ASTM F870-23

(Practice)Standard Practice for Tread Footprints of Passenger Car Tires Groove Area Fraction and Dimensional Measurements

Standard Practice for Tread Footprints of Passenger Car Tires Groove Area Fraction and Dimensional Measurements

SIGNIFICANCE AND USE

5.1 The tread of a tire, the annular band that contacts the pavement, normally contains geometric tread pattern elements that are defined by grooves or voids. These are employed to confer appropriate traction properties to the tire, mainly on wet or snow-covered roads.

5.2 One characteristic feature of tire tread patterns that is important for both traction and tire wear behavior is the percent or “fractional” groove area. The groove-area fraction is calculated with respect to the total or gross contact area.

SCOPE

1.1 This practice covers a technique for measuring the groove or void area of a tire tread pattern. The void area is measured on the inked impression of a tire tread statically loaded against heavyweight paper on a load platen.

1.2 This procedure is intended to serve as a reference practice for measuring groove or tread pattern void areas in a tire-footprint impression. This technique is usable by any laboratory without special equipment although more sophisticated procedures are also commonly employed, such as optical or video camera processes.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F870 − 23

Standard Practice for

Tread Footprints of Passenger Car Tires Groove Area

1

Fraction and Dimensional Measurements

This standard is issued under the fixed designation F870; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions:

1.1 This practice covers a technique for measuring the

3.1.1 circumferential line, n—on a tire, any real or imagi-

groove or void area of a tire tread pattern. The void area is

nary circle on the surface of a tire, lying in a plane that is

measured on the inked impression of a tire tread statically

perpendicular to the spin axis. (F538)

loaded against heavyweight paper on a load platen.

3.1.2 developed footprint length, [L], n—the maximum

1.2 This procedure is intended to serve as a reference

footprint dimension in the circumferential direction of the tire,

practice for measuring groove or tread pattern void areas in a

under stated conditions of measurement.

tire-footprint impression. This technique is usable by any

3.1.3 developed footprint width, [L], n—the maximum lat-

laboratory without special equipment although more sophisti-

cated procedures are also commonly employed, such as optical eral dimension of a tire footprint under stated conditions of

measurement. (F538)

or video camera processes.

3.1.4 element, n—an isolated (totally bounded by void)

1.3 The values stated in SI units are to be regarded as the

projection. (F538)

standard. The values given in parentheses are for information

2

only. 3.1.5 footprint area, [L ], n—the gross contact area of a tire

that is loaded (under stated conditions) against a smooth flat

1.4 This standard does not purport to address all of the

surface. (F538)

safety concerns, if any, associated with its use. It is the

3.1.6 groove, n—a void that is relatively narrow compared

responsibility of the user of this standard to establish appro-

to its length. (F538)

priate safety, health, and environmental practices and deter-

2

mine the applicability of regulatory limitations prior to use.

3.1.7 groove (void) area, [L ], n—that portion of tire foot-

1.5 This international standard was developed in accor- print area that is not contacted by ribs or elements.

dance with internationally recognized principles on standard-

3.1.8 groove (void) area fraction, [nd], n—the ratio of the

ization established in the Decision on Principles for the

groove (void) area to the footprint area of a tire. (F538)

Development of International Standards, Guides and Recom-

3.1.9 kerf, n—synonym for sipe. (F538)

mendations issued by the World Trade Organization Technical

3.1.10 lateral groove, n—a groove that has its long dimen-

Barriers to Trade (TBT) Committee.

sion oriented at direction non-parallel to the tire circumferen-

tial centerline; it most frequently opens into a void at both

2. Referenced Documents

ends. (F538)

2

2.1 ASTM Standards:

3.1.11 notch, n—a groove smaller in both width and length

F538 Terminology Relating to Characteristics and Perfor-

than a lateral groove, that contains one closed end. (F538)

mance of Tires

3.1.11.1 Discussion—For the purpose of this practice, it is

wider than 1 mm and more than 25 % as deep as a groove in

the same tire (see Fig. 1).

1

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is

3.1.12 projection, n—a pavement contacting area of the

the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular)

Testing. tread band, bounded by void. (F538)

Current edition approved May 1, 2023. Published June 2023. Originally

3.1.13 rib, n—a continuous circumferential projection.

approved in 1984. Last previous edition approved in 2016 as F870 – 94 (2016).

(F538)

DOI: 10.1520/F0870-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 2

3.1.14 rib or element area, [L ], n—that area within the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

outer periphery of a tire footprint that is contacted by ribs or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. elements.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F870 − 23

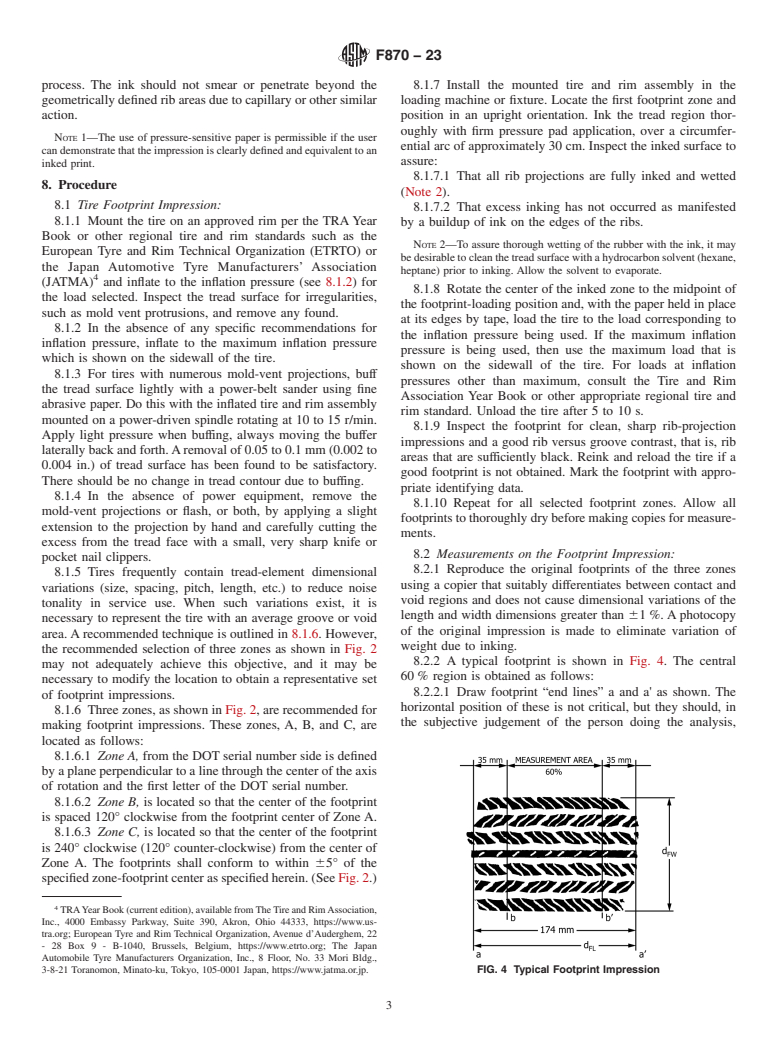

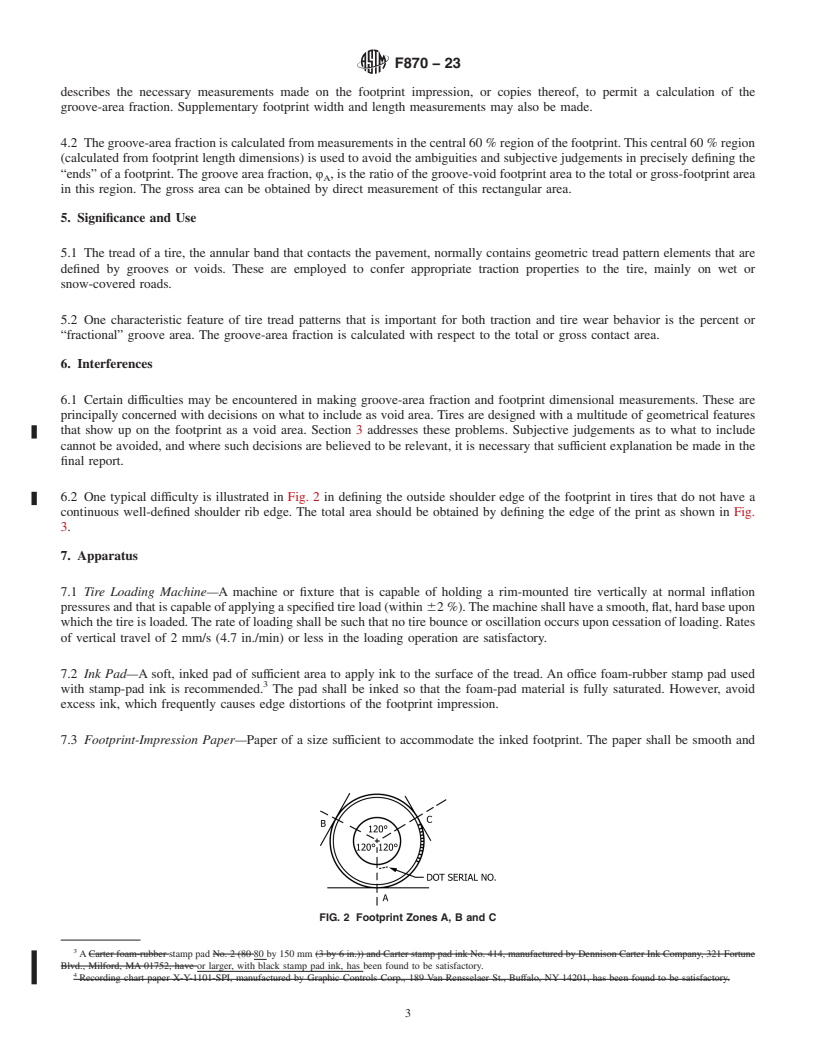

FIG. 2 Footprint Zones A, B and C

FIG. 1 Schematic Diagrams Kerf (Sipe) and Notch

3.1.15 sipe, n—a molded or cut rectangular void that is

substantially nar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F870 − 94 (Reapproved 2016) F870 − 23

Standard Practice for

Tread Footprints of Passenger Car Tires Groove Area

1

Fraction and Dimensional Measurements

This standard is issued under the fixed designation F870; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers a technique for measuring the groove or void area of a tire tread pattern. The void area is measured on

the inked impression of a tire tread statically loaded against heavyweight paper on a load platen.

1.2 This procedure is intended to serve as a reference practice for measuring groove or tread pattern void areas in a tire-footprint

impression. This technique is usable by any laboratory without special equipment although more sophisticated procedures are also

commonly employed, such as optical or video camera processes.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F538 Terminology Relating to Characteristics and Performance of Tires

3. Terminology

3.1 Definitions:

3.1.1 circumferential line, n—on a tire, any real or imaginary circle on the surface of a tire, lying in a plane that is perpendicular

to the spin axis. (F538)

3.1.2 developed footprint length, [L],n—the maximum footprint dimension in the circumferential direction of the tire, under stated

conditions of measurement.

1

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular) Testing.

Current edition approved Jan. 1, 2016May 1, 2023. Published February 2016June 2023. Originally approved in 1984. Last previous edition approved in 20102016 as

F870 – 94 (2010).(2016). DOI: 10.1520/F0870-94R16.10.1520/F0870-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F870 − 23

3.1.3 developed footprint width, [L],n—the maximum lateral dimension of a tire footprint under stated conditions of measurement.

(F538)

3.1.4 element, n—an isolated (totally bounded by void) projection. (F538)

2

3.1.5 footprint area, [L ],n—the gross contact area of a tire that is loaded (under stated conditions) against a smooth flat surface.

(F538)

3.1.6 groove, n—a void that is relatively narrow compared to its length. (F538)

2

3.1.7 groove (void) area, [L ],n—that portion of tire footprint area that is not contacted by ribs or elements.

3.1.8 groove (void) area fraction, [nd],n—the ratio of the groove (void) area to the footprint area of a tire. (F538)

3.1.9 kerf, n—synonym for sipe. (F538)

3.1.10 lateral groove, n—a groove that has its long dimension oriented at direction non-parallel to the tire circumferential

centerline; it most frequently opens into a void at both ends. (F538)

3.1.11 notch, n—a groove smaller in both width and length than a lateral groove, that contains one closed end. (F538)

3.1.11.1 Discussion—

For the purpose of this practice, it is wider than 1 mm and more than 25 % as deep as a groove in the same tire (see Fig. 1).

3.1.12 projection, n—a pavement contacting area of the tread band, bounded by void. (F538)

3.1.13 rib, n—a continuous circumferential projection. (F538)

2

3.1.14 rib or element area, [L ],n—that area within the outer periphery of a tire footprint

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.