ASTM E608/E608M-13(2019)

(Specification)Standard Specification for Mineral-Insulated, Metal-Sheathed Base Metal Thermocouples

Standard Specification for Mineral-Insulated, Metal-Sheathed Base Metal Thermocouples

ABSTRACT

This specification covers the requirements for mineral-insulated, metal-sheathed base metal thermocouples for industrial or high-reliability applications. Provisions are made herein for selecting thermoelements, and insulation and sheath materials, and measuring junction configuration, thermocouple assembly length, and the type of transition or termination. This specification also includes provisions for quality assurance or verification program requirements, or both, as the purchaser's option.

SIGNIFICANCE AND USE

4.1 This specification describes the physical requirements of mineral-insulated, metal-sheathed base metal thermocouples and establishes suitable test criteria for their evaluation.

4.2 Standardized dimensional requirements and acceptable allowances for manufacturing variations, are given.

4.3 A set of standard tests to be applied to all thermocouples covered by this specification are described, in addition to optional tests from which applicable additional requirements may be selected.

4.4 Warning—Users should be aware that certain characteristics of thermocouples might change with time and use.

4.4.1 If a thermocouple's designed shipping, storage, installation, or operating temperature has been exceeded, the thermocouple’s moisture seal may have been compromised and may no longer prevent the deleterious intrusion of water vapor. Consequently, the thermocouple's condition established by test at the time of manufacture may not apply later after an extended period of use, and retesting may become necessary.

4.4.2 In addition, inhomogeneities can develop in thermoelements because of exposure to temperature, even in cases where the maximum exposure temperatures have been lower than the suggested upper temperature limits of Table 1. For this reason, calibration of thermocouples destined for delivery to a customer is not recommended (see S6.1).

4.4.3 Furthermore, because the EMF indication of any thermocouple depends upon the condition of the thermoelements along their entire length, as well as the temperature profile pattern in the region of any inhomogeneity, the EMF output of a used thermocouple will be unique to its installation. Because temperature profiles in calibration equipment are unlikely to duplicate those of the installation, removal of a used thermocouple to a separate apparatus for calibration is not recommended. Instead, in-situ calibration by comparison to a similar thermocouple of known accuracy is recommended.

SCOPE

1.1 This specification covers the requirements for mineral-insulated, metal-sheathed base metal thermocouples for industrial or high-reliability applications. It applies specifically to thermocouples fabricated from sheathed thermocouple material in accordance with Specification E585/E585M. The specification provides for the selection of thermoelements, insulation, sheath material, measuring junction configuration, thermocouple assembly length, and the type of transition or termination.

1.2 This specification also includes provisions for either quality assurance or verification program requirements, or both, as a purchaser’s option.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of Inter...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E608/E608M −13 (Reapproved 2019) An American National Standard

Standard Specification for

Mineral-Insulated, Metal-Sheathed Base Metal

Thermocouples

This standard is issued under the fixed designation E608/E608M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers the requirements for mineral- 2.1 ASTM Standards:

insulated, metal-sheathed base metal thermocouples for indus- E165/E165M Practice for Liquid Penetrant Testing for Gen-

trial or high-reliability applications. It applies specifically to eral Industry

thermocouples fabricated from sheathed thermocouple mate- E220 Test Method for Calibration of Thermocouples By

rial in accordance with Specification E585/E585M. The speci- Comparison Techniques

fication provides for the selection of thermoelements, E230/E230M Specification for Temperature-Electromotive

insulation, sheath material, measuring junction configuration, Force (emf) Tables for Standardized Thermocouples

thermocouple assembly length, and the type of transition or E344 Terminology Relating to Thermometry and Hydrom-

termination. etry

E585/E585M Specification for Compacted Mineral-

1.2 This specification also includes provisions for either

Insulated, Metal-Sheathed, Base Metal Thermocouple

quality assurance or verification program requirements, or

Cable

both, as a purchaser’s option.

E780 Test Method for Measuring the Insulation Resistance

1.3 The values stated in either SI units or inch-pound units

of Mineral-Insulated, Metal-Sheathed Thermocouples and

are to be regarded separately as standard. The values stated in

Mineral-Insulated, Metal-Sheathed Cable at Room Tem-

each system are not necessarily exact equivalents; therefore, to

perature

ensure conformance with the standard, each system shall be

E839 Test Methods for Sheathed Thermocouples and

used independently of the other, and values from the two

Sheathed Thermocouple Cable

systems shall not be combined.

2.2 AWS Standards:

1.4 This standard does not purport to address all of the

A5.9 Specification for Corrosion-Resisting Chromium and

safety concerns, if any, associated with its use. It is the

Chromium-Nickel Steel Welding Rods and Bare Elec-

responsibility of the user of this standard to establish appro-

trodes

priate safety, health, and environmental practices and deter-

A5.14 Specification for Nickel and Nickel-Alloy BareWeld-

mine the applicability of regulatory limitations prior to use.

ing Rods and Electrodes

1.5 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1 Definitions—ThedefinitionsgiveninTerminologyE344

Development of International Standards, Guides and Recom-

shall apply to this specification.

mendations issued by the World Trade Organization Technical

3.2 Definitions of Terms Specific to This Standard:

Barriers to Trade (TBT) Committee.

1 2

This specification is under the jurisdiction of ASTM Committee E20 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Temperature Measurement and is the direct responsibility of Subcommittee E20.12 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Thermocouples - Specifications. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedMay1,2019.PublishedJuly2019.Originallyapproved the ASTM website.

in 1977. Last previous edition approved in 2013 as E608/E608M – 13. DOI: Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

10.1520/E0608_E0608M-13R19. Miami, FL 33126, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E608/E608M−13 (2019)

TABLE 1 Suggested Upper Temperature Limits for Sheathed Thermocouples

NOTE 1—This table gives the suggested upper temperature limits for the various thermocouples in several common sheath sizes. It does not take into

account environmental temperature limitations of the sheath material itself, nor does it address compatibility considerations between the thermoelement

materials and the sheath containing them. The actual maximum practical temperature in a particular situation will generally be limited to the lowest

temperature among the several factors involved. The purchaser should consult ASTM Manual 12 and other literature sources for further information

about applications.

NOTE 2—The temperature limits given here are intended only as a guide to the purchaser and should not be taken as absolute values nor as guarantees

ofsatisfactorylifeorperformance.Thesetypesandsizesaresometimesusedattemperaturesabovethegivenlimits,butusuallyattheexpenseofstability

or service life, or both. In other instances, it may be necessary to reduce the given limits in order to achieve adequate service.

Upper Temperature Limit for Various Sheath Diameters °C [°F]

Nominal Sheath Diameter Thermocouple Type

mm in. T J E K, N

0.5 0.020 260 (500) 260 (500) 300 (570) 700 (1290)

. . . 0.032 260 (500) 260 (500) 300 (570) 700 (1290)

1.0 0.040 260 (500) 260 (500) 300 (570) 700 (1290)

1.5 0.062 260 (500) 440 (825) 510 (950) 920 (1690)

2.0 . . . 260 (500) 440 (825) 510 (950) 920 (1690)

. . . 0.093 260 (500) 480 (900) 580 (1075) 1000 (1830)

3.0 0.125 315 (600) 520 (970) 650 (1200) 1070 (1960)

4.5 0.188 370 (700) 620 (1150) 730 (1350) 1150 (2100)

6.0 0.250 370 (700) 720 (1330) 820 (1510) 1150 (2100)

8.0 0.375 370 (700) 720 (1330) 820 (1510) 1150 (2100)

3.2.1 common ungrounded junction, n—measuring junc- 4.4.2 In addition, inhomogeneities can develop in thermo-

tions within the same multi-pair thermocouple that are electri- elements because of exposure to temperature, even in cases

callyisolatedfromthesheathbutelectricallyconnectedtoeach where the maximum exposure temperatures have been lower

other. thanthesuggesteduppertemperaturelimitsofTable1.Forthis

reason, calibration of thermocouples destined for delivery to a

3.2.2 isolated ungrounded junction, n—measuring junctions

customer is not recommended (see S6.1).

within the same multi-pair thermocouple that are electrically

4.4.3 Furthermore, because the EMF indication of any

isolated from the sheath and electrically isolated from each

thermocouple depends upon the condition of the thermoele-

other.

ments along their entire length, as well as the temperature

3.2.3 lot, n—a quantity of thermocouples manufactured

profile pattern in the region of any inhomogeneity, the EMF

from the same continuous length of mineral-insulated, metal-

outputofausedthermocouplewillbeuniquetoitsinstallation.

sheathed thermocouple cable.

Because temperature profiles in calibration equipment are

3.2.4 sheathed thermocouple material, n—a combination of

unlikelytoduplicatethoseoftheinstallation,removalofaused

two or more continuous thermoelements embedded in ceramic

thermocouple to a separate apparatus for calibration is not

insulation compacted within a metal protecting sheath.

recommended. Instead, in-situ calibration by comparison to a

similar thermocouple of known accuracy is recommended.

4. Significance and Use

5. Ordering Information

4.1 Thisspecificationdescribesthephysicalrequirementsof

mineral-insulated, metal-sheathed base metal thermocouples

5.1 The purchase documents shall specify the following:

and establishes suitable test criteria for their evaluation.

5.1.1 The type and quantity of thermoelement pairs, and the

4.2 Standardized dimensional requirements and acceptable tolerances, if other than standard (see 6.4 and 6.5).

5.1.2 The nominal sheath diameter. See Table 1 or Specifi-

allowances for manufacturing variations, are given.

cation E585/E585M for preferred nominal diameters.

4.3 Asetofstandardteststobeappliedtoallthermocouples

5.1.3 The insulating material (either MgO orAl O ) and its

2 3

covered by this specification are described, in addition to

respective type. See Specification E585/E585M.

optional tests from which applicable additional requirements

5.1.4 The sheath material. See Specification E585/E585M.

may be selected.

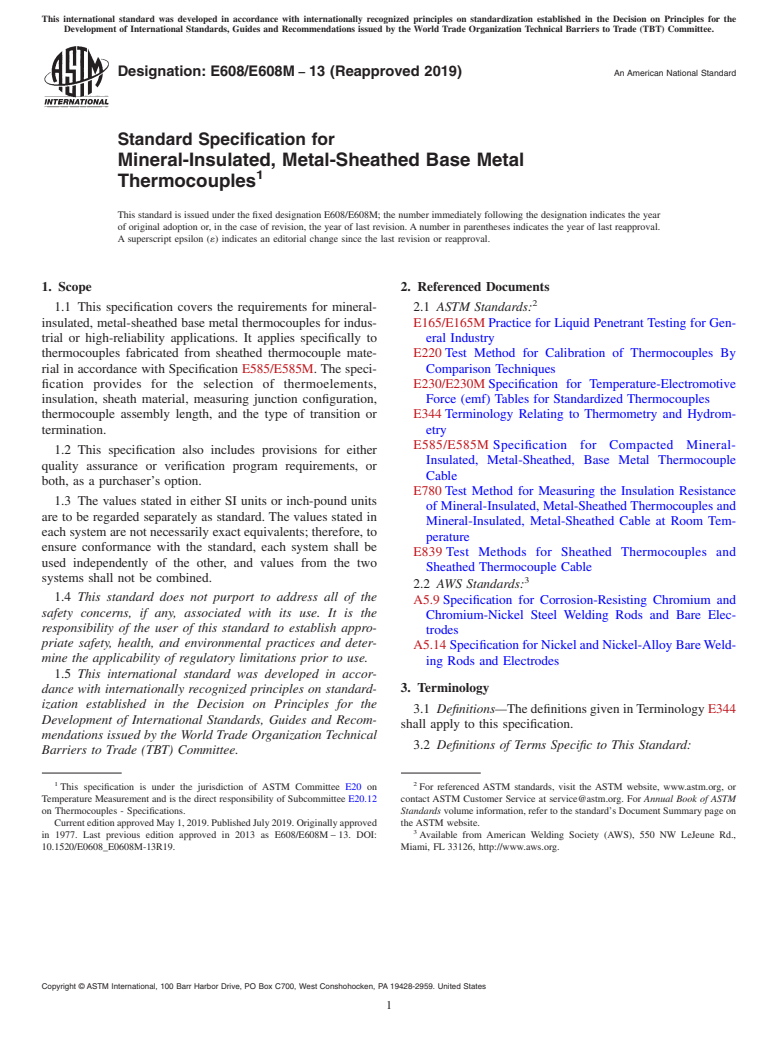

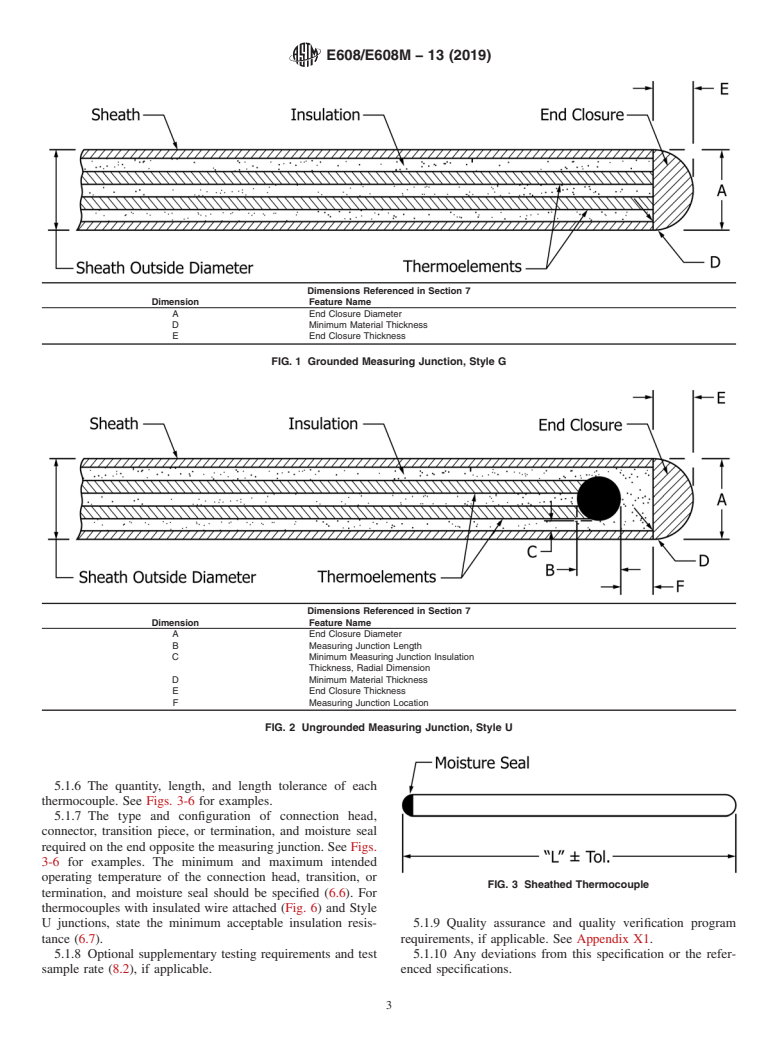

5.1.5 The style of measuring junction: Style G (grounded)

4.4 Warning—Users should be aware that certain charac-

or Style U (ungrounded). See Figs. 1 and 2. If more than one

teristics of thermocouples might change with time and use.

pair of thermoelements is specified, Style U is further subdi-

4.4.1 If a thermocouple’s designed shipping, storage,

vided into Style CU (common ungrounded) and Style IU

installation, or operating temperature has been exceeded, the

(isolated ungrounded).

thermocouple’smoisturesealmayhavebeencompromisedand

may no longer prevent the deleterious intrusion of water vapor.

Consequently, the thermocouple’s condition established by test

Style G, Style U, Style CU, and Style IU measuring junctions were previously

at the time of manufacture may not apply later after an

termed Class 1, Class 2, Class 2A, and Class 2B measuring junctions respectively.

extended period of use, and retesting may become necessary.

E608/E608M−13 (2019)

Dimensions Referenced in Section 7

Dimension Feature Name

A End Closure Diameter

D Minimum Material Thickness

E End Closure Thickness

FIG. 1 Grounded Measuring Junction, Style G

Dimensions Referenced in Section 7

Dimension Feature Name

A End Closure Diameter

B Measuring Junction Length

C Minimum Measuring Junction Insulation

Thickness, Radial Dimension

D Minimum Material Thickness

E End Closure Thickness

F Measuring Junction Location

FIG. 2 Ungrounded Measuring Junction, Style U

5.1.6 The quantity, length, and length tolerance of each

thermocouple. See Figs. 3-6 for examples.

5.1.7 The type and configuration of connection head,

connector, transition piece, or termination, and moisture seal

required on the end opposite the measuring junction. See Figs.

3-6 for examples. The minimum and maximum intended

operating temperature of the connection head, transition, or

FIG. 3 Sheathed Thermocouple

termination, and moisture seal should be specified (6.6). For

thermocouples with insulated wire attached (Fig. 6) and Style

U junctions, state the minimum acceptable insulation resis- 5.1.9 Quality assurance and quality verification program

tance (6.7). requirements, if applicable. See Appendix X1.

5.1.8 Optional supplementary testing requirements and test 5.1.10 Any deviations from this specification or the refer-

sample rate (8.2), if applicable. enced specifications.

E608/E608M−13 (2019)

TABLE 2 Weld Closure Filler Metal

AWS

Weld Rod AWS

Sheath Material Specifica-

Type

tion

Austenitic Stainless Steels

TP 304 ER 308 A5.9

TP 304L ER 308L A5.9

TP 310 ER 310 A5.9

TP 316 ER 316 A5.9

TP 316L ER 316L A5.9

TP 317 ER 317 A5.9

TP 321 ER 347 A5.9

TP 347 ER 347 A5.9

FIG. 4 Sheathed Thermocouple with Exposed Wires

TP 348 ER 348 A5.9

Nickel-chromium-iron alloy ER NiCrFe-5 A5.14

6.4 Standard Tolerances—Sheathed thermocouples fabri-

cated to this specification shall conform to the standard

tolerances (see Table 3) in accordance with Specification

E230/E230M, unless otherwise specified.

6.5 Special Tolerances—If specified in the purchase

FIG. 5 Sheathed Thermocouple Assembly with Connector or

document, the special tolerances (see Table 3) in accordance

Connection Head (Any Type Specified)

with Specification E230/E230M shall apply.

6.6 Termination—The sheathed thermocouples shall be ter-

minated at their reference junction end (the end opposite the

measuring junction end) as specified by the purchaser. All

exposed MgO or Al O shall be sealed from moisture to keep

2 3

the insulation dry. All connectors, connection heads, or transi-

tionsshallincludeapositivemethodofpreventingstrainonthe

thermoelements emerging from the sheathed material. All

FIG. 6 Sheathed Thermocouple Assembly with Transition Piece transitional wire connections shall be brazed or welded. The

moisture seal and termination (see Figs. 3-6) shall be compat-

ible with their intended installation and operating conditions

5.1.11 Shipping method and straightness criteria, if required

5 (see 5.1.7).

(see 10.2).

5.1.12 The minimum and maximum intended operating 6.7 Room Temperature Insulation Resistance (Style U

temperatures of the thermocouple (see S6.1). Junctions)—The minimum room temperature electrical insula-

tion resistance between the thermoelement pairs and the sheath

6. General Requirements

for sheathed thermocouples with Style U junctions shall be as

specified in Table 4 for the dc test voltage noted. In addition,

6.1 Tagging—During fabrication, each thermocouple shall

for Style IU (isolated ungrounded) junctions, the minimum

be tagged with a unique identification number to maintain

electrical insulation specified in Table 4 shall also apply

traceability to materials and test data. The producer’s standard

between thermoelement pairs. The minimum insulation value

tagging method may be used.

shall be negotiated between the purchaser and the producer for

6.2 Welding Rod—Filler material used for welding or plug-

Fig. 6 assemblies with purchaser-specified insulated thermo-

ging the end closure shall comply with Table 2.

couple extension wire or other devices attached. For Fig. 5

6.3 Measuring Junctions:

assemblies, the minimum insulation resistance values of Table

6.3.1 The end closure shall be impervious to gases and

4 shall be imposed before the thermocouple is terminated

liquids. There shall be no cracks, holes, or voids that penetrate

(when it is like Fig. 4).The insulation resistance shall be tested

through the metal wall. Any mineral oxide removed during

in accordance with Test Method E780.

fabricationofthemeasuringjunctionshallbereplacedwithdry

6.8 Sheath Condition—The surface of the completed ther-

oxide of the same type that is in accordance with the purity

mocouples shall be visually clean and dry.

requirementsofSpecificationE585/E585M.StyleUmeasuring

6.9 The tests specified in 8.1 are required to determine if the

junctions shall be fabricated by welding the thermoelements

specification requirements have been met. Additional optional

without filler metal or flux.

requirements are listed in the Supplementary Requirements

6.3.2 The measuring junction end closures shall be sealed

section and may be included in the purchase order require-

by welding.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.