ASTM D5581-07A(2021)e1

(Test Method)Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 in. Diameter Specimen)

Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 in. Diameter Specimen)

SIGNIFICANCE AND USE

3.1 This test method is used in the laboratory mix design of bituminous mixtures. Specimens are prepared in accordance with the method and tested for maximum load and flow. Density and voids properties may also be determined on specimens prepared in accordance with the method. The testing section of this method can also be used to obtain maximum load and flow for bituminous paving specimens cored from pavements or prepared by other methods. These results may differ from values obtained on specimens prepared by this test method.

SCOPE

1.1 This test method covers the measurement of the resistance to plastic flow of cylindrical specimens of bituminous paving mixture loaded on the lateral surface by means of the Marshall apparatus. This test method is for use with mixtures containing asphalt cement and aggregate up to 11/2 in. (37.5 mm) nominal maximum size.

1.2 The values stated in inch-pound units are to be regarded as standard except for reference to sieve sizes and size of aggregate as measured by testing sieves in which SI units are standard according to Specification E11. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D5581 − 07a (Reapproved 2021)

Standard Test Method for

Resistance to Plastic Flow of Bituminous Mixtures Using

Marshall Apparatus (6 in. Diameter Specimen)

This standard is issued under the fixed designation D5581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Section 1 was updated editorially in December 2021.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the measurement of the resis-

C670 Practice for Preparing Precision and Bias Statements

tance to plastic flow of cylindrical specimens of bituminous

for Test Methods for Construction Materials

paving mixture loaded on the lateral surface by means of the

D2493/D2493M Practice for Viscosity-Temperature Chart

Marshall apparatus. This test method is for use with mixtures

for Asphalt Binders

containing asphalt cement and aggregate up to 1 ⁄2 in.

D6926 Practice for Preparation of Asphalt Mixture Speci-

(37.5 mm) nominal maximum size.

mens Using Marshall Apparatus

1.2 The values stated in inch-pound units are to be regarded

D6927 Test Method for Marshall Stability and Flow of

as standard except for reference to sieve sizes and size of

Asphalt Mixtures

aggregate as measured by testing sieves in which SI units are

E11 Specification for Woven Wire Test Sieve Cloth and Test

standard according to Specification E11. The values given in

Sieves

parentheses are mathematical conversions to SI units that are

2.2 AASTHO Standards:

provided for information only and are not considered standard.

T 316 Viscosity Determination of Asphalt Binder Using

Rotational Viscometer

1.3 The text of this standard references notes and footnotes

which provide explanatory material. These notes and footnotes

3. Significance and Use

(excluding those in tables and figures) shall not be considered

3.1 This test method is used in the laboratory mix design of

as requirements of the standard.

bituminous mixtures. Specimens are prepared in accordance

1.4 This standard does not purport to address all of the with the method and tested for maximum load and flow.

safety concerns, if any, associated with its use. It is the Density and voids properties may also be determined on

responsibility of the user of this standard to establish appro- specimenspreparedinaccordancewiththemethod.Thetesting

priate safety, health, and environmental practices and deter- section of this method can also be used to obtain maximum

mine the applicability of regulatory limitations prior to use. load and flow for bituminous paving specimens cored from

pavements or prepared by other methods. These results may

1.5 This international standard was developed in accor-

differ from values obtained on specimens prepared by this test

dance with internationally recognized principles on standard-

method.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Apparatus

mendations issued by the World Trade Organization Technical

4.1 Specimen Mold Assembly—Mold cylinders nominal

Barriers to Trade (TBT) Committee.

6.5 in. (165.1 mm) outside diameter steel tubing with

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee D04 on Road contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Paving Materials and is the direct responsibility of Subcommittee D04.20 on Standards volume information, refer to the standard’s Document Summary page on

Mechanical Tests of Asphalt Mixtures. the ASTM website.

Current edition approved Dec. 15, 2021. Published December 2021. Originally Available from American Association of State Highway and Transportation

approved in 1994. Last previous edition approved in 2013 as D5581 – 07a (2013). Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

DOI: 10.1520/D5581-07AR21E01. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5581 − 07a (2021)

FIG. 2 Compaction Hammer (Generic)

FIG. 1 Compaction Mold

other wood having an average dry weight of 42 to 48 lb/ft

6.000 6 0.008 in. (152.4 6 0.2 mm) inside diameter by 4.5 in. (0.67 to 0.77 g/cm ).The wooden post shall be secured by four

(114.3 mm) in height, base plates, and extension collars shall angle brackets to a solid concrete slab. The steel cap shall be

conform to the details shown in Fig. 1. Nine mold cylinders are firmly fastened to the post. The pedestal assembly shall be

recommended. installed so that the post is plumb and the cap is level.

4.2 Specimen Extractor, steel, in the form of a disk with a 4.5 Specimen Mold Holder, mounted on the compaction

diameter from 5.950 to 5.990 in. (151.1 to 152.1 mm) and pedestal so as to center the compaction mold over the center of

the post as shown in Fig. 3 or equivalent arrangement. It shall

0.5 in. (13 mm) thick for extracting the compacted specimen

from the specimen mold with the use of the mold collar. A hold the compaction mold, collar, and base plate securely in

suitable bar is required to transfer the load from the ring position during compaction of the specimen.

dynamometer adapter to the extension collar while extracting

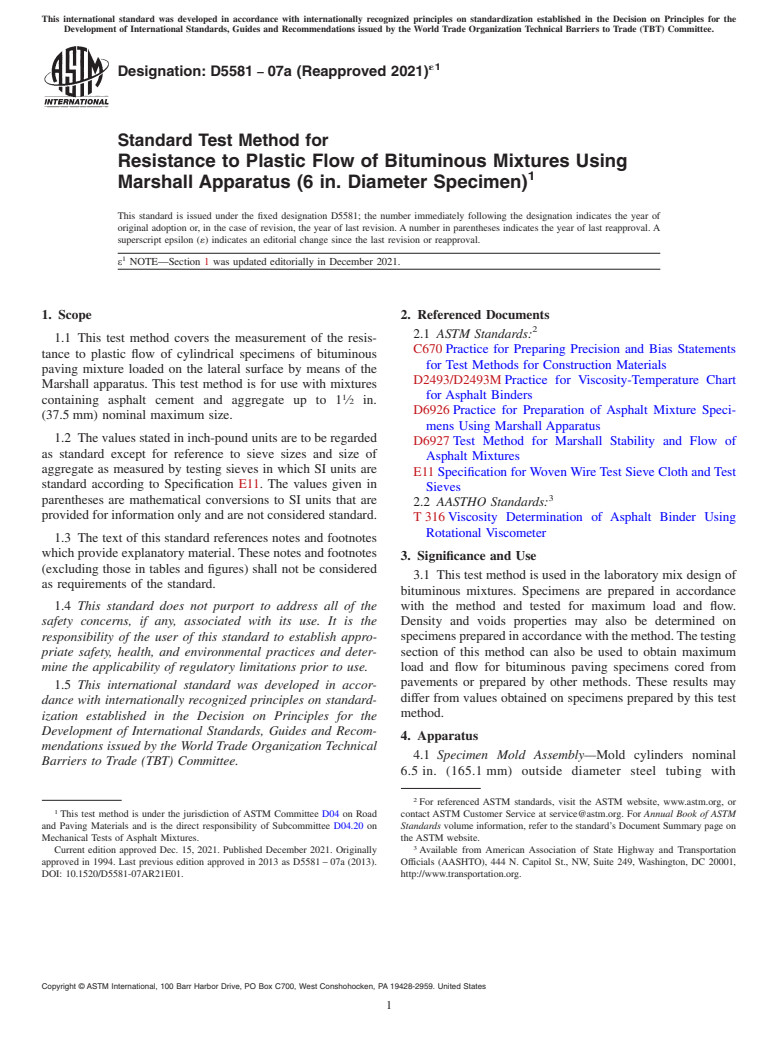

4.6 Breaking Head—The breaking head (Fig. 4) shall con-

the specimen.

sist of upper and lower cylindrical segments or test heads

4.3 Mechanical Compactor and Compaction Hammer— having an inside radius of curvature of 3 in. (76.2 mm)

Compactor with ⁄3 hp (250 W) minimum motor, chain lift, accurately machined. The lower segment shall be mounted on

frame, and automatic sliding weight release. The compaction a base having two perpendicular guide rods or posts extending

hammer (Fig. 2) shall have a flat, circular tamping face 5.88 in. upward. Guide sleeves in the upper segments shall be in such

(149.4 mm) in diameter and a 22.50 6 0.02 lb a position as to direct the two segments together without

(10.21 6 0.01 kg) sliding weight with a free fall of appreciable binding or loose motion on the guide rods. When

18.0 6 0.1 in. (457.2 6 2.5 mm). Two compaction hammers a 6.000 in. (152.4 mm) diameter by 4 in. (100 mm) thick metal

are recommended. block is placed between the two segments, the inside diameters

and the gaps between the segments shall conform to Fig. 4.All

4.4 Compaction Pedestal—The compaction pedestal shall

steel components shall be plated.

consist of an 8 by 8 by 18 in. (203.2 by 203.2 by 457.2 mm)

wooden post capped with a 12 by 12 by 1 in. (304.8 by 304.8 4.7 LoadingJack—The loading jack (Fig. 5) shall consist of

by 25.4 mm) steel plate.The wooden post shall be oak, pine, or a screw jack mounted in a test frame and shall produce a

´1

D5581 − 07a (2021)

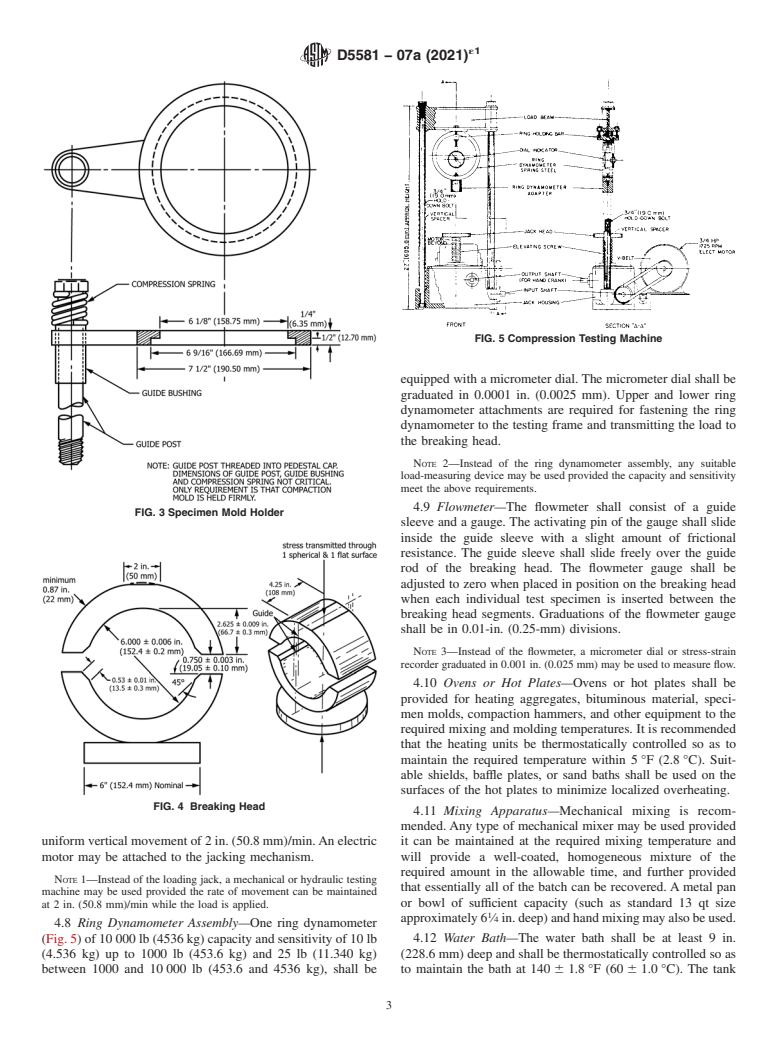

FIG. 5 Compression Testing Machine

equipped with a micrometer dial. The micrometer dial shall be

graduated in 0.0001 in. (0.0025 mm). Upper and lower ring

dynamometer attachments are required for fastening the ring

dynamometer to the testing frame and transmitting the load to

the breaking head.

NOTE 2—Instead of the ring dynamometer assembly, any suitable

load-measuring device may be used provided the capacity and sensitivity

meet the above requirements.

4.9 Flowmeter—The flowmeter shall consist of a guide

FIG. 3 Specimen Mold Holder

sleeve and a gauge. The activating pin of the gauge shall slide

inside the guide sleeve with a slight amount of frictional

resistance. The guide sleeve shall slide freely over the guide

rod of the breaking head. The flowmeter gauge shall be

adjusted to zero when placed in position on the breaking head

when each individual test specimen is inserted between the

breaking head segments. Graduations of the flowmeter gauge

shall be in 0.01-in. (0.25-mm) divisions.

NOTE 3—Instead of the flowmeter, a micrometer dial or stress-strain

recorder graduated in 0.001 in. (0.025 mm) may be used to measure flow.

4.10 Ovens or Hot Plates—Ovens or hot plates shall be

provided for heating aggregates, bituminous material, speci-

men molds, compaction hammers, and other equipment to the

required mixing and molding temperatures. It is recommended

that the heating units be thermostatically controlled so as to

maintain the required temperature within 5 °F (2.8 °C). Suit-

able shields, baffle plates, or sand baths shall be used on the

surfaces of the hot plates to minimize localized overheating.

FIG. 4 Breaking Head

4.11 Mixing Apparatus—Mechanical mixing is recom-

mended. Any type of mechanical mixer may be used provided

uniform vertical movement of 2 in. (50.8 mm)/min.An electric it can be maintained at the required mixing temperature and

motor may be attached to the jacking mechanism. will provide a well-coated, homogeneous mixture of the

required amount in the allowable time, and further provided

NOTE 1—Instead of the loading jack, a mechanical or hydraulic testing

that essentially all of the batch can be recovered. A metal pan

machine may be used provided the rate of movement can be maintained

or bowl of sufficient capacity (such as standard 13 qt size

at 2 in. (50.8 mm)/min while the load is applied.

approximately6 ⁄4in.deep)andhandmixingmayalsobeused.

4.8 Ring Dynamometer Assembly—One ring dynamometer

(Fig. 5) of 10 000 lb (4536 kg) capacity and sensitivity of 10 lb 4.12 Water Bath—The water bath shall be at least 9 in.

(4.536 kg) up to 1000 lb (453.6 kg) and 25 lb (11.340 kg) (228.6 mm) deep and shall be thermostatically controlled so as

between 1000 and 10 000 lb (453.6 and 4536 kg), shall be to maintain the bath at 140 6 1.8 °F (60 6 1.0 °C). The tank

´1

D5581 − 07a (2021)

shallhaveaperforatedfalsebottomorbeequippedwithashelf 5.4.1 Weigh into separate pans for each test specimen the

for supporting specimens 2 in. (50.8 mm) above the bottom of amount of each size fraction required to produce a batch that

the bath. will result in a compacted specimen 3.75 6 0.10 in.

(95.2 6 2.54 mm) in height (about 4050 g). Place the pans on

4.13 Miscellaneous Equipment:

the hot plate or in the oven and heat to a temperature not

4.13.1 Containers for heating aggregates, flat-bottom metal

exceeding the mixing temperature established in 5.3 by more

pans, or other suitable containers.

than approximately 50 °F (28 °C). Charge the mixing bowl

4.13.2 Containers for heating bituminous material, either

with the heated aggregate and dry mix thoroughly. Form a

gill-type tins, beakers, pouring pots, or saucepans may be used.

crater in the dry blended aggregate and weigh the preheated

4.13.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.