ASTM F1168-88(1994)

(Guide)Guide for Use in the Establishment of Thermal Processes for Foods Packaged in Flexible Containers (Withdrawn 2000)

Guide for Use in the Establishment of Thermal Processes for Foods Packaged in Flexible Containers (Withdrawn 2000)

SCOPE

1.1 This guide contains guidelines and recommended procedures for use in the establishment of thermal processes necessary to produce commercially sterile foods packaged in hermetically sealed flexible containers. It applies to foods packaged in flexible containers that are sterilized by the application of heat from fluid heating media, particularly steam, air, water, their combinations, and their mixtures.

1.2 Specifically, this guide describes procedures for determining environmental conditions in the retort during thermal processing of foods in flexible containers and for determining heating and cooling characteristics of such products during processing. Procedures are described by which these data are used in the determination or evaluation, or both, of safe thermal processes for food packaged in flexible containers.

1.3 Limitations- This guide does not cover the theoretical and practical considerations that justify thermal processing as a means of rendering a packaged food product commercially sterile, nor does this guide describe methods by which thermal processes are verified or confirmed by biological methods, such as by inoculated pack and count reduction techniques.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 The sections in this guide appear in the following sequence: Section Scope 1 Terminology 2 Summary of Guide 3 Significance and Use 4 Procedures: Temperature Measurement 5 Evaluation of Retort Performance 6 Process Time Determination by Heat Penetration 7 Tests Process Verification 8 Records of Temperature Distribution and Heat Pene- 9 tration Studies Retort Equipment Requirements X1 References

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1168 – 88 (Reapproved 1994)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Guide for

Use in the Establishment of Thermal Processes for Foods

Packaged in Flexible Containers

This standard is issued under the fixed designation F 1168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Terminology

1.1 This guide contains guidelines and recommended pro- 2.1 Definitions of Terms Specific to This Standard:

cedures for use in the establishment of thermal processes

2.1.1 ballast container—a filled and sealed flexible retort-

necessary to produce commercially sterile foods packaged in able container enclosing a fixed volume of nonbiological

hermetically sealed flexible containers. It applies to foods

material that is approximately equal to a food-filled container

packaged in flexible containers that are sterilized by the of the same size and shape in terms of the rate and extent to

application of heat from fluid heating media, particularly

which it will absorb thermal energy by convection and con-

steam, air, water, their combinations, and their mixtures. duction.

1.2 Specifically, this guide describes procedures for deter-

2.1.2 come-up time—time required following the introduc-

mining environmental conditions in the retort during thermal

tion of heating media into the retort to raise the temperature at

processing of foods in flexible containers and for determining

the reference thermometer location in the retort to the process

heating and cooling characteristics of such products during

temperature.

processing. Procedures are described by which these data are

2.1.3 cook time—time span during which the retort is

used in the determination or evaluation, or both, of safe thermal

maintained at or above the specified processing temperature

processes for food packaged in flexible containers.

(that is, time span between end of come-up and beginning of

1.3 Limitations—This guide does not cover the theoretical

cooling, sometimes referred to as the operator’s process time).

and practical considerations that justify thermal processing as

2.1.4 cooling time—time required following the introduc-

a means of rendering a packaged food product commercially

tion of cooling water into the retort to lower the product

sterile, nor does this guide describe methods by which thermal

internal temperature to a specified value (commonly 40 to

processes are verified or confirmed by biological methods,

45°C).

such as by inoculated pack and count reduction techniques.

2.1.5 critical factors—physical and chemical factors that

1.4 This standard does not purport to address all of the

influence the thermal response of a product to thermal process-

safety concerns, if any, associated with its use. It is the

ing or the inhibition or inactivation of microorganisms, or

responsibility of the user of this standard to establish appro-

combination thereof, of public health significance, and which

priate safety and health practices and determine the applica-

pertain to the flexible container, the enclosed substances

bility of regulatory limitations prior to use.

(including gases), the retort, and environmental conditions

1.5 The sections in this guide appear in the following

within and around the container from the time of product filling

sequence:

to the end of thermal processing.

Section

2.1.6 operator’s process time—time between the end of

Scope 1

come-up and steam off.

Terminology 2

2.1.7 temperature stability—the degree to which tempera-

Summary of Guide 3

Significance and Use 4

ture remains constant at a particular location.

Procedures:

2.1.8 temperature uniformity—the degree to which tem-

Temperature Measurement 5

Evaluation of Retort Performance 6 peratures are equal throughout a particular volume.

Process Time Determination by Heat Penetration Tests 7

2.2 Symbols:

Process Verification 8

2.2.1 F —the F value for a hypothetical product that

M o

Records of Temperature Distribution and Heat Pene- 9

tration Studies uniformly exhibits temperatures that are synchronously iden-

Retort Equipment Requirements X1

tical to that of the internal retort environment at the designated

References

retort location during the designated process cycle, and under

the designated process conditions.

2.2.2 F —the equivalent time in minutes at 121.1°C for

o

This guide is under the jurisdiction of ASTM Committee F-2 on Flexible

product at the slowest heating point within the container under

Barrier Materials and is the direct responsibility of Subcommittee F02.30 on Test

the designated process conditions to achieve the same level of

Methods.

Current edition approved Aug. 26, 1988. Published October 1988. destruction of bacterial spores or vegetative cells of a particular

F 1168

organism and z value as by the existence of that reference foods and having access to all necessary facilities for making

temperature at that point for that time (centerpoint lethality). thermal process determinations.

2.2.3 F —the equivalent time in minutes at 121.1°C for all

s

PROCEDURES

points within the container under the designated process

conditions to achieve the same level of destruction of bacterial

5. Temperature Measurement

spores or vegetative cells of a particular organism and z value

5.1 Introduction:

as by the existence of that temperature for that time (integrated

5.1.1 Temperature measurement within the flexible con-

lethality).

tainer can be made difficult by its thin profile and flexibility,

2.2.4 z—number of Celsius degrees required for the thermal

and from the potential for irregularity of its thickness. The

destruction to traverse one log cycle.

shorter process times that can be expected for products

3. Summary of Guide

packaged in thin profile containers (thickness # width) de-

mand a high accuracy and precision of the temperature

3.1 A food product is prepared and sealed within a flexible

measuring system, since product internal temperatures change

container. Information pertaining to its formulation and condi-

quickly, and because data must be acquired at a rapid rate.

tions prior to thermal processing treatment is recorded. The

5.1.2 Factors that can produce errors or may affect tempera-

packaged product is subjected to a program of temperature,

ture measurements are:

pressure, and other relevant conditions within a retort, com-

5.1.2.1 The interaction of heat transfer media with tempera-

prising a come-up phase, a cook phase, and a cooling phase.

ture sensing devices,

Temperature measurements of the food product at its slowest

5.1.2.2 Heat conduction along a temperature sensor or its

heating location are made, along with measurements describ-

support device,

ing processing conditions, at regular time intervals. These data

5.1.2.3 Sudden or rapid changes in temperature or pressure

are used to obtain heating and cooling rates for the specific

conditions, or both, and

product-retort system, and are used in determining the process-

5.1.2.4 Stray voltages that exist between the contents of the

ing time necessary to achieve the specified lethality (for

container and its environment.

example, F ) for the product.

o

5.1.3 The acquisition of accurate time-temperature data

3.2 The procedures involve the following aspects:

describing the heating and cooling temperatures attained in the

3.2.1 Selection, assembly, and testing of the temperature

measurement system, retort, as well as the stability and uniformity of temperature

conditions in the product zone of the retort is essential for a

3.2.2 Evaluation and testing of the retort system,

3.2.3 Measurement of (1) heating and cooling medium meaningful process validation. Measurements of the tempera-

ture of the heating media are subject to many of the same

temperatures during processing, and (2) the stability and

precautions that apply to product temperature measurements,

distribution of these temperatures in the retort during each

and these may be further affected by container racking arrange-

phase of processing,

ments and specific factors related to the retort design.

3.2.4 Identification of data requirements and measurement

5.2 Thermometry Systems:

and reporting of critical factors,

5.2.1 Thermocouples:

3.2.5 Selection of the number of containers to be tested, the

5.2.1.1 Thermocouples are used extensively for heat pen-

number of replicate tests, and the simulation conditions,

etration studies and retort temperature distribution tests be-

3.2.6 Fitting and placement of the temperature sensing

cause they are simply constructed, rugged, and inexpensive.

element in the product,

However, care must be exercised when using thermocouples to

3.2.7 Process lethality and process time determinations,

ensure that measurements result strictly from the temperature

3.2.8 Verification of the process, and

of the thermocouple junction and not from stray electrical

3.2.9 Reporting of results and scheduled process.

currents, poorly constructed circuitry, or poorly designed or

4. Significance and Use

constructed instrumentation. Copper-constantan (Type T) ther-

4.1 Food products processed in flexible containers carry mocouple wire insulated with TFE-fluorocarbon is recom-

with them the same hazard potential as any other thermally mended for use in the temperature range of interest in thermal

processed food product packaged in a hermetically sealed processing. This wire has the advantage of being resistant to

container and subjected to a thermal sterilization process. heat and corrosion in moist environments. It is recommended

Stringent process development and control procedures must be that stranded thermocouple lead wire which is 22 gage or larger

employed and maintained to avoid a significant risk to human be used to minimize cold working effects. The effects of shunt

health from resulting products. The use of this guide in leakage between two lead wires or connections is minimized

developing these procedures should help to ensure that foods by using a larger wire size.

packaged in flexible retort containers will be commercially 5.2.1.2 Conditions inside the retort or inside the filled

sterile. container necessitate special requirements and precautions in

4.2 The intention of this guide is to provide standardized, the use of thermocouples. The following are considered to be

reproducible, and reliable procedures leading to the establish- particularly important:

ment of safe thermal processes for foods in flexible containers. (a) Keep connections for thermocouple lead wires to a

Application of this guide should not be made except by minimum, using plug and jack connectors designed for this

specialists competent in the commercial thermal processing of purpose. Ideally, thermocouple connections should not be

F 1168

made inside the retort vessel, and a continuous lead of thermocouple wire or sheath than through the food product,

thermocouple wire from the measuring junction to the outside and may lead to large temperature measurement errors. An

of the retort should be employed. Clean connections scrupu-

insertion depth of at least ten times the probe diameter is

lously before each use to ensure intimate electrical contact.

required. Probe-induced errors in temperature measurement are

Exposed (for example, soldered) connections inside the retort

discussed by Kemper and Harper (2).

should be hermetically and electrically insulated using a high

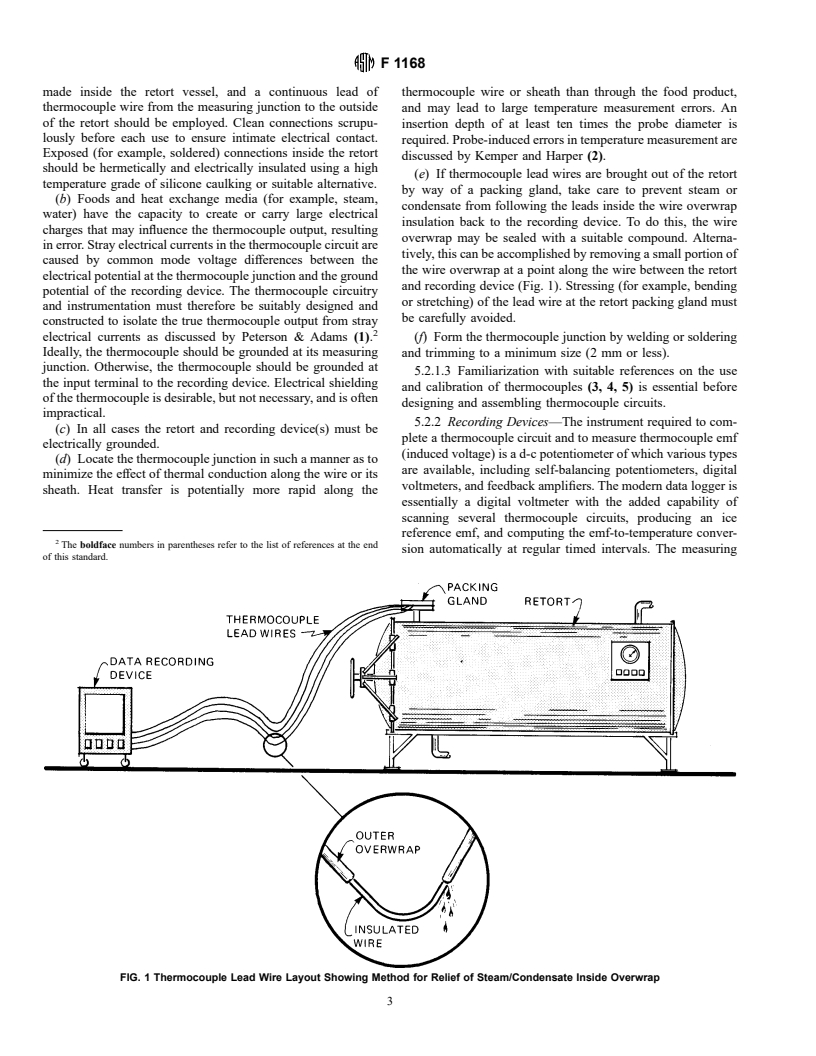

(e) If thermocouple lead wires are brought out of the retort

temperature grade of silicone caulking or suitable alternative.

by way of a packing gland, take care to prevent steam or

(b) Foods and heat exchange media (for example, steam,

condensate from following the leads inside the wire overwrap

water) have the capacity to create or carry large electrical

insulation back to the recording device. To do this, the wire

charges that may influence the thermocouple output, resulting

overwrap may be sealed with a suitable compound. Alterna-

in error. Stray electrical currents in the thermocouple circuit are

tively, this can be accomplished by removing a small portion of

caused by common mode voltage differences between the

the wire overwrap at a point along the wire between the retort

electrical potential at the thermocouple junction and the ground

and recording device (Fig. 1). Stressing (for example, bending

potential of the recording device. The thermocouple circuitry

or stretching) of the lead wire at the retort packing gland must

and instrumentation must therefore be suitably designed and

be carefully avoided.

constructed to isolate the true thermocouple output from stray

electrical currents as discussed by Peterson & Adams (1). (f) Form the thermocouple junction by welding or soldering

Ideally, the thermocouple should be grounded at its measuring and trimming to a minimum size (2 mm or less).

junction. Otherwise, the thermocouple should be grounded at

5.2.1.3 Familiarization with suitable references on the use

the input terminal to the recording device. Electrical shielding

and calibration of thermocouples (3, 4, 5) is essential before

of the thermocouple is desirable, but not necessary, and is often

designing and assembling thermocouple circuits.

impractical.

5.2.2 Recording Devices—The instrument required to com-

(c) In all cases the retort and recording device(s) must be

plete a thermocouple circuit and to measure thermocouple emf

electrically grounded.

(induced voltage) is a d-c potentiometer of which various types

(d) Locate the thermocouple junction in such a manner as to

are available, including self-balancing potentiometers, digital

minimize the effect of thermal conduction along the wire or its

voltmeters, and feedback amplifiers. The modern data logger is

sheath. Heat transfer is potentially more rapid along the

essentially a digital voltmeter with the added capability of

scanning several thermocouple circuits, producing an ice

reference emf, and computing the emf-to-temperature conver-

The boldface numbers in parentheses refer to the list of references at the end

sion automatically at regular timed intervals. The measuring

of this standard.

FIG. 1 Thermocouple Lead Wire Layout Showing Method for Relief of Steam/Condensate Inside Overwrap

F 1168

and recording device should be designed to operate satisfacto- or both, in the heating medium in which they are to be used.

rily in a common mode voltage difference of at least

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.