ASTM B963-08

(Test Method)Standard Test Methods for Oil Content, Oil-Impregnation Efficiency, and Interconnected Porosity of Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle

Standard Test Methods for Oil Content, Oil-Impregnation Efficiency, and Interconnected Porosity of Sintered Powder Metallurgy (PM) Products Using Archimedes<span class='unicode'>’</span> Principle

SIGNIFICANCE AND USE

Oil content values are generally contained in specifications for oil-impregnated PM bearings.

The oil-impregnation efficiency provides an indication of how well the as-received parts had been impregnated.

The desired self-lubricating performance of PM bearings requires a minimum amount of interconnected porosity and satisfactory oil impregnation of the interconnected porosity. A minimum oil content is specified.

The results from these test methods may be used for quality control or compliance purposes.

SCOPE

1.1 This standard describes three related test methods that cover the measurement of physical properties of oil-impregnated powder metallurgy products.

1.1.1 Determination of the volume percent of oil contained in the material.

1.1.2 Determination of the efficiency of the oil-impregnation process.

1.1.3 Determination of the percent interconnected porosity by oil impregnation.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are converted in accordance with IEEE/ASTM SI 10 and are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B963–08

Standard Test Methods for

Oil Content, Oil-Impregnation Efficiency, and Interconnected

Porosity of Sintered Powder Metallurgy (PM) Products

Using Archimedes’Principle

This standard is issued under the fixed designation B963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope SI 10 American National Standard for Use of the Interna-

tional System of Units (SI): The Modern Metric System

1.1 This standard describes three related test methods that

cover the measurement of physical properties of oil-

3. Terminology

impregnated powder metallurgy products.

3.1 Definitions of powder metallurgy (PM) terms can be

1.1.1 Determination of the volume percent of oil contained

found in Terminology B243.Additional descriptive material is

in the material.

available in the Related Material section of Vol. 02.05 of the

1.1.2 Determination of the efficiency of the oil-

Annual Book of ASTM Standards.

impregnation process.

1.1.3 Determination of the percent interconnected porosity

4. Summary of Test Method

by oil impregnation.

4.1 Thepartortestspecimenisfirstweighedinair.Itisthen

1.2 The values stated in SI units are to be regarded as the

oil impregnated to fill the surface-connected porosity and the

standard. The values in parentheses are converted in accor-

specimen is reweighed. The test specimen is then weighed

dance with IEEE/ASTM SI 10 and are for information only.

when immersed in water and its volume calculated based on

1.3 This standard does not purport to address all of the

Archimedes’ principle. The oil is then removed and the

safety concerns, if any, associated with its use. It is the

specimen is reweighed.

responsibility of the user of this standard to establish appro-

4.2 The oil content of an oil-impregnated part or test

priate safety and health practices and determine the applica-

specimen is then calculated as a percentage of the volume of

bility of regulatory limitations prior to use.

the specimen. This may be done for the as-received and the

2. Referenced Documents fully oil-impregnated specimen.

2 4.3 The oil-impregnation effıciency is calculated by dividing

2.1 ASTM Standards:

the as-received oil content by the fully impregnated oil content

B243 Terminology of Powder Metallurgy

and expressing the result as a percentage.

D1217 Test Method for Density and Relative Density (Spe-

4.4 The volume percentage of interconnected porosity (as

cific Gravity) of Liquids by Bingham Pycnometer

measured by oil impregnation) is then calculated based on the

D1298 Test Method for Density, Relative Density (Specific

amount of oil in the fully oil-impregnated specimen.

Gravity), or API Gravity of Crude Petroleum and Liquid

Petroleum Products by Hydrometer Method

5. Significance and Use

2.2 IEEE/ASTM Standard:

5.1 Oil content values are generally contained in specifica-

tions for oil-impregnated PM bearings.

5.2 The oil-impregnation efficiency provides an indication

These test methods are under the jurisdiction of ASTM Committee B09 on

of how well the as-received parts had been impregnated.

Metal Powders and Metal Powder Products and are the direct responsibility of

5.3 The desired self-lubricating performance of PM bear-

Subcommittee B09.04 on Bearings.

ings requires a minimum amount of interconnected porosity

Current edition approved Nov. 1, 2008. Published December 2008. DOI:

10.1520/B0963-08.

and satisfactory oil impregnation of the interconnected poros-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ity. A minimum oil content is specified.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 The results from these test methods may be used for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. quality control or compliance purposes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B963–08

6. Apparatus 7.3 Take care with cut specimens to avoid rough surfaces to

whichanairbubblemayadhere.A100-gritsandingorabrasive

6.1 Analytical Balance—Precision single-pan balance that

grinding is recommended to remove all rough surfaces.

will permit readings within 0.01 % of the test specimen mass.

See Table 1.

8. Procedure

6.2 Water Container—A glass beaker or other suitable

transparent container should be used to contain the water. 8.1 It is important that the part or test specimen, the

analytical balance and surrounding air be at a uniform tem-

NOTE 1—A transparent container makes it easier to see air bubbles

perature when weighing is performed.

adhering to the test specimen and specimen support when immersed in

8.2 For the most precise volume determinations, duplicate

water.

NOTE 2—For the most precise determination, the water container weighings should be made for all mass measurements. The

should be of a size that the level of the water does not rise more than

analytical balance should be adjusted to zero prior to each

2.5 mm (0.10 in.) when the test specimen is lowered into the water.

weighing. Duplicate mass determinations should be averaged

before performing any calculations.

6.3 Water—Distilledordeionizedwatertowhich0.05to0.1

8.3 For improved repeatability and reproducibility, the ana-

volumepercentofawettingagenthasbeenaddedtoreducethe

lytical balance should be verified periodically with a standard

effects of surface tension.

mass that is approximately equal to the part or test specimen

NOTE 3—Degassing the water by evacuation, boiling, or ultrasonic

mass.

agitation helps to prevent air bubbles from collecting on the test specimen

8.4 Determination of Oil Content, Oil-Impregnation Effı-

and support when immersed in water.

ciency, and Interconnected Porosity:

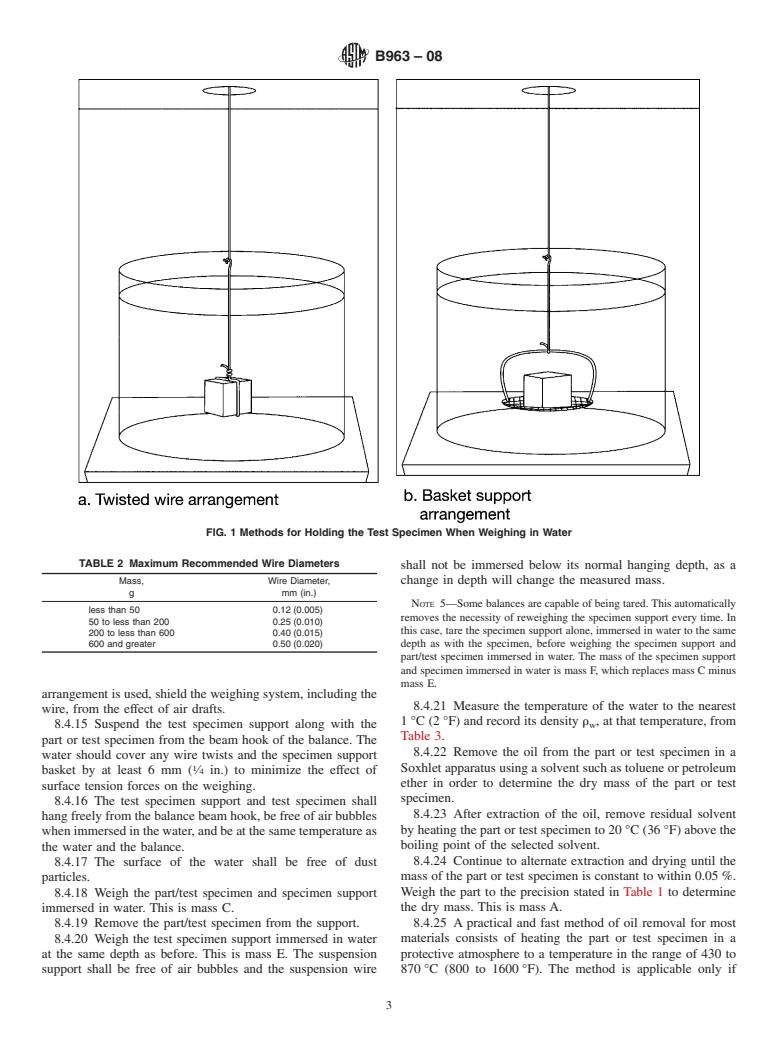

6.4 Test Specimen Support for Weighing in Water—Two

8.4.1 Determine the mass of the as-received part or test

typical arrangements are shown in Fig. 1. The suspension wire

specimen. This is mass J. This and all subsequent weighings

may be twisted around the test specimen or the test specimen

shall be to the precision stated in Table 1.

may be supported in a wire basket that is attached to the

8.4.2 Oil impregnate the as-received part or test specimen

suspension wire. For either arrangement, a single corrosion-

using one of the following procedures:

resistant wire—for example, austenitic stainless steel, copper,

or nichrome—shall be used for the basket and suspension wire.

Vacuum Oil Impregnation—Preferred Procedure

The maximum recommended diameter of suspension wire to

8.4.3 Immerse the part or test specimen in oil at room

be used for various mass ranges is shown in Table 2.

temperature.

NOTE 4—For the most precise determinations, it is important that the

8.4.4 Reduce the pressure over the sample to 7 kPa (1 psi)

massandvolumeofallsupportingwiresimmersedinwaterbeminimized.

or less for 30 minutes, then increase the pressure back to

6.5 Oil for Oil-Impregnation—Thesametypeofoilthatwas

atmospheric pressure and keep the sample immersed for at

used to impregnate the parts originally.

least 30 minutes.

6.5.1 If parts are not already impregnated, oil with a

8.4.5 Remove excess oil by wiping gently with an absor-

-6 -6 2

viscosity of 20 3 10 to 65 3 10 m /s (20 to 65 cSt or 100

bent, lint-free material. Take care not to extract oil absorbed

to 300 SSU) at 38 °C (100 °F) has been found to be suitable.

within the part or test specimen.

6.6 Vacuum Impregnation Apparatus—Equipment for im-

8.4.6 Do not place or store parts on porous surfaces such as

pregnation of the part or test specimen with oil.

paper, cloth, or cardboard as these will absorb oil.

6.7 Thermometer—A thermometer with an accuracy of

8.4.7 Proceed to 8.4.13.

0.5 °C (1 °F) to measure the temperature of the water.

6.8 Soxhlet Apparatus—Glass laboratory unit consisting of

Immersion Oil Impregnation—Alternative Procedure

a condenser, extractor, filter, flask with a suitable solvent for

8.4.8 Immerse the part or test specimen in oil at a tempera-

the oil such as petroleum ether, and a heating mantle.

ture of 82 6 5 °C (180 6 10 °F) for at least 4 hours.

8.4.9 Cool by immersing in a bath of the same oil held at

7. Preparation of Test Specimens

room temperature and keep in this oil for at least 30 minutes.

7.1 The mass of the test specimen shall be a minimum of

8.4.10 Remove excess oil by wiping gently with an absor-

1.0 g. For small parts, several parts may be combined to reach

bent, lint-free material. Take care not to extract oil absorbed

the minimum mass.

within the part or test specimen.

7.2 Thoroughly wipe clean all surfaces of the test specimen

8.4.11 Donotplaceorstorepartsonporoussurfacessuchas

to remove any adhering foreign materials such as dirt or oxide

paper, cloth, or cardboard as these will absorb oil.

scale.

8.4.12 Procee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.