ASTM F1502-23

(Test Method)Standard Test Method for Static Measurements on Tires for Passenger Cars, Light Trucks, and Medium Duty Vehicles

Standard Test Method for Static Measurements on Tires for Passenger Cars, Light Trucks, and Medium Duty Vehicles

SIGNIFICANCE AND USE

4.1 Static measurements of tires are important to tire manufacturers, processing engineers, and vehicle design engineers for purposes of commerce (in consumer/vendor agreements) and in tire research and development.

4.2 The procedures are sufficiently detailed to achieve commercially acceptable reproducibility among laboratories and may therefore be used for specification, compliance, or reference purposes.

4.3 Changes attributable to growth after inflation may be obtained by comparing measurements made immediately after inflation with those made 18 to 24 h later.

SCOPE

1.1 This test method covers methods for performing certain mechanical static measurements on tires. The term “static” implies that the tire is not rotating while measurements are being made.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1502 − 23

Standard Test Method for

Static Measurements on Tires for Passenger Cars, Light

1

Trucks, and Medium Duty Vehicles

This standard is issued under the fixed designation F1502; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Groove Area Fraction and Dimensional Measurements

1.1 This test method covers methods for performing certain

3. Terminology

mechanical static measurements on tires. The term “static”

implies that the tire is not rotating while measurements are 3.1 Definitions:

3.1.1 outside diameter, n—the maximum diameter of a tire

being made.

when it is mounted and inflated. F538

1.2 The values stated in SI units are to be regarded as

3.1.2 overall width, n—the maximum cross-sectional width

standard. The values given in parentheses are for information

of a tire, including protective or decorative ribs. F538

only.

3.1.3 tire weight, n—the weight of an unmounted tire

1.3 This standard does not purport to address all of the

without tube or flap. F538

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.4 tread arc width, n—the length of the arc measured

priate safety, health, and environmental practices and deter-

from one extreme of the tread design proper to the opposite

mine the applicability of regulatory limitations prior to use.

extreme; that is, from shoulder to shoulder perpendicular to the

1.4 This international standard was developed in accor-

circumferential center line. F538

dance with internationally recognized principles on standard-

3.1.5 tread hardness, n—the hardness of an element in the

ization established in the Decision on Principles for the

tread design as measured by a designated standard gage. F538

Development of International Standards, Guides and Recom-

3.1.6 tread radius, n—the radius of a circle whose arc best

mendations issued by the World Trade Organization Technical

fits the tread surface when the appropriate radius template is

Barriers to Trade (TBT) Committee.

held perpendicular to the circumferential center line of an

inflated tire. F538

2. Referenced Documents

2

2.1 ASTM Standards:

4. Significance and Use

D2240 Test Method for Rubber Property—Durometer Hard-

4.1 Static measurements of tires are important to tire

ness

manufacturers, processing engineers, and vehicle design engi-

D4483 Practice for Evaluating Precision for Test Method

neers for purposes of commerce (in consumer/vendor agree-

Standards in the Rubber and Carbon Black Manufacturing

ments) and in tire research and development.

Industries

F421 Test Method for Measuring Groove and Void Depth in

4.2 The procedures are sufficiently detailed to achieve

Passenger Car Tires

commercially acceptable reproducibility among laboratories

F538 Terminology Relating to Characteristics and Perfor-

and may therefore be used for specification, compliance, or

mance of Tires

reference purposes.

F870 Practice for Tread Footprints of Passenger Car Tires

4.3 Changes attributable to growth after inflation may be

obtained by comparing measurements made immediately after

inflation with those made 18 to 24 h later.

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires

and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-

Vehicular) Testing.

5. Tire Marking

Current edition approved May 1, 2023. Published May 2023. Originally

5.1 For measurements other than weight, the tire shall be

approved in 1994. Last previous edition approved in 2016 as F1502 – 05 (2016).

DOI: 10.1520/F1502-23.

marked at six equally spaced locations around the circumfer-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ence. Starting at the DOT tire identification number (outboard

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

side if applicable) or other serial number, make radial lines

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. from bead to bead, perpendicular to the tread center line, at 60°

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1502 − 23

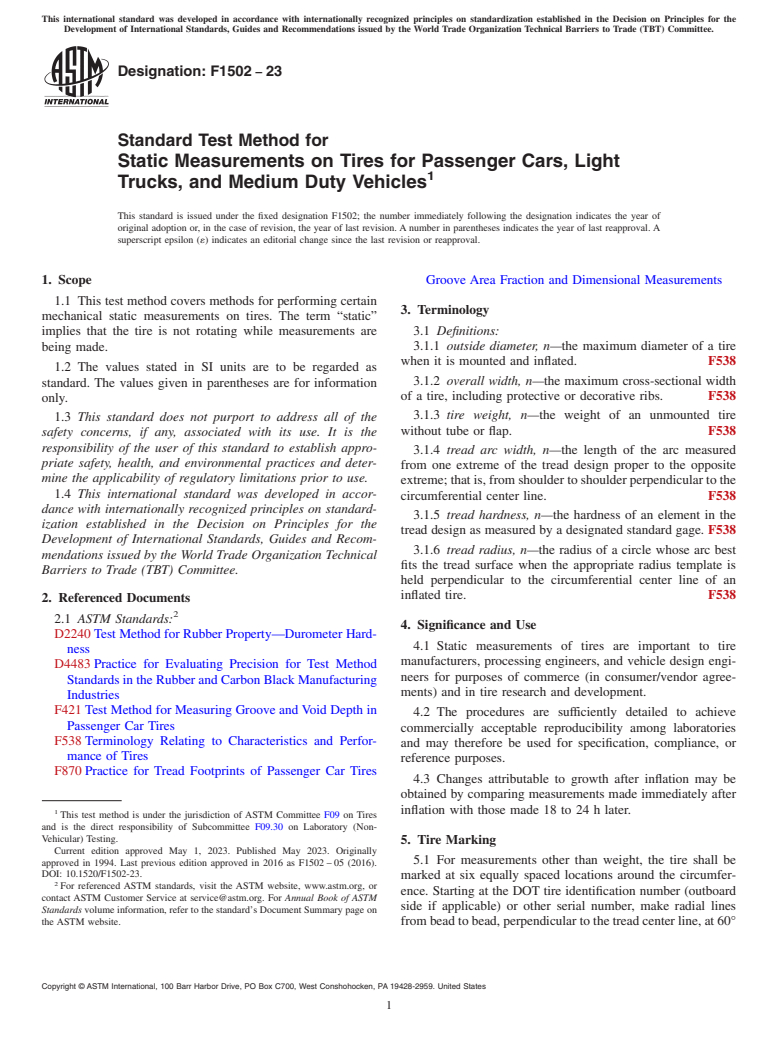

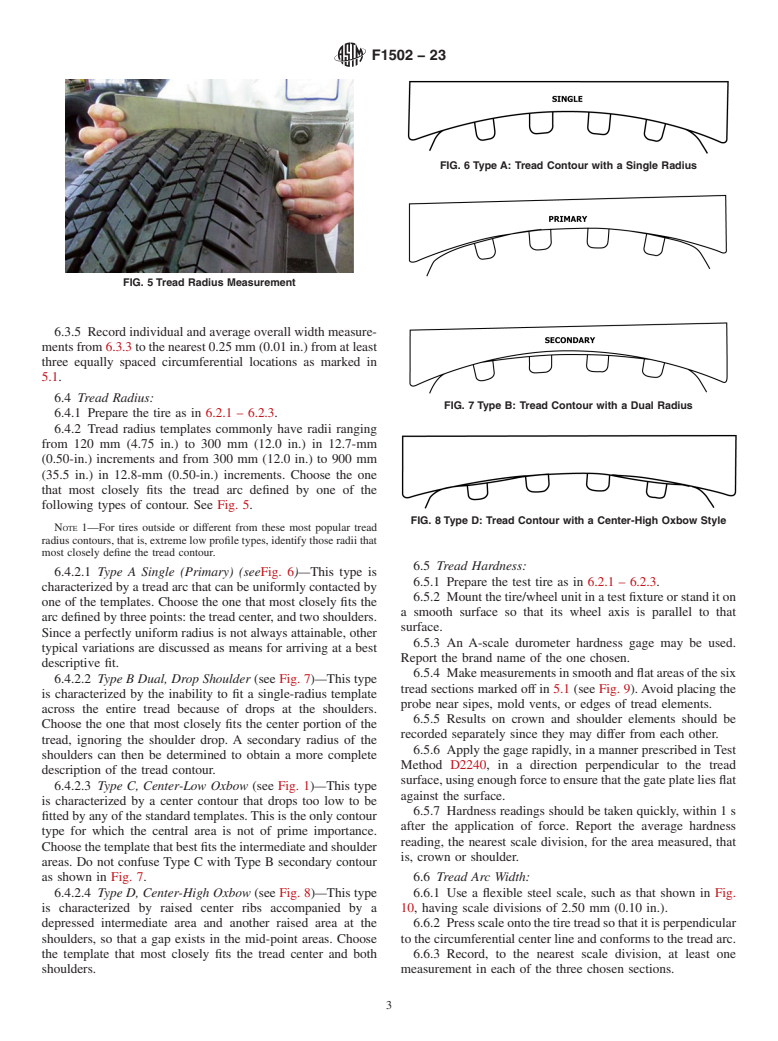

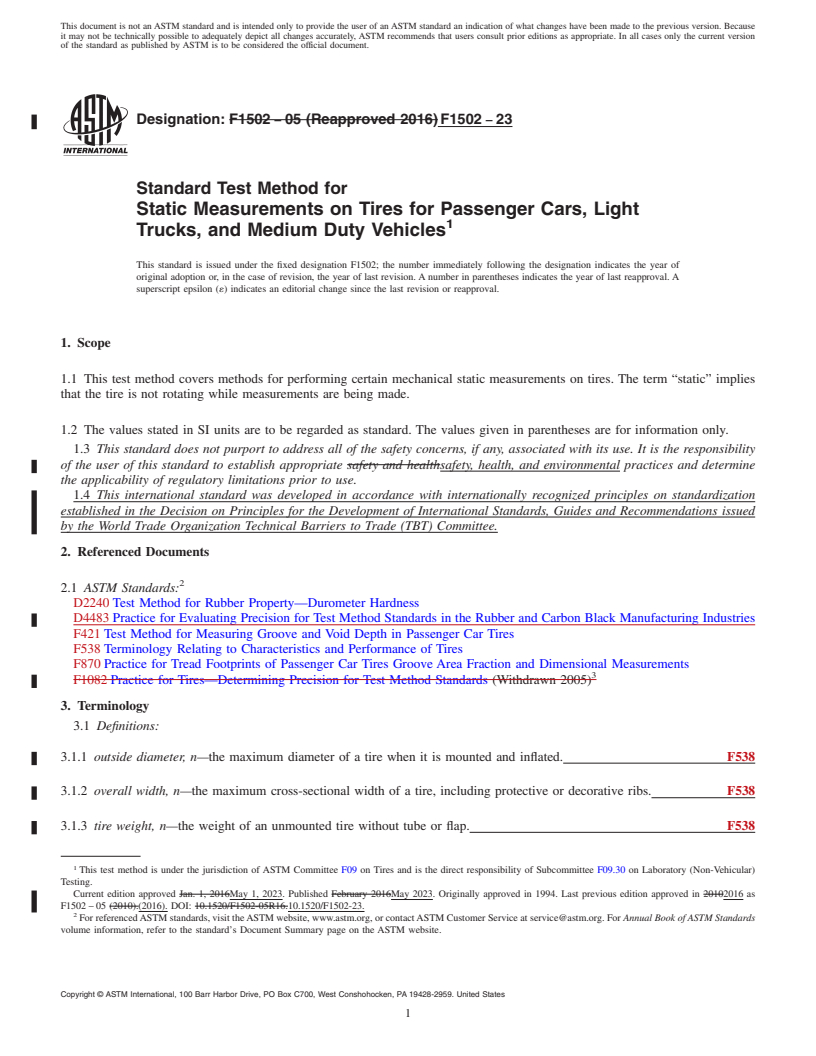

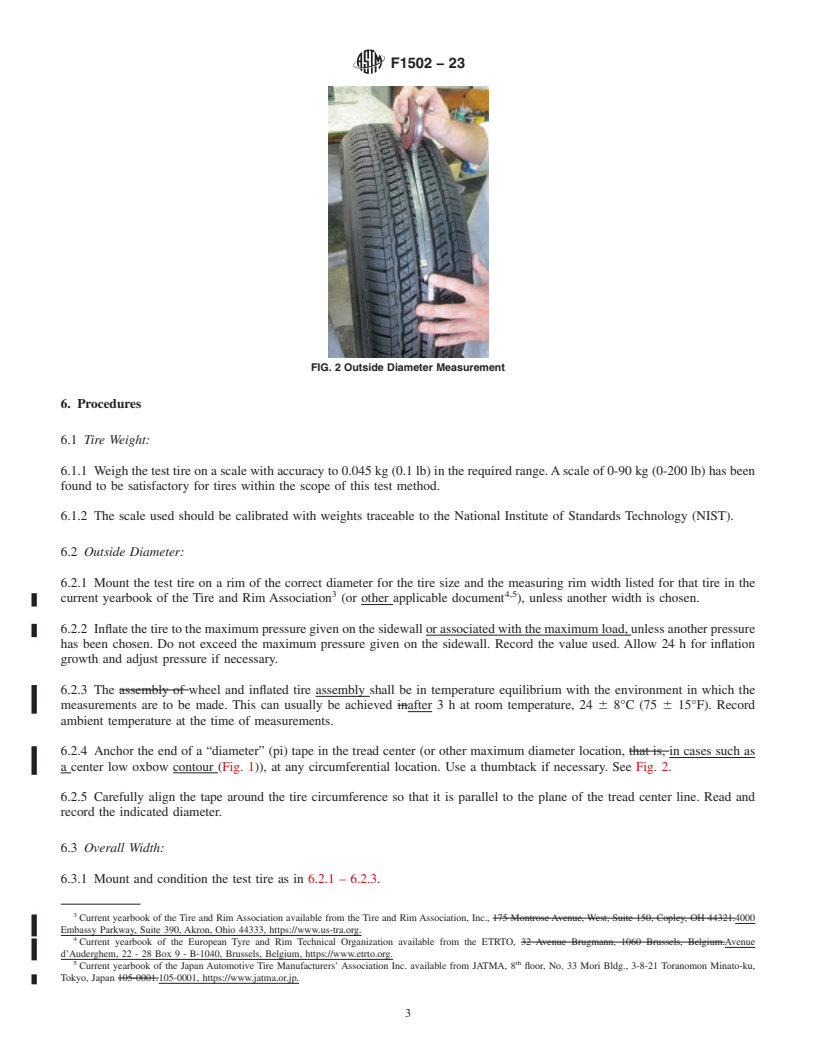

FIG. 1 Type C: Tread Contour with a Center-Low Oxbow

intervals. Number the resulting sections “1” through “6” in a

clockwise sequence as viewed, if applicable, from the outboard

side, conta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1502 − 05 (Reapproved 2016) F1502 − 23

Standard Test Method for

Static Measurements on Tires for Passenger Cars, Light

1

Trucks, and Medium Duty Vehicles

This standard is issued under the fixed designation F1502; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers methods for performing certain mechanical static measurements on tires. The term “static” implies

that the tire is not rotating while measurements are being made.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D2240 Test Method for Rubber Property—Durometer Hardness

D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries

F421 Test Method for Measuring Groove and Void Depth in Passenger Car Tires

F538 Terminology Relating to Characteristics and Performance of Tires

F870 Practice for Tread Footprints of Passenger Car Tires Groove Area Fraction and Dimensional Measurements

3

F1082 Practice for Tires—Determining Precision for Test Method Standards (Withdrawn 2005)

3. Terminology

3.1 Definitions:

3.1.1 outside diameter, n—the maximum diameter of a tire when it is mounted and inflated. F538

3.1.2 overall width, n—the maximum cross-sectional width of a tire, including protective or decorative ribs. F538

3.1.3 tire weight, n—the weight of an unmounted tire without tube or flap. F538

1

This test method is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular)

Testing.

Current edition approved Jan. 1, 2016May 1, 2023. Published February 2016May 2023. Originally approved in 1994. Last previous edition approved in 20102016 as

F1502 – 05 (2010).(2016). DOI: 10.1520/F1502-05R16.10.1520/F1502-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1502 − 23

FIG. 1 Type C: Tread Contour with a Center-Low Oxbow

3.1.4 tread arc width, n—the length of the arc measured from one extreme of the tread design proper to the opposite extreme; that

is, from shoulder to shoulder perpendicular to the circumferential center line. F538

3.1.5 tread hardness, n—the hardness of an element in the tread design as measured by a designated standard gage. F538

3.1.6 tread radius, n—the radius of a circle whose arc best fits the tread surface when the appropriate radius template used is held

perpendicular to the circumferential center line of an inflated tire. F538

3.2 For additional definitions of terms used in this test method, refer to Terminology F538.

4. Significance and Use

4.1 Static measurements of tires are important to tire manufacturers, processing engineers, and vehicle design engineers for

purposes of commerce (in consumer/vendor agreements) and in tire research and development.

4.2 The procedures are sufficiently detailed to achieve commercially acceptable reproducibility among laboratories and may

therefore be used for specification, compliance, or reference purposes.

4.3 Changes attributable to growth after inflation may be obtained by comparing measurements made immediately after inflation

with those made 18 to 24 h later.

5. Tire Marking

5.1 For measurements other than weight, the tire sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.