ASTM D7423-09(2014)

(Test Method)Standard Test Method for Determination of Oxygenates in C2, C3, C4, and C5 Hydrocarbon Matrices by Gas Chromatography and Flame Ionization Detection

Standard Test Method for Determination of Oxygenates in C2, C3, C4, and C5 Hydrocarbon Matrices by Gas Chromatography and Flame Ionization Detection

SIGNIFICANCE AND USE

5.1 The determination of oxygenates is important in the manufacture of ethene, propene, 1-3 butadiene, C4 hydrocarbons, and C5 hydrocarbons. Alcohols, ethers, aldehydes, and ketones are trace impurities in these hydrocarbons. Oxygenates decrease catalyst activity in downstream polymerization processes.

SCOPE

1.1 This test method covers the gas chromatographic procedure for the quantitative determination of organic oxygenates in C2, C3, C4, and C5 matrices by multidimensional gas chromatography and flame ionization detection. This test method is applicable when the hydrocarbon matrices have a final boiling point not greater than 200°C. Oxygenate compounds include, but are not limited to, those listed in Table 1. The linear working range for oxygenates is 0.50 mg/kg to 100 mg/kg.

1.2 This test method is intended to determine the mass concentration of each oxygenate in the hydrocarbon matrix. Oxygenate compound identification is determined by reference standards and column elution retention order.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7423 − 09(Reapproved 2014)

Standard Test Method for

Determination of Oxygenates in C2, C3, C4, and C5

Hydrocarbon Matrices by Gas Chromatography and Flame

Ionization Detection

This standard is issued under the fixed designation D7423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

1.1 This test method covers the gas chromatographic pro-

Measurement System Performance

cedureforthequantitativedeterminationoforganicoxygenates

D6849 Practice for Storage and Use of Liquefied Petroleum

in C2, C3, C4, and C5 matrices by multidimensional gas

Gases (LPG) in Sample Cylinders for LPG Test Methods

chromatography and flame ionization detection. This test

E355 Practice for Gas Chromatography Terms and Relation-

method is applicable when the hydrocarbon matrices have a

ships

final boiling point not greater than 200°C. Oxygenate com-

pounds include, but are not limited to, those listed in Table 1.

3. Terminology

The linear working range for oxygenates is 0.50 mg/kg to 100

3.1 Additional terminology related to the practice of gas

mg/kg.

chromatography can be found in Practice E355.

1.2 This test method is intended to determine the mass

3.2 Definitions:

concentration of each oxygenate in the hydrocarbon matrix.

3.2.1 liquefied petroleum gas (LPG), n—a mixture of nor-

Oxygenate compound identification is determined by reference

mally gaseous hydrocarbons, predominantly propane or

standards and column elution retention order.

butane, or both, that has been liquefied by compression or

1.3 The values stated in SI units are to be regarded as

cooling, or both, to facilitate storage, transport, and handling.

standard. No other units of measurement are included in this

D4175

standard.

3.2.2 oxygenate, n—an oxygen-containing ashless organic

1.4 This standard does not purport to address all of the

compound, such as an alcohol or ether, which may be used as

safety concerns, if any, associated with its use. It is the

a fuel or fuel supplement. D4175

responsibility of the user of this standard to establish appro-

3.3 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.3.1 Dean’s switching method—representative aliquot of

bility of regulatory limitations prior to use.

sampleisinjectedon-columnusingasamplevalve(orviaagas

chromatograph split inlet). The sample passes onto a nonpolar

2. Referenced Documents

column, which elutes the lighter hydrocarbons in boiling point

2.1 ASTM Standards:

order to the analytical column and backflushes the heavier

D1265 Practice for Sampling Liquefied Petroleum (LP)

hydrocarbons to vent. The oxygenate compounds elute from

Gases, Manual Method

the analytical column and are detected via a flame ionization

D1835 Specification for Liquefied Petroleum (LP) Gases

detector.

D4175 Terminology Relating to Petroleum, Petroleum

3.3.2 Dean’s switching method direct inject—gas chromato-

Products, and Lubricants

graphic valve configuration equipped with a valve connected

directlytotheprecolumn.Thistechniqueiscommonlyusedfor

1 the determination of oxygenates in ethene and propene con-

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of centrates. This configuration provides the lowest detection

Subcommittee D02.D0.04 on C4 Hydrocarbons.

limitssuchasthosecommonlyrequiredforetheneandpropene

CurrenteditionapprovedMay1,2014.PublishedJuly2014.Originallyapproved

concentrates.

in 2009. Last pervious edition approved in 2009 as D7423 – 09. DOI: 10.1520/

D7423-09R14.

3.3.3 Dean’s switching method equipped with a split inlet—

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

gas chromatographic valve configuration equipped with a gas

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

chromatograph split inlet for sample introduction into the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. precolumn. This configuration is commonly used for the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7423 − 09 (2014)

TABLE 1 Oxygenates and Typical Retention Times

Components Retention Time (min)

Dimethyl ether 6.18

Diethyl ether 8.44

Acetaldehyde 8.89

Ethyl tert-butyl ether 10.66

Methyl tert-butyl ether (MTBE) 10.92

Diisopropyl ether 11.22

Propionaldehyde (Propanal) 12.00

Tertiary amyl methyl ether (TAME) 13.19

Propyl ether 14.00

Isobutylaldehyde 14.10

Butylaldehyde 14.50

Methanol 14.91

Acetone 15.39

Isovaleraldehyde 16.00

Valeraldehyde 16.10

2-Butanone (MEK) 17.14

Ethanol 17.51

N-propyl alcohol and isopropanol 19.20 (co-elution)

Allyl Alcohol 20.00

Isobutanol, Tert-butyl alcohol, Sec-Butanol 20.24 (co-elution)

N-butanol 20.84

determination of oxygenates in C5 hydrocarbon mixtures. This 4.2 The detector response and retention times for each

technique using this configuration might not provide the oxygenate peak in a calibration standard is measured and used

detection limits noted in the scope of this test method. If lower to externally calibrate the flame ionization detector response.

detection limits are required, then the user should consider The concentration of each oxygenate is calculated by the

using the on-column valve direct injection technique. external standard technique. Calibration materials are listed in

Table 1.

3.3.4 valve cut method—commonly used for the determina-

tion of oxygenates in C4 hydrocarbon mixtures.This technique

5. Significance and Use

using a split inlet might not provide the detection limits noted

5.1 The determination of oxygenates is important in the

in the scope of this test method. If lower detection limits are

manufacture of ethene, propene, 1-3 butadiene, C4

required, then the user should consider using the on-column

hydrocarbons, and C5 hydrocarbons. Alcohols, ethers,

valve direct injection technique.

aldehydes, and ketones are trace impurities in these hydrocar-

3.3.5 valve cut method equipped with a split inlet—

bons. Oxygenates decrease catalyst activity in downstream

representative aliquot of sample is injected via a gas chromato-

polymerization processes.

graph split inlet for sample introduction into the precolumn.

The sample passes onto a nonpolar column, which elutes the

6. Apparatus

lighter hydrocarbons in boiling point order to the analytical

6.1 Gas Chromatograph—Any gas chromatograph

column and the heavier hydrocarbons to vent. The oxygenate

equipped with a flame ionization detector (FID) and having

compounds elute from the analytical column and are detected

sensitivity of 0.01 mg/kg. The gas chromatograph must be

via a flame ionization detector.

capable of linear temperature control from 50 to 320°C for the

3.4 Acronyms:

capillary column oven. The gas chromatograph must be ca-

3.4.1 DIPE—diisopropylether.

pable of controlling multiple valve events. Carrier gas flow

3.4.2 ETBE—ethyl tert-butylether.

controllers and or electronic pressure control modules shall be

capableofprecisecontrolwheretherequiredflowratesarelow

3.4.3 MEK—2-butanone.

(see Table 2). Pressure control devices and gages shall be

3.4.4 MTBE—methyl tert-butylether.

capable of precise control for the typical pressures required.

3.4.5 TAME—tert-amyl methylether.

The temperature program rate must repeat to within 0.1°C and

3.4.6 PLOT—porous layer open tubular capillary column. provide retention time repeatability of 0.05 min throughout the

temperature program.

3.4.7 WCOT—wall coated open tubular capillary column.

6.2 Carrier Gas Preparation:

4. Summary of Test Method

6.2.1 Moisture present in the carrier gas causes chromato-

4.1 This test method shall be configured using either the graphic problems. The oxygenates column has very high

Dean’s switching method or the valve cut method. Each retention. Due to this characteristic, moisture and trace impu-

method shall be configured using an on-column valve direct rities in the carrier gas are trapped at the beginning of this

inject technique or a gas chromatograph split inlet. The column. Therefore carrier gas filters or the use of any device

on-column valve direct inject technique is configured by which can be used to eliminate trace levels of oxygen and

connecting the head of the precolumn directly to the injection water are strongly recommended.Additionally, frequent recon-

valve. ditioning and longer than usual column condition times may be

D7423 − 09 (2014)

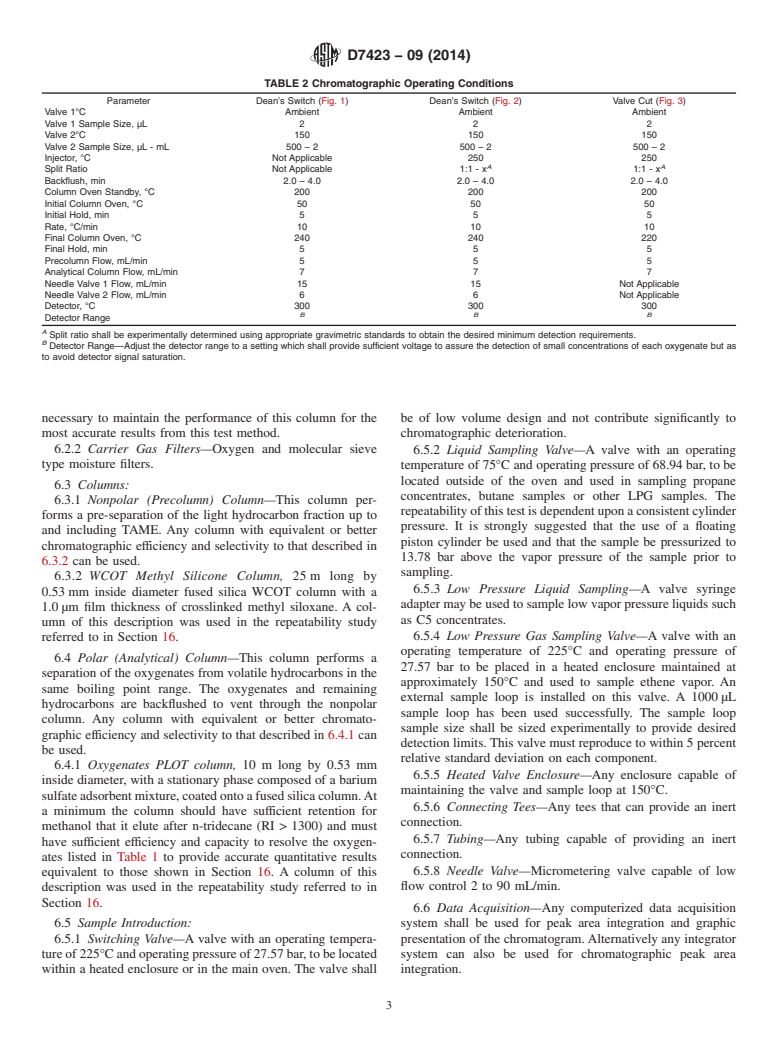

TABLE 2 Chromatographic Operating Conditions

Parameter Dean’s Switch (Fig. 1) Dean’s Switch (Fig. 2) Valve Cut (Fig. 3)

Valve 1°C Ambient Ambient Ambient

Valve 1 Sample Size, µL 2 2 2

Valve 2°C 150 150 150

Valve 2 Sample Size, µL - mL 500 – 2 500 – 2 500 – 2

Injector, °C Not Applicable 250 250

A A

Split Ratio Not Applicable 1:1 - x 1:1 - x

Backflush, min 2.0 – 4.0 2.0 – 4.0 2.0 – 4.0

Column Oven Standby, °C 200 200 200

Initial Column Oven, °C 50 50 50

Initial Hold, min 5 5 5

Rate, °C/min 10 10 10

Final Column Oven, °C 240 240 220

Final Hold, min 5 5 5

Precolumn Flow, mL/min 5 5 5

Analytical Column Flow, mL/min 7 7 7

Needle Valve 1 Flow, mL/min 15 15 Not Applicable

Needle Valve 2 Flow, mL/min 6 6 Not Applicable

Detector, °C 300 300 300

BBB

Detector Range

A

Split ratio shall be experimentally determined using appropriate gravimetric standards to obtain the desired minimum detection requirements.

B

Detector Range—Adjust the detector range to a setting which shall provide sufficient voltage to assure the detection of small concentrations of each oxygenate but as

to avoid detector signal saturation.

necessary to maintain the performance of this column for the be of low volume design and not contribute significantly to

most accurate results from this test method. chromatographic deterioration.

6.2.2 Carrier Gas Filters—Oxygen and molecular sieve

6.5.2 Liquid Sampling Valve—A valve with an operating

type moisture filters.

temperature of 75°C and operating pressure of 68.94 bar, to be

located outside of the oven and used in sampling propane

6.3 Columns:

concentrates, butane samples or other LPG samples. The

6.3.1 Nonpolar (Precolumn) Column—This column per-

repeatabilityofthistestisdependentuponaconsistentcylinder

forms a pre-separation of the light hydrocarbon fraction up to

pressure. It is strongly suggested that the use of a floating

and including TAME. Any column with equivalent or better

piston cylinder be used and that the sample be pressurized to

chromatographic efficiency and selectivity to that described in

13.78 bar above the vapor pressure of the sample prior to

6.3.2 can be used.

sampling.

6.3.2 WCOT Methyl Silicone Column, 25 m long by

6.5.3 Low Pressure Liquid Sampling—A valve syringe

0.53 mm inside diameter fused silica WCOT column with a

adapter may be used to sample low vapor pressure liquids such

1.0 µm film thickness of crosslinked methyl siloxane. A col-

as C5 concentrates.

umn of this description was used in the repeatability study

6.5.4 Low Pressure Gas Sampling Valve—A valve with an

referred to in Section 16.

operating temperature of 225°C and operating pressure of

6.4 Polar (Analytical) Column—This column performs a

27.57 bar to be placed in a heated enclosure maintained at

separation of the oxygenates from volatile hydrocarbons in the

approximately 150°C and used to sample ethene vapor. An

same boiling point range. The oxygenates and remaining

external sample loop is installed on this valve. A 1000 µL

hydrocarbons are backflushed to vent through the nonpolar

sample loop has been used successfully. The sample loop

column. Any column with equivalent or better chromato-

sample size shall be sized experimentally to provide desired

graphic efficiency and selectivity to that described in 6.4.1 can

detection limits. This valve must reproduce to within 5 percent

be used.

relative standard deviation on each component.

6.4.1 Oxygenates PLOT column, 10 m long by 0.53 mm

6.5.5 Heated Valve Enclosure—Any enclosure capable of

inside diameter, with a stationary phase composed of a barium

maintaining the valve and sample loop at 150°C.

sulfateadsorbentmixture,coatedontoafusedsilicacolumn.At

6.5.6 Connecting Tees—Any tees that can provide an inert

a minimum the column should have sufficient retention for

connection.

methanol that it elute after n-tridecane (RI > 1300) and must

6.5.7 Tubing—Any tubing capable of providing an inert

have sufficient efficiency and capacity to resolve the oxygen-

connection.

ates listed in Table 1 to provide accurate quantitative results

6.5.8 Needle Valve—Micrometering valve capable of low

equivalent to those shown in Section 16. A column of this

flow control 2 to 90 mL/min.

description was used in the repeatability study referred to in

Section 16.

6.6 Data Acquisition—Any computerized data acquisition

6.5 Sample Introduction: system shall be used for peak area integration and graphic

6.5.1 Switching Valve—A valve with an operating tempera- presentation of the chromatogram.Alternatively any integrator

tureof225°Candoperatingpressureof27.57bar,tobelocated system can also be used for chromatographic peak area

within a heated enclosure or in the main oven. The valve shall integration.

D7423 − 09 (2014)

7. Reagents and Materials recommendations of Practice D1265, D1835, D6849 or their

equivalent, when obtaining and storing samples from bulk

7.1 Purity of Reagents—Before preparing the calibration

storage or pipelines.

standards, determine the purity of the oxygenate stocks and

make corrections for the impurities found. Whenever possible,

9. Installation of Carrier Gas Filters

use stocks of 98 % purity or better. The calibration materials

are listed in Table 1.

9.1 The carrier gas shall require pretreatment with an

oxygen and water removal system.

7.2 Calibration Standard Mixture—Astandard mixture con-

taining known concentrations of each oxygenate listed in Table

9.2 Onthegaschromatographcarriergassupplyline,install

1 should be prepared gravimetrically. This mixture shall be

theoxygenandwaterremovalfilters.Anyfilters,trapsorgetter

used as an external calibration standard.

type device can be used to assure removal of both oxygen and

7.3 Compressed Hydrogen—Less than 1 mg/kg hydrocar- water from the carrier gas used for this gas chromatograph.

bon impurities for FID fuel gas.

10. Preparation of Apparatus a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7423 − 09 D7423 − 09 (Reapproved 2014)

Standard Test Method for

Determination of Oxygenates in C2, C3, C4, and C5

Hydrocarbon Matrices by Gas Chromatography and Flame

Ionization Detection

This standard is issued under the fixed designation D7423; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the gas chromatographic procedure for the quantitative determination of organic oxygenates in C2,

C3, C4, and C5 matrices by multidimensional gas chromatography and flame ionization detection. This test method is applicable

when the hydrocarbon matrices have a final boiling point not greater than 200°C. Oxygenate compounds include, but are not

limited to, those listed in Table 1. The linear working range for oxygenates is 0.50 mg/kg to 100 mg/kg.

1.2 This test method is intended to determine the mass concentration of each oxygenate in the hydrocarbon matrix. Oxygenate

compound identification is determined by reference standards and column elution retention order.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases, Manual Method

D1835 Specification for Liquefied Petroleum (LP) Gases

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6849 Practice for Storage and Use of Liquefied Petroleum Gases (LPG) in Sample Cylinders for LPG Test Methods

E355 Practice for Gas Chromatography Terms and Relationships

3. Terminology

3.1 Additional terminology related to the practice of gas chromatography can be found in Practice E355.

3.2 Definitions:

3.2.1 liquefied petroleum gas (LPG), n—a mixture of normally gaseous hydrocarbons, predominantly propane or butane, or

both, that has been liquefied by compression or cooling, or both, to facilitate storage, transport, and handling. D4175

3.2.2 oxygenate, n—an oxygen-containing ashless organic compound, such as an alcohol or ether, which may be used as a fuel

or fuel supplement. D4175

3.3 Definitions of Terms Specific to This Standard:

3.3.1 Dean’s switching method—representative aliquot of sample is injected on-column using a sample valve (or via a gas

chromatograph split inlet). The sample passes onto a nonpolar column, which elutes the lighter hydrocarbons in boiling point order

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.D0.04 on C4 Hydrocarbons.

Current edition approved July 1, 2009May 1, 2014. Published September 2009July 2014. Originally approved in 2009. Last pervious edition approved in 2009 as

D7423 – 09. DOI: 10.1520/D7423-09.10.1520/D7423-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7423 − 09 (2014)

TABLE 1 Oxygenates and Typical Retention Times

Components Retention Time (min)

Dimethyl ether 6.18

Diethyl ether 8.44

Acetaldehyde 8.89

Ethyl tert-butyl ether 10.66

Methyl tert-butyl ether (MTBE) 10.92

Diisopropyl ether 11.22

Propionaldehyde (Propanal) 12.00

Tertiary amyl methyl ether (TAME) 13.19

Propyl ether 14.00

Isobutylaldehyde 14.10

Butylaldehyde 14.50

Methanol 14.91

Acetone 15.39

Isovaleraldehyde 16.00

Valeraldehyde 16.10

2-Butanone (MEK) 17.14

Ethanol 17.51

N-propyl alcohol and isopropanol 19.20 (co-elution)

Allyl Alcohol 20.00

Isobutanol, Tert-butyl alcohol, Sec-Butanol 20.24 (co-elution)

N-butanol 20.84

to the analytical column and backflushes the heavier hydrocarbons to vent. The oxygenate compounds elute from the analytical

column and are detected via a flame ionization detector.

3.3.2 Dean’s switching method direct inject—gas chromatographic valve configuration equipped with a valve connected directly

to the precolumn. This technique is commonly used for the determination of oxygenates in ethene and propene concentrates. This

configuration provides the lowest detection limits such as those commonly required for ethene and propene concentrates.

3.3.3 Dean’s switching method equipped with a split inlet—gas chromatographic valve configuration equipped with a gas

chromatograph split inlet for sample introduction into the precolumn. This configuration is commonly used for the determination

of oxygenates in C5 hydrocarbon mixtures. This technique using this configuration might not provide the detection limits noted

in the scope of this test method. If lower detection limits are required, then the user should consider using the on-column valve

direct injection technique.

3.3.4 valve cut method—commonly used for the determination of oxygenates in C4 hydrocarbon mixtures. This technique using

a split inlet might not provide the detection limits noted in the scope of this test method. If lower detection limits are required,

then the user should consider using the on-column valve direct injection technique.

3.3.5 valve cut method equipped with a split inlet—representative aliquot of sample is injected via a gas chromatograph split

inlet for sample introduction into the precolumn. The sample passes onto a nonpolar column, which elutes the lighter hydrocarbons

in boiling point order to the analytical column and the heavier hydrocarbons to vent. The oxygenate compounds elute from the

analytical column and are detected via a flame ionization detector.

3.4 Acronyms:

3.4.1 DIPE—diisopropylether.

3.4.2 ETBE—ethyl tert-butylether.

3.4.3 MEK—2-butanone.

3.4.4 MTBE—methyl tert-butylether.

3.4.5 TAME—tert-amyl methylether.

3.4.6 PLOT—porous layer open tubular capillary column.

3.4.7 WCOT—wall coated open tubular capillary column.

4. Summary of Test Method

4.1 This test method shall be configured using either the Dean’s switching method or the valve cut method. Each method shall

be configured using an on-column valve direct inject technique or a gas chromatograph split inlet. The on-column valve direct

inject technique is configured by connecting the head of the precolumn directly to the injection valve.

4.2 The detector response and retention times for each oxygenate peak in a calibration standard is measured and used to

externally calibrate the flame ionization detector response. The concentration of each oxygenate is calculated by the external

standard technique. Calibration materials are listed in Table 1.

D7423 − 09 (2014)

5. Significance and Use

5.1 The determination of oxygenates is important in the manufacture of ethene, propene, 1-3 butadiene, C4 hydrocarbons, and

C5 hydrocarbons. Alcohols, ethers, aldehydes, and ketones are trace impurities in these hydrocarbons. Oxygenates decrease

catalyst activity in downstream polymerization processes.

6. Apparatus

6.1 Gas Chromatograph—Any gas chromatograph equipped with a flame ionization detector (FID) and having sensitivity of

0.01 mg/kg. The gas chromatograph must be capable of linear temperature control from 50 to 320°C for the capillary column oven.

The gas chromatograph must be capable of controlling multiple valve events. Carrier gas flow controllers and or electronic pressure

control modules shall be capable of precise control where the required flow rates are low (see Table 2). Pressure control devices

and gages shall be capable of precise control for the typical pressures required. The temperature program rate must repeat to within

0.1°C and provide retention time repeatability of 0.05 min throughout the temperature program.

6.2 Carrier Gas Preparation:

6.2.1 Moisture present in the carrier gas causes chromatographic problems. The oxygenates column has very high retention. Due

to this characteristic, moisture and trace impurities in the carrier gas are trapped at the beginning of this column. Therefore carrier

gas filters or the use of any device which can be used to eliminate trace levels of oxygen and water are strongly recommended.

Additionally, frequent reconditioning and longer than usual column condition times may be necessary to maintain the performance

of this column for the most accurate results from this test method.

6.2.2 Carrier Gas Filters—Oxygen and molecular sieve type moisture filters.

6.3 Columns:

6.3.1 Nonpolar (Precolumn) Column—This column performs a pre-separation of the light hydrocarbon fraction up to and

including TAME. Any column with equivalent or better chromatographic efficiency and selectivity to that described in 6.3.2 can

be used.

6.3.2 WCOT Methyl Silicone Column, 25 m 25 m long by 0.53 mm 0.53 mm inside diameter fused silica WCOT column with

a 1.0 μm 1.0 μm film thickness of crosslinked methyl siloxane. A column of this description was used in the repeatability study

referred to in Section 16.

6.4 Polar (Analytical) Column—This column performs a separation of the oxygenates from volatile hydrocarbons in the same

boiling point range. The oxygenates and remaining hydrocarbons are backflushed to vent through the nonpolar column. Any

column with equivalent or better chromatographic efficiency and selectivity to that described in 6.4.1 can be used.

6.4.1 Oxygenates PLOT column, 10 m long by 0.53 mm inside diameter, with a stationary phase composed of a barium sulfate

adsorbent mixture, coated onto a fused silica column. At a minimum the column should have sufficient retention for methanol that

it elute after n-tridecane (RI > 1300) and must have sufficient efficiency and capacity to resolve the oxygenates listed in Table 1

to provide accurate quantitative results equivalent to those shown in Section 16. A column of this description was used in the

repeatability study referred to in Section 16.

6.5 Sample Introduction:

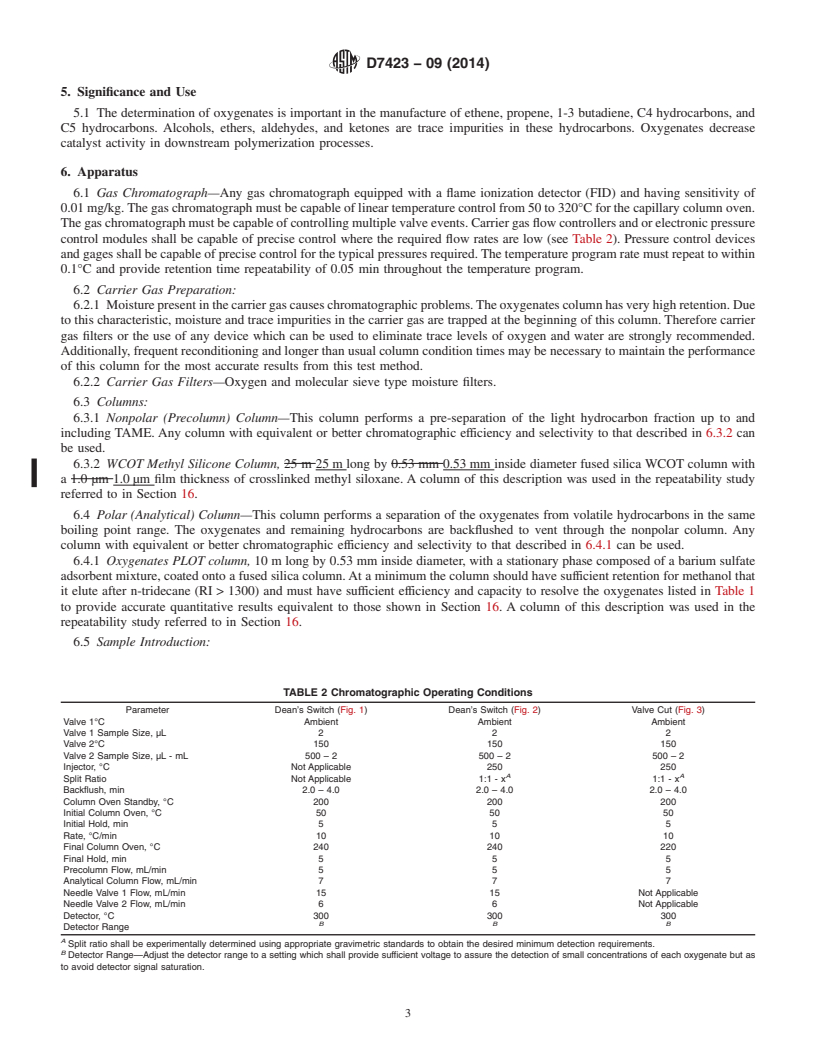

TABLE 2 Chromatographic Operating Conditions

Parameter Dean’s Switch (Fig. 1) Dean’s Switch (Fig. 2) Valve Cut (Fig. 3)

Valve 1°C Ambient Ambient Ambient

Valve 1 Sample Size, μL 2 2 2

Valve 2°C 150 150 150

Valve 2 Sample Size, μL - mL 500 – 2 500 – 2 500 – 2

Injector, °C Not Applicable 250 250

A A

Split Ratio Not Applicable 1:1 - x 1:1 - x

Backflush, min 2.0 – 4.0 2.0 – 4.0 2.0 – 4.0

Column Oven Standby, °C 200 200 200

Initial Column Oven, °C 50 50 50

Initial Hold, min 5 5 5

Rate, °C/min 10 10 10

Final Column Oven, °C 240 240 220

Final Hold, min 5 5 5

Precolumn Flow, mL/min 5 5 5

Analytical Column Flow, mL/min 7 7 7

Needle Valve 1 Flow, mL/min 15 15 Not Applicable

Needle Valve 2 Flow, mL/min 6 6 Not Applicable

Detector, °C 300 300 300

B B B

Detector Range

A

Split ratio shall be experimentally determined using appropriate gravimetric standards to obtain the desired minimum detection requirements.

B

Detector Range—Adjust the detector range to a setting which shall provide sufficient voltage to assure the detection of small concentrations of each oxygenate but as

to avoid detector signal saturation.

D7423 − 09 (2014)

6.5.1 Switching Valve—A valve with an operating temperature of 225°C and operating pressure of 27.57 bar, to be located within

a heated enclosure or in the main oven. The valve shall be of low volume design and not contribute significantly to

chromatographic deterioration.

6.5.2 Liquid Sampling Valve—A valve with an operating temperature of 75°C and operating pressure of 68.94 bar, to be located

outside of the oven and used in sampling propane concentrates, butane samples or other LPG samples. The repeatability of this

test is dependent upon a consistent cylinder pressure. It is strongly suggested that the use of a floating piston cylinder be used and

that the sample be pressurized to 13.78 bar above the vapor pressure of the sample prior to sampling.

6.5.3 Low Pressure Liquid Sampling—A valve syringe adapter may be used to sample low vapor pressure liquids such as C5

concentrates.

6.5.4 Low Pressure Gas Sampling Valve—A valve with an operating temperature of 225°C and operating pressure of 27.57 bar

to be placed in a heated enclosure maintained at approximately 150°C and used to sample ethene vapor. An external sample loop

is installed on this valve. A1000 μLA 1000 μL sample loop has been used successfully. The sample loop sample size shall be sized

experimentally to provide desired detection limits. This valve must reproduce to within 5 percent relative standard deviation on

each component.

6.5.5 Heated Valve Enclosure—Any enclosure capable of maintaining the valve and sample loop at 150°C.

6.5.6 Connecting Tees—Any tees that can provide an inert connection.

6.5.7 Tubing—Any tubing capable of providing an inert connection.

6.5.8 Needle Valve—Micrometering valve capable of low flow control 2 to 90 mL/min.

6.6 Data Acquisition—Any computerized data acquisition system shall be used for peak area integration and graphic

presentation of the chromatogram. Alternatively any integrator system can also be used for chromatographic peak area integration.

7. Reagents and Materials

7.1 Purity of Reagents—Before preparing the calibration standards, determine the purity of the oxygenate stocks and make

corrections for the impurities found. Whenever possible, use stocks of 98%98 % purity or better. The calibration materials are listed

in Table 1.

7.2 Calibration Standard Mixture—A standard mixture containing known concentrations of each oxygenate listed in Table 1

should be prepared gravimetrically. This mixture shall be used as an external calibration standard.

7.3 Compressed Hydrogen—Less than 1 mg/kg hydrocarbon impurities for FID fuel gas.

7.4 Compressed Helium—Gas purity 99.999 %. Note that helium supplies often contain low level amounts of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.