ASTM F1470-01

(Guide)Standard Guide for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

Standard Guide for Fastener Sampling for Specified Mechanical Properties and Performance Inspection

SCOPE

1.1 This guide provides sampling methods for determining how many fasteners to include in a random sample in order to determine the acceptability or disposition of a given lot of fasteners.

1.2 This guide is for mechanical properties, physical properties, coating requirements, and other quality requirements specified in the standards of ASTM Committee F16. Dimensional and thread criteria sampling plans are the responsibility of ASME Committee B18.

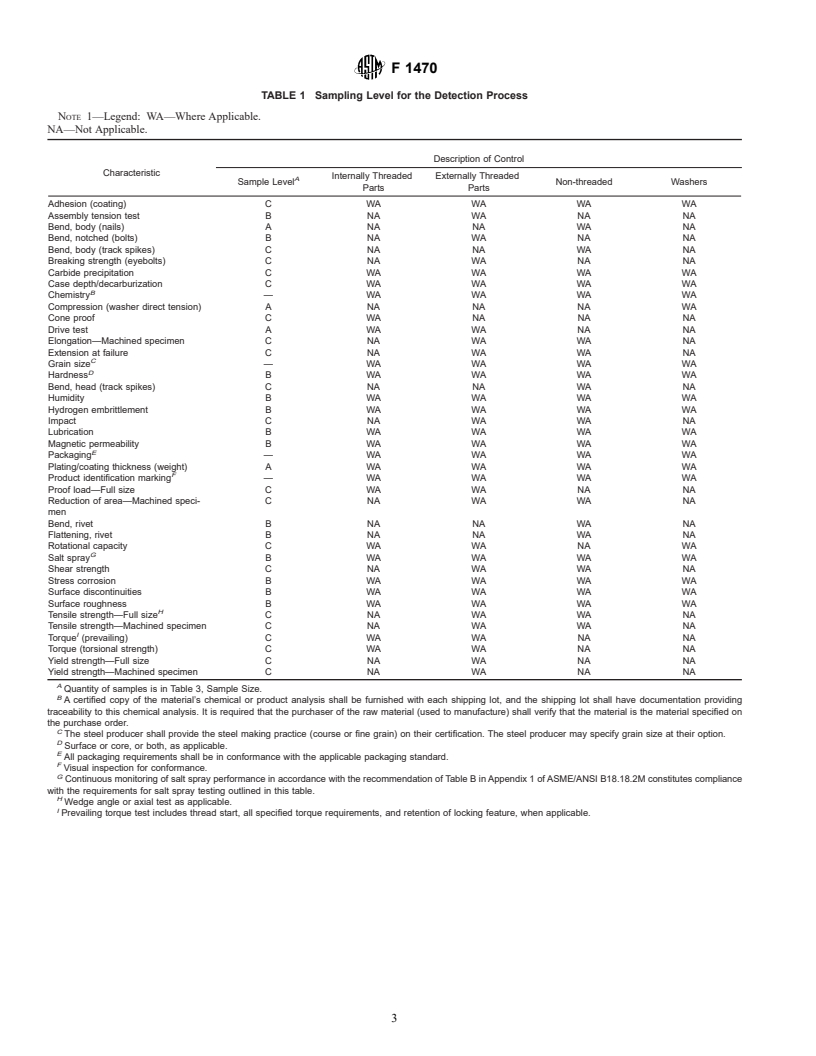

1.3 This guide provides for two sampling plans: one designated the "detection process," as described in Terminology F 1789, and one designated the "prevention process," as described in Terminology F 1789.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1470 – 01

Standard Guide for

Fastener Sampling for Specified Mechanical Properties and

1

Performance Inspection

This standard is issued under the fixed designation F 1470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Throughout this guide the terms detection and prevention apply to quality control systems. A brief

description of both is provided to assist the purchaser in the application of this guide.

The detection system relies on inspection as the primary means of controlling the quality of

furnished material. Methods include in-process and final inspection. In-process inspection is typically

performed by the individual performing the process and generally includes a first-piece inspection by

someone other than the operator. Quality-control inspection may perform audit inspections on the

process output during the course of the production run. In addition, a final inspection is performed by

quality control inspectors according to a prescribed sample plan. The other sample plans utilize zero

defects as their acceptance criteria.

The prevention system uses advanced quality planning in addition to many of the techniques used

in the detection system. Quality planning incorporates a systems approach to quality control that

focuses on defect prevention and continual improvement. In addition, Statistical Process Control

(SPC) is usually applied to control the process, thereby reducing the variability of the output.

The ISO 9000 and/or the ANSI/ASQC Q9000 quality system standards are models that may be used

in establishing a prevention-based quality systems.

1. Scope ASME/ANSI B18.18.3M Inspection and Quality Assurance

2

for Special Purpose Fasteners

1.1 This guide provides sampling methods for determining

ASME/ANSI B18.18.5M Inspection and Quality Assurance

how many fasteners to include in a random sample in order to

2

Plan Requiring In-Process Inspection and Controls

determine the acceptability of a given lot of fasteners.

ASME/ANSI B18.18.6M Quality Assurance Plan for Fas-

1.2 This guide is for mechanical properties, physical prop-

2

teners Produced in Third Party Accreditation System

erties, coating requirements, and other quality requirements

ASME-FAP-1 Quality Assurance Program Requirements

specified in the standards of ASTM Committee F-16. Dimen-

2

for Fastener Manufacturers and Distributors

sional and thread criteria sampling plans are the responsibility

ANSI/ASQC Q9000 Quality Management and Quality

of ASME Committee B18. Therefore, unless otherwise speci-

2

Assurance Standards—Guidelines for Selection and Use

fied in this guide, dimensional and thread fit sampling shall be

ANSI/ASQC Q9001 Quality Systems—Model for Quality

in accordance with ANSI/ASME B18.18.3M.

Assurance in Design/Development, Production, Installa-

1.3 This guide provides for two sampling plans: one desig-

2

tion, and Servicing

nated the “detection process,” as described in Terminology

ANSI/ASQC Q9002 Quality Systems—Model for Quality

F 1789, and one designated the “prevention process,” as

2

Assurance in Production and Installation

described in Terminology F 1789.

ANSI/ASQC Q9004 Quality Management and Quality

2

2. Referenced Documents System Elements—Guidelines

3

QS 9004 Quality System Requirements

2.1 ASTM Standards:

2.3 ISO Standards:

F 1789 Terminology for F-16 Mechanical Fasteners

ISO 9000 Quality Management and Quality Assurance

2.2 ANSI Standards:

2

Standards—Guidelines for Selection and Use

1

This guide is under the jurisdiction of ASTM Committee F16 on Fasteners and

2

is the direct responsibility of Subcommittee F16.93 on Quality Assurance Provisions Available from the American National Standards Institute, 11 W. 42nd St., 13th

for Fasteners. Floor, New York, NY 10036.

3

Current edition approved Jan. 10, 2001. Published March 2001. Originally Available from Automotive Industry Action Group (AIAG), 26200 Lahser

published as F 1470–93. Last previous edition F 1470–00. Road, Suite 2000, Southfield, MI 48034–9738.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1470

ISO 9001 Quality Systems—Model for Quality Assurance Purchasers shall retain the right to specify the Prevention or

in Design/Development, Production, Installation and Ser- Detection process at the time of inquiry or order (see Table 2).

2

vicing

7. Acceptance Criteria

ISO 9002 Quality Systems—Model for Quality Assurance

2

7.1 The acceptance criteria for Table 3 is to accept the lot if

in Production and In

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.