ASTM B819-18

(Specification)Standard Specification for Seamless Copper Tube for Medical Gas Systems

Standard Specification for Seamless Copper Tube for Medical Gas Systems

ABSTRACT

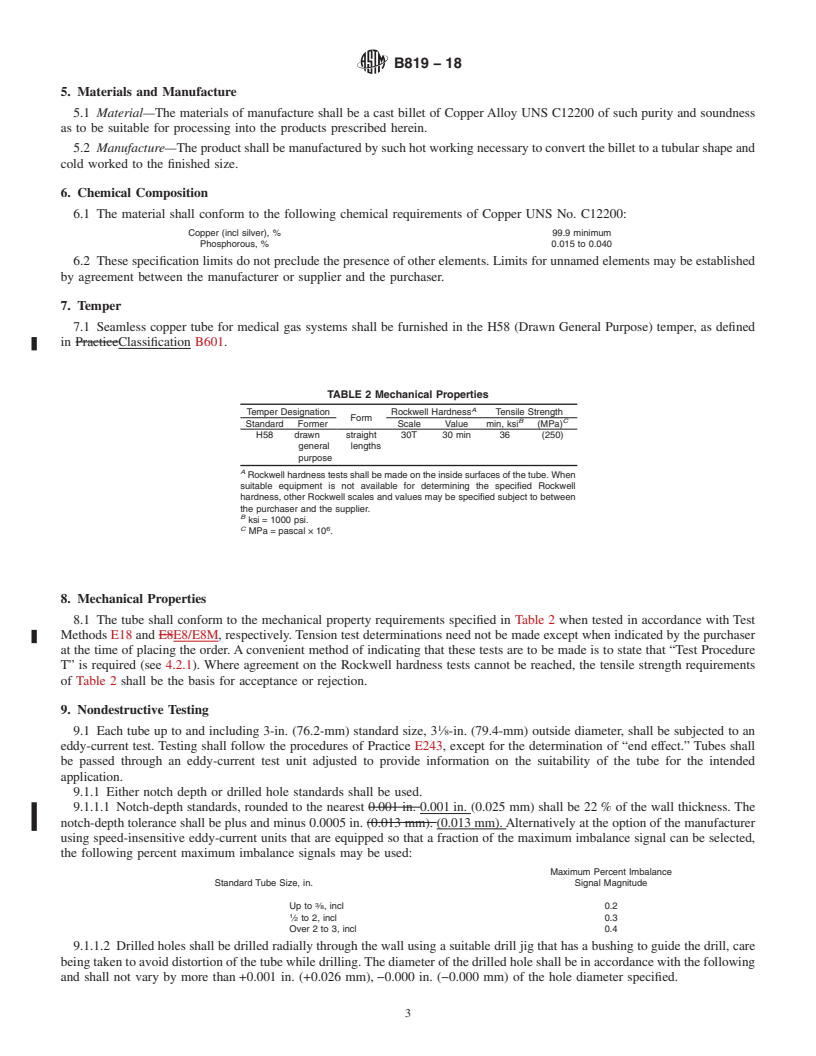

This specification establishes the requirements for two wall thickness schedules of specially cleaned, straight lengths of seamless copper tube, identified as Types K and L, suitable for medical gas systems. The product shall be manufactured by such hot working necessary to convert the billet to a tubular shape and cold worked to the finished size. Seamless copper tube for medical gas systems shall be furnished in the H58 (Drawn General Purpose) temper. Tension test and Rockwell hardness test shall be performed to determine the tube's tensile strength and hardness, respectively. Eddy-current test, a nondestructive test, shall be performed as well. The tubes used for medical gas systems shall be cleaned by any of the following recommended methods: alkaline washing, steam solvent washing, steam detergent washing, steam washing, vapor degreasing, and refrigerant degreasing.

SIGNIFICANCE AND USE

17.1 For purpose of determining compliance with the specified limits for requirements of the properties listed in Table 9, an observed value or calculated value shall be rounded as indicated in accordance with the rounding of Practice E29.

SCOPE

1.1 This specification establishes the requirements for two wall thickness schedules of specially cleaned, straight lengths of seamless copper tube, identified as Types K and L, suitable for medical gas systems. The tube shall be installed in conformance with the requirements of the National Fire Protection Association (NFPA) Standard 99, Gas and Vacuum Systems (NFPA) Standard 99C, Standard for Hypobaric Facilities (NFPA) Standard 99B, and Canadian Standards Association (CSA) Standard Z 305.1/Z 7396.1, Nonflammable Medical Gas Piping Systems.

Note 1: Types K and L tube are defined in Specification B88.

Note 2: Drawn temper tube is suitable for use with capillary (solder joint) fittings for brazing.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion of Section 12 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.2

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B819 −18

Standard Specification for

1

Seamless Copper Tube for Medical Gas Systems

This standard is issued under the fixed designation B819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This specification establishes the requirements for two

B88Specification for Seamless Copper Water Tube

wall thickness schedules of specially cleaned, straight lengths

B280Specification for Seamless Copper Tube for Air Con-

of seamless copper tube, identified as Types K and L, suitable

ditioning and Refrigeration Field Service

for medical gas systems. The tube shall be installed in

B601ClassificationforTemperDesignationsforCopperand

conformance with the requirements of the National Fire

Copper Alloys—Wrought and Cast

Protection Association (NFPA) Standard99, Gas and Vacuum

B846Terminology for Copper and Copper Alloys

Systems(NFPA)Standard99C,StandardforHypobaricFacili-

E8/E8MTest Methods for Tension Testing of Metallic Ma-

ties (NFPA) Standard 99B, and Canadian Standards Associa-

terials

tion (CSA) Standard Z305.1⁄Z7396.1, Nonflammable Medi-

E18Test Methods for Rockwell Hardness of Metallic Ma-

cal Gas Piping Systems.

terials

E29Practice for Using Significant Digits in Test Data to

NOTE 1—Types K and L tube are defined in Specification B88.

Determine Conformance with Specifications

NOTE 2—Drawn temper tube is suitable for use with capillary (solder

joint) fittings for brazing. E53Test Method for Determination of Copper in Unalloyed

Copper by Gravimetry

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

E62Test Methods for Chemical Analysis of Copper and

as standard. The values given in parentheses are mathematical

4

CopperAlloys(PhotometricMethods)(Withdrawn2010)

conversions to SI units that are provided for information only

E243PracticeforElectromagnetic(EddyCurrent)Examina-

and are not considered standard.

tion of Copper and Copper-Alloy Tubes

1.3 The following safety hazard caveat pertains only to the E255Practice for Sampling Copper and Copper Alloys for

the Determination of Chemical Composition

test method portion of Section 12 of this specification.This

E527Practice for Numbering Metals and Alloys in the

standard does not purport to address all of the safety concerns,

Unified Numbering System (UNS)

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health, and

2.2 Other Standards:

environmental practices and determine the applicability of

National Fire Protection Association (NFPA) 99,Gas and

2

regulatory limitations prior to use. Vacuum Systems (NFPA) 99C and Standard for Hypo-

5

baric Facilities (NFPA) 99B

1.4 This international standard was developed in accor-

CompressedGasAssociation(CGA)G-4.1,CleaningEquip-

dance with internationally recognized principles on standard-

6

ment for Oxygen Service

ization established in the Decision on Principles for the

Canadian Standards Association (CSA) Z305.1⁄Z7396.1,

Development of International Standards, Guides and Recom-

7

Nonflammable Medical Gas Piping Systems

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper Standards volume information, refer to the standard’s Document Summary page on

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe the ASTM website.

4

and Tube. The last approved version of this historical standard is referenced on

Current edition approved March 1, 2018. Published March 2018. Originally www.astm.org.

5

approved in 1992. Last previous edition approved in 2011 as B819–00 (2011). Available from National Fire Protection Association (NFPA), 1 Batterymarch

DOI: 10.1520/B0819-18. Park, Quincy, MA 02169, http://www.nfpa.org.

2 6

The UNS system for copper and copper alloys (see Practice E527) is a simple Available from Compressed Gas Association (CGA), 14501 George Carter

expansion of the former standard system accomplished by the addition of a prefix Way, Suite 103, Chantilly VA 20151-2923, http://www.cganet.com.

7

“C”andasuffix“00.”Thesuffixcanbeusedtoaccommodatecompositionvariation Available from Canadian Standards Association (CSA), 178 Rexdale Blvd.,

of the base alloy. Toronto, ON M9W 1R3, Canada, http://www.csagroup.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B819 − 00 (Reapproved 2011) B819 − 18

Standard Specification for

1

Seamless Copper Tube for Medical Gas Systems

This standard is issued under the fixed designation B819; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification establishes the requirements for two wall thickness schedules of specially cleaned, straight lengths of

seamless copper tube, identified as Types K and L, suitable for medical gas systems. The tube shall be installed in conformance

with the requirements of the National Fire Protection Association (NFPA) Standard 99, Gas and Vacuum Systems (NFPA) Standard

99C, Standard for Hypobaric Facilities (NFPA) Standard 99B, and Canadian Standards Association (CSA) Standard

Z 305.1 ⁄Z 7396.1, Nonflammable Medical Gas Piping Systems.

NOTE 1—Types K and L tube are defined in Specification B88.

NOTE 2—Drawn temper tube is suitable for use with capillary (solder joint) fittings for brazing.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 TheThe following safety hazard caveat pertains only to the test method portion of Section 12 of this specification.This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

2

of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B88 Specification for Seamless Copper Water Tube

B251 Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube (Metric) B0251_B0251M

B280 Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

4

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E243 Practice for Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2011March 1, 2018. Published March 2012March 2018. Originally approved in 1992. Last previous edition approved in 20062011 as

B819 – 00 (2006).(2011). DOI: 10.1520/B0819-00R11. 10.1520/B0819-18.

2

The UNS system for copper and copper alloys (see Practice E527) is a simple expansion of the former standard system accomplished by the addition of a prefix “C”

and a suffix “00”.“00.” The suffix can be used to accommodate composition variation of the base alloy.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B819 − 18

2.2 Other Standard

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.