ASTM B811-02

(Specification)Standard Specification for Wrought Zirconium Alloy Seamless Tubes for Nuclear Reactor Fuel Cladding

Standard Specification for Wrought Zirconium Alloy Seamless Tubes for Nuclear Reactor Fuel Cladding

SCOPE

1.1 This specification covers seamless wrought zirconium-alloy tubes for nuclear fuel cladding application, in the outside diameter (OD) size range of 0.200 in. (5.1 mm) to 0.650 in. (16.5 mm) and wall thickness range of 0.010 in. (0.25 mm) to 0.035 in. (0.89 mm).

1.2 Two grades of reactor grade zirconium alloys are described.

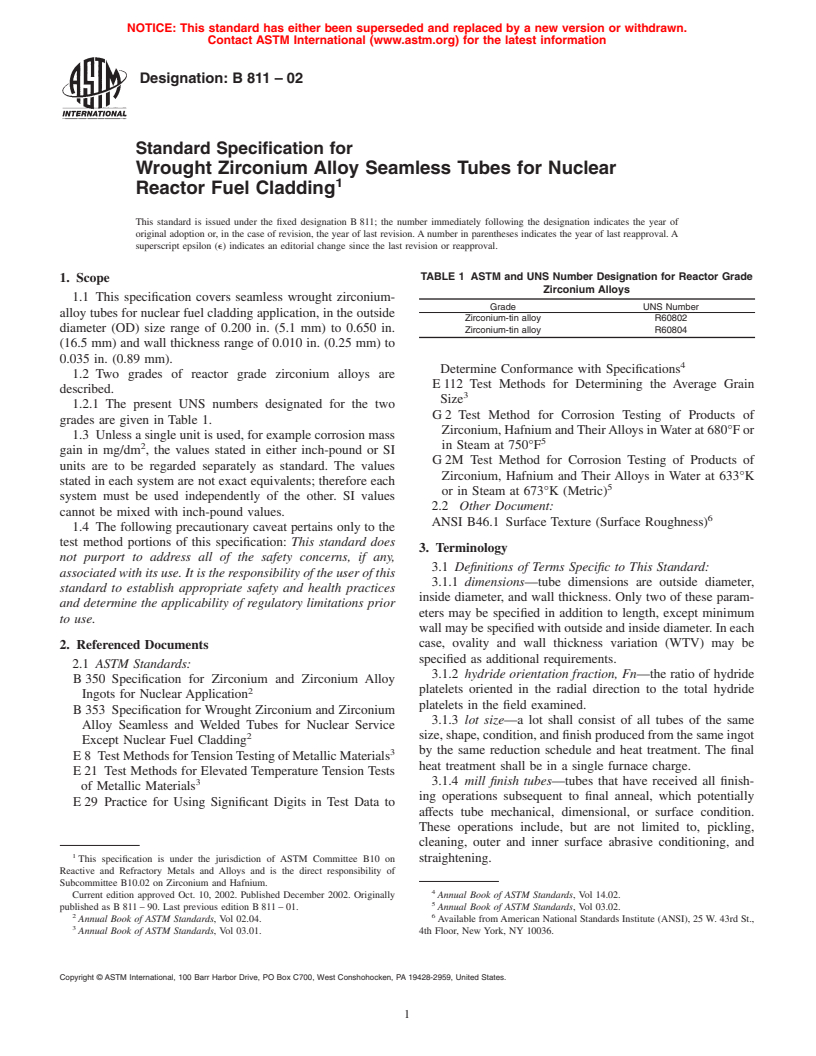

1.2.1 The present UNS numbers designated for the two grades are given in Table 1.

1.3 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.4 The following precautionary caveat pertains only to the test method portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 811 – 02

Standard Specification for

Wrought Zirconium Alloy Seamless Tubes for Nuclear

1

Reactor Fuel Cladding

This standard is issued under the fixed designation B 811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 ASTM and UNS Number Designation for Reactor Grade

1. Scope

Zirconium Alloys

1.1 This specification covers seamless wrought zirconium-

Grade UNS Number

alloy tubes for nuclear fuel cladding application, in the outside

Zirconium-tin alloy R60802

diameter (OD) size range of 0.200 in. (5.1 mm) to 0.650 in.

Zirconium-tin alloy R60804

(16.5 mm) and wall thickness range of 0.010 in. (0.25 mm) to

0.035 in. (0.89 mm).

4

Determine Conformance with Specifications

1.2 Two grades of reactor grade zirconium alloys are

E 112 Test Methods for Determining the Average Grain

described.

3

Size

1.2.1 The present UNS numbers designated for the two

G 2 Test Method for Corrosion Testing of Products of

grades are given in Table 1.

Zirconium,HafniumandTheirAlloysinWaterat680°For

1.3 Unless a single unit is used, for example corrosion mass

5

2 in Steam at 750°F

gain in mg/dm , the values stated in either inch-pound or SI

G 2M Test Method for Corrosion Testing of Products of

units are to be regarded separately as standard. The values

Zirconium, Hafnium and Their Alloys in Water at 633°K

stated in each system are not exact equivalents; therefore each

5

or in Steam at 673°K (Metric)

system must be used independently of the other. SI values

2.2 Other Document:

cannot be mixed with inch-pound values.

6

ANSI B46.1 Surface Texture (Surface Roughness)

1.4 The following precautionary caveat pertains only to the

test method portions of this specification: This standard does

3. Terminology

not purport to address all of the safety concerns, if any,

3.1 Definitions of Terms Specific to This Standard:

associated with its use. It is the responsibility of the user of this

3.1.1 dimensions—tube dimensions are outside diameter,

standard to establish appropriate safety and health practices

inside diameter, and wall thickness. Only two of these param-

and determine the applicability of regulatory limitations prior

eters may be specified in addition to length, except minimum

to use.

wallmaybespecifiedwithoutsideandinsidediameter.Ineach

case, ovality and wall thickness variation (WTV) may be

2. Referenced Documents

specified as additional requirements.

2.1 ASTM Standards:

3.1.2 hydride orientation fraction, Fn—the ratio of hydride

B 350 Specification for Zirconium and Zirconium Alloy

platelets oriented in the radial direction to the total hydride

2

Ingots for Nuclear Application

platelets in the field examined.

B 353 Specification for Wrought Zirconium and Zirconium

3.1.3 lot size—a lot shall consist of all tubes of the same

Alloy Seamless and Welded Tubes for Nuclear Service

2 size, shape, condition, and finish produced from the same ingot

Except Nuclear Fuel Cladding

by the same reduction schedule and heat treatment. The final

3

E 8 TestMethodsforTensionTestingofMetallicMaterials

heat treatment shall be in a single furnace charge.

E 21 Test Methods for Elevated Temperature Tension Tests

3 3.1.4 mill finish tubes—tubes that have received all finish-

of Metallic Materials

ing operations subsequent to final anneal, which potentially

E 29 Practice for Using Significant Digits in Test Data to

affects tube mechanical, dimensional, or surface condition.

These operations include, but are not limited to, pickling,

cleaning, outer and inner surface abrasive conditioning, and

1

This specification is under the jurisdiction of ASTM Committee B10 on straightening.

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.02 on Zirconium and Hafnium.

4

Current edition approved Oct. 10, 2002. Published December 2002. Originally Annual Book of ASTM Standards, Vol 14.02.

5

published as B 811 – 90. Last previous edition B 811 – 01. Annual Book of ASTM Standards, Vol 03.02.

2 6

Annual Book of ASTM Standards, Vol 02.04. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

Annual Book of ASTM Standards, Vol 03.01. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B811–02

3.1.5 ovality—the difference between the maximum and 4.2 In addition to the information in 4.1, the following

minimum diameter, either outer or inner, as determined at any points of agreement between the manufacturer and purchaser

one transverse cross-section of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.