ASTM E585/E585M-99

(Specification)Standard Specification for Compacted Mineral-Insulated, Metal-Sheathed, Base Metal Thermocouple Cable

Standard Specification for Compacted Mineral-Insulated, Metal-Sheathed, Base Metal Thermocouple Cable

SCOPE

1.1 This specification establishes requirements for compacted, mineral-insulated, metal-sheathed, base-metal thermocouple cable, with at least two thermoelements.

1.2 This specification describes the required material, processing and testing requirements, and also the optional supplementary testing and quality assurance and verification choices.

1.3 The material of construction includes standard base metal thermoelements, austenitic stainless steel or other corrosion resistant sheath material, and either magnesia (MgO) or alumina(Al2O3) insulation.

1.4 The values stated in inch-pound units or SI units may be regarded separately as standard. The values stated in each system are not exact equivalents, and each system shall be used independently of the other.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 585/E 585M – 99

Standard Specification for

Compacted Mineral-Insulated, Metal-Sheathed, Base Metal

Thermocouple Cable

This standard is issued under the fixed designation E 585/E 585M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 632 Specification for Seamless and Welded Austenitic

Stainless Steel Tubing (Small-Diameter) for General Ser-

1.1 This specification establishes requirements for com-

vice

pacted, mineral-insulated, metal-sheathed, base metal thermo-

2 3

B 163 Specification for Seamless Nickel and Nickel Alloy

couple cable, with at least two thermoelements.

Condenser and Heat-Exchanger Tubes

1.2 This specification describes the required material, pro-

B 167 Specification for Nickel-Chromium-Iron Alloy (UNS

cessing and testing requirements, and also the optional supple-

N06600, N06601, and N06690) Seamless Pipe and Tube

mentary testing and quality assurance and verification choices.

B 516 Specification for Welded Nickel-Chromium-Iron Al-

1.3 The material of construction includes standard base

loy (UNS N06600, UNS N06603, UNS N06025, and UNS

metal thermoelements, austenitic stainless steel or other corro-

N06045) Tubes

sion resistant sheath material, and either magnesia (MgO) or

E 220 Method for Calibration of Thermocouples by Com-

alumina (Al O ) insulation.

2 3

parison Techniques

1.4 The values stated in inch-pound units or SI (metric)

E 230 Specification for Temperature—Electromotive Force

units may be regarded separately as standard. The values stated

(EMF) Tables for Standardized Thermocouples

in each system are not the exact equivalents, and each system

E 235 Specification for Thermocouples, Sheathed, Type K,

shall be used independently of the other.

for Nuclear or for Other High-Reliability Applications

1.5 This standard does not purport to address all of the

E 344 Terminology Relating to Thermometry and Hydrom-

safety concerns, if any, associated with its use. It is the

etry

responsibility of the user of this standard to establish appro-

E 608 Specification for Metal-Sheathed Base-Metal Ther-

priate safety and health practices and determine the applica-

mocouples

bility of regulatory limitations prior to use.

E 780 Test Method for Measuring the Insulation Resistance

2. Referenced Documents of Sheathed Thermocouple Material at Room Temperature

E 839 Test Methods for Sheathed Thermocouples and

2.1 The following documents of the latest issue form a part

Sheathed Thermocouple Material

of this specification to the extent specified herein. In the event

E 1652 Specification for Magnesium Oxide and Aluminum

of a conflict between this specification and other specifications

Oxide Powder and Crushable Insulators used in the Manu-

referenced herein, this specification shall take precedence.

facture of Metal-Sheathed Platinum Resistance Thermom-

2.2 ASTM Standards:

eters and Noble Metal Thermocouples

A 213/A 213M Specification for Seamless Ferritic and

2.3 ANSI Standard:

Austenitic Alloy-Steel Boiler, Superheater, and Heat-

B46.1 Surface Texture

Exchanger Tubes

A 249/A 249M Specification for Welded Austenitic Steel

3. Terminology

Boiler, Superheater, Heat-Exchanger, and Condenser

3.1 Definitions—The definitions given in Terminology

Tubes

E 344 shall apply to this specification.

A 269 Specification for Seamless and Welded Austenitic

3.2 Definitions of Terms Specific to This Standard:

Stainless Steel Tubing for General Service

3.2.1 adjacent thermoelement configuration, n—thermo-

element configuration within a multi-pair cable where two or

more positive thermoelements are immediately adjacent to one

This specification is under the jurisdiction of ASTM Committee E20 on

another around the circular pattern and two or more negative

Temperature Measurement and is the direct responsibility of Subcommittee E20.04

on Thermocouples.

thermoelements are also immediately adjacent to one another

Current edition approved Dec. 10, 1999. Published February 2000. Originally

published as E 585/E 585M-96. Last previous edition E 585/E 585M-98.

2 5

The terms “metal sheathed thermocouple cable” or “cable” will be used to Annual Book of ASTM Standards, Vol 02.04.

describe the subject description. Annual Book of ASTM Standards, Vol 14.03.

3 7

“Wire” is also used to describe “thermoelements.” Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 01.01. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 585/E 585M

FIG. 2 Examples of Alternating Configurations

FIG. 1 Examples of Adjacent Configurations

5.1.7 The kind of end seal applied to the open ends, prior to

around the circular pattern as shown in Fig. 1 (compare with

shipment (see 11.1).

alternating thermoelement configuration in Fig. 2).

5.1.8 Supplementary testing or material requirements (see

3.2.1.1 Discussion—By default, a multi-pair cable with a

Supplementary Requirements).

thermoelement in the center must be considered an adjacent

5.1.9 The quality assurance or verification program require-

configuration.

ments or both (see Appendix X1).

3.2.2 alternating thermoelement configuration, n—thermo-

5.1.10 Any deviations from this specification or the refer-

element configuration within a multi-pair cable where positive

enced documents.

thermoelements and negative thermoelements alternate around

the circular pattern as shown in Fig. 2 (compare with adjacent 6. General Requirements

thermoelement configuration in Fig. 1).

6.1 Mineral-Insulated, Metal–Sheathed Thermocouple

3.2.2.1 Discussion—In an alternating thermoelement pat-

Cable— Cable shall be in accordance with this specification

tern, there are never two or more positive thermoelements nor

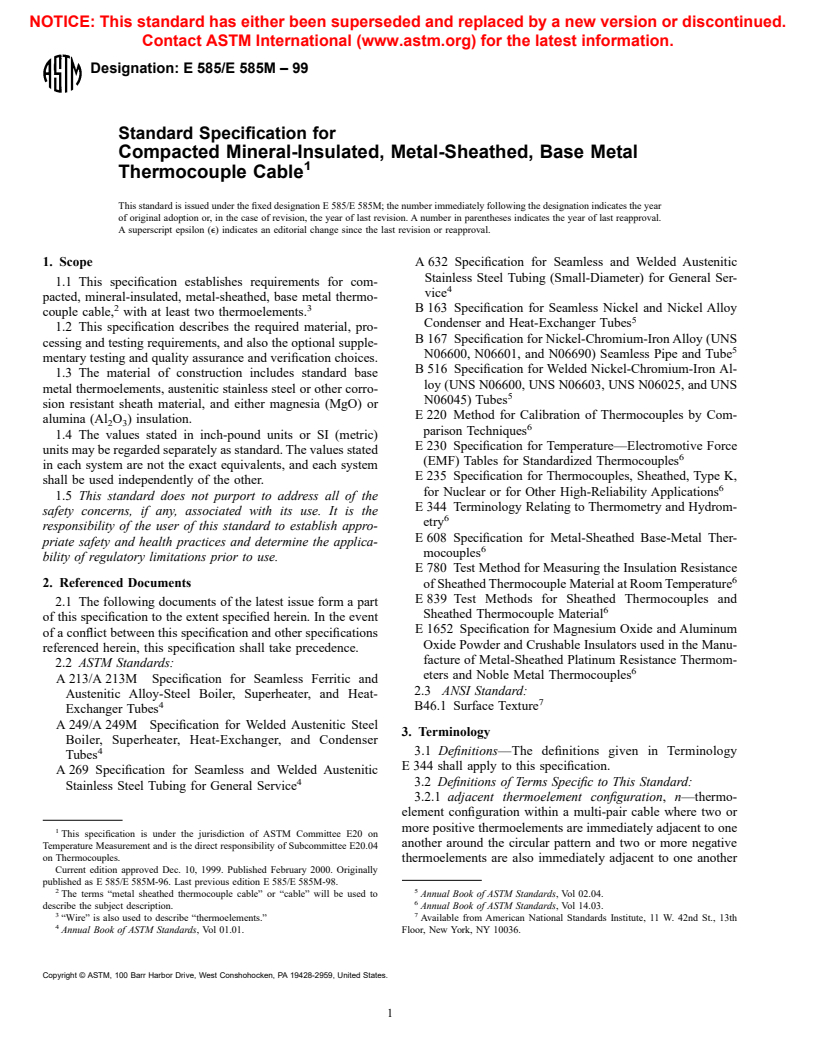

(see Fig. 3). This figure describes a cable with two thermoele-

two or more negative thermoelements immediately adjacent to

ments, but more than two thermoelements may be specified.

one another.

6.2 Tolerances on Initial Values of Emf versus

3.2.3 lot, n—a quantity of finished mineral-insulated, metal-

Temperature—The standard tolerances of Specification E 230

sheathed thermocouple cable manufactured from tubing from

apply unless otherwise stated in the ordering information.

the same heat, wire from the same spool and heat, and

6.3 Dimensions—The dimensional and tolerance require-

insulation from the same batch then assembled and processed

ments for sheath diameter and wall thickness, thermoelement

together under controlled production conditions to the required

diameter, and insulation thickness depicted in Fig. 3 shall be

final outside diameter.

based on nominal sheath outside diameters. The preferred

3.2.4 raw material, n—tubing, insulation, and wires used in

cable sizes are listed in Table 1. For any nominal sheath size,

fabrication of the sheathed thermocouple cable.

the outside diameter tolerance, A, shall be 60.025 mm [0.001

in.] or 61 %, whichever is greater. The wall thickness, B, shall

4. Significance and Use

be at least 10 % of the nominal sheath outside diameter and

4.1 Thermocouple Cable may be Used as Follows:

shall be uniform within 20 %. The thermoelement diameters,

4.1.1 Sheathed thermocouple cable for use in manufacturing

D, shall be at least 15 % of the nominal sheath outside diameter

thermocouples (see Specification E 608).

if 2 thermoelements are included, at least 12 % of the nominal

4.1.2 Sheathed thermocouple cable for use as extension

sheath outside diameter if 4 thermoelements are included, or at

cable in extremely harsh environments.

least 9 % of the nominal sheath outside diameter if 6 thermo-

elements are included. The insulation thickness, C, either

5. Ordering Information and Basis for Purchase

thermoelement to thermoelement or thermoelement to inside

5.1 The purchasing documents shall specify the following surface of the sheath, shall be at least 10% of the inside

options: diameter of the sheath. The inside sheath diameter is equal to

5.1.1 The total length of finished thermocouple cable and Diameter A minus 2 times dimension B. Dimensions shall be

the length of each piece of finished thermocouple cable. measured per Test Methods E 839. The purchaser need only

5.1.2 The type and quantity of thermoelements, the thermo- specify the outside diameter and number of thermoelements in

element configuration (see 3.2.1 and 3.2.2), and the tolerance the ordering documents.

on initial values of emf versus temperature if other than 6.4 Materials—The thermocouple cable shall be fabricated

standard (see 6.2). Consult individual manufacturers for the from component parts specified in Section 7.

number of thermoelements limited by cable size. 6.5 Insulation Resistance at Room Temperature—The mini-

5.1.3 The kind of sheath material (see 7.3) and whether it mum electric insulation resistance between thermoelements

shall be seamless or welded and drawn. Note that other sheath and between each thermoelement and the sheath (at room

material may be used with purchaser and producer agreement. temperature) shall be as specified in Table 2, for the voltages

5.1.4 The nominal outside diameter of the sheath (see 6.3). noted. The values of insulation resistance, given in megohms,

5.1.5 The kind of ceramic insulation (see 7.2). Note that shall apply to the supplied lengths. See Test Methods E 780

other insulation composition and impurity levels may be used and E 839.

with purchaser and producer agreement. 6.6 Minimum Insulation Density—The minimum density of

5.1.6 The intended operating temperature range of the cable the compacted electric insulation shall be 70 % of the maxi-

3 3

(see 9.8). mum theoretical density which is 3580 kg/m [0.129 lb/in. ] for

E 585/E 585M

and may be included in the purchasing order requirements, as

desired by the purchaser.

7. Material Requirements

7.1 Thermoelements:

7.1.1 The thermoelements shall be solid wire, round in cross

section.

FIG. 3 Sheathed Thermocouple Material Construction

7.1.2 The thermoelements shall only be of thermoelectric

(See Table 1)

types: E, J, K, N, or T. All wire used for fabrication shall meet

the supplemental cleanliness requirements of Specification

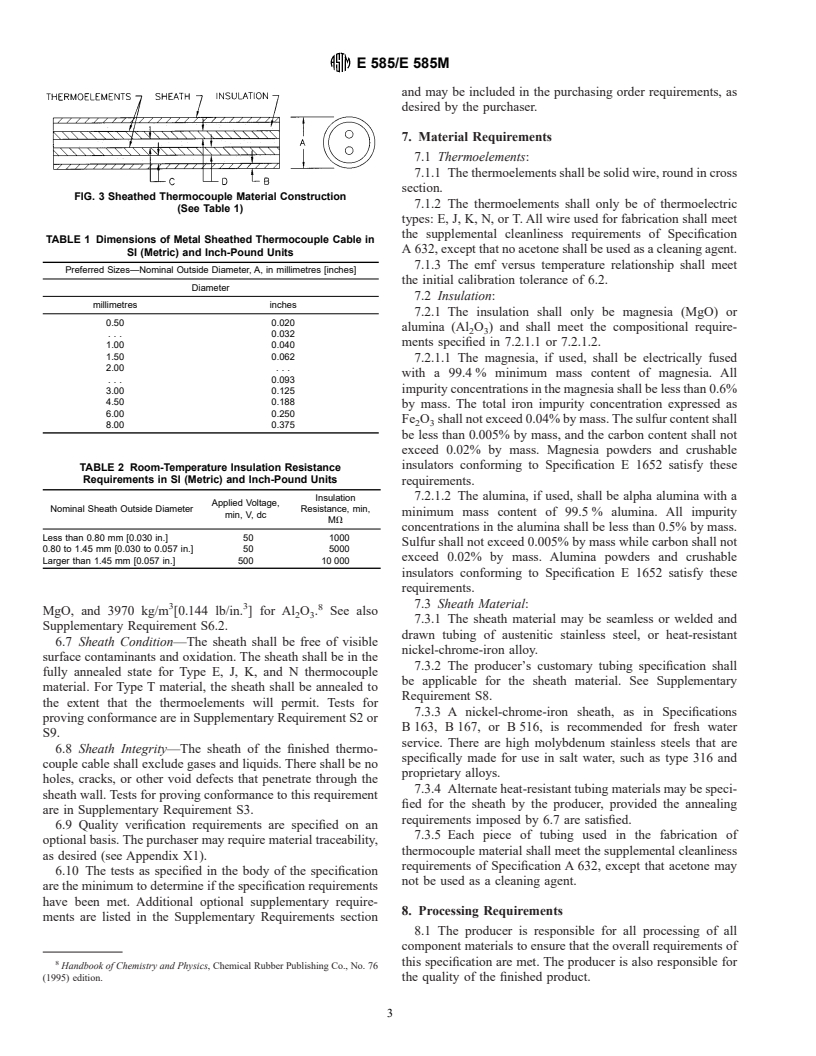

TABLE 1 Dimensions of Metal Sheathed Thermocouple Cable in

A 632, except that no acetone shall be used as a cleaning agent.

SI (Metric) and Inch-Pound Units

7.1.3 The emf versus temperature relationship shall meet

Preferred Sizes—Nominal Outside Diameter, A, in millimetres [inches]

the initial calibration tolerance of 6.2.

Diameter

7.2 Insulation:

millimetres inches

7.2.1 The insulation shall only be magnesia (MgO) or

0.50 0.020

alumina (Al O ) and shall meet the compositional require-

2 3

. . . 0.032

ments specified in 7.2.1.1 or 7.2.1.2.

1.00 0.040

1.50 0.062

7.2.1.1 The magnesia, if used, shall be electrically fused

2.00 . . .

with a 99.4 % minimum mass content of magnesia. All

. . . 0.093

impurity concentrations in the magnesia shall be less than 0.6%

3.00 0.125

4.50 0.188

by mass. The total iron impurity concentration expressed as

6.00 0.250

Fe O shall not exceed 0.04% by mass. The sulfur content shall

2 3

8.00 0.375

be less than 0.005% by mass, and the carbon content shall not

exceed 0.02% by mass. Magnesia powders and crushable

insulators conforming to Specification E 1652 satisfy these

TABLE 2 Room-Temperature Insulation Resistance

Requirements in SI (Metric) and Inch-Pound Units

requirements.

Insulation 7.2.1.2 The alumina, if used, shall be alpha alumina with a

Applied Voltage,

Nominal Sheath Outside Diameter Resistance, min,

minimum mass content of 99.5 % alumina. All impurity

min, V, dc

MV

concentrations in the alumina shall be less than 0.5% by mass.

Less than 0.80 mm [0.030 in.] 50 1000

Sulfur shall not exceed 0.005% by mass while carbon shall not

0.80 to 1.45 mm [0.030 to 0.057 in.] 50 5000

exceed 0.02% by mass. Alumina powders and crushable

Larger than 1.45 mm [0.057 in.] 500 10 000

insulators conforming to Specification E 1652 satisfy these

requirements.

7.3 Sheath Material:

3 3

MgO, and 3970 kg/m [0.144 lb/in. ] for Al O . See also

2 3

7.3.1 The sheath material may be seamless or welded and

Supplementary Requirement S6.2.

drawn tubing of austenitic stainless steel, or heat-resistant

6.7 Sheath Condition—The sheath shall be free of visible

nickel-chrome-iron alloy.

surface contaminants and oxidation. The sheath shall be in the

7.3.2 The producer’s customary tubing specification shall

fully annealed state for Type E, J, K, and N thermocouple

be applicable for the sheath material. See Supplementary

material. For Type T material, the sheath shall be annealed to

Requirement S8.

the extent that the thermoelements will permit. Tests for

7.3.3 A nickel-chrome-iron sheath, as in Specifications

proving conformance are in Supplementary Requirement S2 or

B 163, B 167, or B 516, is recommended for fresh water

S9.

service. There are high molybdenum stainless steels that are

6.8 Sheath Integrity—The sheath of the finished thermo-

specifically made for use in salt water, such as type 316 and

couple cable shall exclude gases and liquids. There shall be no

proprietary alloys.

holes, cracks, or other void defects that penetrate through the

7.3.4 Alternate heat-resistant tubing materials may be speci-

sheath wall. Tests for proving conformance to this requirement

fied for the sheath by the producer, provided the annealing

are in Supplementary Requirement S3.

requirements imposed by 6.7 are satisfied.

6.9 Quality verification requirements are specified on an

7.3.5 Each piece of tubing used in the fabrication of

optional basis. The purchaser may require material traceability,

thermocouple material shall meet the supplemental cleanliness

as desired (see Appendix X1).

requirements of Specification A 632, except that acetone may

6.10 The tests as specified in the body of the specification

not be used as a cleaning agent.

are the minimum to determine if the specification requirements

have been met. Additional optional supplementary require-

8. Processing Requirements

ments are listed in the Supplementary Requirements section

8.1 The producer is responsible for all processing of all

component materials to ensure that the overall requirements of

this specification are met. The producer is also responsible for

Handbook of Chemistry and Physics, Chemical Rubber Publishing Co., No. 76

(1995) edition. the quality of the finished product.

E 585/E 585M

TABLE 3 Standard Tests TABLE 4 Calibration Temperatures for Standard Thermocouples

Sec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.