ASTM F414-21

(Test Method)Standard Test Method for Energy Absorbed by a Tire When Deformed by Slow-Moving Plunger

Standard Test Method for Energy Absorbed by a Tire When Deformed by Slow-Moving Plunger

SIGNIFICANCE AND USE

5.1 This test method establishes a standard procedure of test and provides data that can be related to tire strength, but does not measure tire performance or establish specification or tolerances.

SCOPE

1.1 This test method covers the determination of tire plunger energy required to completely penetrate the tread area of an inflated tire as indicated by a rupture, loss of inflation pressure, sudden drop in plunger force or bottom-out. The test requires utilization of a laboratory testing machine capable of slowly penetrating the tread surface of a tire with a plunger having a hemispherical end.

1.2 This test method is applicable to pneumatic tires for vehicles normally used on the road.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F414 − 21

Standard Test Method for

Energy Absorbed by a Tire When Deformed by Slow-Moving

1

Plunger

ThisstandardisissuedunderthefixeddesignationF414;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F538Terminology Relating to Characteristics and Perfor-

mance of Tires

1.1 This test method covers the determination of tire

F1082Practice for Tires—Determining Precision for Test

plunger energy required to completely penetrate the tread area

3

Method Standards (Withdrawn 2005)

of an inflated tire as indicated by a rupture, loss of inflation

IEEE/ASTM SI10-02American National Standard for Use

pressure, sudden drop in plunger force or bottom-out. The test

of the International System of Units (SI): The Modern

requires utilization of a laboratory testing machine capable of

Metric System

slowly penetrating the tread surface of a tire with a plunger

having a hemispherical end.

3. Terminology

1.2 This test method is applicable to pneumatic tires for

3.1 Definitions:

vehicles normally used on the road.

3.1.1 bottom out, v—to deform a tire by radial load on the

1.3 The values stated in SI units are to be regarded as the

tread until radial movement of the inside surface is stopped by

standard. The values given in parentheses are provided for

the rim or other tire inside surface. F538

information only.

3.1.2 groove, n—a void that is relatively narrow compared

1.4 This standard does not purport to address all of the

to its length. F538

safety concerns, if any, associated with its use. It is the

3.1.3 load range, n—aletterdesignation(A,B,C,D)or,for

responsibility of the user of this standard to establish appro-

P-metrictires,standardload(SL),lightload(LL),orextraload

priate safety, health, and environmental practices and deter-

(XL), used to identify a given size tire with its load and

mine the applicability of regulatory limitations prior to use.

inflation limits when used in a specific type of service. F538

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.1.4 load rating [M], n—the maximum load a tire is rated

ization established in the Decision on Principles for the

to carry for a given usage at a specific cold inflation pressure.

Development of International Standards, Guides and Recom-

F538

mendations issued by the World Trade Organization Technical

3.1.5 maximum load rating [M], n—of a passenger tire, the

Barriers to Trade (TBT) Committee.

load rating at the maximum permissible cold inflation pressure

for that tire. F538

2. Referenced Documents

2

3.1.6 maximum plunger travel [L], n—in tire testing, the

2.1 ASTM Standards:

relative displacement of tread surface by a plunger, measured

D4483Practice for Evaluating Precision for Test Method

from the point of initial contact of the plunger with the tread

StandardsintheRubberandCarbonBlackManufacturing

surface to the point of maximum force at rupture or at the

Industries

bottom-out point. F538

E4Practices for Force Calibration and Verification of Test-

ing Machines 3.1.7 nominal plunger energy,W=(F× P)/2, n—in tire

testing, one half of the product of a peak force (required to

rupture the tire structure in tread area) and maximum plunger

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires

travel into a tire at the time of rupture. F538

and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-

Vehicular) Testing.

3.1.8 plunger, n—in tire testing, a cylindrical rod with a

Current edition approved Sept. 1, 2021. Published October 2021. Originally

hemispherical end. F538

approved in 1975. Last previous edition approved in 2015 as F414–15. DOI:

10.1520/F0414-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F414 − 21

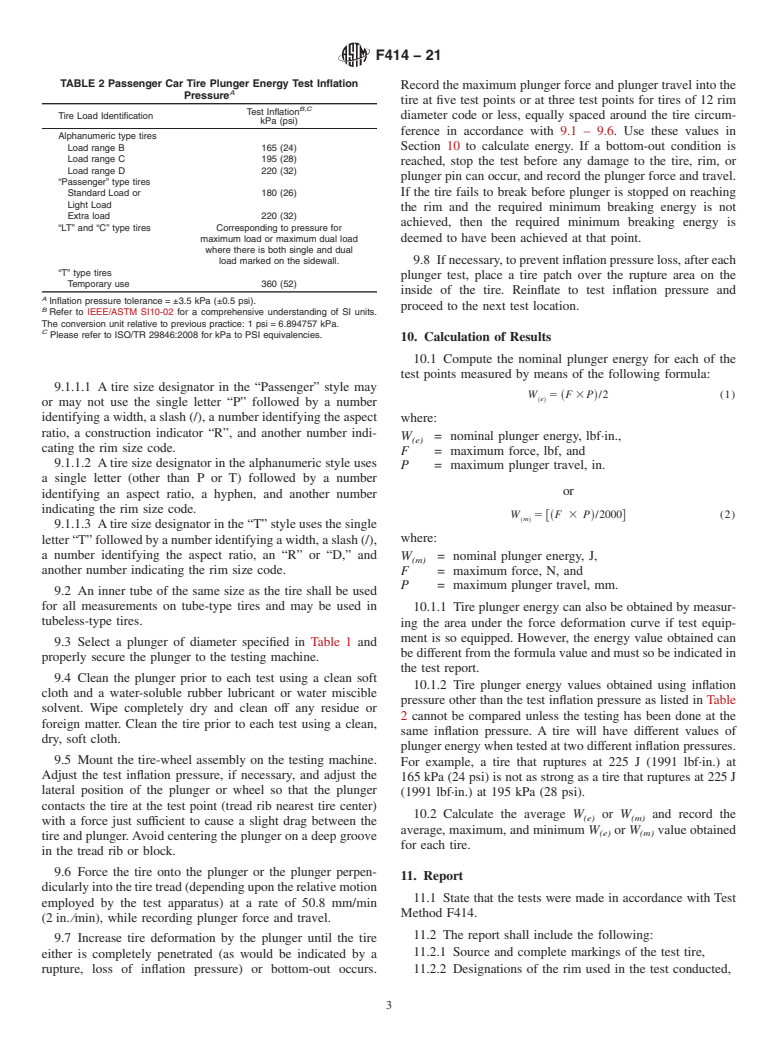

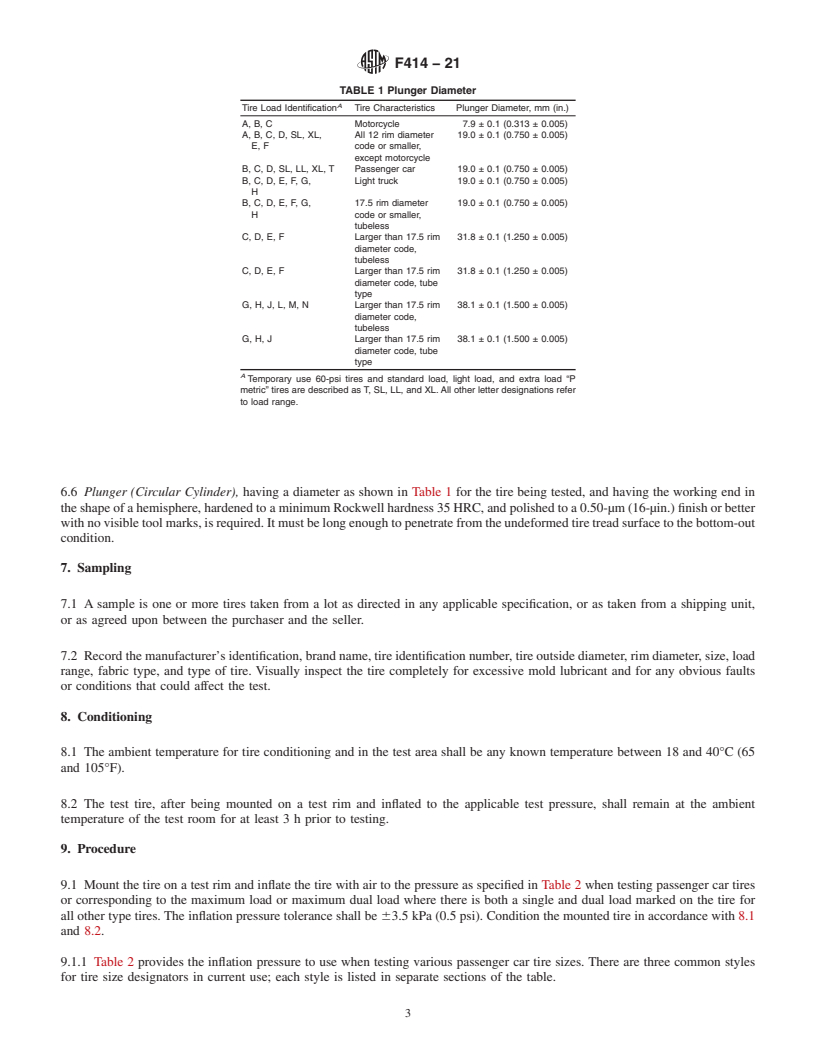

TABLE 1 Plunger Diameter

3.1.9 void, n—a volume (in the tread band) defined by the

A

lack of rubber; the depth dimension of this volume may vary Tire Load Identification Tire Characteristics Plunger Diameter, mm (in.)

from point to point in (on) the tread band. F

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F414 − 15 F414 − 21

Standard Test Method for

Energy Absorbed by a Tire When Deformed by Slow-Moving

1

Plunger

This standard is issued under the fixed designation F414; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of tire plunger energy required to completely penetrate the tread area of an inflated

tire as indicated by a rupture, loss of inflation pressure, sudden drop in plunger force or bottom-out. The test requires utilization

of a laboratory testing machine capable of slowly penetrating the tread surface of a tire with a plunger having a hemispherical end.

1.2 This test method is applicable to pneumatic tires for vehicles normally used on the road.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

E4 Practices for Force Calibration and Verification of Testing Machines

F538 Terminology Relating to Characteristics and Performance of Tires

3

F1082 Practice for Tires—Determining Precision for Test Method Standards (Withdrawn 2005)

IEEE/ASTM SI10-02 American National Standard for Use of the International System of Units (SI): The Modern Metric System

3. Terminology

3.1 Definitions:

3.1.1 bottom out, v—to deform a tire by radial load on the tread until radial movement of the inside surface is stopped by the rim

or other tire inside surface. F538

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular)

Testing.

Current edition approved June 1, 2015Sept. 1, 2021. Published August 2015October 2021. Originally approved in 1975. Last previous edition approved in 20092015 as

F414 – 09.F414 – 15. DOI: 10.1520/F0414-15.10.1520/F0414-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F414 − 21

3.1.2 groove, n—a void that is relatively narrow compared to its length. F538

3.1.3 load range, n—a letter designation (A, B, C, D) or, for P-metric tires, standard load (SL), light load (LL), or extra load (XL),

used to identify a given size tire with its load and inflation limits when used in a specific type of service. F538

3.1.4 load rating [M], n—the maximum load a tire is rated to carry for a given usage at a specific cold inflation pressure. F538

3.1.5 maximum load rating [M], n—of a passenger tire, the load rating at the maximum permissible cold inflation pressure for

that tire. F538

3.1.6 maximum plunger travel [L], n—in tire testing, the relative displacement of tread surface by a plunger, measured from the

point of initial contact of the plunger with the tread surface to the point of maximum force at rupture or at the bottom-out point.

F538

3.1.7 nominal plunger energy, W = (F × P)/2, n—in tire testing, one half of the product of a peak force (required to rupture the

tire structure in tread area) and maximum plunger travel into a tire at the time of rupture. F538

3.1.8 plunger, n—in tire testing, a cylindrical rod with a hemispherical end. F538

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.