ASTM D6573/D6573M-01(2007)

(Specification)Standard Specification for General Purpose Wirebound Shipping Boxes

Standard Specification for General Purpose Wirebound Shipping Boxes

ABSTRACT

This specification covers the fabrication of new wire-bound general purpose panelboard shipping boxes for use as containers for domestic and overseas shipment of materials and supplies. This specification does not include wirebound box performance under all atmosphere, handling, shipping, and storage conditions. Methods other than those detailed here may be used for the construction of the boxes, provided, that the finished products are of equal or better performance than those produced using the recommended procedures. The boxes are grouped into three types according to the load each box can carry, three classes according to shipment specifications, three styles, and two grades. It is recommended that the boxes be made from recycled materials, lumber, wires, and fasteners that meet the requirements of this specification. Each box side and joint should be assembled according to the recommended procedures.

SCOPE

1.1 This specification covers the fabrication of new wirebound general purpose (GP) panelboard (hereafter referred to as wirebound boxes) shipping boxes intended for use as containers for domestic and overseas shipment of general materials and supplies, not exceeding 500 lb [226.8 kg] for class 1 domestic, 400 lb [181.4 kg] for Class 2 overseas shipments or 300 lb [136.0 kg] for Class 3 extreme distribution hazard conditions or military contingency purposes.

1.2 Wirebound box performance is dependent on its fabricated components; therefore, a variety of types, classes, styles, and treatments reflecting varied performance are specified. This specification does not cover wirebound box performance under all atmosphere, handling, shipping, and storage conditions. Wirebound boxes in compliance with Hazardous Material Modal Regulations or United States Code of Federal Regulations (CFRs) are found in the Supplementary Requirements.

1.3 The use of other construction methods or techniques are acceptable and shall be permitted, provided the resulting packaging systems are of equal or better performance than would result from the use of these specified materials and procedures. The appropriate Practice D 4169 distribution cycle(s) can be used to develop comparative procedures and criteria.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The SI values given in brackets are mathematical. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. See IEEE/SI 10 for conversion of units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6573/D6573M −01(Reapproved 2007)

Standard Specification for

General Purpose Wirebound Shipping Boxes

This standard is issued under the fixed designation D6573/D6573M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This specification covers the fabrication of new wire-

bound general purpose (GP) panelboard (hereafter referred to

2. Referenced Documents

as wirebound boxes) shipping boxes intended for use as

2.1 ASTM Standards:

containers for domestic and overseas shipment of general

A641/A641M Specification for Zinc–Coated (Galvanized)

materials and supplies, not exceeding 500 lb [226.8 kg] for

Carbon Steel Wire

class 1 domestic, 400 lb [181.4 kg] for Class 2 overseas

A777 Specification for Galvanized Round Steel Tying Wire

shipments or 300 lb [136.0 kg] for Class 3 extreme distribution

(Withdrawn 1995)

hazard conditions or military contingency purposes.

D996 Terminology of Packaging and Distribution Environ-

1.2 Wirebound box performance is dependent on its fabri-

ments

cated components; therefore, a variety of types, classes, styles,

D1990 Practice for Establishing Allowable Properties for

and treatments reflecting varied performance are specified.

Visually-Graded Dimension Lumber from In-Grade Tests

This specification does not cover wirebound box performance

of Full-Size Specimens

under all atmosphere, handling, shipping, and storage condi-

D3953 Specification for Strapping, Flat Steel and Seals

tions. Wirebound boxes in compliance with Hazardous Mate-

D4169 Practice for Performance Testing of Shipping Con-

rial Modal Regulations or United States Code of Federal

tainers and Systems

Regulations (CFRs) are found in the Supplementary Require-

D6199 Practice for Quality ofWood Members of Containers

ments.

and Pallets

D6254/D6254M Specification for Wirebound Pallet-Type

1.3 The use of other construction methods or techniques are

Wood Boxes

acceptable and shall be permitted, provided the resulting

F1667 Specification for Driven Fasteners: Nails, Spikes, and

packaging systems are of equal or better performance than

Staples

would result from the use of these specified materials and

IEEE/ASTM SI 10 Standard for Use of the International

procedures. The appropriate Practice D4169 distribution

System of Units (SI) (the Modern Metric System)

cycle(s) can be used to develop comparative procedures and

2.2 Federal Specification:

criteria.

Fed-Std-123 Federal Standard Marking for Shipment (Civil

1.4 Units—The values stated in inch-pound units are to be

Agencies)

regarded as standard. The SI values given in brackets are

2.3 Military Specification:

mathematical. The values stated in each system are not exact

MIL-HDBK-129 DepartmentofDefenseHandbookMilitary

equivalents; therefore, each system must be used indepen-

Marking

dently of the other. Combining values from the two systems

2.4 National Motor Freight Traffıc Association Standard:

may result in non-conformance with the standard. See IEEE/

National Motor Freight Classification

ASTM SI 10 for conversion of units.

1.5 This standard does not purport to address all of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

safety concerns, if any, associated with its use. It is the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of the user of this standard to establish appro-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org.

1 4

This specification is under the jurisdiction of ASTM Committee D10 on Available from Superintendent of Documents, U.S. Government Printing

Packaging and is the direct responsibility of Subcommittee D10.12 on Shipping Office, Washington, DC 20402.

Containers, Crates, Pallets, Skids and Related Structures. Available from Standardization Documents Order Desk, Bldg. 4, Section D,

Current edition approved April 1, 2007. Published May 2007. Originally 700 Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS.

approved in 2000. Last previous edition approved in 2001 as D6573/D6573M – 01. Available from the National Motor Freight Traffic Association, American

DOI: 10.1520/D6573_D6573M-01R07. Trucking Associations, 2200 Mill Road, Alexandria, VA 22314.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6573/D6573M−01 (2007)

2.5 APA—The Engineered Wood Association Standard: 5.1.4 Intermediate cleats for special designs, their size and

PS1-95 Construction and Industrial Plywood location. (see 7.3.1).

5.1.5 Weight of contents or load specified in lbs (kg).

2.6 ANSI Standard:

5.1.6 Type of girth wire (see 7.7).

ANSI/ASQC Q91–1987 Quality Systems-Model for Quality

5.1.7 When palletization is required (see S3.1.4.3).

Assurance and Design/Development, Production,

5.1.8 Marking required (see S4).

Installation, and Servicing

5.1.9 Exceptions to these specifications, if authorized.

5.1.10 When preservation treatment GradeAis required for

3. Terminology

class 2 or 3 boxes for overseas shipments (see 6.1.4).

3.1 Definitions—General definitions for packaging and dis-

5.1.11 When four-way entry skids are required and when

tribution environments are found in Terminology D996.

3 ⁄2 by 4-in. [76 by 89 mm] built-up skids are required (see

7.13).

4. Classification

5.1.12 Purchasers should reference by paragraph number

4.1 Types:

any supplemental requirements applicable to their purchase

4.1.1 Type 1—Easyload,oneinteriorcontainerthatsupports

request (see S1.1).

thetop,bottom,andsidesoftheouterwireboundshippingbox.

4.1.2 Type 2—Average load, interior or intermediate con-

6. Materials and Manufacture

tainers that support and fill the voids of outer wirebound

6.1 Materials—It is encouraged that recycled material be

container.

used when practical. All recovered, recycled, or virgin mate-

4.1.3 Type 3—Difficult load, interior contents that require a

rials used in the box manufacture shall meet the requirements

high degree of protection. Interior contents will not support

of this specification and APA/EWA PSI-95.

outer wirebound shipping container top, bottom, or sides.

6.1.1 Lumber—Lumber shall perform to Practice D6199,

4.2 Classes:

Class 2 requirements, for cleats (see 7.3, Group III) for skids

4.2.1 Class 1—Domestic shipments capable of passing

see Specification D6254/D6254M. Properties of lumber are in

Practice D4169, distribution Cycle 1 testing as a minimum,

accordance with Practice D1990

with no maritime shipment testing required.

6.1.1.1 Plywood Panel—Requirements are found in APA

4.2.2 Class 2—OverseasshipmentscapableofpassingPrac-

PS1–95.

tice D4169 distribution Cycles 1 with 15, 16, or 17 as

6.1.1.2 Faceboards—The material used for the faces of a

applicable to the type of shipping container selected.

box. Faceboards shall be as specified (see 7.2):

4.2.3 Class 3—Extreme Distribution hazards or military

6.1.2 Wires:

contingency operations the wirebound container will be ca-

6.1.2.1 Binding Wire and Staple Wire—Binding wire shall

pableofpassingPracticeD4169distributioncycle18testingas

be low carbon annealed steel wire and have the properties

a minimum requirement.

listed in Table 1. Staple wire shall be hard tempered, low

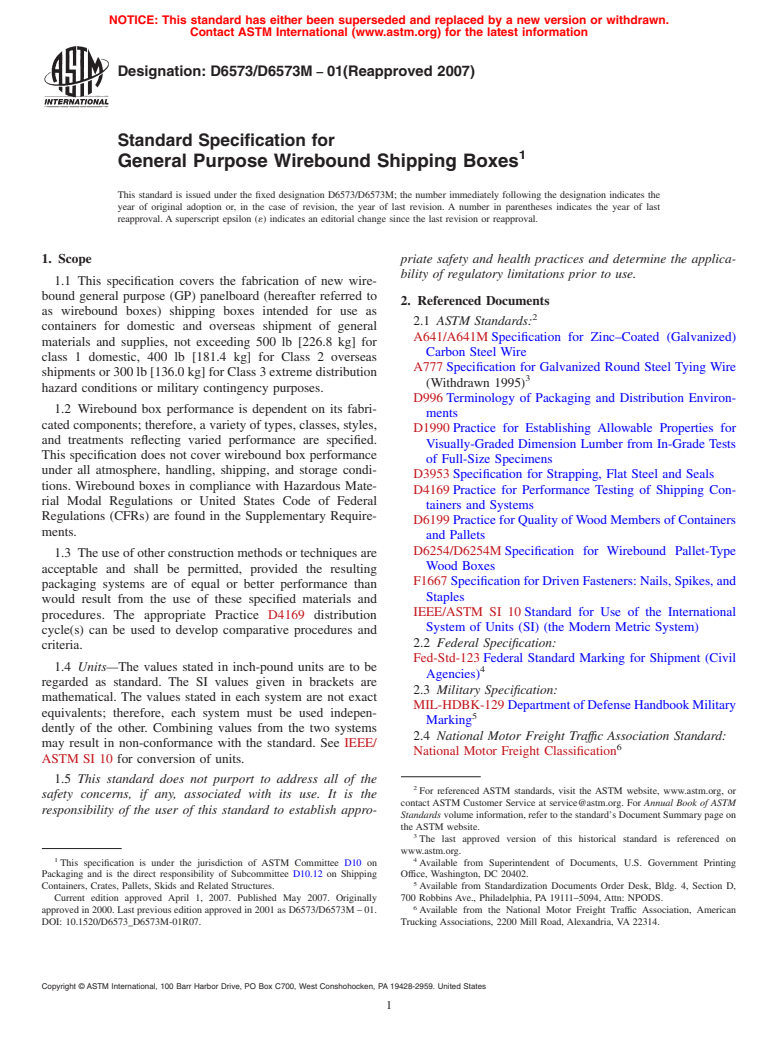

4.3 Style (based on the method of closure, see Fig. 1 ):

carbon steel wire, and have the properties listed in Table 1.

4.3.1 Style 1—Twisted wire closure. 6.1.2.2 Wire Coatings—The surfaces of binding wire and

4.3.2 Style 2—Looped wire closure.

staple wire for Class 2 and 3 boxes shall be galvanized. The

4.3.3 Style 3—Looped wire closure with wired ends. surface of binding and staple wires for Class 1 boxes need not

be galvanized. Galvanized coating shall be smooth and shall

4.4 Treatment:

not flake or peel when tested in accordance with Specification

4.4.1 Grade A—With preservative treatment.

A641/A641M.

4.4.2 Grade B—Without water preservative treatment.

6.1.3 Fasteners:

6.1.3.1 Nails—Nails shall be made of steel wire and shall

5. Ordering Information

conform to the requirements of Specification F1667. Nails will

5.1 Purchasers should cite the following information in

be clinched, cement-coated, or chemical etched to prevent

procurement and purchase order documents:

premature withdrawal.

5.1.1 This specification title, ASTM number, and date.

6.1.3.2 Staples or Wire Stitches—Staples or wire stitches

5.1.2 Type of load, box type, class, style, and treatment, if

shall be made of steel wire not less than 0.0625 in. [2 mm] and

specified, (see 4.1-4.4 and S2.1 respectively).

comply with Specification F1667.

5.1.3 The material/product shall conform to the require-

6.1.4 Wood Preservative, Water Repellent—Water repellent

ments stated in United States Customary Units of Specification

preservative shall be composed of either a 2 % copper

IEEE/ASTM SI 10.

naphthenate, a 3 % zinc naphthenate, or a 1.8 % oxine copper

5.1.3.1 Inside box dimensions (see 7.1).

(formerly referred to as copper-8-quinolinolate) solution.

7. Construction

7 th

Available from theAPA, the EngineeredWoodAssociation, 7011 S. 19 Street,

P.O. Box 11700, Tacoma, WA 98411–0700.

7.1 Dimensions—Boxes shall be furnished having the di-

Available from the American National Standards Institute, 25 West 43rd St.,

mensions as specified (see 5.1.3). Dimensions of boxes are

New York, NY 10036.

measured between the inside surfaces of the faceboards, and

Dean, School of Military Packaging Technology, 360 Lanyard Rd., Building

360, Attn: ATSL-MP, Aberdeen Proving Ground, MD 21005–5282. calculated to the nearest ⁄8 in. [3 mm], the preferred sequence

D6573/D6573M−01 (2007)

FIG. 1Styles of Closures

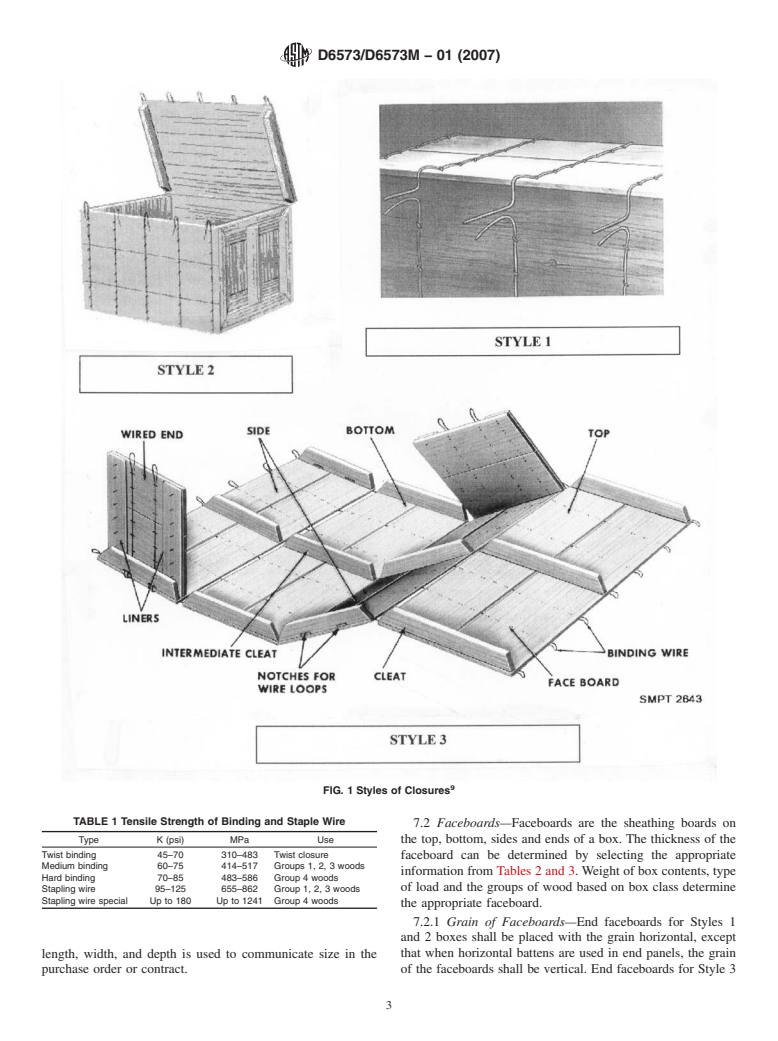

TABLE 1 Tensile Strength of Binding and Staple Wire

7.2 Faceboards—Faceboards are the sheathing boards on

Type K (psi) MPa Use

the top, bottom, sides and ends of a box. The thickness of the

Twist binding 45–70 310–483 Twist closure

faceboard can be determined by selecting the appropriate

Medium binding 60–75 414–517 Groups 1, 2, 3 woods

information from Tables 2 and 3. Weight of box contents, type

Hard binding 70–85 483–586 Group 4 woods

of load and the groups of wood based on box class determine

Stapling wire 95–125 655–862 Group 1, 2, 3 woods

Stapling wire special Up to 180 Up to 1241 Group 4 woods

the appropriate faceboard.

7.2.1 Grain of Faceboards—End faceboards for Styles 1

and 2 boxes shall be placed with the grain horizontal, except

that when horizontal battens are used in end panels, the grain

length, width, and depth is used to communicate size in the

purchase order or contract. of the faceboards shall be vertical. End faceboards for Style 3

D6573/D6573M−01 (2007)

TABLE 2 Minimum Thickness of Faceboards TABLE 3 Minimum Faceboard Requirements

Group 1 Woods in Fractional Resawn faceboard Faceboard edge piece Space between

Weight of Contents in lbs [kg]

in. [mm] thickness not less than not less than 2- ⁄2 in. Faceboards not more

1 1

⁄32 in. [1 mm] Less than [63.5 mm] wide than ⁄4 in. [6 mm]

Exceeding Not Exceeding Type 1 Load Type 2 Load Type 3 Load

specified in Table 2

Class I Boxes

Faceboards no less than One full piece of plywood

7 1 5

0 85 [38.5] ⁄32 [6] ⁄4 [6] ⁄16 [8] 1

2 ⁄2 in. [63.5 mm] in width thickness not less than

1 5 3

85 [38.5] 125 [56.7] ⁄4 [6] ⁄16 [8] ⁄8 [10]

25 %

5 3 7

125 [56.7] 200 [90.7] ⁄16 [8] ⁄8 [10] ⁄16 [11]

A

3 7

200 [90.7] 300 [136.1] ⁄8 [10] ⁄16 [11]

AAA

300 [136.1] 400 [181.4]

AAA

shall be located approximately 1 in. [25 mm] from the parallel

400 [181.4] 500 [226.8]

Class 2 Boxes

to each horizontal edge of the end faceboard (see 7.8). The

A

5 3

0 85 [38.5] ⁄16 [8] ⁄8 [10]

direction of grain of the ply to which the end wire is stitched

A

3 3

85 [38.5] 125 [56.7] ⁄8 [10] ⁄8 [10]

AAA

shall be vertical.

125 [56.7] 200 [90.7]

AAA

200 [90.7] 300 [136.1]

AAA

7.3 Cleats—Cleats are pieces of lumber which form the

300 [136.1] 400 [181.4]

Group I Woods Fractional, in. framework of the box and to which faceboards of the top,

Weight of Box Contents in lbs [kg]

[mm]

bottom, and sides are stapled. Cleats shall be made from wood

Class 3 Boxes

Not Exceeding Type 1 Load Type 2 Load Type 3 Load

specified in Practice D6199.The cleats shall be made of Group

Exceeding

A

3 3

0 85 [38.5] ⁄8 [10] ⁄8 [10]

2, 3, or 4 woods only. Each cleat shall be single piece of wood

AAA

85 [38.5] 125 [56.7]

without joints. Cleats shall be made with mitered ends or with

AAA

125 [56.7] 200 [90.7]

AAA

mortised and tenoned ends tongue- and groove. Dimensions

200 [90.7] 500 [226.8]

Group 2 and 3 Woods in

shall be actual dimensions, 1 ⁄32 in. [9 mm]. Edge cleats of all

Weight of Box Contents in lbs [kg]

Fractional in. [mm]

13 7

styles of boxes shall be ⁄16 in. [21 mm] wide and ⁄8 in. [22

Class 1 Boxes

Not Exceeding Type 1 Load Type 2 Load Type 3 Load

mm]inthicknessforboxeshavingweightofcontentsupto300

Exceeding

1 1 3

0 85 [38.5] ⁄7 [4] ⁄6 [4] ⁄16 [5]

lb [136 kg]. Boxes having weight of contents from 300 to 500

1 3 7

85 [38.5] 125 [56.7] ⁄6 [4] ⁄16 [5] ⁄32 [6]

lb [136 to 227 kg] edge cleats shall be 1 ⁄8 in. [29 mm] wide

3 7 1

125 [56.7] 200 [90.7] ⁄16 [5] ⁄32 [6] ⁄4 [6]

7 7 1

and 1 ⁄8 in. [29 mm] in thickness, except that HVB or HVBW

200 [90.7] 300 [136.1] ⁄32 [6] ⁄32 [6] ⁄4 [6]

1 1 5

300 [136.1] 400 [181.4] ⁄4 [6] ⁄4 [6] ⁄16 [8]

end patterns are used (see Fig. 2), edge cleats shall be ⁄16 in.

5 5 3

400 [181.4] 500 [226.8] ⁄16 [8] ⁄16 [8] ⁄8 [10]

[21 mm] wide and ⁄8 in. [22 mm] in thickness.

Class 2 Boxes

3 7 5

7.3.1 Intermediate Cleats—Boxes for Types 2 and 3 loads,

0 85 [38.5] ⁄16 [5] ⁄32 [6] ⁄16 [8]

7 1 5

85 [38.5] 125 [56.7] ⁄32 [6] ⁄4 [6] ⁄16 [8]

having greater between-cleat dimensions than specified in

7 1 5

125 [56.7] 200 [90.7] ⁄32 [6] ⁄4 [6] ⁄16 [8]

Table 4, shall be reinforced with one or more rows of

1 3 3

200 [90.7] 300 [136.1] ⁄4 [6] ⁄8 [10] ⁄8 [10]

5 3 3

intermediate cleats, except as below. Rows of intermediate

300 [136.1] 400 [181.4] ⁄16 [8] ⁄8 [10] ⁄8 [10]

Class 3 Boxes

cleats are not required on boxes for Type 1 loads. The distance

1 1 5

0 85 [38.5] ⁄4 [6] ⁄4 [6] ⁄16 [8]

between adjacent rows of cleats shall not exceed the distance

1 5 5

85 [38.5] 125 [56.7] ⁄4 [6] ⁄16 [8] ⁄16 [8]

1 5 3

indicatedinTable5.InspecialdesignsforTypes2and3loads,

125 [56.7] 200 [90.7] ⁄4 [6] ⁄16 [8] ⁄8 [10]

5 3 3

200 [90.7] 500 [226.8] ⁄16 [8] ⁄8 [10] ⁄8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.