ASTM D6557-10

(Test Method)Standard Test Method for Evaluation of Rust Preventive Characteristics of Automotive Engine Oils

Standard Test Method for Evaluation of Rust Preventive Characteristics of Automotive Engine Oils

SIGNIFICANCE AND USE

This bench test method was designed as a replacement for Test Method D5844. Test Method D5844 was designed to measure the ability of an engine oil to protect valve train components against rusting or corrosion under low temperature, short-trip service, and was correlated with vehicles in that type of service prior to 1978.

Correlation between these two test methods has been demonstrated for most, but not all, of the test oils evaluated.

SCOPE

1.1 This test method covers a Ball Rust Test (BRT) procedure for evaluating the anti-rust ability of fluid lubricants. The procedure is particularly suitable for the evaluation of automotive engine oils under low-temperature, acidic service conditions.

1.2 Information Letters are published occasionally by the ASTM Test Monitoring Center (TMC) to update this test method. Copies of these letters can be obtained by writing the center.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exceptions—Where there is no direct equivalent, such as the units for screw threads, national pipe threads/diameters, and tubing size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 7.1.1-7.1.3 and 8.2.1.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6557–10

Standard Test Method for

Evaluation of Rust Preventive Characteristics of Automotive

1

Engine Oils

This standard is issued under the fixed designation D6557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4175 Terminology Relating to Petroleum, Petroleum

Products, and Lubricants

1.1 This test method covers a Ball Rust Test (BRT) proce-

D5844 Test Method for Evaluation of Automotive Engine

dure for evaluating the anti-rust ability of fluid lubricants. The

4

Oils for Inhibition of Rusting (Sequence IID)

procedure is particularly suitable for the evaluation of automo-

D6984 Test Method for Evaluation of Automotive Engine

tive engine oils under low-temperature, acidic service condi-

Oils in the Sequence IIIF, Spark-Ignition Engine

tions.

1.2 Information Letters are published occasionally by the

3. Terminology

2

ASTM Test Monitoring Center (TMC) to update this test

3.1 Definitions:

method. Copies of these letters can be obtained by writing the

3.1.1 calibrate, v—to determine the indication or output of

center.

a device (e.g., thermometer, manometer, engine) with respect

1.3 The values stated in SI units are to be regarded as

to a standard.

standard. No other units of measurement are included in this

3.1.2 corrosion, n—the chemical or electrochemical reac-

standard.

tion between a material, usually a metal surface, and its

1.3.1 Exceptions—Where there is no direct equivalent, such

environment that can produce a deterioration of the material

as the units for screw threads, national pipe threads/diameters,

and its properties. D4175

and tubing size.

3.1.3 non-reference oil, n—any oil other than a reference

1.4 This standard does not purport to address all of the

oil, such as a research formulation, commercial oil, or candi-

safety concerns, if any, associated with its use. It is the

date oil. D4175

responsibility of the user of this standard to establish appro-

3.1.4 reference oil, n—an oil of known performance char-

priate safety and health practices and determine the applica-

acteristics, used as a basis for comparison. D4175

bility of regulatory limitations prior to use. See 7.1.1-7.1.3 and

3.1.4.1 Discussion—Reference oils are used to calibrate

8.2.1.1.

testing facilities, to compare the performance of other oils, or

2. Referenced Documents to evaluate other materials (such as seals) that interact with

3

oils.

2.1 ASTM Standards:

3.1.5 rust (coatings), n—the reddish material, primarily

hydratedironoxide,formedonironoritsalloys,resultingfrom

1

This test method is under the jurisdiction of ASTM Committee D02 on

exposure to humid or chemical attack. D6984

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.1.6 test oil, n—any oil subjected to evaluation in an

D02.B0.01 on Passenger Car Engine Oils.

established procedure.

Current edition approved June 15, 2010. Published June 2010. Originally

approved in 2000. Last previous edition approved in 2009 as D6557–09. DOI:

3.2 Definitions of Terms Specific to This Standard:

10.1520/D6557-10.

3.2.1 average gray value (AGV), n—measurement of

2

Until the next revision of this test method, the ASTM Test Monitoring Center

brightnessunitsontestspecimens,indicatingthedegreeofrust

will update changes in the test method by means of information letters. Information

protection.

lettersmaybeobtainedfromtheASTMTestMonitoringCenter,6555PennAvenue,

Pittsburgh, PA 15206-4489. This test method is supplemented by Information

3.2.2 specimen, n—acarbonsteelball,5.6mm(AISI1040).

Letters and Memoranda issued by the ASTM TMC. This edition incorporates

revisions in all Information Letters through No. 07–01.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6557–10

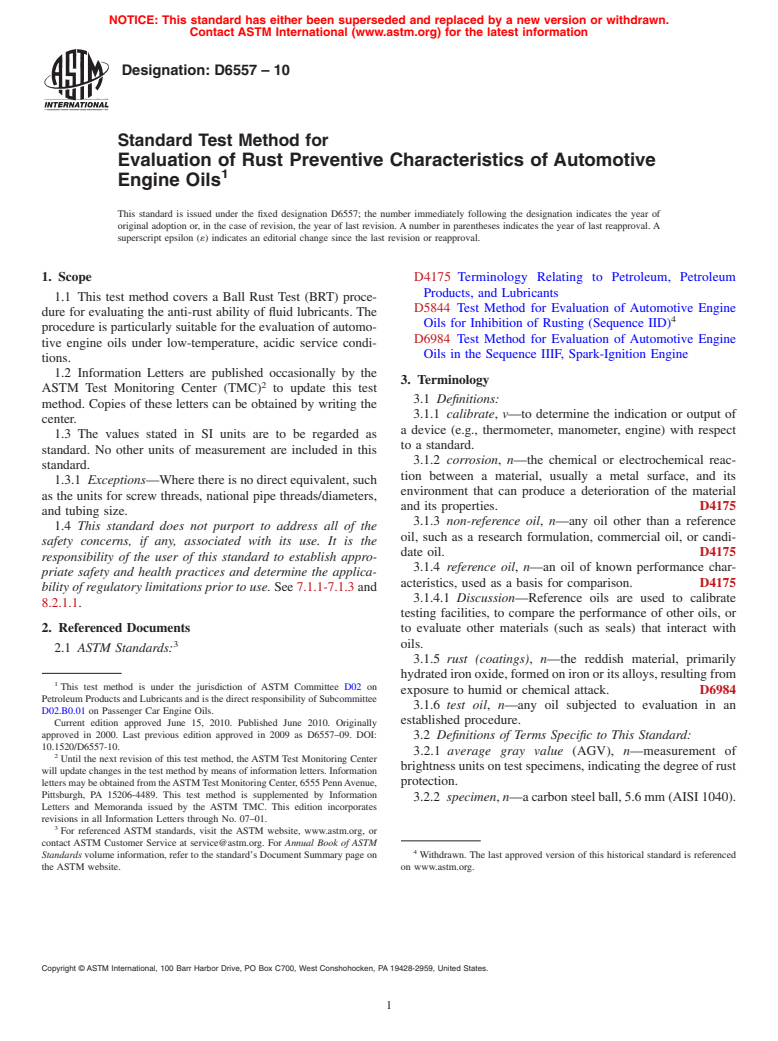

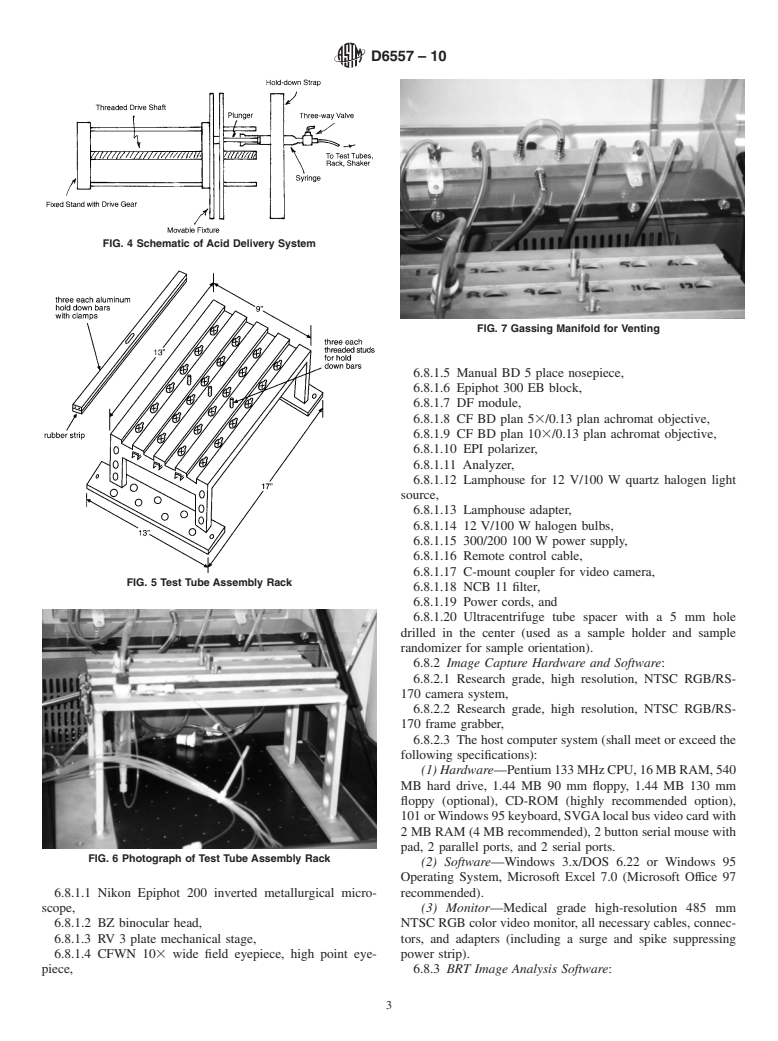

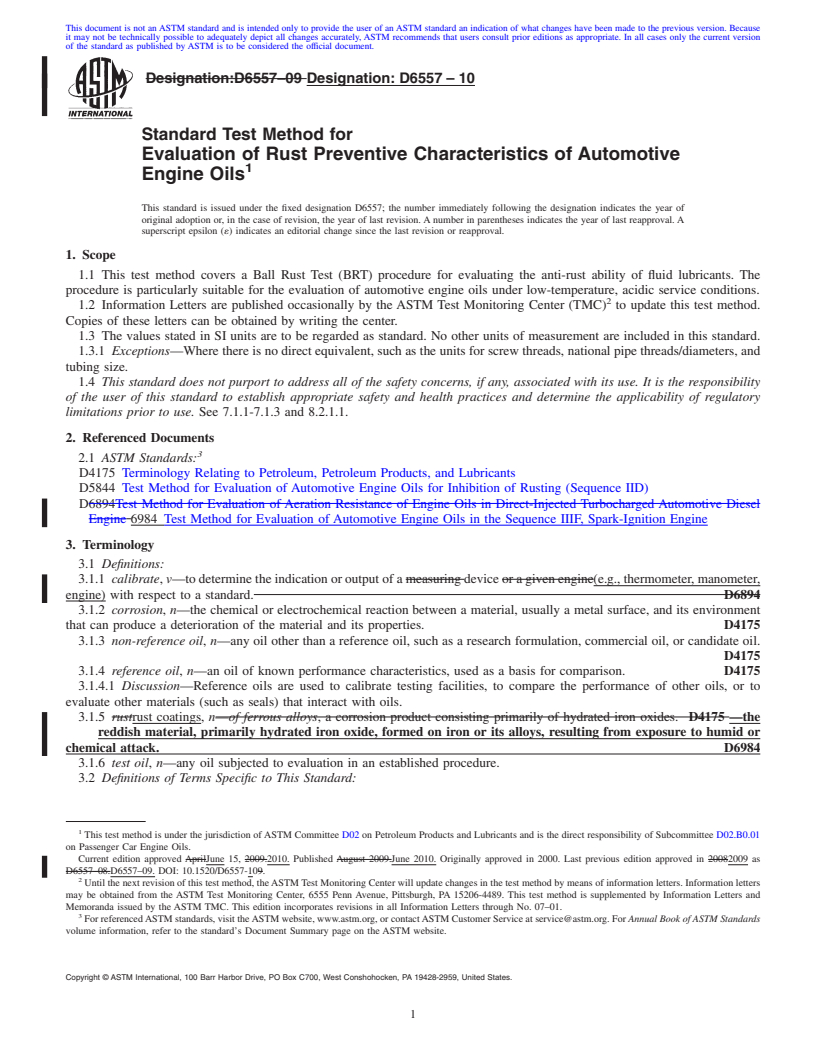

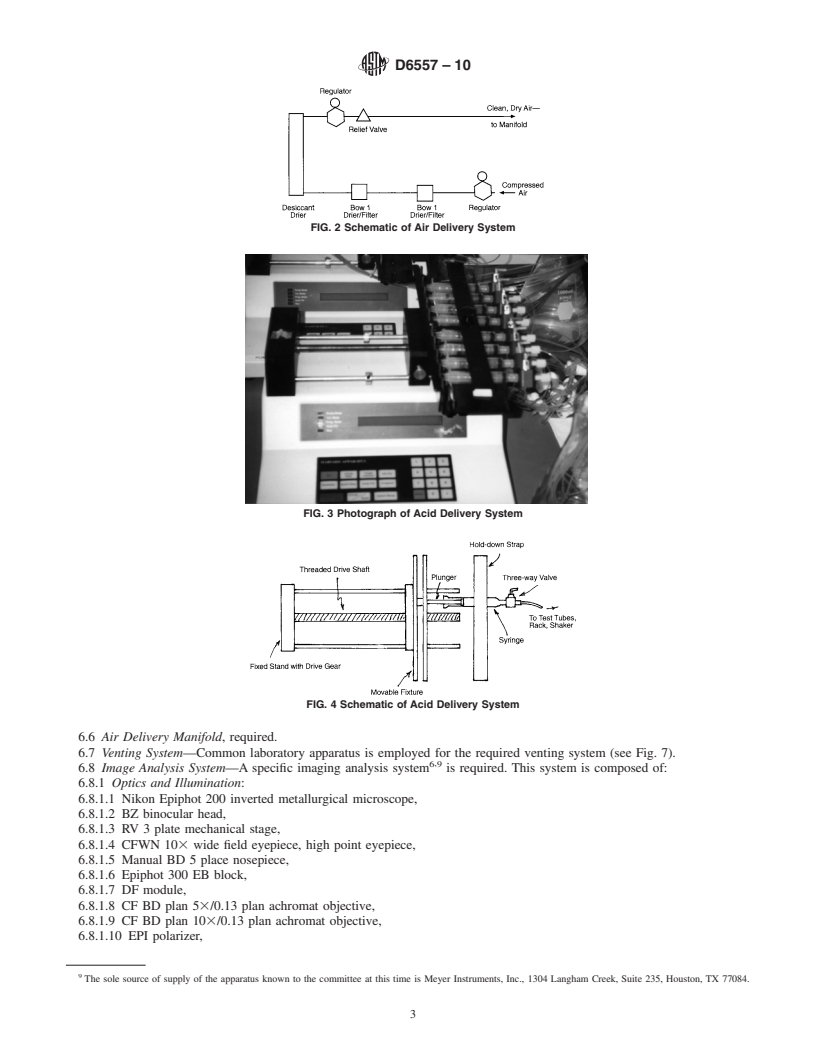

4. Summary of Test Method

4.1 Multiple test tubes, each containing test oil and a

specimen, are placed in a test tube rack, which is attached to a

mechanical shaker. The shaker speed and temperature are

controlled.

4.2 Airandanacidicsolutionarecontinuouslyfedintoeach

test tube over an 18 h period to create a corrosive environment.

4.3 The specimens are then removed, rinsed, and analyzed

by an optical imag

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6557–09 Designation:D6557–10

Standard Test Method for

Evaluation of Rust Preventive Characteristics of Automotive

1

Engine Oils

This standard is issued under the fixed designation D6557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a Ball Rust Test (BRT) procedure for evaluating the anti-rust ability of fluid lubricants. The

procedure is particularly suitable for the evaluation of automotive engine oils under low-temperature, acidic service conditions.

2

1.2 Information Letters are published occasionally by the ASTM Test Monitoring Center (TMC) to update this test method.

Copies of these letters can be obtained by writing the center.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exceptions—Where there is no direct equivalent, such as the units for screw threads, national pipe threads/diameters, and

tubing size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See 7.1.1-7.1.3 and 8.2.1.1.

2. Referenced Documents

3

2.1 ASTM Standards:

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D5844 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Rusting (Sequence IID)

D6894Test Method for Evaluation of Aeration Resistance of Engine Oils in Direct-Injected Turbocharged Automotive Diesel

Engine 6984 Test Method for Evaluation of Automotive Engine Oils in the Sequence IIIF, Spark-Ignition Engine

3. Terminology

3.1 Definitions:

3.1.1 calibrate, v—todeterminetheindicationoroutputofameasuringdeviceoragivenengine(e.g.,thermometer,manometer,

engine) with respect to a standard. D6894

3.1.2 corrosion, n—the chemical or electrochemical reaction between a material, usually a metal surface, and its environment

that can produce a deterioration of the material and its properties. D4175

3.1.3 non-reference oil, n—any oil other than a reference oil, such as a research formulation, commercial oil, or candidate oil.

D4175

3.1.4 reference oil, n—an oil of known performance characteristics, used as a basis for comparison. D4175

3.1.4.1 Discussion—Reference oils are used to calibrate testing facilities, to compare the performance of other oils, or to

evaluate other materials (such as seals) that interact with oils.

3.1.5 rustrust coatings, n—of ferrous alloys, a corrosion product consisting primarily of hydrated iron oxides. D4175 —the

reddish material, primarily hydrated iron oxide, formed on iron or its alloys, resulting from exposure to humid or

chemical attack. D6984

3.1.6 test oil, n—any oil subjected to evaluation in an established procedure.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.B0.01

on Passenger Car Engine Oils.

Current edition approved AprilJune 15, 2009.2010. Published August 2009.June 2010. Originally approved in 2000. Last previous edition approved in 20082009 as

D6557–08.D6557–09. DOI: 10.1520/D6557-109.

2

Until the next revision of this test method, theASTM Test Monitoring Center will update changes in the test method by means of information letters. Information letters

may be obtained from the ASTM Test Monitoring Center, 6555 Penn Avenue, Pittsburgh, PA 15206-4489. This test method is supplemented by Information Letters and

Memoranda issued by the ASTM TMC. This edition incorporates revisions in all Information Letters through No. 07–01.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6557–10

3.2.1 average gray value (AGV), n—measurement of brightness units on test specimens, indicating the degre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.