ASTM B1021-21

(Test Method)Standard Test Method for Peel Resistance of Metal Sheets Joined by High Strength Bonds

Standard Test Method for Peel Resistance of Metal Sheets Joined by High Strength Bonds

SIGNIFICANCE AND USE

5.1 Use this test method for acceptance and process control testing. This test method may be used as an alternative to Test Method D1876 when the bond strength is sufficiently high that failure of the pulling tabs may occur before peeling initiates. This test method extends the bond strength measurement range by limiting the bend radius of the sample to concentrate the peeling action at the bond line. The test fixture also uses a smaller specimen size than Test Method D1876.

SCOPE

1.1 This test method covers the determination of the relative peel resistance of cohesive or adhesive bonds between two adherends when tested under specified preparation and testing conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are English units provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B1021 − 21

Standard Test Method for

Peel Resistance of Metal Sheets Joined by High Strength

1

Bonds

This standard is issued under the fixed designation B1021; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of the terms used in this test method

not explicitly found here, see D907 – 15.

1.1 This test method covers the determination of the relative

3.1.2 adherend, n—a body bonded to another body.

peel resistance of cohesive or adhesive bonds between two

3.1.3 adhesive bond, n—a bond between two adherends

adherends when tested under specified preparation and testing

formed by an intermediate substance capable of holding

conditions.

materials together by surface attachment.

1.2 The values stated in SI units are to be regarded as the

3.1.4 cohesive bond, n—a bond between two adherends

standard. The values given in parentheses are English units

formed by solid state diffusion where the atoms of two solid,

provided for information purposes only.

metallic surfaces intersperse themselves.

1.3 This standard does not purport to address all of the

3.1.5 energy release rate, n—the force per unit width of

safety concerns, if any, associated with its use. It is the

bond line times the increment in crosshead displacement

responsibility of the user of this standard to establish appro-

divided by the increase in debond length of the two adherends.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1.6 hot isostatic pressing (HIP), n—a method of diffusion

1.4 This international standard was developed in accor-

bonding two sheets of metal such as aluminum or titanium.

dance with internationally recognized principles on standard-

3.1.7 peel strength, n—the average force per unit width of

ization established in the Decision on Principles for the

bond line required to progressively separate a flexible member

Development of International Standards, Guides and Recom-

from a rigid member or another flexible member.

mendations issued by the World Trade Organization Technical

3.2 Definitions of Terms Specific to This Standard:

Barriers to Trade (TBT) Committee.

3.2.1 ductile, adj—indicates that the adherends are ductile

or flexible enough to permit bending them through an angle up

2. Referenced Documents

to 120° without cracking or breaking. The subject peel test

2

2.1 ASTM Standards:

method uses sample lever-arms to provide backing support to

B209/B209M Specification for Aluminum and Aluminum-

limit the bend radius when peel testing high strength bonds

Alloy Sheet and Plate

between metal sheets.

D907 Terminology of Adhesives

3.2.2 parasitic tab bending force, n—the force required to

D1876 Test Method for Peel Resistance of Adhesives (T-

bend the peel specimen tabs of two unbonded adherends.

Peel Test)

3.2.2.1 Discussion—The parasitic force must be measured

E4 Practices for Force Calibration and Verification of Test-

so that it can be subtracted from the peel test force to measure

ing Machines

the net peel force of debonding.

3. Terminology

4. Summary of Test Method

3.1 Definitions:

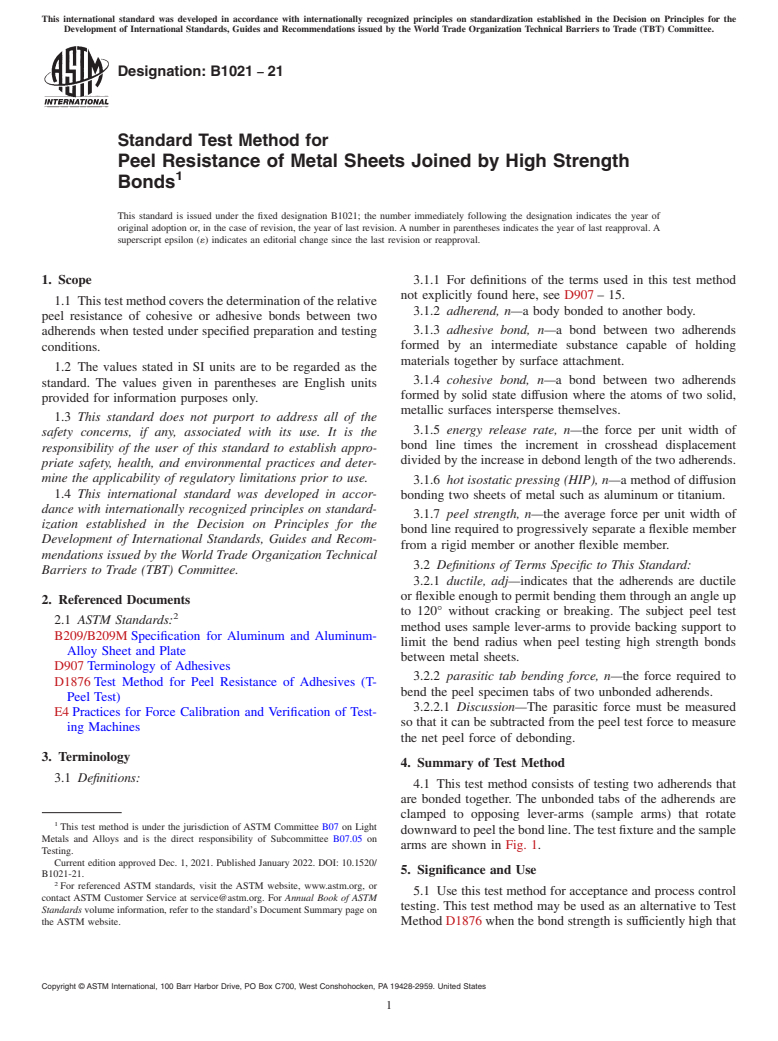

4.1 This test method consists of testing two adherends that

are bonded together. The unbonded tabs of the adherends are

clamped to opposing lever-arms (sample arms) that rotate

1

This test method is under the jurisdiction of ASTM Committee B07 on Light

downwardtopeelthebondline.Thetestfixtureandthesample

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

arms are shown in Fig. 1.

Testing.

Current edition approved Dec. 1, 2021. Published January 2022. DOI: 10.1520/

5. Significance and Use

B1021-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Use this test method for acceptance and process control

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

testing. This test method may be used as an alternative to Test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Method D1876 when the bond strength is sufficiently high that

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1021 − 21

FIG. 1 Lever-Arm Peel Test Fixture

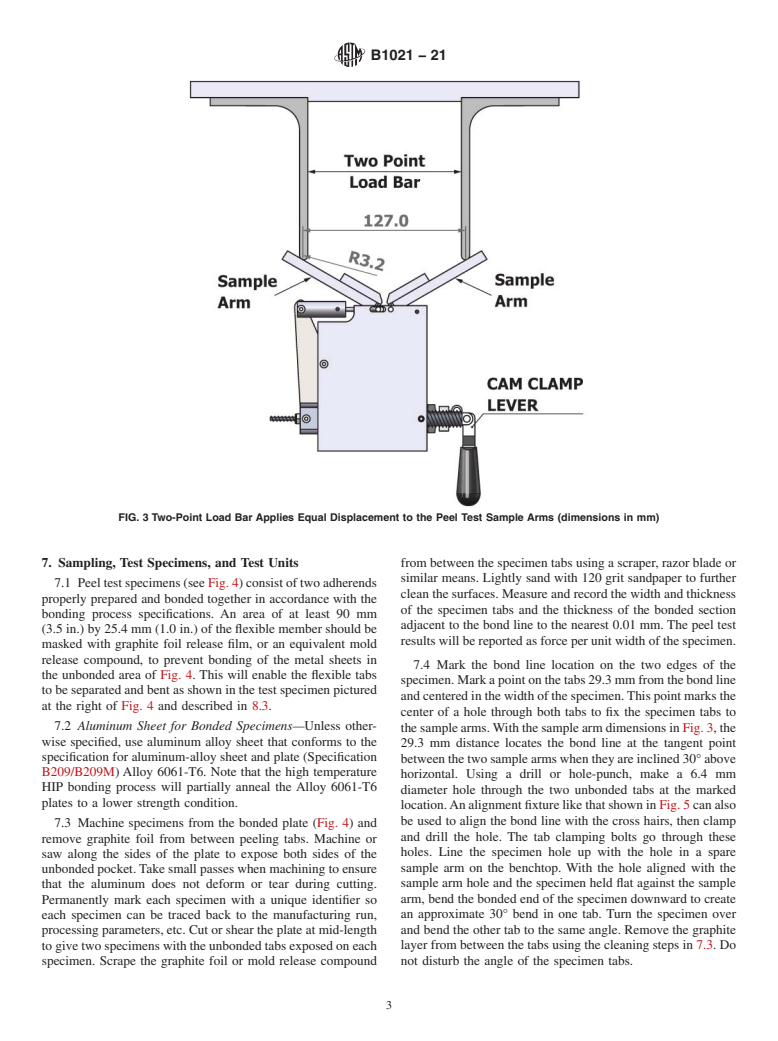

failure of the pulling tabs may occur before peeling initiates. 6.3 Peel Fixture—The peel fixture, shown schematically in

This

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.