ASTM F1035-03(2015)

(Practice)Standard Practice for Use of Rubber-Cord Pie Disk to Demonstrate the Discernment Capability of a Tire X-ray Imaging System

Standard Practice for Use of Rubber-Cord Pie Disk to Demonstrate the Discernment Capability of a Tire X-ray Imaging System

SIGNIFICANCE AND USE

5.1 All X-ray systems are subject to changing efficiencies, so a practice for checking the overall operation is needed. This practice will assure the operator of an optimized image when ambient conditions are controlled and the X-ray high voltage generator is adjusted as prescribed.

5.2 The densities of some tire cord materials are very close to that of the rubber matrix in which they are enclosed, so the resolving capability of an X-ray system is critical to the detection of abnormalities. The rubber-cord pie disk provides a means for optimizing the resolving power in a particular apparatus and for comparing its performance over any period of time.

5.3 The rubber-cord pie disk can be used to compare the performances of X-ray systems in different laboratories. It can also be used in special cases to optimize system performance for a particular sector or cord-type, as may be required for examining a specific tire.

SCOPE

1.1 This practice describes the construction and use of a rubber-cord pie-shaped standard disk for demonstrating the discernment capability of an X-ray imaging system.

1.2 This practice is applicable to direct viewing (fluoroscopic) X-ray imaging systems and film, plate or paper (radiographic) X-ray imaging systems that are used for checking the construction consistency of pneumatic tires.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address the safety concernss associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1035 − 03 (Reapproved 2015)

Standard Practice for

Use of Rubber-Cord Pie Disk to Demonstrate the

Discernment Capability of a Tire X-ray Imaging System

This standard is issued under the fixed designation F1035; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for demonstrating the discernment capability of an X-ray

imaging system. (F538)

1.1 This practice describes the construction and use of a

3.1.2 X-ray image plane, n— in tire testing, a surface

rubber-cord pie-shaped standard disk for demonstrating the

locatedataspecifieddistancefromtheX-raytube“focalspot.”

discernment capability of an X-ray imaging system.

3.1.2.1 Discussion—The centerline of the cone of radiation

1.2 This practice is applicable to direct viewing (fluoro-

from the X-ray tube is normal to the image plane. F538

scopic) X-ray imaging systems and film, plate or paper

3.1.3 X-ray imaging system, n— in tire testing, a collection

(radiographic) X-ray imaging systems that are used for check-

of the components and subsystems needed to produce a

ing the construction consistency of pneumatic tires.

fluoroscopic or radiographic image of the tire.

1.3 The values stated in SI units are to be regarded as the

3.1.3.1 Discussion—The collection includes the X-ray high

standard.

voltage generator, X-ray tube, and X-ray screen or radiograph.

1.4 This standard does not purport to address the safety

F538

concernss associated with its use. It is the responsibility of the

3.1.4 X-ray radiograph, n—an X-ray film, plate, or paper

user of this standard to establish appropriate safety and health

that is placed at the image plane and is used for recording an

practices and determine the applicability of regulatory limita-

X-ray image of the object being examined. F538

tions prior to use.

3.1.5 X-ray screen, n—a fluorescent screen, placed at the

image plane, that produces an X-ray image of the object being

2. Referenced Documents

examined.

2.1 ASTM Standards:

3.1.5.1 Discussion—This visible light may be photographed

D1349 Practice for Rubber—Standard Conditions for Test-

or input to a television system. F538

ing

D3186 Test Methods for Rubber—Evaluation of SBR

4. Summary of Practice

(Styrene-Butadiene Rubber) Mixed With Carbon Black or

4.1 The pie disk is a rubber-cord composite that is used as

Carbon Black and Oil

the subject in an X-ray imaging system. Each of the six

F538 Terminology Relating to the Characteristics and Per-

sections of the disk has a different cord material which,

formance of Tires

together, represent the cords commonly used in vehicle tires.

The X-ray absorption of these cords range from very nearly the

3. Terminology

same as that of the rubber matrix to quite different from it.

3.1 Definitions:

4.2 The rubber-cord pie disk shall be placed between the

3.1.1 pie disk, rubber-cord, n— in tire X-ray testing,a

X-ray tube and the X-ray image plane at a specified distance

circular disk of a specified diameter having six pie-shaped

from the image plane (see Fig. 1). The ambient conditions are

sections, each containing cord of different materials; it is used

controlled or monitored, and recorded.

4.3 The image of the disk on a fluorescent screen or

This practice is under the jurisdiction ofASTM Committee F09 on Tires and is photograph can be studied for clarity of detail for each cord

the direct responsibility of Subcommittee F09.10 on Equipment, Facilities and

material. The voltage and current of the X-ray high voltage

Calibration.

generator shall be adjusted for optimum detail and contrast

Current edition approved June 1, 2015. Published September 2015. Originally

sensitivity to view all cord materials simultaneously.

approved in 1986. Last previous edition approved in 2008 as F1035 – 03 (2008).

DOI: 10.1520/F1035-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 All X-ray systems are subject to changing efficiencies,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. so a practice for checking the overall operation is needed. This

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1035 − 03 (2015)

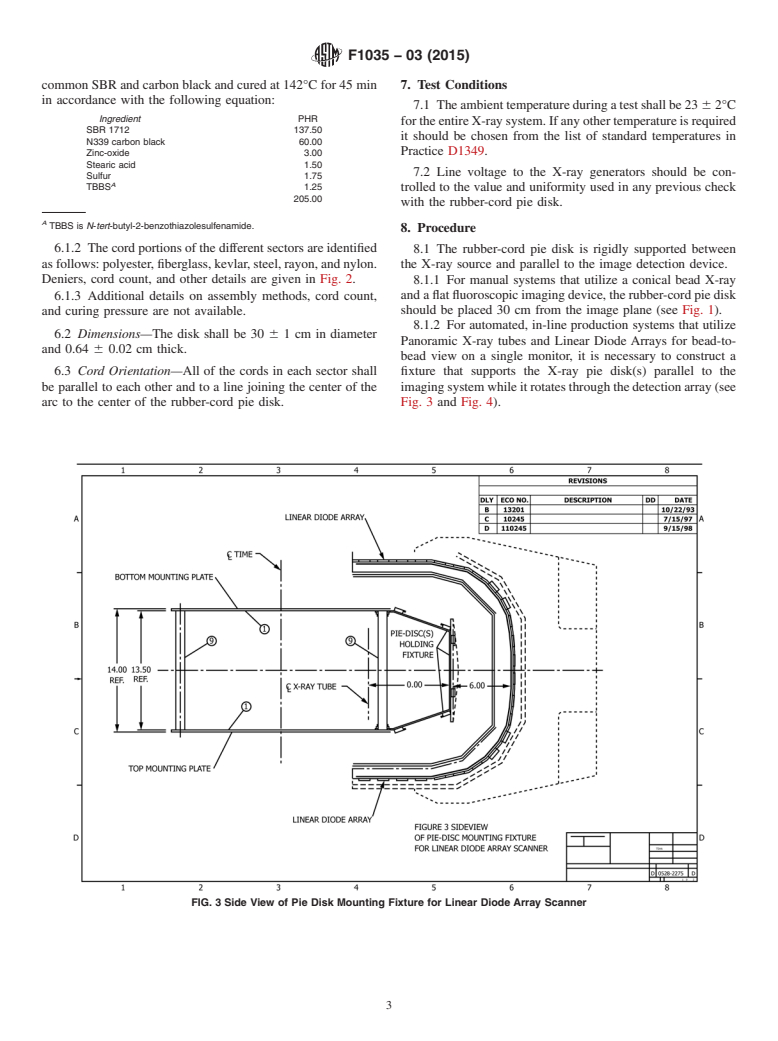

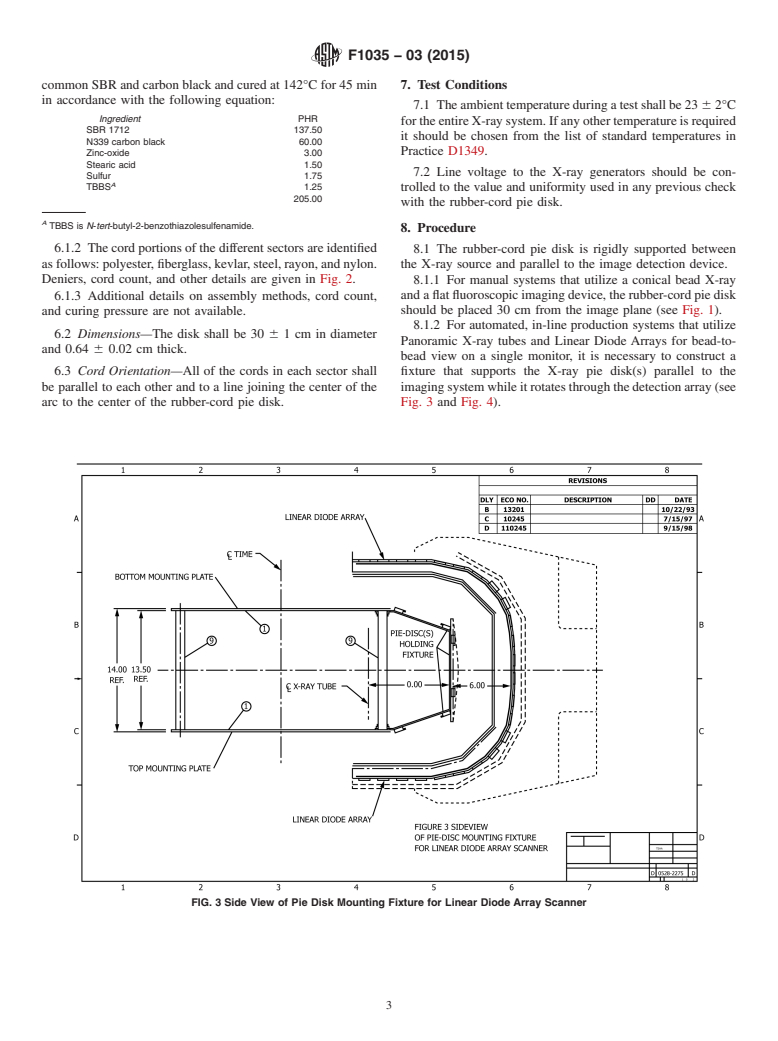

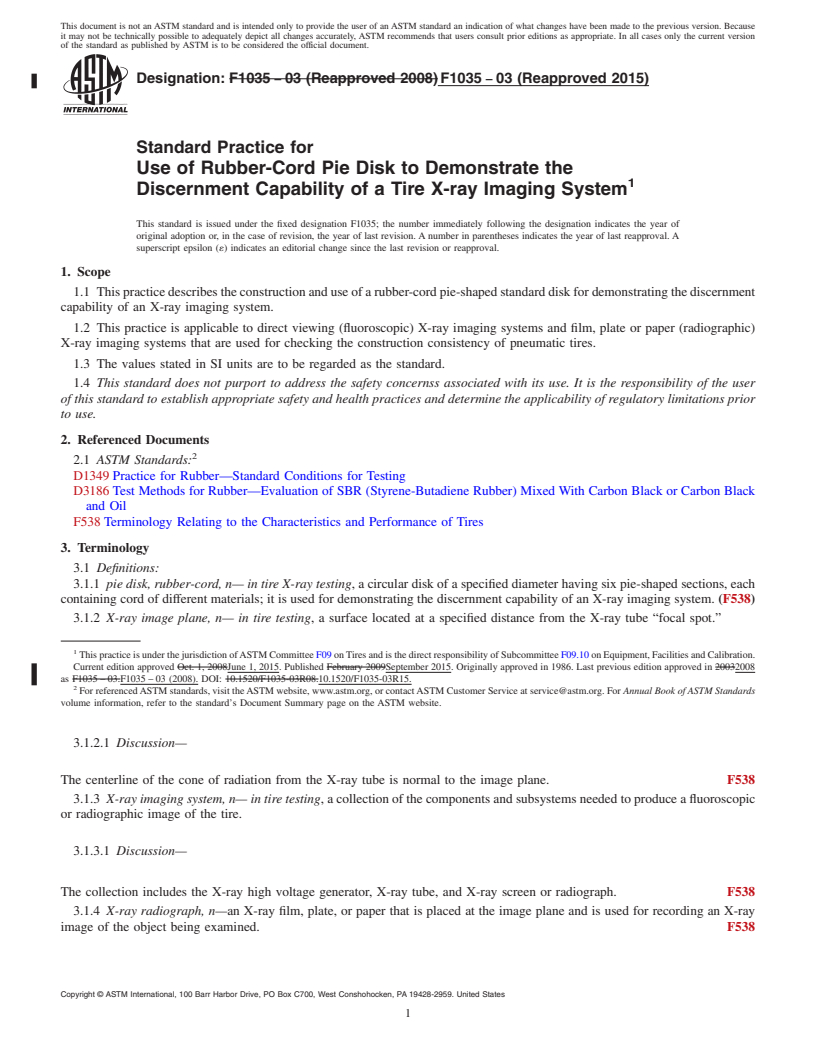

FIG. 1 Pie-Cord Disk Test Fixture Positioning for Tire X-Ray System

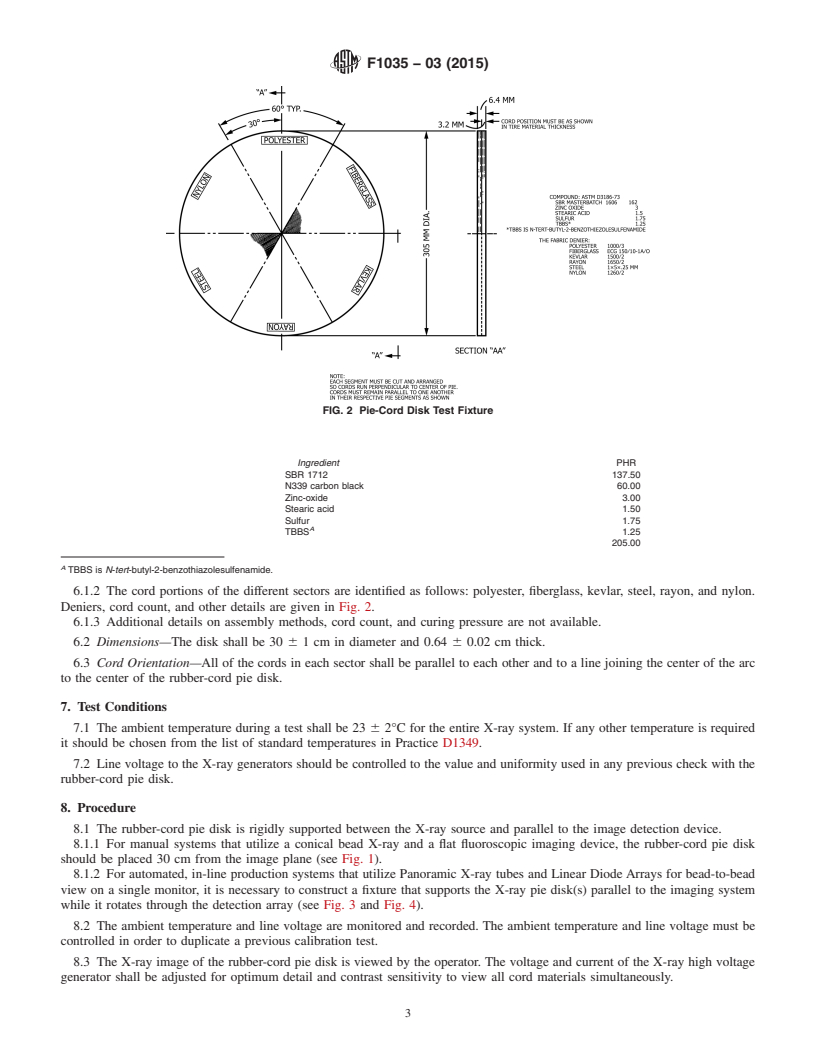

FIG. 2 Pie-Cord Disk Test Fixture

practice will assure the operator of an optimized image when for a particular sector or cord-type, as may be required for

ambient conditions are controlled and the X-ray high voltage examining a specific tire.

generator is adjusted as prescribed.

6. Preparation of Rubber-Cord Pie Disk

5.2 The densities of some tire cord materials are very close

6.1 Composition:

to

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1035 − 03 (Reapproved 2015)

Standard Practice for

Use of Rubber-Cord Pie Disk to Demonstrate the

Discernment Capability of a Tire X-ray Imaging System

This standard is issued under the fixed designation F1035; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for demonstrating the discernment capability of an X-ray

imaging system. (F538)

1.1 This practice describes the construction and use of a

3.1.2 X-ray image plane, n— in tire testing, a surface

rubber-cord pie-shaped standard disk for demonstrating the

located at a specified distance from the X-ray tube “focal spot.”

discernment capability of an X-ray imaging system.

3.1.2.1 Discussion—The centerline of the cone of radiation

1.2 This practice is applicable to direct viewing (fluoro-

from the X-ray tube is normal to the image plane. F538

scopic) X-ray imaging systems and film, plate or paper

3.1.3 X-ray imaging system, n— in tire testing, a collection

(radiographic) X-ray imaging systems that are used for check-

of the components and subsystems needed to produce a

ing the construction consistency of pneumatic tires.

fluoroscopic or radiographic image of the tire.

1.3 The values stated in SI units are to be regarded as the

3.1.3.1 Discussion—The collection includes the X-ray high

standard.

voltage generator, X-ray tube, and X-ray screen or radiograph.

1.4 This standard does not purport to address the safety

F538

concernss associated with its use. It is the responsibility of the

3.1.4 X-ray radiograph, n—an X-ray film, plate, or paper

user of this standard to establish appropriate safety and health

that is placed at the image plane and is used for recording an

practices and determine the applicability of regulatory limita-

X-ray image of the object being examined. F538

tions prior to use.

3.1.5 X-ray screen, n—a fluorescent screen, placed at the

image plane, that produces an X-ray image of the object being

2. Referenced Documents

examined.

2.1 ASTM Standards:

3.1.5.1 Discussion—This visible light may be photographed

D1349 Practice for Rubber—Standard Conditions for Test-

or input to a television system. F538

ing

D3186 Test Methods for Rubber—Evaluation of SBR

4. Summary of Practice

(Styrene-Butadiene Rubber) Mixed With Carbon Black or

4.1 The pie disk is a rubber-cord composite that is used as

Carbon Black and Oil

the subject in an X-ray imaging system. Each of the six

F538 Terminology Relating to the Characteristics and Per-

sections of the disk has a different cord material which,

formance of Tires

together, represent the cords commonly used in vehicle tires.

The X-ray absorption of these cords range from very nearly the

3. Terminology

same as that of the rubber matrix to quite different from it.

3.1 Definitions:

4.2 The rubber-cord pie disk shall be placed between the

3.1.1 pie disk, rubber-cord, n— in tire X-ray testing, a

X-ray tube and the X-ray image plane at a specified distance

circular disk of a specified diameter having six pie-shaped

from the image plane (see Fig. 1). The ambient conditions are

sections, each containing cord of different materials; it is used

controlled or monitored, and recorded.

4.3 The image of the disk on a fluorescent screen or

photograph can be studied for clarity of detail for each cord

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is

the direct responsibility of Subcommittee F09.10 on Equipment, Facilities and

material. The voltage and current of the X-ray high voltage

Calibration.

generator shall be adjusted for optimum detail and contrast

Current edition approved June 1, 2015. Published September 2015. Originally

sensitivity to view all cord materials simultaneously.

approved in 1986. Last previous edition approved in 2008 as F1035 – 03 (2008).

DOI: 10.1520/F1035-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 All X-ray systems are subject to changing efficiencies,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. so a practice for checking the overall operation is needed. This

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1035 − 03 (2015)

FIG. 1 Pie-Cord Disk Test Fixture Positioning for Tire X-Ray System

FIG. 2 Pie-Cord Disk Test Fixture

practice will assure the operator of an optimized image when for a particular sector or cord-type, as may be required for

ambient conditions are controlled and the X-ray high voltage examining a specific tire.

generator is adjusted as prescribed.

6. Preparation of Rubber-Cord Pie Disk

5.2 The densities of some tire cord materials are very close

6.1 Composition:

to that of the rubber matrix in which they are enclosed, so the

6.1.1 The disk shall have six equal-s

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1035 − 03 (Reapproved 2008) F1035 − 03 (Reapproved 2015)

Standard Practice for

Use of Rubber-Cord Pie Disk to Demonstrate the

Discernment Capability of a Tire X-ray Imaging System

This standard is issued under the fixed designation F1035; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the construction and use of a rubber-cord pie-shaped standard disk for demonstrating the discernment

capability of an X-ray imaging system.

1.2 This practice is applicable to direct viewing (fluoroscopic) X-ray imaging systems and film, plate or paper (radiographic)

X-ray imaging systems that are used for checking the construction consistency of pneumatic tires.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address the safety concernss associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

D1349 Practice for Rubber—Standard Conditions for Testing

D3186 Test Methods for Rubber—Evaluation of SBR (Styrene-Butadiene Rubber) Mixed With Carbon Black or Carbon Black

and Oil

F538 Terminology Relating to the Characteristics and Performance of Tires

3. Terminology

3.1 Definitions:

3.1.1 pie disk, rubber-cord, n— in tire X-ray testing, a circular disk of a specified diameter having six pie-shaped sections, each

containing cord of different materials; it is used for demonstrating the discernment capability of an X-ray imaging system. (F538)

3.1.2 X-ray image plane, n— in tire testing, a surface located at a specified distance from the X-ray tube “focal spot.”

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.10 on Equipment, Facilities and Calibration.

Current edition approved Oct. 1, 2008June 1, 2015. Published February 2009September 2015. Originally approved in 1986. Last previous edition approved in 20032008

as F1035 – 03.F1035 – 03 (2008). DOI: 10.1520/F1035-03R08.10.1520/F1035-03R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.2.1 Discussion—

The centerline of the cone of radiation from the X-ray tube is normal to the image plane. F538

3.1.3 X-ray imaging system, n— in tire testing, a collection of the components and subsystems needed to produce a fluoroscopic

or radiographic image of the tire.

3.1.3.1 Discussion—

The collection includes the X-ray high voltage generator, X-ray tube, and X-ray screen or radiograph. F538

3.1.4 X-ray radiograph, n—an X-ray film, plate, or paper that is placed at the image plane and is used for recording an X-ray

image of the object being examined. F538

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1035 − 03 (2015)

3.1.5 X-ray screen, n—a fluorescent screen, placed at the image plane, that produces an X-ray image of the object being

examined.

3.1.5.1 Discussion—

This visible light may be photographed or input to a television system. F538

4. Summary of Practice

4.1 The pie disk is a rubber-cord composite that is used as the subject in an X-ray imaging system. Each of the six sections of

the disk has a different cord material which, together, represent the cords commonly used in vehicle tires. The X-ray absorption

of these cords range from very nearly the same as that of the rubber matrix to quite different from it.

4.2 The rubber-cord pie disk shall be placed between the X-ray tube and the X-ray image plane at a specified distance from the

image plane (see Fig. 1). The ambient conditions are controlled or monitored, and recorded.

4.3 The image of the disk on a fluorescent screen or photograph can be studied for clarity of detail for each cord material. The

voltage and current of the X-ray high voltage generator shall be adjusted for optimum detail and contrast sensitivity to view all

cord materials simultaneously.

5. Significance and Use

5.1 All X-ray systems are subject to changing efficiencies, so a practice for checking the overall operation is needed. This

practice will assure the operator of an optimized image when ambient conditions are controlled and the X-ray high voltage

generator is adjusted as prescribed.

5.2 The densities of some tire cord materials are very close to that of the rubber matrix in which they are enclosed, so the

resolving capability of an X-ray system is critical to the detection of abnormalities. The rubber-cord pie disk provides a means for

optimizing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.