ASTM F1650-21

(Practice)Standard Practice for Evaluating Tire Traction Performance Data Under Varying Test Conditions

Standard Practice for Evaluating Tire Traction Performance Data Under Varying Test Conditions

ABSTRACT

This practice covers the required correction procedures for examining sequential control tire data for any systematic or bias (not random) variation due to changing test conditions that may influence absolute and also comparative performance of candidate tires, as they are tested over any short or extended time period. The procedures provided here may be used for any repetitive tire traction testing in any environment (for example, dry, wet, snow, ice) where test conditions are subject to change. This practice does not address the issue of rejecting outlier data points or test values that might occur among a set of otherwise acceptable data values obtained under identical test conditions in a short time period. Method A uses the initial operational conditions defined by the first control traction test as a reference point. The calculations correct all traction test performance parameters (for example, traction coefficients) to the initial level or condition of the pavement or other testing conditions, or both. With this method, corrections may be made after only a few candidate and control sets have been evaluated. Method B uses essentially the midpoint of any evaluation program, with the grand average traction test value as a reference point. This grand average value is obtained with higher precision than the initial control traction test average of Method A because it contains more values. However, Method B corrections cannot be made until the grand average value is established, which is normally at the end of any program.

SCOPE

1.1 This practice covers the required procedures for examining sequential control tire data for any variation due to changing test conditions. Such variations may influence absolute and also comparative performance of candidate tires, as they are tested over any short or extended time period. The variations addressed in this practice are systematic or bias variations and not random variations. See Appendix X1 for additional details.

1.1.1 Two types of variation may occur: time or test sequence “trend variations,” either linear or curvilinear, and the less common transient or abrupt shift variations. If any observed variations are declared to be statistically significant, the calculation procedures are given to correct for the influence of these variations. This approach is addressed in Method A.

1.2 In some testing programs, a policy is adopted to correct all candidate traction test data values without the application of a statistical routine to determine if a significant trend or shift is observed. This option is part of this practice and is addressed in Method B.

1.3 The issue of rejecting outlier data points or test values that might occur among a set of otherwise acceptable data values obtained under identical test conditions in a short time period is not part of this practice. Specific test method or other outlier rejection standards that address this issue may be used on the individual data sets prior to applying this practice and its procedures.

1.4 Although this practice applies to various types of tire traction testing (for example, dry, wet, snow, ice), the procedures as given in this practice may be used for any repetitive tire testing in an environment where test conditions are subject to change.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1650 − 21

Standard Practice for

Evaluating Tire Traction Performance Data Under Varying

1

Test Conditions

This standard is issued under the fixed designation F1650; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Tiretractiontestingprogramsatprovinggroundsorotherexteriortestsitesareoftenextendedover

a period of days or weeks. During this time period test conditions may change due to a number of

varying factors, for example, temperature, rain or snow fall, surface texture, water depth, and wind

velocity and direction. If tire performance comparisons are to be made over any part of the test

program(ortheentireprogram)wherethesetestconditionvariationsareknownorsuspectedtoaffect

performance, the potential influence of these variations must be considered in any final evaluation of

traction performance.

1. Scope 1.4 Although this practice applies to various types of tire

traction testing (for example, dry, wet, snow, ice), the proce-

1.1 This practice covers the required procedures for exam-

dures as given in this practice may be used for any repetitive

ining sequential control tire data for any variation due to

tire testing in an environment where test conditions are subject

changing test conditions. Such variations may influence abso-

to change.

lute and also comparative performance of candidate tires, as

1.5 This standard does not purport to address all of the

they are tested over any short or extended time period. The

variations addressed in this practice are systematic or bias safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

variations and not random variations. See Appendix X1 for

additional details. priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1.1 Two types of variation may occur: time or test

sequence“trendvariations,”eitherlinearorcurvilinear,andthe 1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

less common transient or abrupt shift variations. If any

observed variations are declared to be statistically significant, ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

thecalculationproceduresaregiventocorrectfortheinfluence

of these variations. This approach is addressed in Method A. mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.2 In some testing programs, a policy is adopted to correct

allcandidatetractiontestdatavalueswithouttheapplicationof

2. Referenced Documents

astatisticalroutinetodetermineifasignificanttrendorshiftis

2

2.1 ASTM Standards:

observed. This option is part of this practice and is addressed

E501Specification for Standard Rib Tire for Pavement

in Method B.

Skid-Resistance Tests

1.3 The issue of rejecting outlier data points or test values

E524Specification for Standard Smooth Tire for Pavement

that might occur among a set of otherwise acceptable data

Skid-Resistance Tests

values obtained under identical test conditions in a short time

E826Practice for Testing Homogeneity of a Metal Lot or

period is not part of this practice. Specific test method or other

Batch in Solid Form by Spark Atomic Emission Spec-

outlier rejection standards that address this issue may be used

trometry

ontheindividualdatasetspriortoapplyingthispracticeandits

E1136Specification for P195/75R14 Radial Standard Refer-

procedures.

ence Test Tire

1

This practice is under the jurisdiction ofASTM Committee F09 on Tires and is

2

the direct responsibility of Subcommittee F09.20 on Vehicular Testing. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2021. Published April 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 1995. Last previous edition approved in 2014 as F1650–98 (2014) . Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1650-21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

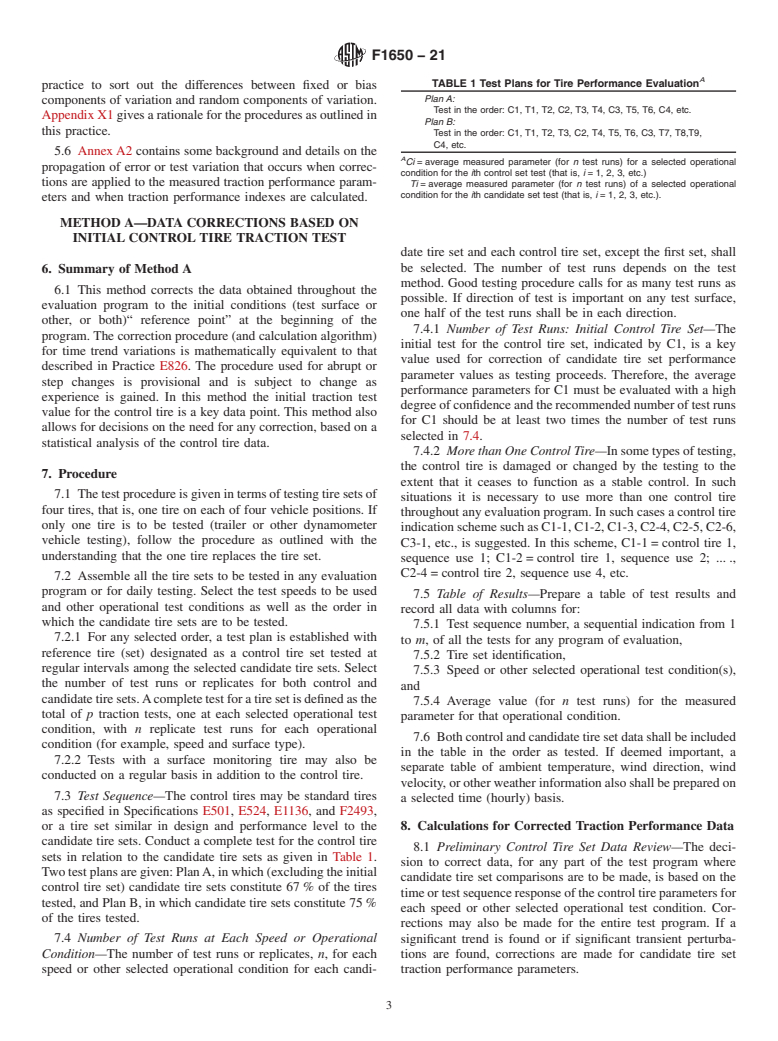

F1650 − 21

F538Terminology Relating to the Characteristics and Per- 4. Significance and Use

formance of Tires

4.1 Tire testing is

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1650 − 98 (Reapproved 2014) F1650 − 21

Standard Practice for

Evaluating Tire Traction Performance Data Under Varying

1

Test Conditions

This standard is issued under the fixed designation F1650; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorially corrected Subsection X2.4 in April 2014.

INTRODUCTION

Tire traction testing programs at proving grounds or other exterior test sites are often extended over

a period of days or weeks. During this time period test conditions may change due to a number of

varying factors, for example, temperature, rain or snow fall, surface texture, water depth, and wind

velocity and direction. If tire performance comparisons are to be made over any part of the test

program (or the entire program) where these test condition variations are known or suspected to affect

performance, the potential influence of these variations must be considered in any final evaluation of

traction performance.

1. Scope

1.1 This practice covers the required procedures for examining sequential control tire data for any variation due to changing test

conditions. Such variations may influence absolute and also comparative performance of candidate tires, as they are tested over

any short or extended time period. The variations addressed in this practice are systematic or bias variations and not random

variations. See Appendix X1 for additional details.

1.1.1 Two types of variation may occur: time or test sequence “trend variations,” either linear or curvilinear, and the less common

transient or abrupt shift variations. If any observed variations are declared to be statistically significant, the calculation procedures

are given to correct for the influence of these variations. This approach is addressed in Method A.

1.2 In some testing programs, a policy is adopted to correct all candidate traction test data values without the application of a

statistical routine to determine if a significant trend or shift is observed. This option is part of this practice and is addressed in

Method B.

1.3 The issue of rejecting outlier data points or test values that might occur among a set of otherwise acceptable data values

obtained under identical test conditions in a short time period is not part of this practice. Specific test method or other outlier

rejection standards that address this issue may be used on the individual data sets prior to applying this practice and its procedures.

1.4 Although this practice applies to various types of tire traction testing (for example, dry, wet, snow, ice), the procedures as given

in this practice may be used for any repetitive tire testing in an environment where test conditions are subject to change.

1

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.20 on Vehicular Testing.

Current edition approved Jan. 1, 2014April 1, 2021. Published February 2014April 2021. Originally approved in 1995. Last previous edition approved in 20052014 as

ε1

F1650 – 98 (2005).(2014) . DOI: 10.1520/F1650-98R14E01.10.1520/F1650-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1650 − 21

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E501 Specification for Standard Rib Tire for Pavement Skid-Resistance Tests

E524 Specification for Standard Smooth Tire for Pavement Skid-Resistance Tests

E826 Practice for Testing Homogeneity of a Metal Lot or Batch in Solid Form by Spark Atomic Emission Spectrometry

E1136 Specification for P195/75R14 Radial Standard Reference Test Tire

F538 Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.