ASTM D7820-12

(Test Method)Standard Test Method for Engine Coolant Corrosion Protection Under Accelerated Thermal and Oxidizing Conditions Using a Rotating Pressure Vessel

Standard Test Method for Engine Coolant Corrosion Protection Under Accelerated Thermal and Oxidizing Conditions Using a Rotating Pressure Vessel

SIGNIFICANCE AND USE

4.1 Engines operating under severe conditions involving high temperatures, hot spot areas, entrained air, and/or small cooling systems are placing greater emphasis on engine coolant oxidation stability and corrosion protection. This standard provides an accelerated test method to assess engine coolant performance under high temperature oxidizing test conditions of new, used, and/or recycled engine coolants. The test method may also serve as a screening tool to determine oxidation stability. The test results of this method cannot stand alone as evidence of satisfactory oxidation stability and corrosion protection. The actual service of an engine coolant formulation can be determined only by more comprehensive bench, dynamometer, and field tests.

SCOPE

1.1 This test method covers determination of engine coolant corrosion protection and stability under accelerated thermal and oxidizing conditions using a rotary pressure vessel.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 6.2, 6.3, 6.4, 6.5, 6.7, 6.8, 6.9, 6.10, 11.1, 12.8, 12.9, and 12.10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7820 − 12

Standard Test Method for

Engine Coolant Corrosion Protection Under Accelerated

Thermal and Oxidizing Conditions Using a Rotating

1

Pressure Vessel

This standard is issued under the fixed designation D7820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope equipped with a pressure gauge.The pressure vessel is charged

with air or oxygen to a gage pressure of 620 kPa (90 psi, 6.2

1.1 This test method covers determination of engine coolant

bar) (see conversion factor 1), placed in a constant–tempera-

corrosion protection and stability under accelerated thermal

ture oil bath set at a controlled temperature (typically 115°C

and oxidizing conditions using a rotary pressure vessel.

(239°F) or 150°C (302°F)) and rotated axially at 100 rpm at an

1.2 The values stated in SI units are to be regarded as the

angle of 30° from horizontal for 168 h. The use of air or

standard. The values given in parentheses are for information

oxygen and test temperature is left to the discretion of the user

only.

of the test. Engine coolant performance is assessed for corro-

1.3 This standard does not purport to address all of the

sion protection based on changes in metal coupon weights and

safety concerns, if any, associated with its use. It is the coolant stability is evaluated based on changes in coolant

responsibility of the user of this standard to establish appro-

physical and compositional properties. The test method is

priate safety and health practices and determine the applica- based on a combination of ASTM D1384 (modified metal

bility of regulatory limitations prior to use. Specific hazard

coupon bundle) andASTM D2272 (glassware, pressure vessel,

statements are given in 6.2, 6.3, 6.4, 6.5, 6.7, 6.8, 6.9, 6.10, and bath apparatus) test procedures.

11.1, 12.8, 12.9, and 12.10.

100 kPa 5 1.00 bar 5 14.5 psi (1)

2. Referenced Documents

4. Significance and Use

2

2.1 ASTM Standards:

4.1 Engines operating under severe conditions involving

B32 Specification for Solder Metal

high temperatures, hot spot areas, entrained air, and/or small

D1176 Practice for Sampling and Preparing Aqueous Solu-

coolingsystemsareplacinggreateremphasisonenginecoolant

tions of Engine Coolants orAntirusts forTesting Purposes

oxidation stability and corrosion protection. This standard

D1193 Specification for Reagent Water

provides an accelerated test method to assess engine coolant

D1384 Test Method for Corrosion Test for Engine Coolants

performance under high temperature oxidizing test conditions

in Glassware

of new, used, and/or recycled engine coolants. The test method

D2272 Test Method for Oxidation Stability of Steam Tur-

may also serve as a screening tool to determine oxidation

bine Oils by Rotating Pressure Vessel

stability. The test results of this method cannot stand alone as

E1 Specification for ASTM Liquid-in-Glass Thermometers

evidence of satisfactory oxidation stability and corrosion

E230 Specification and Temperature-Electromotive Force

protection.The actual service of an engine coolant formulation

(EMF) Tables for Standardized Thermocouples

can be determined only by more comprehensive bench,

dynamometer, and field tests.

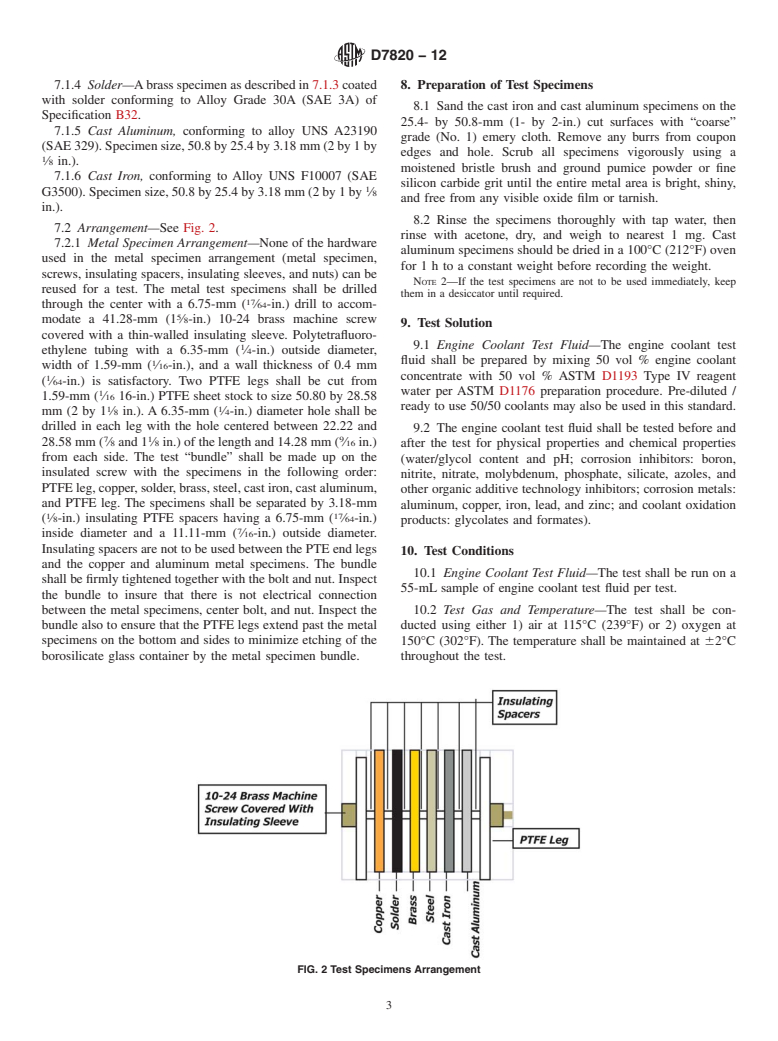

3. Summary of Test Method

5. Apparatus

3.1 The engine coolant test fluid and a metal coupon bundle

areplacedinacoveredglasswarecontainerinapressurevessel

5.1 Oxidation Vessel, Glass Sample Container with Four-

Hole Polytetrafluoroethylene (PTFE) Disk, Hold-Down

1

Spring, Pressure Gage, and Test Bath, as described in Annex

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Coolants and Related Fluids and is the direct responsibility of Subcommittee

A1. The assembled apparatus is shown schematically in Fig. 1

D15.21 on Extended Life Coolants.

and Fig. A1.5.

Current edition approved Nov. 1, 2012. Published December 2012. DOI:

10.1520/D7820-12.

5.2 Temperature-Measuring Instrument (Environmentally

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Safe Thermometer or Thermocouple)—An ASTM partial im-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mersion temperature-measuring instrument having a range

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. from –20 to 150°C (0 to 302°F) and conforming to the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7820 − 12

FIG. 1 Schematic Drawing of Rotary Pressure Vessel Test Apparatus

requirements for Thermometer 1C (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.