ASTM D6721-01(2006)

(Test Method)Standard Test Method for Determination of Chlorine in Coal by Oxidative Hydrolysis Microcoulometry

Standard Test Method for Determination of Chlorine in Coal by Oxidative Hydrolysis Microcoulometry

SIGNIFICANCE AND USE

This test method permits measurements of the chlorine content of coals.

SCOPE

1.1 This test method covers the determination of total chlorine in coal.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6721 − 01(Reapproved 2006)

Standard Test Method for

Determination of Chlorine in Coal by Oxidative Hydrolysis

Microcoulometry

This standard is issued under the fixed designation D6721; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Chlorineisconvertedtohydrochloricacid.Oncethechlorideis

captured in the electrolyte of the titration cell, it can be

1.1 This test method covers the determination of total

quantitatively determined by microcoulometery, where chlo-

chlorine in coal.

ride ions react with silver ions present in the electrolyte. The

silver ion thus consumed is coulometrically replaced and the

2. Referenced Documents

total electrical work needed to replace it is proportional to the

2.1 ASTM Standards:

chloride in the test sample.

D2013 Practice for Preparing Coal Samples for Analysis

D3173 Test Method for Moisture in the Analysis Sample of

4. Significance and Use

Coal and Coke

4.1 This test method permits measurements of the chlorine

D3180 Practice for Calculating Coal and Coke Analyses

content of coals.

from As-Determined to Different Bases

D4621 Guide for Quality Management in an Organization

5. Interferences

That Samples or Tests Coal and Coke (Withdrawn 2010)

5.1 Bromides and iodides, if present are calculated as

D5142 Test Methods for ProximateAnalysis of theAnalysis

chloride. However, fluorides are not detected by this test

Sample of Coal and Coke by Instrumental Procedures

method.

(Withdrawn 2010)

E29 Practice for Using Significant Digits in Test Data to

6. Apparatus

Determine Conformance with Specifications

E691 Practice for Conducting an Interlaboratory Study to 6.1 Hydrolysis Furnace, which can maintain a minimum

Determine the Precision of a Test Method temperature of 900°C.

2.2 Other Standards

6.2 Hydrolysis Tube, made of quartz and constructed such

ISO 5725-6:1994 Accuracy of measurement methods and

that when the sample is combusted in the presence of tungsten

results-Part 6: Use in practice of accuracy values

accelerator and humidified oxygen, the byproducts of combus-

tion are swept into a humidified hydrolysis zone. The inlet end

3. Summary of Test Method

shall allow for the introduction and advancement of the sample

3.1 A 5.00 to 40.00 mg sample of coal is combusted with boatintotheheatedzone.Theinletshallhaveasidearmforthe

tungstenacceleratorinahumidifiedoxygengasflow,at900°C. introduction of the humidified oxygen gas.The hydrolysis tube

Halogens are oxidized and converted to hydrogenated halides, must be of ample volume, and have a heated zone with quartz

wool so that complete hydrolysis of the halogens is ensured.

which are flushed into a titration cell where they accumulate.

6.3 Titration Cell, containing a reference electrode, a work-

ing electrode, and a silver sensor electrode, a magnetic stirrer

This test method is under the jurisdiction of ASTM Committee D05 on Coal

as well as an inlet from the hydrolysis tube.

and Coke and is the direct responsibility of Subcommittee D05.29 on Major

Elements in Ash and Trace Elements of Coal.

6.4 Microcoulometer, capable of measuring the potential of

Current edition approved April 1, 2006. Published April 2006. Originally

the sensing-reference electrode pair, comparing this potential

approved in 2001. Last previous edition approved in 2001 as D6721 – 01. DOI:

with a bias potential, and amplifying the difference to the

10.1520/D6721-01R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

working electrode pair to generate current. The microcoulom-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

eter output voltage should be proportional to the generating

Standards volume information, refer to the standard’s Document Summary page on

current.

the ASTM website.

The last approved version of this historical standard is referenced on

6.5 Controller, with connections for the reference, working,

www.astm.org.

and sensor electrodes, for setting operating parameters and for

Available from International Organization for Standardization 1 Rue de

Varembé, Case Postale 56, CH-1211, Geneva 20, Switzerland data integration.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

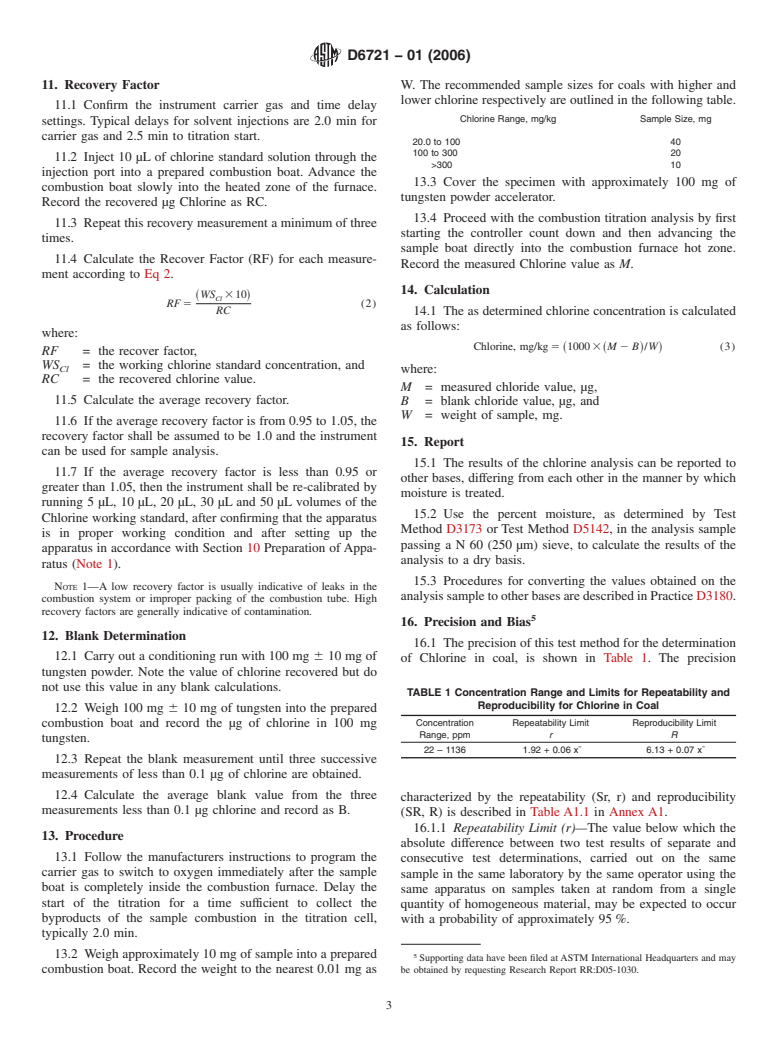

D6721 − 01 (2006)

6.6 Hydration Tube, containing water, positioned before the 7.18 Methanol (MeOH) (CH OH), 99.9 % minimum purity.

gasinletonthesidearmofthecombustiontube,throughwhich

7.19 Working Chlorine Standard (1µg/µL)—Weigh accu-

oxygen gas bubbles to provide a hydrated gas flow.

rately 0.1856 g of 2,4,6-Trichlorophenol to the nearest 0.1 mg.

6.7 Dehydration Tube, positioned at the end of the hydro- Transfer to a 100 mLvolumetric flask. Dilute to the mark with

lysis tube so that effluent gases are bubbled through a 95 %

methanol.

sulfuric acid solution. Water vapor is subsequently trapped

WS 5 ~gofTCP 30.5386 31000/100! (1)

CI

while other gases flow into the titration cell.

where:

6.8 Gas-Tight Sampling Syringe, having a 50 µL capacity,

TCP = 2,4,6-Trichlorophenol, and

capable of accurately delivering 10 to 40 µL of standard

WS = the working chlorine standard concentration.

CI

solution.

6.9 Sample Boats, made of quartz, ceramic or platinum.

8. Hazards

6.10 Balance, analytical, with a sensitivity to 0.00001 g.

8.1 Consult the current version of OSHA regulations, sup-

plier’s Material Safety Data Sheets, and local regulations for

7. Reagents and Materials

all materials used in this test method.

7.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

9. Sampling

allreagentsshallconformtothespecificationoftheCommittee

9.1 Prepare the analysis sample in accordance with Method

on Analytical Reagents of the American Chemical Society,

D2013 to pass a 250-µm (60 mesh) sieve.

where such specifications are available. Other grades may be

9.2 Analyze a separate portion of the analysis sample for

used, provided that the reagent is of sufficiently high purity to

moisture content in accordance with Test Method D3173 or

permit its use without lessening the accuracy of the determi-

Test Methods D5142.

nation.

7.2 Purity of Water—Unless otherwise indicated, references

10. Preparation of Apparatus

towatershallbeunderstoodtomeanreagentwaterconforming

10.1 Fill the hydration tower with water and connect it to

to Specification D1193, Type II or Type III.

the quartz furnace tube inlet.

7.3 Acetic Acid (sp gr. 1.05), glacial acetic acid

10.2 Set the furnace temperature to 900°C.

(CH COOH).

10.3 Adjust the gas flows according to manufacturers

7.4 Argon or Helium, carrier gas, minimum 99.9 % purity.

specification, typically 200 mL/min for oxygen and 100

7.5 SodiumAcetate, anhydrous, (NaCH CO ), fine granular.

3 2

mL/min for the carrier gas.

7.6 Cell Electrolyte Solution—Dissolve 1.35 g sodium ac-

10.4 Prepare the sulfuric acid dehydration scrubber, and

etate (NaCH CO ) in 100 mL water. Add to 850 mL of acetic

3 2

connect it to the outlet of the quartz furnace combustion tube.

acid (CH COOH) and dilute to 1000 mL with water.

10.5 Clean and prepare the electrode system for the titration

7.7 Tungsten Powder, combustion accelerator, (-100 mesh)

cell per instrument specifications.

minimum 99.9 % purity.

10.6 Fill the titration cell with fresh electrolyte solution to

7.8 Oxygen, combustion gas minimum 99.6 % purity.

just above the top fill mark.

7.9 Gas Regulators—Use two-stage gas regulators for the

10.7 Place the titration cell on the magnetic stirring device

carrier and combustion gases.

and connect the electrode system to the controller. Do not

7.10 Potassium Nitrate (KNO ), fine granular.

connect the gas flow from the dehydration scrubber to the

titration cell.

7.11 Potassium Chloride (KCl), fine granular.

10.8 Initiate a conditioning run of the titration cell to

7.12 Working Electrode Solution (10% KNO ), Dissolve

establish titration gain and endpoint values.

50 g potassium nitrate (KNO ) in 500 mL of water.

10.9 Once the titration cell is properly conditioned, connect

7.13 Inner Chamber Reference Electrode Solution (1 M

the gas flow from the dehydration scrubber to the titration cell.

KCl)—Dissolve 7.46 g potassium chloride (KCl) in 100 mL of

water.

10.10 Let the titration cell stabilize to a background poten-

tial of less then 1.0 mv.

7.14 Outer Chamber Reference Electrode Solution (1 M

KNO )—Dissolve 10.1 g potassium nitrate (KNO ) in 100 mL

10.11 To ensure quality data, care must be taken to avoid

3 3

of water.

contaminating the sample boats during the course of the

analytical procedure. Do not touch the boats with fingers.

7.15 Sodium Chloride (NaCl), fine granular.

Handle and transfer the boats using tongs and store said boats

7.16 Sulfuric Acid (sp gr. 1.84), (H SO ), concentrated.

2 4

in a sealed container such as a glass desiccator, containing no

7.17 2,4,6-Trichlorophenol (TCP) (C H OCl ), fine granu- desiccant. Prepare the combustion boats by he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.