ASTM C1369-97

(Specification)Standard Specification for Secondary Edge Sealants for Structurally Glazed Insulating Glass Units

Standard Specification for Secondary Edge Sealants for Structurally Glazed Insulating Glass Units

SCOPE

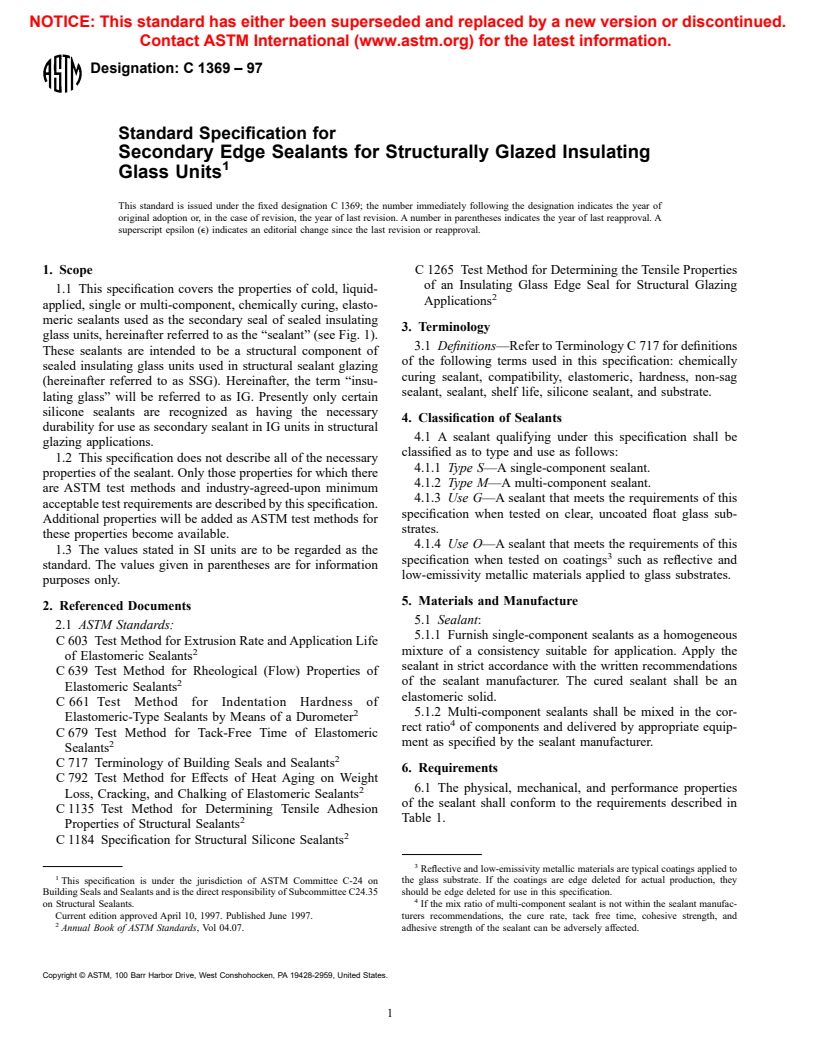

1.1 This specification covers the properties of cold, liquid-applied, single or multi-component, chemically curing, elastomeric sealants used as the secondary seal of sealed insulating glass units, hereinafter referred to as the "sealant" (see Fig. 1). These sealants are intended to be a structural component of sealed insulating glass units used in structural sealant glazing (hereinafter referred to as SSG). Hereinafter, the term "insulating glass" will be referred to as IG. Presently only certain silicone sealants are recognized as having the necessary durability for use as secondary sealant in IG units in structural glazing applications.

1.2 This specification does not describe all of the necessary properties of the sealant. Only those properties for which there are ASTM test methods and industry-agreed-upon minimum acceptable test requirements are described by this specification. Additional properties will be added as ASTM test methods for these properties become available.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1369 – 97

Standard Specification for

Secondary Edge Sealants for Structurally Glazed Insulating

Glass Units

This standard is issued under the fixed designation C 1369; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 1265 Test Method for Determining the Tensile Properties

of an Insulating Glass Edge Seal for Structural Glazing

1.1 This specification covers the properties of cold, liquid-

Applications

applied, single or multi-component, chemically curing, elasto-

meric sealants used as the secondary seal of sealed insulating

3. Terminology

glass units, hereinafter referred to as the “sealant” (see Fig. 1).

3.1 Definitions—Refer to Terminology C 717 for definitions

These sealants are intended to be a structural component of

of the following terms used in this specification: chemically

sealed insulating glass units used in structural sealant glazing

curing sealant, compatibility, elastomeric, hardness, non-sag

(hereinafter referred to as SSG). Hereinafter, the term “insu-

sealant, sealant, shelf life, silicone sealant, and substrate.

lating glass” will be referred to as IG. Presently only certain

silicone sealants are recognized as having the necessary

4. Classification of Sealants

durability for use as secondary sealant in IG units in structural

4.1 A sealant qualifying under this specification shall be

glazing applications.

classified as to type and use as follows:

1.2 This specification does not describe all of the necessary

4.1.1 Type S—A single-component sealant.

properties of the sealant. Only those properties for which there

4.1.2 Type M—A multi-component sealant.

are ASTM test methods and industry-agreed-upon minimum

4.1.3 Use G—A sealant that meets the requirements of this

acceptable test requirements are described by this specification.

specification when tested on clear, uncoated float glass sub-

Additional properties will be added as ASTM test methods for

strates.

these properties become available.

4.1.4 Use O—A sealant that meets the requirements of this

1.3 The values stated in SI units are to be regarded as the

specification when tested on coatings such as reflective and

standard. The values given in parentheses are for information

low-emissivity metallic materials applied to glass substrates.

purposes only.

5. Materials and Manufacture

2. Referenced Documents

5.1 Sealant:

2.1 ASTM Standards:

5.1.1 Furnish single-component sealants as a homogeneous

C 603 Test Method for Extrusion Rate and Application Life

2 mixture of a consistency suitable for application. Apply the

of Elastomeric Sealants

sealant in strict accordance with the written recommendations

C 639 Test Method for Rheological (Flow) Properties of

of the sealant manufacturer. The cured sealant shall be an

Elastomeric Sealants

elastomeric solid.

C 661 Test Method for Indentation Hardness of

5.1.2 Multi-component sealants shall be mixed in the cor-

Elastomeric-Type Sealants by Means of a Durometer

rect ratio of components and delivered by appropriate equip-

C 679 Test Method for Tack-Free Time of Elastomeric

ment as specified by the sealant manufacturer.

Sealants

C 717 Terminology of Building Seals and Sealants

6. Requirements

C 792 Test Method for Effects of Heat Aging on Weight

6.1 The physical, mechanical, and performance properties

Loss, Cracking, and Chalking of Elastomeric Sealants

of the sealant shall conform to the requirements described in

C 1135 Test Method for Determining Tensile Adhesion

Table 1.

Properties of Structural Sealants

C 1184 Specification for Structural Silicone Sealants

Reflective and low-emissivity metallic materials are typical coatings applied to

This specification is under the jurisdiction of ASTM Committee C-24 on the glass substrate. If the coatings are edge deleted for actual production, they

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.35 should be edge deleted for use in this specification.

on Structural Sealants. If the mix ratio of multi-component sealant is not within the sealant manufac-

Current edition approved April 10, 1997. Published June 1997. turers recommendations, the cure rate, tack free time, cohesive strength, and

Annual Book of ASTM Standards, Vol 04.07. adhesive strength of the sealant can be adversely affected.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1369

FIG. 1 Cutaway Section of IG Unit Edge Seal

TABLE 1 Requirements for Physical, Mechanical, and Performance Qualities of the Sealant

Property Requirements Test Method

Extrudability 10 s, max C 603

Rheological, max C 639

Vertical 4.8 mm ( ⁄16 in.)

Horizontal none

Hardness, Shore A 20 to 60 C 661

Heat Aging C 792

Weight Loss, max

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.