ASTM D6333-98

(Practice)Standard Practice for Collection of Dislodgeable Pesticide Residues from Floors

Standard Practice for Collection of Dislodgeable Pesticide Residues from Floors

SCOPE

1.1 This practice covers a procedure for collection of dislodgeable pesticide residues from indoor floor surfaces.

1.2 This practice and the sampling methodology described are applicable to bare floors or covered floor surfaces, for example,carpeting and vinyl flooring.

1.3 This practice and the sampling methodology described are applicable to all pesticides listed in Practice D 4861 whether applied directly to the floor surface or transported there by migration within the room or tracked in from outdoors.

1.4 Floor surfaces for which this practice has been successfully applied include nylon plush carpeting, polypropylene level-loop carpeting, and vinyl flooring.

1.5 Sample analysis will be dependent upon the nature of the pesticides targeted and is beyond the scope of this practice; however, the analytical procedures discussed in Practice D 4861 are applicable to this practice.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6333 – 98

Standard Practice for

Collection of Dislodgeable Pesticide Residues from Floors

This standard is issued under the fixed designation D 6333; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 337 Test Method for Measuring Humidity with a Psy-

chrometer (the Measurement of Wet-Bulb and Dry-Bulb

1.1 This practice covers a procedure for collection of

Temperatures)

dislodgeable pesticide residues from indoor floor surfaces.

1.2 This practice and the sampling methodology described

3. Terminology

are applicable to bare floors or covered floor surfaces, for

3.1 Definitions—For definitions of terms used in this prac-

example, carpeting and vinyl flooring.

tice, refer to Terminology D 1356.

1.3 This practice and the sampling methodology described

3.1.1 dislodgeable residue—that part of the residue of a

are applicable to all pesticides listed in Practice D 4861

chemical deposited on a solid surface that may be transferred

whether applied directly to the floor surface or transported

by direct contact to human skin or clothing.

there by migration within the room or tracked in from

3.1.2 sampling traverse—the distance from the starting

outdoors.

point to the end point over which the sampling media contacts

1.4 Floor surfaces for which this practice has been success-

the floor surface for collection of a single sample.

fully applied include nylon plush carpeting, polypropylene

3.1.3 transfer coeffıcient—the ratio of the amount of pesti-

level-loop carpeting, and vinyl flooring.

cide residue collected by the sampling media to the area of the

1.5 Sample analysis will be dependent upon the nature of

surface contacted by the media during a single sampling

the pesticides targeted and is beyond the scope of this practice;

traverse.

however, the analytical procedures discussed in Practice

3.1.4 transfer effıciency—the ratio of the transfer coefficient

D 4861 are applicable to this practice.

to the pesticide surface loading determined by analysis of

1.6 The values stated in SI units are to be regarded as the

deposition coupons placed strategically on the test surface

standard.

before the pesticide application.

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Practice

responsibility of the user of this standard to establish appro-

4.1 The sampling method described in this practice is taken

priate safety and health practices and determine the applica-

from published work (1,2,3,4) .

bility of regulatory limitations prior to its use.

4.2 Dislodgeable pesticide residues from floor surfaces are

collected by transfer to an annular ring of polyurethane foam

2. Referenced Documents

(PUF), which is rolled across the floor at a constant speed and

2.1 ASTM Standards:

2 applied pressure.

D 1193 Specification for Reagent Water

4.3 The PUF sampling ring is slipped over a cylindrical

D 1356 Terminology Relating to Sampling and Analysis of

3 metal axle that functions as the front wheel of the PUF roller

Atmospheres

apparatus. The apparatus is typically constructed of aluminum

D 4861 Practice for Sampling and Selection of Analytical

and consists of a frame with two permanent rear wheels and the

Techniques for Pesticides and Polychlorinated Biphenyls

detachable axle cylinder on the front.

in Air

4 4.4 Weights are attached to the roller frame to apply the

E 1 Specification for ASTM Thermometers

desired downward force on the PUF roller ring (sampling

pressure). A total weight of 3.88 kg provides a sampling

This practice is under the jurisdiction of ASTM Committee D-22 on Sampling pressure of 8300 Pa, corresponding approximately to that of a

and Analysis of Atmospheres and is the direct responsibility of Subcommittee

9 kg child crawling or walking.

D22.05 on Indoor Air.

Current edition approved Oct. 10, 1998. Published January 1999.

Annual Book of ASTM Standards, Vol 11.01.

3 5

Annual Book of ASTM Standards, Vol 11.03. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 14.03. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6333

4.5 A handle is connected at the rear of the roller frame to exposure to dislodgeable pesticide residues. It is the user’s

push or pull the device across the floor surface. responsibility to evaluate the data collected by this practice and

4.6 A template or similar measuring device is used to make such determinations in the light of other available

identify the area to be sampled. The axle cylinder is fitted with information.

a clean PUF ring, and the roller is then pushed at a constant rate

6. Interferences

of approximately 10 cm/s over a distance of 1.0 m and then

immediately pulled in the reverse direction back over the same 6.1 There are no known interferences to the collection of

dislodgeable pesticide residues from floors using this practice.

sampling area at the same rate of speed, ending at the original

starting position. The presence of excessive moisture levels in carpeting, as may

be the case shortly after a wet cleaning operation, may affect

4.7 The PUF ring is removed from the detached axle

cylinder and placed in a sealed container for transport to the the dislodgeability of residues, possibly yielding higher than

normal results.

laboratory for analysis.

4.8 The PUF ring is extracted and analyzed using specific 6.2 Analytical interferences may be caused by contaminants

in the sampling medium, solvents, and reagents and on

analytical procedures for the pesticides of interest. Typical

glassware and other sampling or sample processing hardware

methods involve Soxhlet extraction with analysis of extracts by

gas chromatography/mass spectrometry (GC/MS), gas that result in discrete artifacts and elevated baselines, or both,

in the detector profiles. For potential analytical interferences,

chromatography/electron capture detection (GC/ECD), or

other techniques noted in Practice D 4861. refer to Practice D 4861.

7. Apparatus

5. Significance and Use

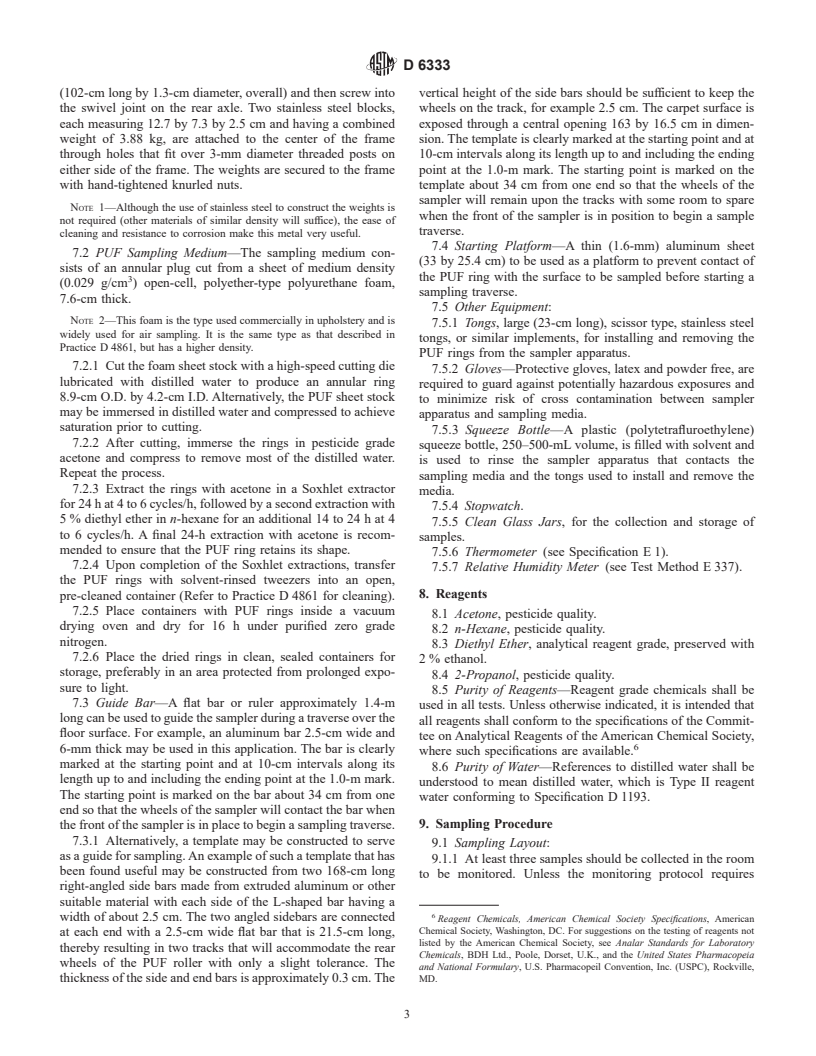

5.1 This practice may be used to estimate the potential for 7.1 PUF Roller Sampler, (as shown in Fig. 1) may be

constructed by a machinist using primarily aluminum materi-

human exposure to pesticide residues that may be dislodged

from residential floor surfaces by dermal contact. The sampling als. The typical apparatus consists of a frame (12.4 by 25.4 cm)

device employed is designed to approximately replicate the that is attached to a rear axle that holds a swivel joint in the

pressure applied bya9kg child crawling or walking on the center for attaching the handle and has two aluminum wheels

floor. (2.5-cm wide by 10.2-cm diameter). The distance between the

5.2 Laboratory tests and field studies have shown that the outside of the two wheels is 21.6 cm and between the inside of

transfer coefficient of the sampling device for collection of the wheels is 16.5 cm. An aluminum cylinder (7.6-cm long by

dried pesticide residues from nylon plush carpets is two to 4.3-cm diameter) is attached to the front of the sampler frame

three times higher than that of a dry hand (palm only) pressed by 6-mm diameter hex head axle bolts on the cylinder that fit

ten times at 7300 Pa over the same area of carpet (2,4,5). into slots on the frame. This cylinder serves as the front axle

5.3 This practice has been found suitable for use on plush and also holds the PUF sampling medium (see 7.2). The front

and level loop carpets and vinyl flooring (2, 3). axle cylinder is secured in the slots by spring steel retaining

5.4 This practice does not describe procedures for evalua- clips that permit easy attachment and removal of the cylinder.

tion of the safety of floor surfaces or the potential for human The handle for the sampler is two pieces that screw together

FIG. 1 PUF Roller: A. In Position for Sampling. B. Axle Cylinder/Frame Assembly.

D 6333

(102-cm long by 1.3-cm diameter, overall) and then screw into vertical height of the side bars should be sufficient to keep the

the swivel joint on the rear axle. Two stainless steel blocks, wheels on the track, for example 2.5 cm. The carpet surface is

each measuring 12.7 by 7.3 by 2.5 cm and having a combined exposed through a central opening 163 by 16.5 cm in dimen-

weight of 3.88 kg, are attached to the center of the frame sion. The template is clearly marked at the starting point and at

through holes that fit over 3-mm diameter threaded posts on 10-cm intervals along its length up to and including the ending

either side of the frame. The weights are secured to the frame point at the 1.0-m mark. The starting point is marked on the

with hand-tightened knurled nuts. template about 34 cm from one end so that the wheels of the

sampler will remain upon the tracks with some room to spare

NOTE 1—Although the use of stainless steel to construct the weights is

when the front of the sampler is in position to begin a sample

not required (other materials of similar density will suffice), the ease of

traverse.

cleaning and resistance to corrosion make this metal very useful.

7.4 Starting Platform—A thin (1.6-mm) aluminum sheet

7.2 PUF Sampling Medium—The sampling medium con-

(33 by 25.4 cm) to be used as a platform to prevent contact of

sists of an annular plug cut from a sheet of medium density

the PUF ring with the surface to be sampled before starting a

(0.029 g/cm ) open-cell, polyether-type polyurethane foam,

sampling traverse.

7.6-cm thick.

7.5 Other Equipment:

NOTE 2—This foam is the type used commercially in upholstery and is

7.5.1 Tongs, large (23-cm long), scissor type, stainless steel

widely used for air sampling. It is the same type as that described in

tongs, or similar implements, for installing and removing the

Practice D 4861, but has a higher density.

PUF rings from the sampler apparatus.

7.2.1 Cut the foam sheet stock with a high-speed cutting die

7.5.2 Gloves—Protective gloves, latex and powder free, are

lubricated with distilled water to produce an annular ring

required to guard against potentially hazardous exposures and

8.9-cm O.D. by 4.2-cm I.D. Alternatively, the PUF sheet stock

to minimize risk of cross contamination between sampler

may be immersed in distilled water and compressed to achieve

apparatus and sampling media.

saturation prior to cutting.

7.5.3 Squeeze Bottle—A plastic (polytetrafluroethylene)

7.2.2 After cutting, immerse the rings in pesticide grade

squeeze bottle, 250–500-mL volume, is filled with solvent and

acetone and compress to remove most of the distilled water.

is used to rinse the sampler apparatus that contacts the

Repeat the process.

sampling media and the tongs used to install and remove the

7.2.3 Extract the rings with acetone in a Soxhlet extractor

media.

for 24 h at 4 to 6 cycles/h, followed by a second extraction with

7.5.4 Stopwatch.

5 % diethyl ether in n-hexane for an additional 14 to 24 h at 4

7.5.5 Clean Glass Jars, for the collection and storage of

to 6 cycles/h. A final 24-h extraction with acetone is recom-

samples.

mended to ensure that the PUF ring retains its shape.

7.5.6 Thermometer (see Specification E 1).

7.2.4 Upon completion of the Soxhlet extractions, transfer

7.5.7 Relative Humidity Meter (see Test Method E 337).

the PUF rings with solvent-rinsed tweezers into an open,

8. Reagents

pre-cleaned container (Refer to Practice D 4861 for cleaning).

7.2.5 Place containers with PUF rings inside a vacuum

8.1 Acetone, pesticide quality.

drying oven and dry for 16 h under purified zero grade

8.2 n-Hexane, pesticide quality.

nitrogen.

8.3 Diethyl Ether, analytical reagent grade, preserved with

7.2.6 Place the dried rings in clean, sealed containers for

2 % ethanol.

storage, preferably in an area protected from prolonged expo-

8.4 2-Propanol, pesticide quality.

sure to light.

8.5 Purity of Reagents—Reagent grade chemicals shall be

7.3 Guide Bar—A flat bar or ruler approximately 1.4-m

used in all tests. Unless otherwise indicated, it is intended that

long can be used to guide the sampler during a traverse over the

all reagents shall conform to the specifications of the Commit-

floor surface. For example, an aluminum bar 2.5-cm wide and

tee on Analytical Reagents of the American Chemical Society,

6-mm thick may be used in this application. The bar is clearly

where such specifications are available.

marked at the starting point and at 10-cm intervals along its

8.6 Purity of Water—References to distilled water shall be

length up to and including the ending point at the 1.0-m mark.

understood to mean distilled water, which is Type II reagent

The starting point is marked on the bar about 34 cm from one

water conforming to Specification D 1193.

end so that the wheels of the sampler will contact the bar when

the front of the sampler is in place to begin a sampling traverse. 9. Sampling Procedure

7.3.1 Alternatively, a template may be constructed to serve

9.1 Sampling Layout:

as a guide for sampling. An example of such a template that has

9.1.1 At least three samples should be collected in the room

been found useful may be constructed from two 168-cm long

to be monitored. Unless the monitoring protocol requires

right-angled side bars made from extruded aluminum or other

suitable material with each side of the L-shaped bar having a

width of about 2.5 cm. The two angled sidebars are connected

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

at each end with a 2.5-cm wide flat bar that is 21.5-cm long,

listed by the American Chemical Society, see Analar Standards for Laboratory

thereby resulting in two tracks that will accommodate the rear

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

wheels of the PUF roller with only a slight tolerance. The

and National Formulary, U.S. Pharmacopeil Convention, Inc. (USPC), Rockville,

thickness of the side and end bars is approximately 0.3 cm. The MD.

D 6333

otherwise, the areas to be sampled should be selected in a 9.3.1 Place the sampler on the aluminum starting platform

manner that reflects the average surface of the floor; typically, with the PUF ring resting on the aluminum surface and

one sample should be taken near a doorway, one in the center centered near the beginning of the 1.0-m long sampling area.

of the room, and one near a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.