ASTM F1304-03

(Test Method)Standard Test Method for Deflection of Resilient Floor Tile

Standard Test Method for Deflection of Resilient Floor Tile

SIGNIFICANCE AND USE

This test method measures a physical property associated with resilient floor tile’ability to conform to an uneven subfloor without breaking or cracking.

SCOPE

1.1 This test method is used to determine the deflection of relatively rigid resilient floor tile such as vinyl composition tile.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1304 – 03

Standard Test Method for

1

Deflection of Resilient Floor Tile

This standard is issued under the fixed designation F 1304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.4 Cutting Device, for cutting the samples to 2 by 9 in. (50

by 229 mm).

1.1 This test method is used to determine the deflection of

relatively rigid resilient floor tile such as vinyl composition

5. Sampling

tile.

5.1 For sampling, refer to ANSI/ASQC Z1.4–1993.

1.2 This standard does not purport to address all of the

1 1

5.2 Specimens for test shall be 2 6 ⁄32 by 9 6 ⁄32 in. (50

safety concerns, if any, associated with its use. It is the

6 0.8 by 229 6 0.8 mm).

responsibility of the user of this standard to establish appro-

5.3 Six samples shall be taken from each test unit, three cut

priate safety and health practices and determine the applica-

with the long dimension in the machine direction, and three

bility of regulatory limitations prior to use.

with the long dimension across the machine direction. These

2. Referenced Documents samples are tested for deflection.

2

2.1 ASTM Standards:

6. Preparation of Apparatus

E 691 Practice for Conducting an Interlaboratory Study to

6.1 Install the deflection frame in the tensile tester. Check to

Determine the Precision of a Test Method

see that the three bars are parallel, and that the center bar is

F 141 Terminology Relating to Resilient Floor Coverings

accurately centered between the two outside bars. Position the

2.2 ANSI Standards:

frame so that the test sample can be placed with the wearing

ANSI/ASQC Z1.4–1993 Sampling Procedures and Tables

3 surface touching the center bar, and the back surface touching

for Inspection by Attributes

the two outer bars, without deflection of the sample.This is the

3. Significance and Use zero point for measuring deflection. Check that the deflection

1

speed of the tester is 4 6 ⁄8 in./min. (102 6 3 mm/min.).

3.1 This test method measures a physical property associ-

Check the deflection measuring device to see that it accurately

ated with resilient floor tile’s ability to conform to an uneven

measures the relative movement between the center bar and the

subfloor without breaking or cracking.

frame holding the two outer bars.

4. Apparatus

NOTE 1—If a pendulum-type weighing system is used on the test

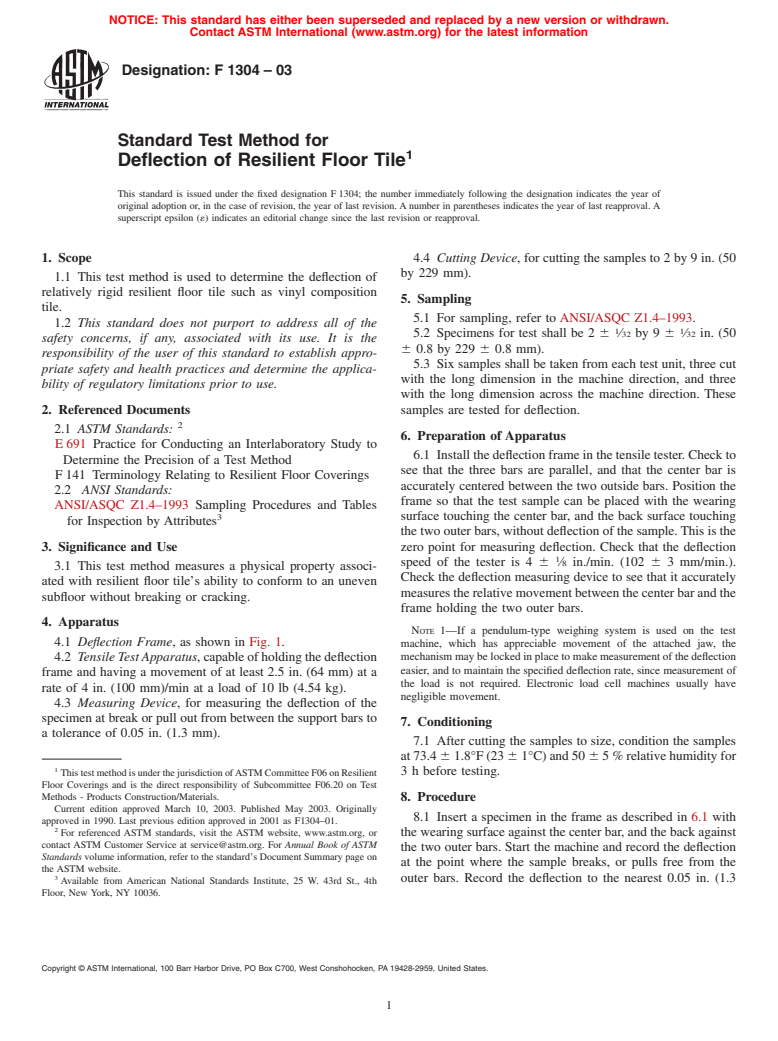

4.1 Deflection Frame, as shown in Fig. 1.

machine, which has appreciable movement of the attached jaw, the

mechanism may be locked in place to make measurement of the deflection

4.2 Tensile Test Apparatus,capableofholdingthedeflection

easier, and to maintain the specified deflection rate, since measurement of

frame and having a movement of at least 2.5 in. (64 mm) at a

the load is not required. Electronic load cell machines usually have

rate of 4 in. (100 mm)/min at a load of 10 lb (4.54 kg).

negligible movement.

4.3 Measuring Device, for measuring the deflection of the

specimen at break or pull out from between the support bars to

7. Conditioning

a tolerance of 0.05 in. (1.3 mm).

7.1 After cutting the samples to size, condition the samples

at73.4 61.8°F(23 61°C)and50 65 %relativehumidityfor

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient 3 h before testing.

Floor Coverings and is the direct responsibility of Subcommittee F06.20 on Test

Methods - Products Construction/Materials.

8. Procedure

Current edition approved March 10, 2003. Published May 2003. Originally

8.1 Insert a specimen in the frame as described in 6.1 with

approved in 1990. Last previous edition approved in 2001 as F1304–01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or the wearing surface against the center bar, and the back against

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the two outer bars. Start the machine and record the deflection

Standards volume information, refer to the standard’s Document Summary page on

at the point where the sample breaks, or pulls free from the

the ASTM website.

3

outer bars. Record the deflection to the nearest 0.05 in. (1.3

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1304–03

FIG. 1 Deflection Frame

mm). Remove the sample from the apparatus, and return the TABLE 1 Precision Data

A B C D E

deflection frame to the zero point described in 6.1. Insert the

Materials Average Sr SR r R

next sample and test.

1 MD 1.68278 0.06852 0.32643 0.19184 0.9

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.