ASTM B705-24

(Specification)Standard Specification for Nickel-Chromium-Molybdenum-Niobium Alloy, Nickel-Chromium-Molybdenum-Silicon Alloy, and Nickel-Iron-Chromium-Molybdenum-Copper Alloy Welded Pipe

Standard Specification for Nickel-Chromium-Molybdenum-Niobium Alloy, Nickel-Chromium-Molybdenum-Silicon Alloy, and Nickel-Iron-Chromium-Molybdenum-Copper Alloy Welded Pipe

ABSTRACT

This specification covers UNS N06625, N06219, and N08825 nickel-alloy welded pipe in the annealed condition. The pipe shall be manufactured from flat-rolled alloy by an automatic welding process with no additional filler metal. The pipe material shall be cold-worked, annealed, and nondestructively tested. The pipe shall be furnished with oxide removed. The material shall conform to the composition required by the specification. The pipe shall be subjected to tensile, yield, elongation, transverse guided bend, and nondestructive test requirements. Nondestructive test includes hydrostatic, pneumatic, eddy current, ultrasonic, leak, and electric testing. Acceptable size limit of cracks or other defect after bending test is specified.

SCOPE

1.1 This specification covers welded UNS N06625,2 UNS N062192 and UNS N088252 pipe in the annealed condition (temper) for general corrosion applications.

1.2 This specification covers pipe sizes in schedules shown in the Permissible Variations in Outside Diameter and Wall Thickness for Welded Pipe table of Specification B775.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B705 − 24

Standard Specification for

Nickel-Chromium-Molybdenum-Niobium Alloy, Nickel-

Chromium-Molybdenum-Silicon Alloy, and Nickel-Iron-

1

Chromium-Molybdenum-Copper Alloy Welded Pipe

This standard is issued under the fixed designation B705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B880 Specification for General Requirements for Chemical

2 Check Analysis Limits for Nickel, Nickel Alloys and

1.1 This specification covers welded UNS N06625, UNS

2 2 Cobalt Alloys

N06219 and UNS N08825 pipe in the annealed condition

B899 Terminology Relating to Non-ferrous Metals and Al-

(temper) for general corrosion applications.

loys

1.2 This specification covers pipe sizes in schedules shown 4

2.2 ASME Boiler and Pressure Vessel Code:

in the Permissible Variations in Outside Diameter and Wall

Section IX Welding and Brazing Qualifications

Thickness for Welded Pipe table of Specification B775.

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3.1 Definitions:

conversions to SI units that are provided for information only

3.1.1 For definitions of terms used in this standard, refer to

and are not considered standard.

Terminology B899.

3.2 Definitions of Terms Specific to This Standard:

1.4 The following precautionary caveat pertains only to the

3.2.1 Class 1—Welded, cold-worked, annealed, and nonde-

test methods portion, Section 8, of this specification: This

structively tested in accordance with 9.1.

standard does not purport to address all of the safety concerns,

3.2.2 Class 2—Welded, cold-worked, annealed, and nonde-

if any, associated with its use. It is the responsibility of the user

structively tested in accordance with 9.2.

of this standard to establish appropriate safety, health, and

3.2.3 Grade 1—Annealed condition, relevant for UNS

environmental practices and determine the applicability of

N06625.

regulatory limitations prior to use.

3.2.4 Grade 2—Solution annealed condition, relevant for

1.5 This international standard was developed in accor-

UNS N06625.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. General Requirement

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 4.1 Material furnished in accordance with this specification

Barriers to Trade (TBT) Committee. shall conform to the applicable requirements of the current

edition of Specification B775 unless otherwise provided

2. Referenced Documents

herein.

3

2.1 ASTM Standards:

5. Ordering Information

B775 Specification for General Requirements for Nickel and

Nickel Alloy Welded Pipe 5.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for the safe and satisfactory

performance of material ordered under this specification.

1

This specification is under the jurisdiction of ASTM Committee B02 on

Examples of such requirements include, but are not limited to,

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

the following:

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved April 1, 2024. Published April 2024. Originally

5.1.1 Alloy name or UNS number,

approved in 1982. Last previous edition approved in 2017 as B705 – 17. DOI:

5.1.2 ASTM designation,

10.1520/B0705-24.

2 5.1.3 Dimensions:

New designation established in accordance with Practice E527 and SAE

J 1086, Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B705 − 24

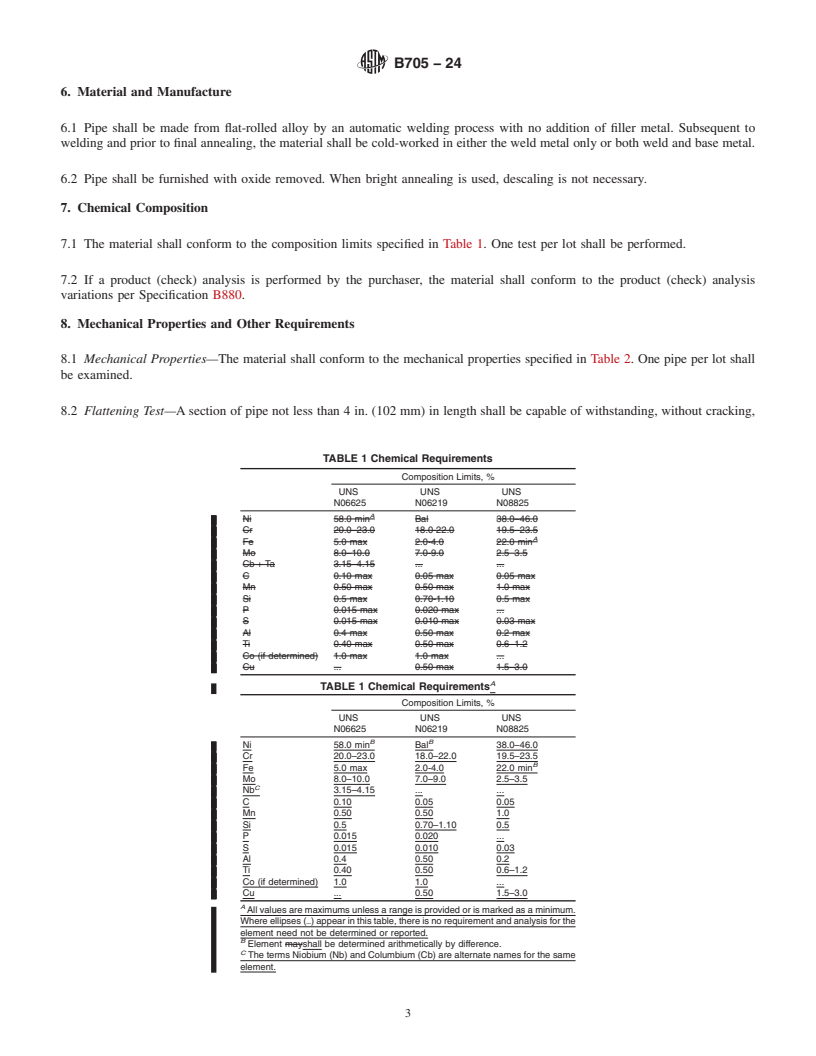

TABLE 2 Mechanical Property Requirements

5.1.3.1 Pipe size,

5.1.3.2 Length (specific or random), Yield Elonga-

Tensile Strength tion in 2

5.1.4 Class (see Section 4),

Alloy Grade Strength 0.2 % Offset, in. or 50

5.1.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B705 − 17 B705 − 24

Standard Specification for

Nickel-Alloy (UNS N06625, N06219 and N08825)Nickel-

Chromium-Molybdenum-Niobium Alloy, Nickel-Chromium-

Molybdenum-Silicon Alloy, and Nickel-Iron-Chromium-

1

Molybdenum-Copper Alloy Welded Pipe

This standard is issued under the fixed designation B705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2 2 2

1.1 This specification covers welded UNS N06625, UNS N06219 and UNS N08825 pipe in the annealed condition (temper)

for general corrosion applications.

1.2 This specification covers pipe sizes in schedules shown in the Permissible Variations in Outside Diameter and Wall Thickness

for Welded Pipe table of Specification B775.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B775 Specification for General Requirements for Nickel and Nickel Alloy Welded Pipe

B880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

B899 Terminology Relating to Non-ferrous Metals and Alloys

4

2.2 ASME Boiler and Pressure Vessel Code:

Section IX Welding and Brazing Qualifications

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Nov. 1, 2017April 1, 2024. Published November 2017April 2024. Originally approved in 1982. Last previous edition approved in 20142017 as

B705B705 – 17. – 05 (2014). DOI: 10.1520/B0705-17. DOI: 10.1520/B0705-24.

2

New designation established in accordance with Practice E527 and SAE J 1086, Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B705 − 24

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this standard, refer to Terminology B899.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Class 1—Welded, cold-worked, annealed, and nondestructively tested in accordance with 9.1.

3.2.2 Class 2—Welded, cold-worked, annealed, and nondestructively tested in accordance with 9.2.

3.2.3 Grade 1—Annealed condition, relevant for UNS N06625.

3.2.4 Grade 2—Solution annealed condition, relevant for UNS N06625.

4. General Requirement

4.1 Material furnished in accordance with this specification shall conform to the applicable requirements of the current edition of

Specification B775 unless otherwise provided herein.

4. Definition of Terms

4.1 Class 1—Welded, cold-worked, annealed, and nondestructively tested in accordance with 9.1.

4.2 Class 2—Welded, cold-worked, annealed, and nondestructively tested in accordance with 9.2.

4.3 Grade 1—Annealed condition, relevant for UNS N06625.

4.4 Grade 2—Solution annealed condition, relevant for UNS N06625.

5. O

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.