ASTM D422-63(1998)

(Test Method)Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils

SCOPE

1.1 This test method covers the quantitative determination of the distribution of particle sizes in soils. The distribution of particle sizes larger than 75 [mu]m (retained on the No. 200 sieve) is determined by sieving, while the distribution of particle sizes smaller than 75 [mu]m is determined by a sedimentation process, using a hydrometer to secure the necessary data (Notes 1 and 2). Note 1-Separation may be made on the No. 4 (4.75-mm), No. 40 (425-[mu]m), or No. 200 (75-[mu]m) sieve instead of the No. 10. For whatever sieve used, the size shall be indicated in the report. Note 2-Two types of dispersion devices are provided: (1) a high-speed mechanical stirrer, and (2) air dispersion. Extensive investigations indicate that air-dispersion devices produce a more positive dispersion of plastic soils below the 20-[mu]m size and appreciably less degradation on all sizes when used with sandy soils. Because of the definite advantages favoring air dispersion, its use is recommended. The results from the two types of devices differ in magnitude, depending upon soil type, leading to marked differences in particle size distribution, especially for sizes finer than 20 [mu]m.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 422 – 63 (Reapproved 1998)

Standard Test Method for

Particle-Size Analysis of Soils

This standard is issued under the fixed designation D 422; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope stirring device in which a suitably mounted electric motor turns

a vertical shaft at a speed of not less than 10 000 rpm without

1.1 This test method covers the quantitative determination

load. The shaft shall be equipped with a replaceable stirring

of the distribution of particle sizes in soils. The distribution of

paddle made of metal, plastic, or hard rubber, as shown in Fig.

particle sizes larger than 75 μm (retained on the No. 200 sieve)

1. The shaft shall be of such length that the stirring paddle will

is determined by sieving, while the distribution of particle sizes

3 1

operate not less than ⁄4 in. (19.0 mm) nor more than 1 ⁄2 in.

smaller than 75 μm is determined by a sedimentation process,

(38.1 mm) above the bottom of the dispersion cup. A special

using a hydrometer to secure the necessary data (Note 1 and

dispersion cup conforming to either of the designs shown in

Note 2).

Fig. 2 shall be provided to hold the sample while it is being

NOTE 1—Separation may be made on the No. 4 (4.75-mm), No. 40

dispersed.

(425-μm), or No. 200 (75-μm) sieve instead of the No. 10. For whatever

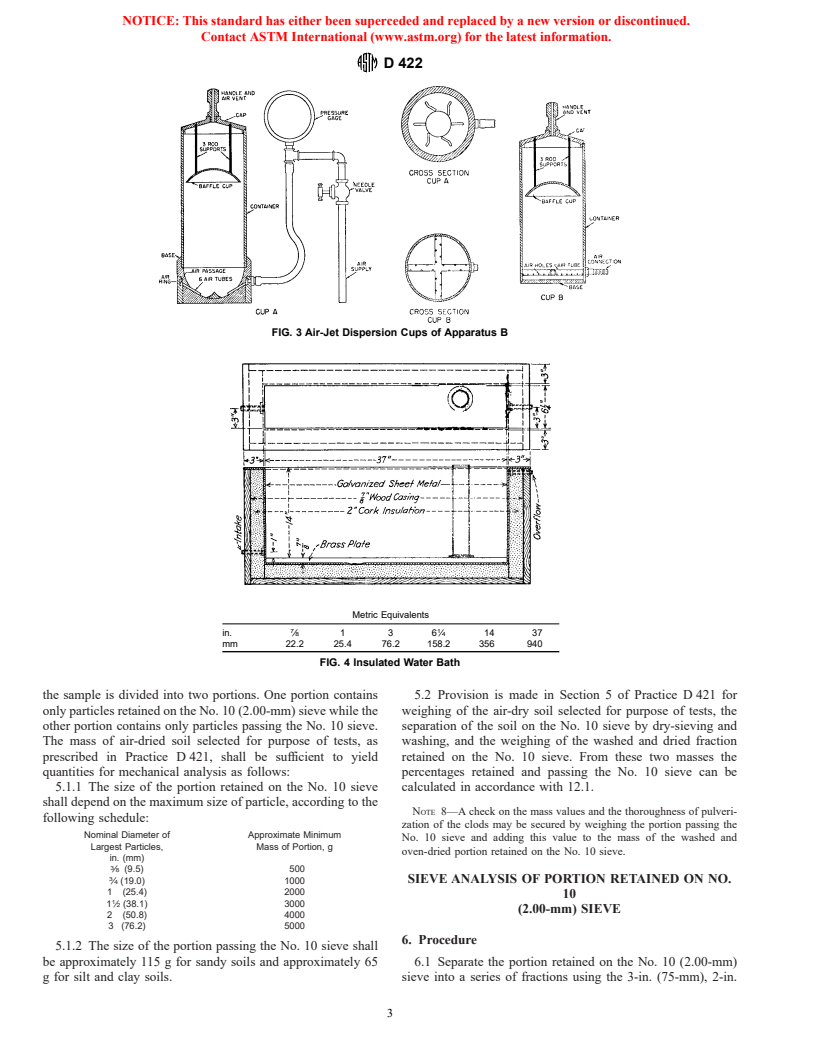

3.2.2 Apparatus B shall consist of an air-jet dispersion cup

sieve used, the size shall be indicated in the report.

(Note 3) conforming to the general details shown in Fig. 3

NOTE 2—Two types of dispersion devices are provided: (1) a high-

(Note 4 and Note 5).

speed mechanical stirrer, and (2) air dispersion. Extensive investigations

indicate that air-dispersion devices produce a more positive dispersion of

NOTE 3—The amount of air required by an air-jet dispersion cup is of

plastic soils below the 20-μm size and appreciably less degradation on all

the order of 2 ft /min; some small air compressors are not capable of

sizes when used with sandy soils. Because of the definite advantages

supplying sufficient air to operate a cup.

favoring air dispersion, its use is recommended. The results from the two

NOTE 4—Another air-type dispersion device, known as a dispersion

types of devices differ in magnitude, depending upon soil type, leading to

tube, developed by Chu and Davidson at Iowa State College, has been

marked differences in particle size distribution, especially for sizes finer

shown to give results equivalent to those secured by the air-jet dispersion

than 20 μm.

cups. When it is used, soaking of the sample can be done in the

sedimentation cylinder, thus eliminating the need for transferring the

2. Referenced Documents

slurry. When the air-dispersion tube is used, it shall be so indicated in the

2.1 ASTM Standards:

report.

NOTE 5—Water may condense in air lines when not in use. This water

D 421 Practice for Dry Preparation of Soil Samples for

must be removed, either by using a water trap on the air line, or by

Particle-Size Analysis and Determination of Soil Con-

2 blowing the water out of the line before using any of the air for dispersion

stants

purposes.

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

3.3 Hydrometer—An ASTM hydrometer, graduated to read

poses

in either specific gravity of the suspension or grams per litre of

E 100 Specification for ASTM Hydrometers

suspension, and conforming to the requirements for hydrom-

3. Apparatus

eters 151H or 152H in Specifications E 100. Dimensions of

both hydrometers are the same, the scale being the only item of

3.1 Balances—A balance sensitive to 0.01 g for weighing

difference.

the material passing a No. 10 (2.00-mm) sieve, and a balance

3.4 Sedimentation Cylinder—A glass cylinder essentially 18

sensitive to 0.1 % of the mass of the sample to be weighed for

in. (457 mm) in height and 2 ⁄2 in. (63.5 mm) in diameter, and

weighing the material retained on a No. 10 sieve.

marked for a volume of 1000 mL. The inside diameter shall be

3.2 Stirring Apparatus—Either apparatus A or B may be

such that the 1000-mL mark is 36 6 2 cm from the bottom on

used.

the inside.

3.2.1 Apparatus A shall consist of a mechanically operated

3.5 Thermometer—A thermometer accurate to 1°F (0.5°C).

3.6 Sieves—A series of sieves, of square-mesh woven-wire

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

cloth, conforming to the requirements of Specification E 11. A

and Rock and is the direct responsibility of Subcommittee D18.03 on Texture,

Plasticity, and Density Characteristics of Soils. full set of sieves includes the following (Note 6):

Current edition approved Nov. 21, 1963. Originally published 1935. Replaces

D 422 – 62.

2 5

Annual Book of ASTM Standards, Vol 04.08. Detailed working drawings for this cup are available at a nominal cost from the

Annual Book of ASTM Standards, Vol 14.02. American Society for Testing and Materials, 100 Barr Harbor Drive, West

Annual Book of ASTM Standards, Vol 14.03. Conshohocken, PA 19428. Order Adjunct No. ADJD0422.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 422

Metric Equivalents

1 3

in. 0.001 0.049 0.203 ⁄2 ⁄4

mm 0.03 1.24 5.16 12.7 19.0

FIG. 1 Detail of Stirring Paddles

3.7 Water Bath or Constant-Temperature Room—A water

bath or constant-temperature room for maintaining the soil

suspension at a constant temperature during the hydrometer

analysis. A satisfactory water tank is an insulated tank that

maintains the temperature of the suspension at a convenient

constant temperature at or near 68°F (20°C). Such a device is

illustrated in Fig. 4. In cases where the work is performed in a

room at an automatically controlled constant temperature, the

water bath is not necessary.

3.8 Beaker—A beaker of 250-mL capacity.

3.9 Timing Device—A watch or clock with a second hand.

4. Dispersing Agent

4.1 A solution of sodium hexametaphosphate (sometimes

called sodium metaphosphate) shall be used in distilled or

demineralized water, at the rate of 40 g of sodium

hexametaphosphate/litre of solution (Note 7).

NOTE 7—Solutions of this salt, if acidic, slowly revert or hydrolyze

back to the orthophosphate form with a resultant decrease in dispersive

action. Solutions should be prepared frequently (at least once a month) or

adjusted to pH of 8 or 9 by means of sodium carbonate. Bottles containing

Metric Equivalents

solutions should have the date of preparation marked on them.

in. 1.3 2.6 3.75

mm 33 66 95.2

4.2 All water used shall be either distilled or demineralized

FIG. 2 Dispersion Cups of Apparatus water. The water for a hydrometer test shall be brought to the

temperature that is expected to prevail during the hydrometer

test. For example, if the sedimentation cylinder is to be placed

3-in. (75-mm) No. 10 (2.00-mm)

in the water bath, the distilled or demineralized water to be

2-in. (50-mm) No. 20 (850-μm)

1 ⁄2-in. (37.5-mm) No. 40 (425-μm) used shall be brought to the temperature of the controlled water

1-in. (25.0-mm) No. 60 (250-μm)

bath; or, if the sedimentation cylinder is used in a room with

⁄4-in. (19.0-mm) No. 140 (106-μm)

3 controlled temperature, the water for the test shall be at the

⁄8-in. (9.5-mm) No. 200 (75-μm)

No. 4 (4.75-mm) temperature of the room. The basic temperature for the

hydrometer test is 68°F (20°C). Small variations of tempera-

NOTE 6—A set of sieves giving uniform spacing of points for the graph,

ture do not introduce differences that are of practical signifi-

as required in Section 17, may be used if desired. This set consists of the

following sieves: cance and do not prevent the use of corrections derived as

3-in. (75-mm) No. 16 (1.18-mm) prescribed.

1 ⁄2-in. (37.5-mm) No. 30 (600-μm)

⁄4-in. (19.0-mm) No. 50 (300-μm)

5. Test Sample

⁄8-in. (9.5-mm) No. 100 (150-μm)

No. 4 (4.75-mm) No. 200 (75-μm) 5.1 Prepare the test sample for mechanical analysis as

No. 8 (2.36-mm)

outlined in Practice D 421. During the preparation procedure

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 422

FIG. 3 Air-Jet Dispersion Cups of Apparatus B

Metric Equivalents

7 1

in. ⁄8 13 6 ⁄4 14 37

mm 22.2 25.4 76.2 158.2 356 940

FIG. 4 Insulated Water Bath

the sample is divided into two portions. One portion contains 5.2 Provision is made in Section 5 of Practice D 421 for

only particles retained on the No. 10 (2.00-mm) sieve while the weighing of the air-dry soil selected for purpose of tests, the

other portion contains only particles passing the No. 10 sieve. separation of the soil on the No. 10 sieve by dry-sieving and

The mass of air-dried soil selected for purpose of tests, as washing, and the weighing of the washed and dried fraction

prescribed in Practice D 421, shall be sufficient to yield retained on the No. 10 sieve. From these two masses the

quantities for mechanical analysis as follows: percentages retained and passing the No. 10 sieve can be

5.1.1 The size of the portion retained on the No. 10 sieve calculated in accordance with 12.1.

shall depend on the maximum size of particle, according to the

NOTE 8—A check on the mass values and the thoroughness of pulveri-

following schedule:

zation of the clods may be secured by weighing the portion passing the

Nominal Diameter of Approximate Minimum

No. 10 sieve and adding this value to the mass of the washed and

Largest Particles, Mass of Portion, g

oven-dried portion retained on the No. 10 sieve.

in. (mm)

⁄8 (9.5) 500

SIEVE ANALYSIS OF PORTION RETAINED ON NO.

⁄4 (19.0) 1000

1 (25.4) 2000

1 ⁄2 (38.1) 3000

(2.00-mm) SIEVE

2 (50.8) 4000

3 (76.2) 5000

6. Procedure

5.1.2 The size of the portion passing the No. 10 sieve shall

be approximately 115 g for sandy soils and approximately 65 6.1 Separate the portion retained on the No. 10 (2.00-mm)

g for silt and clay soils. sieve into a series of fractions using the 3-in. (75-mm), 2-in.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 422

1 3

(50-mm), 1 ⁄2-in. (37.5-mm), 1-in. (25.0-mm), ⁄4-in. (19.0- formed on the stem. For hydrometer 151H the composite

mm), ⁄8-in. (9.5-mm), No. 4 (4.75-mm), and No. 10 sieves, or correction is the difference between this reading and one; for

as many as may be needed depending on the sample, or upon hydrometer 152H it is the difference between the reading and

the specifications for the material under test. zero. Bring the liquid and the hydrometer to the other tempera-

6.2 Conduct the sieving operation by means of a lateral and ture to be used, and secure the composite correction as before.

vertical motion of the sieve, accompanied by a jarring action in

order to keep the sample moving continuously over the surface 8. Hygroscopic Moisture

of the sieve. In no case turn or manipulate fragments in the

8.1 When the sample is weighed for the hydrometer test,

sample through the sieve by hand. Continue sieving until not

weigh out an auxiliary portion of from 10 to 15 g in a small

more than 1 mass % of the residue on a sieve passes that sieve

metal or glass container, dry the sample to a constant mass in

during 1 min of sieving. When mechanical sieving is used, test

an oven at 230 6 9°F (110 6 5°C), and weigh again. Record

the thoroughness of sieving by using the hand method of

the masses.

sieving as described above.

6.3 Determine the mass of each fraction on a balance

9. Dispersion of Soil Sample

conforming to the requirements of 3.1. At the end of weighing,

9.1 When the soil is mostly of the clay and silt sizes, weigh

the sum of the masses retained on all the sieves used should

out a sample of air-dry soil of approximately 50 g. When the

equal closely the original mass of the quantity sieved.

soil is mostly sand the sample should be approximately 100 g.

9.2 Place the sample in the 250-mL beaker and cover with

HYDROMETER AND SIEVE ANALYSIS OF PORTION

125 mL of sodium hexametaphosphate solution (40 g/L). Stir

PASSING THE NO. 10 (2.00-mm) SIEVE

until the soil is thoroughly wetted. Allow to soak for at least 16

h.

7. Determination of Composite Correction for

9.3 At the end of the soaking period, disperse the sample

Hydrometer Reading

further, using either stirring apparatus A or B. If stirring

7.1 Equations for percentages of soil remaining in suspen-

apparatus A is used, transfer the soil-water slurry from the

sion, as given in 14.3, are based on the use of distilled or

beaker into the special dispersion cup shown in Fig. 2, washing

demineralized water. A dispersing agent is used in the water,

any residue from the beaker into the cup with distilled or

however, and the specific gravity of the resulting liquid is

demineralized water (Note 9). Add distilled or demineralized

appreciably greater than that of distilled or demineralized

water, if necessary, so that the cup is more than half full. Stir

water.

for a period of 1 min.

7.1.1 Both soil hydrometers are calibrated at 68°F (20°C),

and variations in temperature from this standard temperature

NOTE 9—A large size syringe is a convenient device for handling the

produce inaccuracies in the actual hydrometer readings. The water in the washing operation. Other devices include the wash-water

bottle and a hose with nozzle connected to a pressurized distilled water

amount of the inaccuracy increases as the variation from the

tank.

standard temperature increases.

7.1.2 Hydrometers are graduated by the manufacturer to be

9.4 If stirring apparatus B (Fig. 3) is used, remove the cover

read at the bottom of the meniscus formed by the liquid on the

cap and connect the cup to a compressed air supply by means

stem. Since it is not possible to secure readings of soil

of a rubber hose. A air gage must be on the line between the

suspensions at the bottom of the meniscus, readings must be

cup and the control valve. Open the control valve so that the

taken at the top and a correction applied.

gage indicates 1 psi (7 kPa) pressure (Note 10). Transfer the

7.1.3 The net amount of the corrections for the three items

soil-water slurry from the beaker to the air-jet dispersion cup

enumerated is designated as the composite correction, and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.