ASTM F88/F88M-23

(Test Method)Standard Test Method for Seal Strength of Flexible Barrier Materials

Standard Test Method for Seal Strength of Flexible Barrier Materials

SIGNIFICANCE AND USE

4.1 Seal strength is a quantitative measure for use in process validation, capability, and control. Seal strength is not only relevant to opening force and package integrity, but to measuring the packaging processes’ ability to produce consistent seals. Seal strength at some minimum level is a necessary package requirement, and at times it is also desirable to have an upper limit to the strength of the seal to facilitate opening.

Note 1: Seal strength values are a measurement of the output of the seal separation and may also involve mechanical properties of the materials that form the seal, given the potential for deformation or elongation over the course of the test. This separation is indicative of the area of the package being sampled and does not take into account simulation of a user interfacing with an entire package during the opening process.

Note 2: Lower seal strength specifications are typically utilized to provide assurance of package closure, which can contribute to seal integrity.

Note 3: Upper seal strength specifications are typically utilized to limit the amount of force required to open a package, ensuring that a user is able to open the design. Upper seal strength specifications are typically limited to seals that are intended to be peeled by the end user.

4.1.1 The maximum seal force is important information, but for some applications, average force to separate the seal may be useful, and in those cases also should be reported.

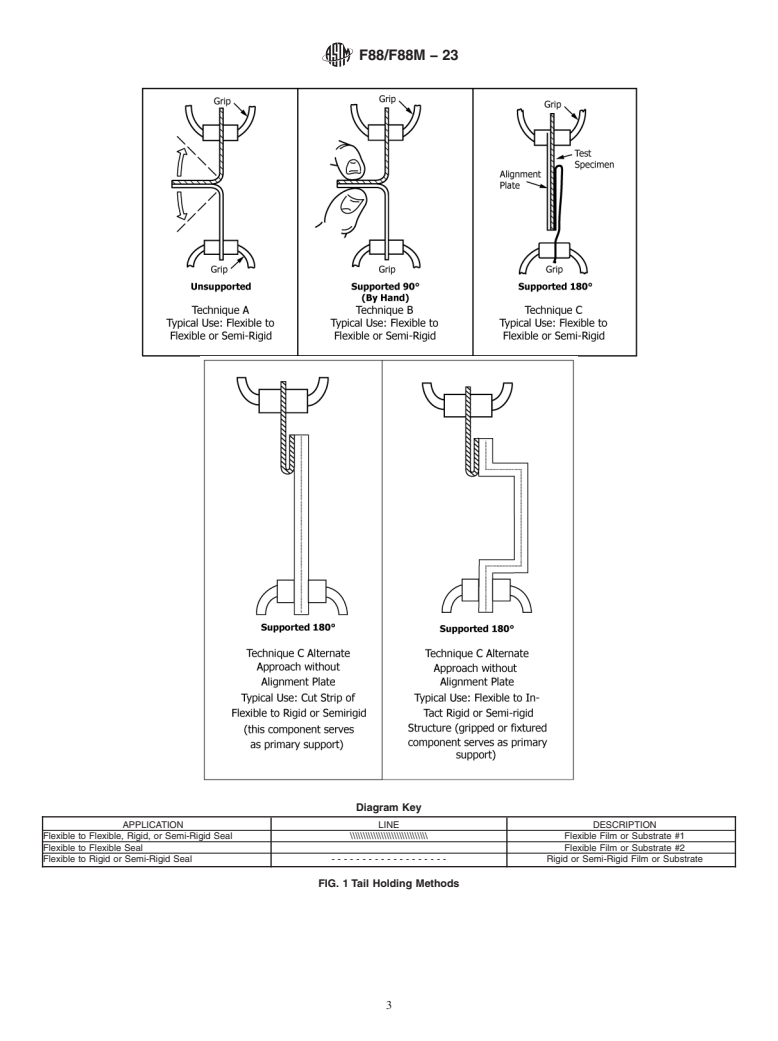

4.2 A portion of the force measured when testing materials may be a bending component and not seal strength alone. A number of fixtures and techniques have been devised to hold samples at various angles to the pull direction to control this bending force. Because the effect of each of these on test results is varied, consistent use of one technique (Technique A, Technique B, or Technique C) throughout a test series is recommended. Examples of techniques are illustrated in Fig. 1.

4.2.1 Technique A: Unsuppor...

SCOPE

1.1 This test method covers the measurement of the strength of seals in flexible barrier materials.

1.2 The test may be conducted on seals between a flexible material and another flexible material, a rigid material, or a semi-rigid material.

1.3 Seals tested in accordance with this test method may be from any source, laboratory or commercial.

1.4 This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode of specimen failure.

1.5 This test method differs from Test Method F2824. Test Method F2824 measures mechanical seal strength while separating an entire lid (cover/membrane) from a rigid or semi-rigid round container.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Apr-2023

- Technical Committee

- F02 - Primary Barrier Packaging

- Drafting Committee

- F02.20 - Physical Properties

- Current Stage

Relations

- Effective Date

- 01-Feb-2024

- Effective Date

- 01-Nov-2023

- Effective Date

- 01-May-2020

- Effective Date

- 01-May-2020

- Effective Date

- 01-Jan-2020

- Effective Date

- 01-Aug-2019

- Effective Date

- 15-Apr-2019

- Effective Date

- 01-Feb-2019

- Effective Date

- 01-Dec-2018

- Effective Date

- 01-Nov-2018

- Effective Date

- 01-Oct-2018

- Effective Date

- 15-Aug-2018

- Effective Date

- 15-Dec-2017

- Effective Date

- 15-Aug-2017

- Effective Date

- 01-Jun-2017

ASTM F88/F88M-23 - Standard Test Method for Seal Strength of Flexible Barrier Materials

REDLINE ASTM F88/F88M-23 - Standard Test Method for Seal Strength of Flexible Barrier Materials

Frequently Asked Questions

ASTM F88/F88M-23 is a standard published by ASTM International. Its full title is "Standard Test Method for Seal Strength of Flexible Barrier Materials". This standard covers: SIGNIFICANCE AND USE 4.1 Seal strength is a quantitative measure for use in process validation, capability, and control. Seal strength is not only relevant to opening force and package integrity, but to measuring the packaging processes’ ability to produce consistent seals. Seal strength at some minimum level is a necessary package requirement, and at times it is also desirable to have an upper limit to the strength of the seal to facilitate opening. Note 1: Seal strength values are a measurement of the output of the seal separation and may also involve mechanical properties of the materials that form the seal, given the potential for deformation or elongation over the course of the test. This separation is indicative of the area of the package being sampled and does not take into account simulation of a user interfacing with an entire package during the opening process. Note 2: Lower seal strength specifications are typically utilized to provide assurance of package closure, which can contribute to seal integrity. Note 3: Upper seal strength specifications are typically utilized to limit the amount of force required to open a package, ensuring that a user is able to open the design. Upper seal strength specifications are typically limited to seals that are intended to be peeled by the end user. 4.1.1 The maximum seal force is important information, but for some applications, average force to separate the seal may be useful, and in those cases also should be reported. 4.2 A portion of the force measured when testing materials may be a bending component and not seal strength alone. A number of fixtures and techniques have been devised to hold samples at various angles to the pull direction to control this bending force. Because the effect of each of these on test results is varied, consistent use of one technique (Technique A, Technique B, or Technique C) throughout a test series is recommended. Examples of techniques are illustrated in Fig. 1. 4.2.1 Technique A: Unsuppor... SCOPE 1.1 This test method covers the measurement of the strength of seals in flexible barrier materials. 1.2 The test may be conducted on seals between a flexible material and another flexible material, a rigid material, or a semi-rigid material. 1.3 Seals tested in accordance with this test method may be from any source, laboratory or commercial. 1.4 This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode of specimen failure. 1.5 This test method differs from Test Method F2824. Test Method F2824 measures mechanical seal strength while separating an entire lid (cover/membrane) from a rigid or semi-rigid round container. 1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. 1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 Seal strength is a quantitative measure for use in process validation, capability, and control. Seal strength is not only relevant to opening force and package integrity, but to measuring the packaging processes’ ability to produce consistent seals. Seal strength at some minimum level is a necessary package requirement, and at times it is also desirable to have an upper limit to the strength of the seal to facilitate opening. Note 1: Seal strength values are a measurement of the output of the seal separation and may also involve mechanical properties of the materials that form the seal, given the potential for deformation or elongation over the course of the test. This separation is indicative of the area of the package being sampled and does not take into account simulation of a user interfacing with an entire package during the opening process. Note 2: Lower seal strength specifications are typically utilized to provide assurance of package closure, which can contribute to seal integrity. Note 3: Upper seal strength specifications are typically utilized to limit the amount of force required to open a package, ensuring that a user is able to open the design. Upper seal strength specifications are typically limited to seals that are intended to be peeled by the end user. 4.1.1 The maximum seal force is important information, but for some applications, average force to separate the seal may be useful, and in those cases also should be reported. 4.2 A portion of the force measured when testing materials may be a bending component and not seal strength alone. A number of fixtures and techniques have been devised to hold samples at various angles to the pull direction to control this bending force. Because the effect of each of these on test results is varied, consistent use of one technique (Technique A, Technique B, or Technique C) throughout a test series is recommended. Examples of techniques are illustrated in Fig. 1. 4.2.1 Technique A: Unsuppor... SCOPE 1.1 This test method covers the measurement of the strength of seals in flexible barrier materials. 1.2 The test may be conducted on seals between a flexible material and another flexible material, a rigid material, or a semi-rigid material. 1.3 Seals tested in accordance with this test method may be from any source, laboratory or commercial. 1.4 This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode of specimen failure. 1.5 This test method differs from Test Method F2824. Test Method F2824 measures mechanical seal strength while separating an entire lid (cover/membrane) from a rigid or semi-rigid round container. 1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. 1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM F88/F88M-23 is classified under the following ICS (International Classification for Standards) categories: 55.040 - Packaging materials and accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM F88/F88M-23 has the following relationships with other standards: It is inter standard links to ASTM D883-24, ASTM D883-23, ASTM F2824-10(2020), ASTM F17-20, ASTM D883-20, ASTM D883-19c, ASTM D883-19a, ASTM D883-19, ASTM D883-18a, ASTM D883-18, ASTM F17-18a, ASTM F17-18, ASTM F3263-17, ASTM D883-17, ASTM F17-17. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM F88/F88M-23 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F88/F88M − 23

Standard Test Method for

Seal Strength of Flexible Barrier Materials

This standard is issued under the fixed designation F88/F88M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the measurement of the strength

D882 Test Method for Tensile Properties of Thin Plastic

of seals in flexible barrier materials.

Sheeting

1.2 The test may be conducted on seals between a flexible

D883 Terminology Relating to Plastics

material and another flexible material, a rigid material, or a

E171 Practice for Conditioning and Testing Flexible Barrier

semi-rigid material.

Packaging

E177 Practice for Use of the Terms Precision and Bias in

1.3 Seals tested in accordance with this test method may be

ASTM Test Methods

from any source, laboratory or commercial.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.4 This test method measures the force required to separate

F17 Terminology Relating to Primary Barrier Packaging

a test strip of material containing the seal. It also identifies the

F2824 Test Method for Mechanical Seal Strength Testing for

mode of specimen failure.

Round Cups and Bowl Containers with Flexible Peelable

1.5 This test method differs from Test Method F2824. Test

Lids

Method F2824 measures mechanical seal strength while sepa-

F3263 Guide for Packaging Test Method Validation

rating an entire lid (cover/membrane) from a rigid or semi-rigid

3. Terminology

round container.

3.1 Definitions:

1.6 The values stated in either SI units or inch-pound units

3.1.1 average seal strength, n—average force per unit width

are to be regarded separately as standard. The values stated in

of seal required to fully separate a flexible material from a rigid

each system may not be exact equivalents; therefore, each

material, semi-rigid material, or another flexible material,

system shall be used independently of the other. Combining

under the conditions of the test.

values from the two systems may result in non-conformance

3.1.1.1 Discussion—The average force normally is calcu-

with the standard.

lated by the testing machine from the digitized plot of force

versus grip travel. The plot starts from zero force after slack

1.7 This standard does not purport to address all of the

has been removed from the test strip. The initial ramp-up from

safety concerns, if any, associated with its use. It is the

zero to the force level required to peel the seal is not indicative

responsibility of the user of this standard to establish appro-

of seal strength, and data from that part of the curve should not

priate safety, health, and environmental practices and deter-

be included in the calculation of average strength, nor should

mine the applicability of regulatory limitations prior to use.

the return to zero following complete failure of the specimen.

1.8 This international standard was developed in accor-

The amount of data actually discarded on each end of the

dance with internationally recognized principles on standard-

measured seal-profile curve must be the same for all tests

ization established in the Decision on Principles for the

within any set of comparisons of average seal strength (see

Development of International Standards, Guides and Recom-

6.1.1 and 9.9.1).

mendations issued by the World Trade Organization Technical

3.1.2 maximum seal strength, n—maximum force per unit

Barriers to Trade (TBT) Committee.

width of seal required to fully separate a flexible material from

a rigid or semi-rigid material, or another flexible material,

under the conditions of the test.

This test method is under the jurisdiction of ASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

Physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published August 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1968. Last previous edition approved in 2021 as F88/F88M – 21. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0088_F0088M-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F88/F88M − 23

flipping of the tail throughout the course of the test; this has potential to

3.1.3 flange, n—any geometric feature of a rigid or semi-

impact the measured strength and should be reported with results.

rigid component, which provides a counterpart surface to

NOTE 6—Test method validation should account for use of fixtures or

which a flexible component can form a seal.

alignment plates, as well as determination of which material is placed into

3.1.4 interferences, n—conditions that may lead to increased which grip as these factors are known to impact results, and feasibility of

each approach may vary depending on design features. Examples of

variation or challenges in obtaining consistent measurement of

optional fixtures and equipment with built in fixturing are included in

test samples.

Appendix X4 for reference. Refer to Guide F3263 for guidance on test

method validation.

4. Significance and Use

4.1 Seal strength is a quantitative measure for use in process

5. Interferences

validation, capability, and control. Seal strength is not only

5.1 The value obtained for seal strength can be affected by

relevant to opening force and package integrity, but to mea-

properties of the specimen other than seal strength. Some

suring the packaging processes’ ability to produce consistent

flexible barrier materials have properties, such as shape and

seals. Seal strength at some minimum level is a necessary

dimension, that may vary or change and need to be taken into

package requirement, and at times it is also desirable to have an

consideration when testing for seal strength. Examples include

upper limit to the strength of the seal to facilitate opening.

materials that may stretch (elongation), flexing around the

NOTE 1—Seal strength values are a measurement of the output of the

perimeter of a seal flange, or the shape/design of the rigid or

seal separation and may also involve mechanical properties of the

semi-rigid material flanges (for example, in a tray), or variation

materials that form the seal, given the potential for deformation or

in material properties such as caliper. These interferences are

elongation over the course of the test. This separation is indicative of the

area of the package being sampled and does not take into account discussed in Annex A1.

simulation of a user interfacing with an entire package during the opening

process.

6. Apparatus

NOTE 2—Lower seal strength specifications are typically utilized to

provide assurance of package closure, which can contribute to seal

6.1 Tensile Testing Machine—A testing machine of the

integrity.

constant rate-of-jaw-separation type. The machine shall be

NOTE 3—Upper seal strength specifications are typically utilized to

equipped with a device for recording the tensile load and the

limit the amount of force required to open a package, ensuring that a user

amount of separation of the grips; both of these measuring

is able to open the design. Upper seal strength specifications are typically

limited to seals that are intended to be peeled by the end user.

systems shall be accurate to 62 %. The rate of separation of

the jaws shall be uniform and capable of adjustment from

4.1.1 The maximum seal force is important information, but

approximately 8 in. to 12 in. [200 mm to 300 mm] ⁄min. The

for some applications, average force to separate the seal may

gripping system shall be capable of minimizing specimen

be useful, and in those cases also should be reported.

slippage and applying an even stress distribution to the

4.2 A portion of the force measured when testing materials

specimen.

may be a bending component and not seal strength alone. A

number of fixtures and techniques have been devised to hold NOTE 7—If the tensile testing machine utilizes a spring and hook-based

apparatus to extend the sample, it is expected to impart more variation in

samples at various angles to the pull direction to control this

results as it travels, as compared to modern equipment. When utilizing

bending force. Because the effect of each of these on test

spring and hook-based apparatus, it is recommended to take this factor

results is varied, consistent use of one technique (Technique A,

into consideration and limit the variation imparted by the weighing system

Technique B, or Technique C) throughout a test series is

movement to a maximum distance of 2 % of the specimen extension

recommended. Examples of techniques are illustrated in Fig. 1. within the range being measured.

NOTE 8—Impact of jaw-separation rate is discussed in Appendix X3.

4.2.1 Technique A: Unsupported—Each tail of the specimen

is secured in opposing grips and the seal remains unsupported

6.1.1 If calculation of average seal strength is required, the

while the test is being conducted.

testing machine system shall have the capability to calculate its

4.2.2 Technique B: Supported 90° (By Hand)—Each tail of

value over a specified range of grip travel programmable by the

the specimen is secured in opposing grips and the seal remains

operator. Preferably, the machine shall have the capability also

hand-supported at a 90° perpendicular angle to the tails while

to plot the curve of force versus grip travel.

the test is being conducted.

6.2 Specimen Cutter, conforming to the requirements of 6.5

NOTE 4—Excessive lateral forces applied via hand may impact results.

of Test Method D882, sized to cut specimens to a width of

Actual gripping of samples is not intended and will influence results;

0.984 in. [25 mm], 0.591 in. [15 mm], or 1.00 in. [25.4 mm].

contact is intended to be loose, only preventing tail movement up or down.

4.2.3 Technique C: Supported 180°—For flexible to flexible NOTE 9—Alternate specimen cutting methods and tools may be utilized

if deemed appropriate for the application.

applications, the least flexible tail is typically supported flat

NOTE 10—Any deviation from sample tolerance or width shall be

against a rigid alignment plate held in one grip. The more

supported through documented rationale and/or supportive data. Recom-

flexible tail is typically folded 180° over the seal and is held in

mended tolerance for sample cutting tool is 60.5 %. Sample cutting

the opposing grip while the test is being conducted.

method and associated variation that may support to establish alternate

Alternatively, in rigid and semi-rigid applications, the package tolerances may be assessed in validation of the test method; refer to Guide

F3263 for test method validation guidance.

structure may be maintained for the least flexible side; with this

NOTE 11—Seal strength is proportional to sample width under the same

structure gripped or fixtured.

test conditions. Impact of variation in sample width is discussed in

NOTE 5—Properties of some flexible materials may cause movement or Appendix X3.

F88/F88M − 23

Diagram Key

APPLICATION LINE DESCRIPTION

Flexible to Flexible, Rigid, or Semi-Rigid Seal \\\\\\\\\\\\\\\\\\\\\\\\\\\\\\ Flexible Film or Substrate #1

Flexible to Flexible Seal Flexible Film or Substrate #2

Flexible to Rigid or Semi-Rigid Seal - - - - - - - - - - - - - - - - - - - Rigid or Semi-Rigid Film or Substrate

FIG. 1 Tail Holding Methods

F88/F88M − 23

7. Sampling 9. Procedure

7.1 The number of test specimens shall be chosen to permit 9.1 Calibrate the tensile machine in accordance with the

an adequate determination of representative performance. manufacturer’s recommendations.

7.2 Testing of samples with visual defects or other devia- 9.2 Prepare sealed test specimens for testing by cutting to

tions from normality may or may not be appropriate depending the dimensions shown in Fig. 2. Edges shall be clean-cut and

on the purpose of the investigation. Indiscriminate elimination perpendicular to the direction of seal. Specimen legs may be

of defects can bias results. shorter than shown, depending on the grip dimensions of the

testing machine, recommended distance between grips, or the

8. Aging and Conditioning

size of the package under test. Multiple locations around the

perimeter of the package may be tested.

8.1 If conditioning before testing is desired and appropriate,

then see Practice E171.

NOTE 12—In some applications, sample webs may be indistinguishable

from each other, but have differences relevant to test results. In these

8.2 Heat seal conditioning periods may be determined by

situations, it is recommended to properly label the tail of each web to

experimentation as sufficient to achieve seal strength stability.

enable consistency in gripping and material direction and support report-

ing considerations in 10.1.8 and 10.1.11.

8.3 Modification of conditioning practices may be necessary

to meet specific test objectives, such as the measurement of 9.3 When preparing test specimens of flexible material

seal strength at specified storage or handling temperature.

(such as a lid) sealed to a rigid material (such as a tray), and

NOTE 1—X is the seal dimension to be tested and this dimension varies with sealer configuration.

NOTE 2—Images above represent typical designs and preparation approaches; other designs compliant with this standard may warrant alternate

approaches.

NOTE 3—Sample width dimensions are referenced as examples only; reference 6.2 for options.

FIG. 2 Recommended Specimen Dimensions

F88/F88M − 23

where the flange thickness and seal geometry allow, cutting test report should indicate the details of any technique used to

through the flexible material (such as a lid), while leaving the control tail orientation.

rigid material intact is acceptable. Alternatively, cutting com-

9.7 The seal shall be tested at a rate of grip separation of

pletely through the flange is another acceptable approach, as

8 in. ⁄min to 12 in. ⁄min [200 mm ⁄min to 300 mm ⁄min].

long as all subsequent seal strength data for comparison is

NOTE 13—Impact of variation in grip separation rate is discussed in

prepared and tested in the same manner. Additionally, caution

Appendix X3.

is needed to avoid damage to the seal or injury to the operator.

9.8 For each cycle, report the maximum force encountered

See A2.2 for further discussion.

as the specimen is stressed to failure and identify the mode of

9.4 Clamp each leg of the test specimen in the tensile testing

specimen failure.

machine. The sealed area of the specimen shall be approxi-

mately equidistant between the grips. Recommended distance 9.9 If the test strip peels apart in the seal area, either by

between grips for specimens comprised of a flexible material adhesive failure, cohesive failure, or delamination, the average

sealed to a rigid material (such as a tray) is dependent on the peel force may be an important index of performance and

size and the design of the rigid material (tray); see Annex A1 should be measured by the testing machine as a part of the test

and Annex A2 for further discussion. Initial grip distance may cycle.

be limited by equipment capability and structure. Consistency

9.9.1 Follow the machine manufacturer’s instructions to

in initial grip distance is subject to reporting per 10.1.6.

select the desired algorithm for calculating average seal

Recommended distance between grips (initial unconstrained

strength. Fig. 3 illustrates the effect of an algorithm that uses

specimen length) for seals between flexible material is:

data only from the central 80 % of the curve to calculate the

average.

Fin and Hot-Wire Seals

A

Highly extensible materials 0.39 in. [10 mm]

9.9.2 If the test strip does not peel significantly in the seal

A

Less extensible materials 1.0 in. [25 mm]

B area and separation is largely by breaking, tearing, or elonga-

Lap Seals X + 10 mm

tion of the substrate material, as opposed to actual separation of

A

Grip separation distance is recommended to be limited for highly extensible the seal between two materials, average force to separate may

materials (100 + % elongation at seal failure) to minimize interferences (see

have little significance in describing seal performance and

annex).

should not be reported in such cases (see Annex A1.1).

B

Refer to Fig. 2, Note 1, for definition of X.

NOTE 14—If average force reporting is conducted for a given dataset,

Warning—Caution should be exercised to avoid injury to the

but not reported for specific samples within that dataset due to interfer-

operator of the machine, or damage to the machine itself based

ences as described above, the rationale shall also be noted with the

on grip travel and potential for contact with the operator, or corresponding interferences per 10.1.13.

collision of machinery apparatus, or related fixtures.

9.10 A plot of force versus grip travel may be useful as an

aid in interpretation of results. In those cases, the testing

9.5 Center the specimen laterally in the grips. Align the

specimen in the grips so the seal line is perpendicular to the machine should be programmed to generate the plot.

direction of pull, allowing sufficient slack so the seal is not

9.11 Other properties, such as energy to cause seal

stressed prior to initiation of the test.

separation, may be appropriate in cases where grip travel

9.6 The orientation of the fin-seal tail during the test can results only in peel. When other failure modes (elongation,

have a significant impact on the measured seal strength. The break, tear, delamination (when not a designed peel seal

FIG. 3 Calculation of Average Seal Strength

F88/F88M − 23

TABLE 2 Test Equipment

separation mode) or other) are present in addition to peel of the

seal, energy, and other functions must be interpreted with Load Cell

Manufacturer Models

caution. lb N

Dillon AFG-50N 11.2 50

10. Report

Instron 4464, 5500R, 5564, 1124, 112.4, 5 kN, 500,

5565, S5R1123, 22.5, 11.2, 2 100, 50, 9

10.1 Report the following:

4442, MN-44

10.1.1 Complete identification of material being tested. Lloyd Instruments 1300-36 22.4 100

MTS Sintech Renew 4204 25 111.2

10.1.2 Equipment and test method or practice used to form

Test Resources 2000ZR 25 111.2

seals, if known.

Thwing Albert EJA 11.2 50

10.1.3 Equipment used to test seals. Vinatoru Enterprises CCT, HST 11.2 50

10.1.4 Ambient conditions during tests; temperature and

humidity.

10.1.5 Grip separation rate.

10.1.15 Maximum force encountered as each specimen is

10.1.6 Initial grip separation distance.

stressed to failure, expressed preferably in Newtons/metre or

10.1.7 Seal width.

lbf/in. of original specimen width. Gmf/in. and lbf/in. are

10.1.8 Machine direction of material in relation to direction

commonly used.

of pull may be noted, if known and relevant to the test

10.1.16 Average Peel Force, if applicable (see 9.9)—If this

outcome.

measurement is reported, a statement of the method or algo-

10.1.9 Force (strength) values to three significant figures.

rithm used to calculate the average should be included.

10.1.10 Technique of holding the tail (Technique A, B, or C)

10.1.17 Plot of force versus grip travel, if deemed signifi-

and any special fixtures used to hold specimens.

cant in interpretation of results.

NOTE 15—Variations on Technique shall also be noted (including

10.1.18 Other data not compromised by interferences, if

support mechanisms for technique C).

such data are relevant to the specific test purpose.

NOTE 16—Locations for clamping or fixturing of samples shall also be

10.1.19 Any statistical calculation deemed appropriate

noted, if known and relevant to the test outcome.

(most commonly used are mean, range, and standard devia-

10.1.11 If the seal is made between two different materials,

tion).

record which material is clamped in each grip.

10.1.12 Number of specimens tested and method of sam-

11. Precision and Bias: Flexible to Flexible Applications

pling.

11.1 Precision—A round robin was conducted using Prac-

10.1.13 Any other pertinent information that may affect test

tice E691 as a guide, involving 18 laboratories measuring a

results such as interferences as described in Annex A1.

total of 1980 samples distributed over three different test

10.1.14 Visual determination of mode of specimen failure.

groups of six laboratories each. In order to maintain a focus on

Frequently more than one mode will occur in the course of

testing the method itself, laboratory samples were used to limit

failure of an individual strip. Record all modes observed. A

the amount of variation in the seals produced. Description of

suggested classification of modes is (see Fig. 4):

materials measured and methods used are listed in Table 1.

Adhesive failure of the seal; peel.

Seven different brands of tensile testing equipment were used

Cohesive failure of the material.

Break or tear of material in seal area or at seal edge.

to collect information. The model identifications and load cell

Delamination of surface layer(s) from substrate.

sizes are listed in Table 2. Statistical summaries of repeatability

Elongation of material.

(within a laboratory) and reproducibility (between laboratories)

Break or tear of material remote from seal.

are listed in Table 4 for SI units and Table 3 in units of pounds

per inch. Fig. 5 is graphical depictions of data.

TABLE 1 Materials and Techniques

11.2 Concept of “r” and “R” in Tables 4 and 3—If S and

Test Series “1”

r

(MAXIMUM Values)

S have been calculated from a large enough body of data, and

R

Heat Seal Coated 50# Basis Weight Paper sealed to Film (48 ga. PET/2

for test results that are averages from testing 10 to 30

mil LDPE)

Supported 90° @ 12 in./min specimens (see Note 17) for each test result, then the following

Unsupported @ 12 in./min

applies:

Unsupported @ 8 in./min

Test Series “2”

NOTE 17—Repeatability and reproducibility comparisons for smaller

(Both MAXIMUM Values and AVERAGE Peel Values were reported)

sample size (n = 10) can be found in Appendix X1 and Appendix X2 of

Uncoated 1073B Tyvek® sealed to Film (48 ga. PET/2 mil LDPE)

this test method.

Supported 90° @ 12 in./min

Unsupported @ 12 in./min

11.2.1 Repeatability “r” is the interval representing the

Supported 180° @ 12 in./min

critical difference between test results for the same material

Reverse direction of materials in grips @ 12 in./min

and method, obtained by the same operator using the same

Test Series “3”

(MAXIMUM Values)

equipment on the same day in the same laboratory. Test results

Coex HDPE 3 mil film with peelable sealant layer sealed face-to-face

Foil Composite 5 mil with same peelable sealant surface sealed

face-to-face

Supporting data have been filed at ASTM International Headquarters and may

Unsupported @ 12 in./min

Supported 180° @ 12 in./min be obtained by requesting Research Report RR:F02-1023. Contact ASTM Customer

Service at service@astm.org.

F88/F88M − 23

NOTE 1—Multiple failure modes/seal separation modes and interferences can occur on a single sample.

Color Key:

NOTE 2—Typical schematic representation of seal failure modes for seals between two webs.

FIG. 4 Test Strip Failure Modes

shall be deemed to be not equivalent if they differ by more than 11.4 Bias—There are no recognized standards by which to

the “r” value for that material or method. estimate the bias of this test method.

11.2.2 Reproducibility “R” is the interval representing the

critical difference between test results for the same material 12. Precision and Bias: Flexible to Rigid Applications

and method, obtained by different operators using the different

12.1 The precision of this test method for Flexible to Rigid

equipment in different laboratories, not necessarily on the same

applications is based on an interlaboratory study of Test

day. Test results shall be deemed to be not equivalent if they

Method F88/F88M, Test Method for Seal Strength of Flexible

differ by more than the “R” value for that material or method.

Barrier Materials, conducted in 2021. Six volunteer laborato-

11.3 Any judgment in accordance with 11.2.1 or 11.2.2 will ries were asked to test four different material configurations.

have approximately 95 % (0.95) probability of being correct. Every “test result” represents an individual determination, and

F88/F88M − 23

TABLE 3 r and R Summary (Inch-Pound Units)

NOTE 1—In accordance with Practice E691, enter the larger of the values obtained by the use of (equation for S ) and (equation for S ) as the final

r R

value of S to be used for precision statements.

R

Units: lb/in. s s r R Grand

r R

Avg

1 Supported 90° 0.0396 0.0473 0.1109 0.1324 0.957

1 Unsupported at 12 in./min 0.0929 0.1286 0.2601 0.3602 1.424

1 Unsupported at 8 in./min 0.1063 0.1488 0.2977 0.4166 1.417

A

2 PEAK 90° 0.2629 0.2539 0.7361 0.7361 0.923

2 AVG 90° 0.1600 0.1599 0.4480 0.4480 0.684

A

2 PEAK Unsupported 0.2683 0.2630 0.7513 0.7513 1.709

A

2 AVG Unsupported 0.2510 0.2492 0.7029 0.7029 1.453

2 PEAK 180° 0.2977 0.3292 0.8335 0.9218 3.239

2 AVG 180° 0.3070 0.3567 0.8596 0.9988 2.990

2 PEAK 180° Reverse 0.5536 0.5971 1.5501 1.6720 1.464

A

2 AVG 180° Reverse 0.2560 0.2451 0.7167 0.7167 0.936

3 3 mil Film Unsupported 0.0605 0.1059 0.1695 0.2966 1.695

3 3 mil Film 180° 0.1786 0.3003 0.5001 0.8408 3.463

3 5 mil Foil Unsupported 0.0382 0.0272 0.1069 0.2051 1.209

3 5 mil Foil 180° 0.3164 0.3476 0.8859 0.9731 4.569

A

Per Practice E691: “Enter the larger of the values obtained by the use of (equation for s ) and (equation for s ) as the final value of s to be used for precision statements.”

r R R

TABLE 4 r and R Summary (SI Units)

NOTE 1—In accordance with Practice E691, enter the larger of the values obtained by the use of (equation for S ) and (equation for S ) as the final

r R

value of S to be used for precision statements.

R

NOTE 2—The values stated were converted from inch-pound units.

Units: N/25.4 mm s s r R Grand

r R

Avg

1 Supported 90° 0.1761 0.2103 0.4932 0.5889 4.2569

1 Unsupported at 12 in./min 0.4132 0.5722 1.1568 1.6021 6.3343

1 Unsupported at 8 in./min 0.4729 0.6618 1.3242 1.8529 6.3031

A

2 PEAK 90° 1.1694 1.1293 3.2742 3.2742 4.1057

2 AVG 90° 0.7117 0.7112 1.9927 1.9927 3.0426

A

2 PEAK Unsupported 1.1936 1.1700 3.3421 3.3421 7.6020

A

2 AVG Unsupported 1.1167 1.1084 3.1267 3.1267 6.4633

2 PEAK 180° 1.3242 1.4643 3.7077 4.1002 14.4078

2 AVG 180° 1.3656 1.5868 3.8236 4.4431 13.3002

2 PEAK 180° Reverse 2.4625 2.6562 6.8950 7.4373 6.5122

A

2 AVG 180° Reverse 1.1386 1.0901 3.1880 3.1880 4.1635

3 3 mil Film Unsupported 0.2693 0.4712 0.7539 1.3194 7.5397

3 3 mil Film 180° 0.7945 1.3357 2.2245 3.7400 15.4042

3 5 mil Foil Unsupported 0.1699 0.3203 0.4757 0.8968 5.3779

3 5 mil Foil 180° 1.4074 1.5460 3.9406 4.3287 20.3239

A

Per Practice E691: “Enter the larger of the values obtained by the use of (equation for s ) and (equation for s ) as the final value of s to be used for precision statements.”

r R R

all participants were instructed to report 30 replicate test results 12.1.1.1 Repeatability limit can be interpreted as the maxi-

for each material. Practice E691 was followed for the design of mum difference between two results, obtained under repeat-

study and analysis of the data; the details are given in Research

ability conditions, that is accepted as plausible due to random

Report RR:F02-2001.

causes under normal and correct operation of the test method.

12.1.1 Repeatability Limit (r)—The difference between re-

12.1.1.2 Repeatability limits are listed in Table 5 and Table

petitive results obtained by the same operator in a given

6 below.

laboratory applying the same test method with the same

12.1.2 Reproducibility Limit (R)—The difference between

apparatus under constant operating conditions on identical test

two single and independent results obtained by different

material within short intervals of time would in the long run, in

operators applying the same test method in different laborato-

the normal and correct operation of the test method, exceed the

ries using different ap

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F88/F88M − 21 F88/F88M − 23

Standard Test Method for

Seal Strength of Flexible Barrier Materials

This standard is issued under the fixed designation F88/F88M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the strength of seals in flexible barrier materials.

1.2 The test may be conducted on seals between a flexible material and another flexible material, a rigid material, or a semi-rigid

material.

1.3 Seals tested in accordance with this test method may be from any source, laboratory or commercial.

1.4 This test method measures the force required to separate a test strip of material containing the seal. It also identifies the mode

of specimen failure.

1.5 This test method differs from Test Method F2824. Test Method F2824 measures mechanical seal strength while separating an

entire lid (cover/membrane) from a rigid or semi-rigid round container.

1.6 This test method differs from Test Method F904. Test Method F904 measures the bond strength or ply adhesion of laminates

made from flexible materials such as cellulose, paper, plastic film, and foil.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

This test method is under the jurisdiction of ASTM Committee F02 on Primary Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on Physical

Properties.

Current edition approved Nov. 15, 2021May 1, 2023. Published December 2021August 2023. Originally approved in 1968. Last previous edition approved in 20152021

as F88/F88M – 15.F88/F88M – 21. DOI: 10.1520/F0088_F0088M-21.10.1520/F0088_F0088M-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F88/F88M − 23

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D883 Terminology Relating to Plastics

E171 Practice for Conditioning and Testing Flexible Barrier Packaging

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F17 Terminology Relating to Primary Barrier Packaging

F904 Practice for Separation of Plies for Bond Strength of Laminated Flexible Materials

F2824 Test Method for Mechanical Seal Strength Testing for Round Cups and Bowl Containers with Flexible Peelable Lids

F3263 Guide for Packaging Test Method Validation

3. Terminology

3.1 Definitions:

3.1.1 average seal strength, n—average force per unit width of seal required to fully separate a flexible material from a rigid

material material, semi-rigid material, or another flexible material, under the conditions of the test.

3.1.1.1 Discussion—

The average force normally is calculated by the testing machine from the digitized plot of force versus grip travel. The plot starts

from zero force after slack has been removed from the test strip. The initial ramp-up from zero to the force level required to peel

the seal is not indicative of seal strength, and data from that part of the curve should not be included in the calculation of average

strength, nor should the return to zero following complete failure of the specimen. The amount of data actually discarded on each

end of the measured seal-profile curve must be the same for all tests within any set of comparisons of average seal strength (see

6.1.1 and 9.8.19.9.1).

3.1.2 maximum seal strength, n—maximum force per unit width of seal required to completelyfully separate a flexible material

from a rigid material or semi-rigid material, or another flexible material, under the conditions of the test.

3.1.3 flange, n—any geometric feature of a rigid or semi-rigid component, which provides a counterpart surface to which a flexible

component can form a seal.

3.1.4 interferences, n—conditions that may lead to increased variation or challenges in obtaining consistent measurement of test

samples.

4. Significance and Use

4.1 Seal strength is a quantitative measure for use in process validation, process control, and capability.capability, and control. Seal

strength is not only relevant to opening force and package integrity, but to measuring the packaging processes’ ability to produce

consistent seals. Seal strength at some minimum level is a necessary package requirement, and at times it is also desirable to limit

have an upper limit to the strength of the seal to facilitate opening.

NOTE 1—Seal strength values are a measurement of the output of the seal separation and may also involve mechanical properties of the materials that

form the seal, given the potential for deformation or elongation over the course of the test. This separation is indicative of the area of the package being

sampled and does not take into account simulation of a user interfacing with an entire package during the opening process.

NOTE 2—Lower seal strength specifications are typically utilized to provide assurance of package closure, which can contribute to seal integrity.

NOTE 3—Upper seal strength specifications are typically utilized to limit the amount of force required to open a package, ensuring that a user is able to

open the design. Upper seal strength specifications are typically limited to seals that are intended to be peeled by the end user.

4.1.1 The maximum seal force is important information, but for some applications, average force to openseparate the seal may

be useful, and in those cases also should be reported.

4.2 A portion of the force measured when testing materials may be a bending component and not seal strength alone. A number

of fixtures and techniques have been devised to hold samples at various angles to the pull direction to control this bending force.

Because the effect of each of these on test results is varied, consistent use of one technique (Technique A, Technique B, or

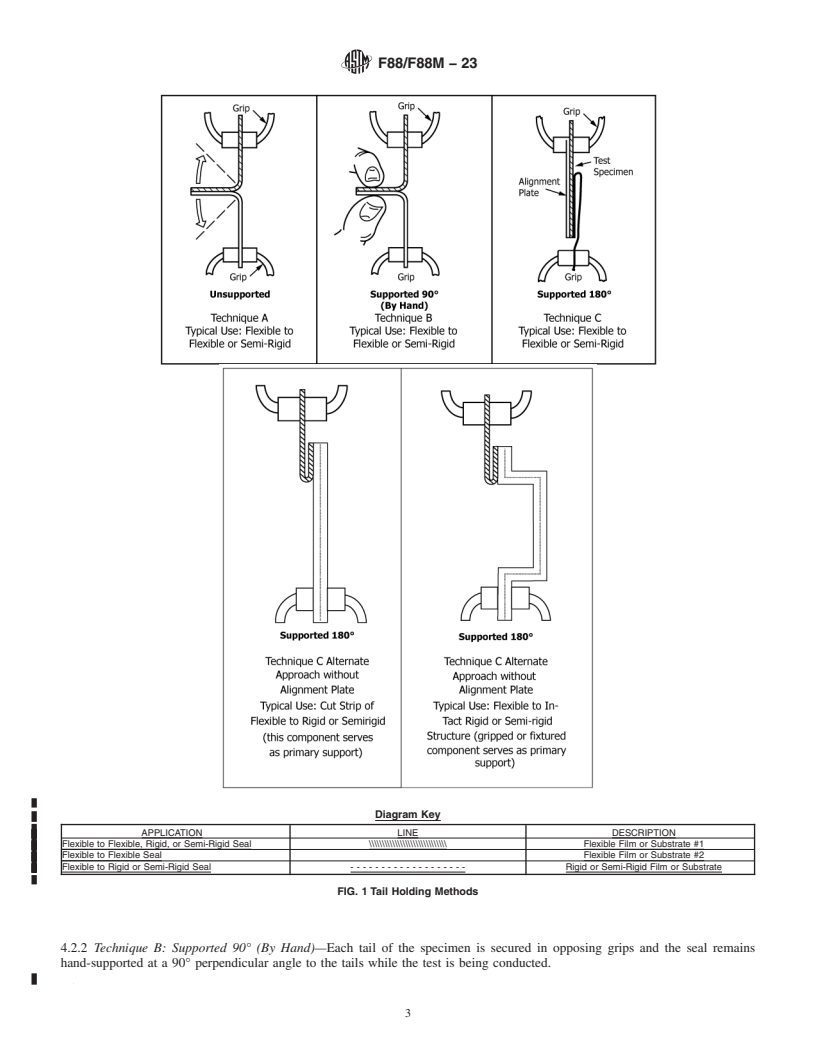

Technique C) throughout a test series is recommended. Examples of fixtures and techniques are illustrated in Fig. 1.

4.2.1 Technique A: Unsupported—Each tail of the specimen is secured in opposing grips and the seal remains unsupported while

the test is being conducted.

F88/F88M − 23

Diagram Key

APPLICATION LINE DESCRIPTION

Flexible to Flexible, Rigid, or Semi-Rigid Seal \\\\\\\\\\\\\\\\\\\\\\\\\\\\\\ Flexible Film or Substrate #1

Flexible to Flexible Seal Flexible Film or Substrate #2

Flexible to Rigid or Semi-Rigid Seal - - - - - - - - - - - - - - - - - - - Rigid or Semi-Rigid Film or Substrate

FIG. 1 Tail Holding Methods

4.2.2 Technique B: Supported 90° (By Hand)—Each tail of the specimen is secured in opposing grips and the seal remains

hand-supported at a 90° perpendicular angle to the tails while the test is being conducted.

F88/F88M − 23

NOTE 4—Excessive lateral forces applied via hand may impact results. Actual gripping of samples is not intended and will influence results; contact is

intended to be loose, only preventing tail movement up or down.

4.2.3 Technique C: Supported 180°—The For flexible to flexible applications, the least flexible tail is typically supported flat

against a rigid alignment plate held in one grip. The more flexible tail is typically folded 180° over the seal and is held in the

opposing grip while the test is being conducted. Alternatively, in rigid and semi-rigid applications, the package structure may be

maintained for the least flexible side; with this structure gripped or fixtured.

NOTE 5—Properties of some flexible materials may cause movement or flipping of the tail throughout the course of the test; this has potential to impact

the measured strength and should be reported with results.

NOTE 6—Test method validation should account for use of fixtures or alignment plates, as well as determination of which material is placed into which

grip as these factors are known to impact results, and feasibility of each approach may vary depending on design features. Examples of optional fixtures

and equipment with built in fixturing are included in Appendix X4 for reference. Refer to Guide F3263 for guidance on test method validation.

5. Interferences

5.1 The value obtained for seal strength can be affected by properties of the specimen other than seal strength. Some flexible

barrier materials have properties, such as shape and dimension, that may vary or change and need to be taken into consideration

when testing for seal strength. Examples include materials that may stretch (elongation), flexing around the perimeter of a seal

flange, or the shape/design of the rigid or semi-rigid material flanges (for example, in a tray), or variation in material properties

such as caliper. These interferences are discussed in Annex A1the annex.

6. Apparatus

6.1 Tensile Testing Machine—A testing machine of the constant rate-of-jaw-separation type. The machine shall be equipped with

a device for recording the tensile load and the amount of separation of the grips; both of these measuring systems shall be accurate

to 62 %. The rate of separation of the jaws shall be uniform and capable of adjustment from approximately 8 to 12 in. [200 to

3008 in. to 12 in. [200 mm to 300 mm] mm]/min. ⁄min. The gripping system shall be capable of minimizing specimen slippage

and applying an even stress distribution to the specimen.

NOTE 7—If the tensile testing machine utilizes a spring and hook-based apparatus to extend the sample, it is expected to impart more variation in results

as it travels, as compared to modern equipment. When utilizing spring and hook-based apparatus, it is recommended to take this factor into consideration

and limit the variation imparted by the weighing system movement to a maximum distance of 2 % of the specimen extension within the range being

measured.

NOTE 8—Impact of jaw-separation rate is discussed in Appendix X3.

6.1.1 If calculation of average seal strength is required, the testing machine system shall have the capability to calculate its value

over a specified range of grip travel programmable by the operator. Preferably, the machine shall have the capability also to plot

the curve of force versus grip travel.

6.2 Specimen Cutter, conforming to the requirements of 6.5 of Test Method D882, sized to cut specimens to a width of 0.984 in.

[25 mm], 0.591 in. [15 mm], or 1.00 in. [25.4 mm]. Tolerance shall be 60.5 %.

NOTE 9—Alternate specimen cutting methods and tools may be utilized if deemed appropriate for the application if still in compliance with

application.F88/F88M.

NOTE 10—Any deviation from sample tolerance or width shall be supported through documented rationale and/or supportive data. Recommended

tolerance for sample cutting tool is 60.5 %. Sample cutting method and associated variation that may support to establish alternate tolerances may be

assessed in validation of the test method; refer to Guide F3263 for test method validation guidance.

NOTE 11—Seal strength is proportional to sample width under the same test conditions. Impact of variation in sample width is discussed in Appendix X3.

7. Sampling

7.1 The number of test specimens shall be chosen to permit an adequate determination of representative performance.

7.2 Testing of samples with visual defects or other deviations from normality may or may not be appropriate depending on the

purpose of the investigation. Indiscriminate elimination of defects can bias results.

F88/F88M − 23

8. Aging and Conditioning

8.1 If conditioning before testing is desired and appropriate, then see Practice E171.

8.2 Heat seal conditioning periods may be determined by experimentation as sufficient to achieve seal strength stability.

8.3 Modification of conditioning practices may be necessary to meet specific test objectives, such as the measurement of seal

strength at specified storage or handling temperature.

9. Procedure

9.1 Calibrate the tensile machine in accordance with the manufacturer’s recommendations.

9.2 Prepare sealed test specimens for testing by cutting to the dimensions shown in Fig. 2. Edges shall be clean-cut and

perpendicular to the direction of seal. Specimen legs may be shorter than shown, depending on the grip dimensions of the testing

machine, recommended distance between grips, or the size of the package under test. Multiple locations around the perimeter of

the package may be tested.

NOTE 1—X is the seal dimension to be tested and this dimension varies with sealer configuration.

NOTE 2—Images above represent typical designs and preparation approaches; other designs compliant with this standard may warrant alternate

approaches.

NOTE 3—Sample width dimensions are referenced as examples only; reference 6.2 for options.

FIG. 2 Recommended Specimen Dimensions

F88/F88M − 23

NOTE 12—In some applications, sample webs may be indistinguishable from each other, but have differences relevant to test results. In these situations,

it is recommended to properly label the tail of each web to enable consistency in gripping and material direction and support reporting considerations

in 10.1.8 and 10.1.11.

9.3 When preparing test specimens of flexible material (such as a lid) sealed to a rigid material (such as a tray), and where the

flange thickness and seal geometry allow, cutting through the flexible material (such as a lid), while leaving the rigid material intact

is acceptable. Alternatively, cutting completely through the flange is another acceptable approach, as long as all subsequent seal

strength data for comparison is prepared and tested in the same manner. Additionally, caution is needed to avoid damage to the

seal or injury to the operator. See A2.2 for further discussion.

9.4 Clamp each leg of the test specimen in the tensile testing machine. The sealed area of the specimen shall be approximately

equidistant between the grips. Recommended distance between grips for specimens comprised of a flexible material sealed to a

rigid material (such as a tray) is dependent on the size and the design of the rigid material (tray); see Annex A1 and Annex A2

for further discussion. Initial grip distance may be limited by equipment capability and structure. Consistency in initial grip

distance is subject to reporting per 10.1.6. Recommended distance between grips (initial unconstrained specimen length) for seals

between flexible material is:

Fin and Hot-Wire Seals

A

Highly extensible materials 0.39 in. [10 mm]

A

Less extensible materials 1.0 in. [25 mm]

B

Lap Seals X + 10 mm

A

Grip separation distance is recommended to be limited for highly extensible materials (100 + % elongation at seal failure) to minimize interferences (see annex).

B

Refer to Fig. 2, Note 1Note 1, , for definition of X.

Warning—Caution should be exercised to avoid injury to the operator of the machine, or damage to the machine itself based on

grip travel and potential for contact with the operator, or collision of machinery apparatus, or related fixtures.

9.5 Center the specimen laterally in the grips. Align the specimen in the grips so the seal line is perpendicular to the direction of

pull, allowing sufficient slack so the seal is not stressed prior to initiation of the test.

9.6 The orientation of the fin-seal tail during the test can have a significant impact on the measured seal strength. The test report

should indicate the details of any technique used to control tail orientation.

9.7 The seal shall be tested at a rate of grip separation of 88 in. ⁄min to 1212 in. in./min⁄min [200 mm [200 to 300 ⁄min to

300 mm mm/min].⁄min].

NOTE 13—Impact of variation in grip separation rate is discussed in Appendix X3.

9.8 For each cycle, report the maximum force encountered as the specimen is stressed to failure and identify the mode of specimen

failure.

9.9 If the test strip peels apart in the seal area, either by adhesive failure, cohesive failure, or delamination, the average peel force

may be an important index of performance and should be measured by the testing machine as a part of the test cycle.

9.9.1 Follow the machine manufacturer’s instructions to select the desired algorithm for calculating average seal strength. Fig. 3

illustrates the effect of an algorithm that uses data only from the central 80 % of the curve to calculate the average.

9.9.2 If the test strip does not peel significantly in the seal area and failureseparation is largely by breaking, tearing, or elongation

of the substrate material, as opposed to actual separation of the seal between two materials, average force to failureseparate may

have little significance in describing seal performance and should not be reported in such cases (see Annex A1.1).

NOTE 14—If average force reporting is conducted for a given dataset, but not reported for specific samples within that dataset due to interferences as

described above, the rationale shall also be noted with the corresponding interferences per 10.1.13.

F88/F88M − 23

FIG. 3 Calculation of Average Seal Strength

9.10 A plot of force versus grip travel may be useful as an aid in interpretation of results. In those cases, the testing machine should

be programmed to generate the plot.

9.11 Other properties, such as energy to cause seal separation, may be appropriate in cases where grip travel results only in peel.

When other failure modes (elongation, break, tear, delamination (when not a designed peel seal separation mode) or other) are

present in addition to peel of the seal, energy, and other functions must be interpreted with caution.

10. Report

10.1 Report the following:

10.1.1 Complete identification of material being tested.

TABLE 1 Materials and Techniques

Test Series “A”

(MAXIMUM Values)

Test Series “1”

(MAXIMUM Values)

Heat Seal Coated 50# Basis Weight Paper sealed to Film (48 ga. PET/2

mil LDPE)

Supported 90° @ 12 in./min

Unsupported @ 12 in./min

Unsupported @ 8 in./min

Test Series “B”

(Both MAXIMUM Values and AVERAGE Peel Values were reported)

Test Series “2”

(Both MAXIMUM Values and AVERAGE Peel Values were reported)

Uncoated 1073B Tyvek sealed to Film (48 ga. PET/2 mil LDPE)

Uncoated 1073B Tyvek® sealed to Film (48 ga. PET/2 mil LDPE)

Supported 90° @ 12 in./min

Unsupported @ 12 in./min

Supported 180° @ 12 in./min

Reverse direction of materials in grips @ 12 in./min

Test Series “C”

(MAXIMUM Values)

Test Series “3”

(MAXIMUM Values)

Coex HDPE 3 mil film with peelable sealant layer sealed face-to-face

Foil Composite 5 mil with same peelable sealant surface sealed

face-to-face

Unsupported @ 12 in./min

Supported 180° @ 12 in./min

F88/F88M − 23

TABLE 2 Test Equipment

Load Cell

Manufacturer Models

lb N

Dillon AFG-50N 11.2 50

Instron 4464, 5500R, 5564, 1124, 112.4, 5 kN, 500,

5565, S5R1123, 22.5, 11.2, 2 100, 50, 9

4442, MN-44

Lloyd Instruments 1300-36 22.4 100

MTS Sintech Renew 4204 25 111.2

Test Resources 2000ZR 25 111.2

Thwing Albert EJA 11.2 50

Vinatoru Enterprises CCT, HST 11.2 50

10.1.2 Equipment and test method or practice used to form seals, if known.

10.1.3 Equipment used to test seals.

10.1.4 Ambient conditions during tests; temperature and humidity.

10.1.5 Grip separation rate.

10.1.6 Initial grip separation distance.

10.1.7 Seal width.

10.1.8 Machine direction of material in relation to direction of pull may be noted, if known and relevant to the test outcome.

10.1.9 Force (strength) values to three significant figures.

10.1.10 Technique of holding the tail (Technique A, B, or C) and any special fixtures used to hold specimens.

NOTE 15—Variations on Technique shall also be noted.noted (including support mechanisms for technique C).

NOTE 16—Locations for clamping or fixturing of samples shall also be noted, if known and relevant to the test outcome.

10.1.11 If the seal is made between two different materials, record which material is clamped in each grip.

10.1.12 Number of specimens tested and method of sampling.

10.1.13 Any other pertinent information that may affect test results such as interferences as described in Annex A1.

10.1.14 Visual determination of mode of specimen failure. Frequently more than one mode will occur in the course of failure of

an individual strip. Record all modes observed. A suggested classification of modes is (see Fig. 4):

Adhesive failure of the seal; peel.

Cohesive failure of the material.

Break or tear of material in seal area or at seal edge.

Delamination of surface layer(s) from substrate.

Elongation of material.

Break or tear of material remote from seal.

10.1.15 Maximum force encountered as each specimen is stressed to failure, expressed preferably in Newtons/metre or lbf/in. of

original specimen width. Gmf/in. and lbf/in. are commonly used.

10.1.16 Average Peel Force, if applicable (see 9.89.9)—If this measurement is reported, a statement of the method or algorithm

used to calculate the average should be included.

10.1.17 Plot of force versus grip travel, if deemed significant in interpretation of results.

F88/F88M − 23

NOTE 1—Multiple failure modes/seal separation modes and interferences can occur on a single sample.

Color Key:

NOTE 2—Typical schematic representation of seal failure modes for seals between two webs.

FIG. 4 Test Strip Failure Modes

10.1.18 Other data not compromised by interferences, if such data are relevant to the specific test purpose.

10.1.19 Any statistical calculation deemed appropriate (most commonly used are mean, range, and standard deviation).

11. Precision and BiasBias: Flexible to Flexible Applications

11.1 Precision—A round robin was conducted using Practice E691 as a guide, involving 18 laboratories measuring a total of 1980

F88/F88M − 23

TABLE 3 r and R Summary (Inch-Pound Units)

NOTE 1—In accordance with Practice E691, enter the larger of the values obtained by the use of (equation for S ) and (equation for S ) as the final

r R

value of S to be used for precision statements.

R

Units: lb/in. s s r R Grand

r R

Avg

A Supported 90° 0.0396 0.0473 0.1109 0.1324 0.957

1 Supported 90° 0.0396 0.0473 0.1109 0.1324 0.957

A Unsupported at 12 in./min 0.0929 0.1286 0.2601 0.3602 1.424

1 Unsupported at 12 in./min 0.0929 0.1286 0.2601 0.3602 1.424

A Unsupported at 8 in./min 0.1063 0.1488 0.2977 0.4166 1.417

1 Unsupported at 8 in./min 0.1063 0.1488 0.2977 0.4166 1.417

A

B PEAK 90° 0.2629 0.2539 0.7361 0.7361 0.923

A

2 PEAK 90° 0.2629 0.2539 0.7361 0.7361 0.923

B AVG 90° 0.1600 0.1599 0.4480 0.4480 0.684

2 AVG 90° 0.1600 0.1599 0.4480 0.4480 0.684

A

B PEAK Unsupported 0.2683 0.2630 0.7513 0.7513 1.709

A

2 PEAK Unsupported 0.2683 0.2630 0.7513 0.7513 1.709

A

B AVG Unsupported 0.2510 0.2492 0.7029 0.7029 1.453

A

2 AVG Unsupported 0.2510 0.2492 0.7029 0.7029 1.453

B PEAK 180° 0.2977 0.3292 0.8335 0.9218 3.239

2 PEAK 180° 0.2977 0.3292 0.8335 0.9218 3.239

B AVG 180° 0.3070 0.3567 0.8596 0.9988 2.990

2 AVG 180° 0.3070 0.3567 0.8596 0.9988 2.990

B PEAK 180° Reverse 0.5536 0.5971 1.5501 1.6720 1.464

2 PEAK 180° Reverse 0.5536 0.5971 1.5501 1.6720 1.464

A

B AVG 180° Reverse 0.2560 0.2451 0.7167 0.7167 0.936

A

2 AVG 180° Reverse 0.2560 0.2451 0.7167 0.7167 0.936

C 3 mil Film Unsupported 0.0605 0.1059 0.1695 0.2966 1.695

3 3 mil Film Unsupported 0.0605 0.1059 0.1695 0.2966 1.695

C 3 mil Film 180° 0.1786 0.3003 0.5001 0.8408 3.463

3 3 mil Film 180° 0.1786 0.3003 0.5001 0.8408 3.463

C 5 mil Foil Unsupported 0.0382 0.0272 0.1069 0.2051 1.209

3 5 mil Foil Unsupported 0.0382 0.0272 0.1069 0.2051 1.209

C 5 mil Foil 180° 0.3164 0.3476 0.8859 0.9731 4.569

3 5 mil Foil 180° 0.3164 0.3476 0.8859 0.9731 4.569

A

Per Practice E691: “Enter the larger of the values obtained by the use of (equation for s ) and (equation for s ) as the final value of s to be used for precision statements.”

r R R

samples distributed over three different test groups of six laboratories each. In order to maintain a focus on testing the method

itself, laboratory samples were used to limit the amount of variation in the seals produced. Description of materials measured and

methods used are listed in Table 1. Seven different brands of tensile testing equipment were used to collect information. The model

identifications and load cell sizes are listed in Table 2. Statistical summaries of repeatability (within a laboratory) and

reproducibility (between laboratories) are listed in Table 4 for SI units and Table 3 in units of pounds per inch. Fig. 5 is graphical

depictions of data.

11.2 Concept of “r” and “R” in Tables 4 and 3—If S and S have been calculated from a large enough body of data, and for

r R

test results that are averages from testing 10 to 30 specimens (see Note 617) for each test result, then the following applies:

NOTE 17—Repeatability and reproducibility comparisons for smaller sample size (n = 10) can be found in Appendix X1 and Appendix X2 of this test

method.

11.2.1 Repeatability “r” is the interval representing the critical difference between test results for the same material and method,

obtained by the same operator using the same equipment on the same day in the same laboratory. Test results shall be deemed to

be not equivalent if they differ by more than the “r” value for that material or method.

11.2.2 Reproducibility “R” is the interval representing the critical difference between test results for the same material and method,

obtained by different operators using the different equipment in different laboratories, not necessarily on the same day. Test results

shall be deemed to be not equivalent if they differ by more than the “R” value for that material or method.

11.3 Any judgment in accordance with 11.2.1 or 11.2.2 will have approximately 95 % (0.95) probability of being correct.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:F02-1023. Contact ASTM Customer

Service at service@astm.org.

F88/F88M − 23

TABLE 4 r and R Summary (SI Units)

NOTE 1—In accordance with Practice E691, enter the larger of the values obtained by the use of (equation for S ) and (equation for S ) as the final

r R

value of S to be used for precision statements.

R

NOTE 2—The values stated were converted from inch-pound units.

Units: N/25.4 mm s s r R Grand

r R

Avg

A Supported 90° 0.1761 0.2103 0.4932 0.5889 4.2569

1 Supported 90° 0.1761 0.2103 0.4932 0.5889 4.2569

A Unsupported at 12 in./min 0.4132 0.5722 1.1568 1.6021 6.3343

1 Unsupported at 12 in./min 0.4132 0.5722 1.1568 1.6021 6.3343

A Unsupported at 8 in./min 0.4729 0.6618 1.3242 1.8529 6.3031

1 Unsupported at 8 in./min 0.4729 0.6618 1.3242 1.8529 6.3031

A

B PEAK 90° 1.1694 1.1293 3.2742 3.2742 4.1057

A

2 PEAK 90° 1.1694 1.1293 3.2742 3.2742 4.1057

B AVG 90° 0.7117 0.7112 1.9927 1.9927 3.0426

2 AVG 90° 0.7117 0.7112 1.9927 1.9927 3.0426

A

B PEAK Unsupported 1.1936 1.1700 3.3421 3.3421 7.6020

A

2 PEAK Unsupported 1.1936 1.1700 3.3421 3.3421 7.6020

A

B AVG Unsupported 1.1167 1.1084 3.1267 3.1267 6.4633

A

2 AVG Unsupported 1.1167 1.1084 3.1267 3.1267 6.4633

B PEAK 180° 1.3242 1.4643 3.7077 4.1002 14.4078

2 PEAK 180° 1.3242 1.4643 3.7077 4.1002 14.4078

B AVG 180° 1.3656 1.5868 3.8236 4.4431 13.3002

2 AVG 180° 1.3656 1.5868 3.8236 4.4431 13.3002

B PEAK 180° Reverse 2.4625 2.6562 6.8950 7.4373 6.5122

2 PEAK 180° Reverse 2.4625 2.6562 6.8950 7.4373 6.5122

A

B AVG 180° Reverse 1.1386 1.0901 3.1880 3.1880 4.1635

A

2 AVG 180° Reverse 1.1386 1.0901 3.1880 3.1880 4.1635

C 3 mil Film Unsupported 0.2693 0.4712 0.7539 1.3194 7.5397

3 3 mil Film Unsupported 0.2693 0.4712 0.7539 1.3194 7.5397

C 3 mil Film 180° 0.7945 1.3357 2.2245 3.7400 15.4042

3 3 mil Film 180° 0.7945 1.3357 2.2245 3.7400 15.4042

C 5 mil Foil Unsupported 0.1699 0.3203 0.4757 0.8968 5.3779

3 5 mil Foil Unsupported 0.1699 0.3203 0.4757 0.8968 5.3779

C 5 mil Foil 180° 1.4074 1.5460 3.9406 4.3287 20.3239

3 5 mil Foil 180° 1.4074 1.5460 3.9406 4.3287 20.3239

A

Per Practice E691: “Enter the larger of the values obtained by the use of (equation for s ) and (equation for s ) as the final value of s to be used for precision statements.”

r R R

FIG. 5 F88/F88M Round Robin r and R (at 95 % confidence) with Average Measured Values

11.4 Bias—There are no recognized standards by which to estimate the bias of this test method.

F88/F88M − 23

12. Precision and Bias: Flexible to Rigid Applications

12.1 The precision of this test method for Flexible to Rigid applications is based on an interlaboratory study of Test Method

F88/F88M, Test Method for Seal Strength of Flexible Barrier Materials, conducted in 2021. Six volunteer laboratories were asked

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...