ASTM E372-21

(Test Method)Standard Test Method for Determination of Calcium and Magnesium in Magnesium Ferrosilicon by EDTA Titrimetry

Standard Test Method for Determination of Calcium and Magnesium in Magnesium Ferrosilicon by EDTA Titrimetry

SIGNIFICANCE AND USE

4.1 This test method for the chemical analysis of metals and alloys is primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use this test method will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 This test method covers the chemical analysis of magnesium ferrosilicon having chemical compositions within the following limits:

Element

Composition Range, %

Aluminum

2.0 max

Calcium

0.25 to 3.00

Carbon

0.50 max

Cerium

1.0 max

Chromium

0.50 max

Magnesium

2.00 to 12.00

Manganese

1.0 max

Silicon

40.00 to 55.00

Sulfur

0.025 max

Titanium

0.2 max

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For general precautions to be observed in this test method, refer to Practices E50.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E372 − 21

Standard Test Method for

Determination of Calcium and Magnesium in Magnesium

1

Ferrosilicon by EDTA Titrimetry

This standard is issued under the fixed designation E372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for Determination of Chemical Composition

E50 Practices for Apparatus, Reagents, and Safety Consid-

1.1 This test method covers the chemical analysis of mag-

erations for Chemical Analysis of Metals, Ores, and

nesium ferrosilicon having chemical compositions within the

Related Materials

following limits:

E135 Terminology Relating to Analytical Chemistry for

Element Composition Range, %

Metals, Ores, and Related Materials

Aluminum 2.0 max E173 Practice for Conducting Interlaboratory Studies of

Calcium 0.25 to 3.00

Methods for Chemical Analysis of Metals (Withdrawn

Carbon 0.50 max

3

1998)

Cerium 1.0 max

Chromium 0.50 max

Magnesium 2.00 to 12.00

3. Terminology

Manganese 1.0 max

3.1 For definitions of terms used in this test method, refer to

Silicon 40.00 to 55.00

Sulfur 0.025 max

Terminology E135.

Titanium 0.2 max

1.2 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This test method for the chemical analysis of metals and

responsibility of the user of this standard to establish appro-

alloys is primarily intended to test such materials for compli-

priate safety, health, and environmental practices and deter-

ance with compositional specifications. It is assumed that all

mine the applicability of regulatory limitations prior to use.

who use this test method will be trained analysts capable of

For general precautions to be observed in this test method,

performing common laboratory procedures skillfully and

refer to Practices E50.

safely. It is expected that work will be performed in a properly

1.3 This international standard was developed in accor-

equipped laboratory.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Hazards

Development of International Standards, Guides and Recom-

5.1 For precautions to be observed in the use of certain

mendations issued by the World Trade Organization Technical

reagents and equipment in this test method, refer to Practices

Barriers to Trade (TBT) Committee.

E50.

2. Referenced Documents

5.2 Specific hazard statements are given in 13.7.1 and 14.1.

2

2.1 ASTM Standards:

6. Sampling

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

6.1 For procedures to sample the material, refer to Practices

E32 Practices for Sampling Ferroalloys and Steel Additives

E32.

7. Rounding Calculated Values

1

This test method is under the jurisdiction of ASTM Committee E01 on

7.1 Rounding of test results obtained using this test method

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

shall be performed as directed in Practice E29, Rounding

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved Jan. 15, 2021. Published February 2021. Originally

Method, unless an alternative rounding method is specified by

approved in 1976. Redesignated E372 in 1980. Last previous edition approved in

the customer or applicable material specification.

2013 as E372 – 13. DOI: 10.1520/E0372-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E372 − 21

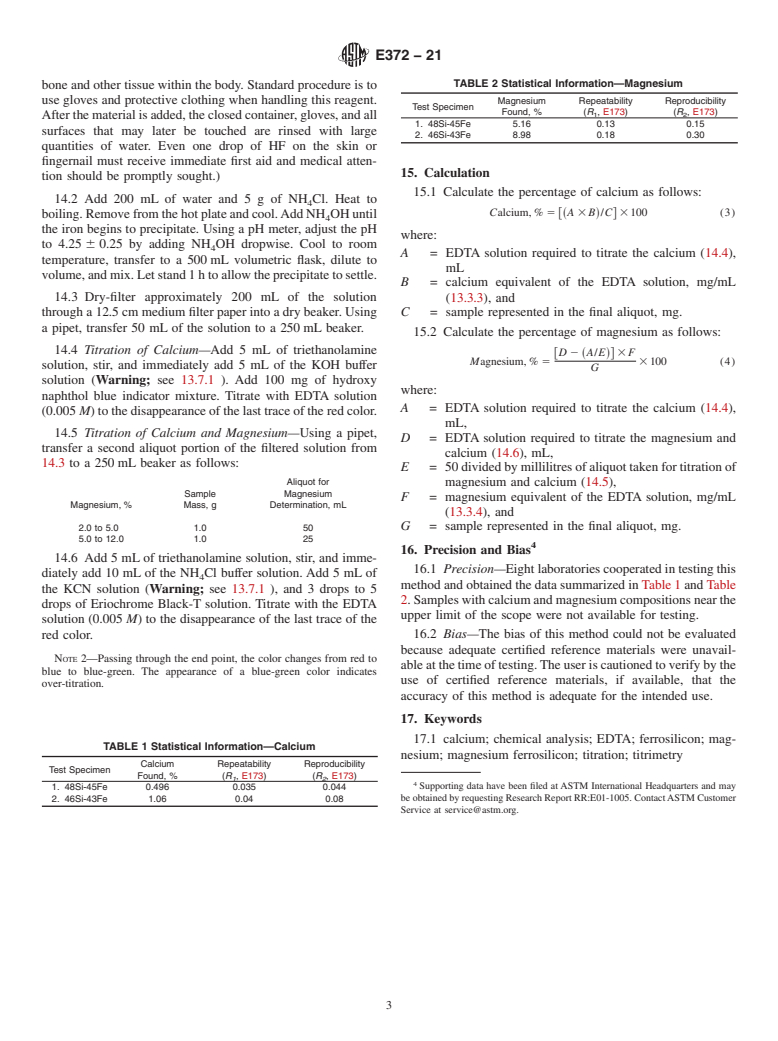

8. Interlaboratory Studies to a 250 mL beaker, add 1 mL of MgCl (13.6) solution and

2

100 mL of water, and proceed as directed in 14.4.

8.1 This test method has been evaluated in accordance with

13.3.3 Calculate the calcium equivalent of the EDTA solu-

Practice E173, unless otherwise noted in the precision and bias

tion as follows:

section.

Calcium equivalent, mg/mL 5 A/B (1)

where:

CALCIUM AND MAGNESIUM BY THE

(ETHYLENEDINITRILO) TETRAACETIC ACID

A = calcium, mg, and

DISODIUM SALT (EDTA) TITRIMETRY METHOD B = EDTA solution required to titrate t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E372 − 13 E372 − 21

Standard Test Method for

Determination of Calcium and Magnesium in Magnesium

1

Ferrosilicon by EDTA TitrationTitrimetry

This standard is issued under the fixed designation E372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the chemical analysis of magnesium ferrosilicon having chemical compositions within the following

limits:

Element Composition Range, %

Aluminum 2.0 max

Calcium 0.25 to 3.00

Carbon 0.50 max

Cerium 1.0 max

Chromium 0.50 max

Magnesium 2.00 to 12.00

Manganese 1.0 max

Silicon 40.00 to 55.00

Sulfur 0.025 max

Titanium 0.2 max

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For general precautions to be observed in this test method, refer to Practices

E50.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E32 Practices for Sampling Ferroalloys and Steel Additives for Determination of Chemical Composition

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

3

E173 Practice for Conducting Interlaboratory Studies of Methods for Chemical Analysis of Metals (Withdrawn 1998)

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and areis the direct responsibility

of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved Nov. 15, 2013Jan. 15, 2021. Published January 2014February 2021. Originally approved in 1976. Redesignated E372 in 1980. Last previous

edition approved in 20062013 as E372 – 01 (2006).E372 – 13. DOI: 10.1520/E0372-13.10.1520/E0372-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

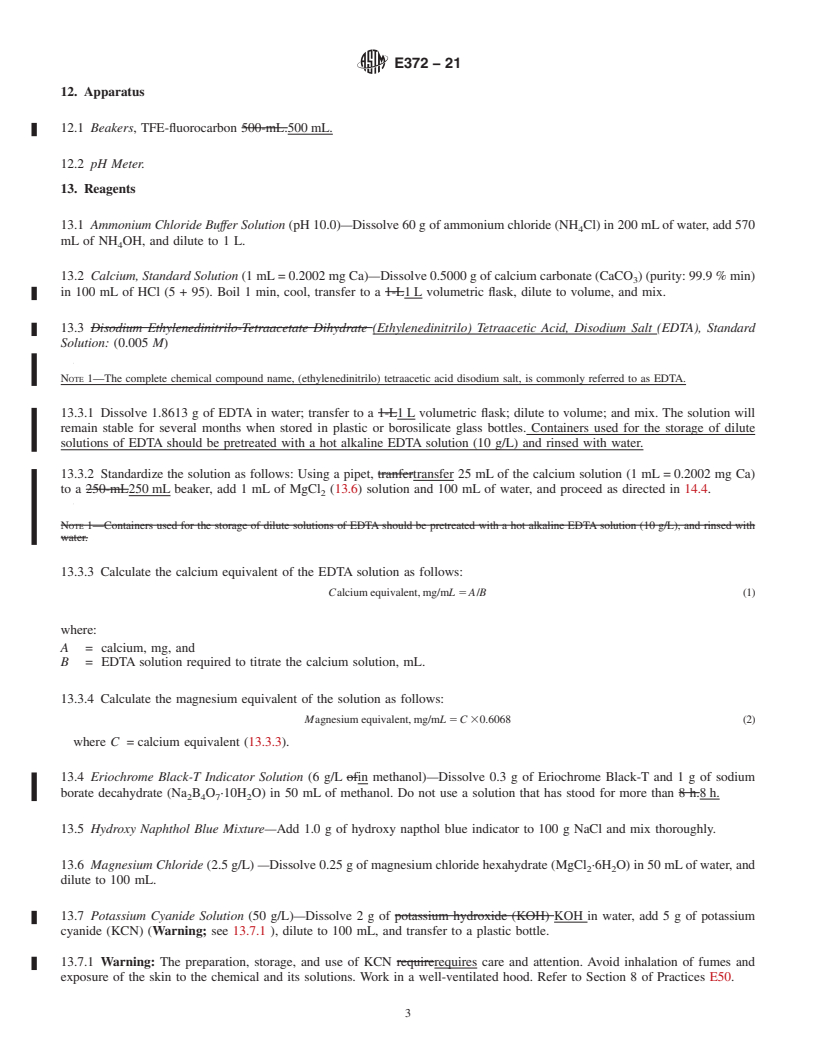

E372 − 21

3. Terminology

3.1 For definitions of terms used in this test method, refer to Terminology E135.

4. Significance and Use

4.1 This test method for the chemical analysis of metals and alloys is primarily intended to test such materials for compliance with

compositional specifications. It is assumed that all who use this test method will be trained analysts capable of performing common

laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

5. Hazards

5.1 For precautions to be observed in the use of certain reagents and equipment in this test method, refer to Practices E50.

5.2 Specific hazard statements are given in 13.7.1 and 14.1.

6. Sampling

6.1 For procedures for samplingto sample the material, refer to Practices E32.

7. Rounding Calculated Values

7.1 Calculated values shall be rounded to the desired number of places Rounding of test results obtained using this test method

shall be performed as directed in Practice E29., Rounding Method, unless an alternative rounding method is specified by the

customer or applicable material specification.

8. Interlaboratory Studies

8.1 This test method has been evaluated in accordance with Practice E173, unless otherwise noted in the precision and bias section.

CALCIUM AND MAGNESIUM BY THE (ETHYLENEDINITRILO)TETRAACETIC ACID (EDTA)

TITRIMETRIC(ETHYLENEDINITRILO) TETRA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.