard does not purport to address all of the safety concerns,

D2564 Specification for Solvent Cements for Poly(Vinyl

if any, associated with its use. It is the responsibility of the user Chloride) (PVC) Plastic Piping Systems

of this standard to establish appropriate safety, health, and

F2135 Specification for Molded Drain, Waste, and Vent

environmental practices and determine the applicability of (DWV) Short-Pattern Plastic Fittings

regulatory limitations prior to use.

D3311 Specification for Drain, Waste, and Vent (DWV)

Plastic Fittings Patterns

NOTE 1—Pressurized (compressed) air or other compressed gases

F402 Practice for Safe Handling of Solvent Cements,

contain large amounts of stored energy which present serious safety

Primers, and Cleaners Used for Joining Thermoplastic

hazards should a system fail for any reason.

Pipe and Fittings

1.5 This international standard was developed in accor-

F412 Terminology Relating to Plastic Piping Systems

dance with internationally recognized principles on standard-

F1498 Specification forTaper PipeThreads 60° forThermo-

ization established in the Decision on Principles for the

plastic Pipe and Fittings

Development of International Standards, Guides and Recom-

F1866 Specification for Poly (Vinyl Chloride) (PVC) Plastic

mendations issued by the World Trade Organization Technical

Schedule 40 Drainage and DWV Fabricated Fittings

Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2021. Published August 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin2007.Lastpreviouseditionapprovedin2017asF2390–12(2017).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2390-21. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2390−21

3. Terminology 5.3 Rework Material—The manufacturer is permitted to use

his own clean pipe or fitting rework material, except as

3.1 Definitions—Definitions are in accordance with Termi-

specified in 5.4, provided that the pipe or fittings produced

nology in F412, and abbreviations are in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2390 − 12 (Reapproved 2017) F2390 − 21 An American National Standard

Standard Specification for

Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent

(DWV) Pipe and Fittings Having Post-Industrial Recycle

1

Content

This standard is issued under the fixed designation F2390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers requirements and test methods for materials, dimensions and tolerances, pipe stiffness, crush

resistance, impact resistance, hydrostatic burst resistance, and solvent cement for poly(vinyl chloride) plastic drain, waste, and vent

(DWV) pipe and fittings.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should a

system fail for any reason.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784 Classification System and Basis for Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated

Poly(Vinyl Chloride) (CPVC) Compounds

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. Current

edition approved Aug. 1, 2017Aug. 1, 2021. Published September 2017August 2021. Originally approved in 2007. Last previous edition approved in 20122017 as

F2390F2390–12(2017).–12. DOI: 10.1520/F2390-12R17.10.1520/F2390-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2390 − 21

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Practice for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

D2564 Specification for Solvent Cements for Poly(Vinyl Chloride) (PVC) Plastic Piping Systems

F2135 Specification for Molded Drain, Waste, and Vent (DWV) Short-Pattern Plastic Fittings

D3311 Specification for Drain, Waste, and Vent (DWV) Plastic Fittings Patterns

F402 Practice for Safe Handling of Solvent Cements, Primers, and Cleaners Used for Joining Thermoplastic Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F1498 Specification for Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

F1866 Specification for Poly (Vinyl Chloride) (PVC) Plastic Schedule 40 Drainage and DWV Fabricated Fittings

3. Terminology

3.1 Definitions—Definitions are in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.