ASTM C722-18(2023)

(Specification)Standard Specification for Chemical-Resistant Monolithic Floor Surfacings

Standard Specification for Chemical-Resistant Monolithic Floor Surfacings

ABSTRACT

This specification covers the requirements for aggregate-filled, resin-based, monolithic surfacing for use over concrete floors in areas where chemical resistance and the protection of concrete are required. The application methods for these floor surfacing shall include troweled, broadcast, slurry broadcast, self-leveling, sprayed, and reinforced. The resin chemistries include epoxy, urethane, polyester, and vinyl ester. Service conditions such as chemical exposure; traffic, and temperature conditions shall be considered in selecting the flooring system. The flooring material shall conform to the physical properties, chemical resistance, and performance requirements of the specific flooring system. The following methods shall be performed for the specific system to be tested: chemical resistance of mortars, grouts, and monolithic surfacing; test method for tensile strength of chemical-resistant mortars, grouts, and monolithic surfacing; test method for absorption of chemical-resistant mortars, grouts, and monolithic surfacing; test method for compressive strength of chemical-resistant mortars, grouts, monolithic surfacing, and polymer concretes; test method for flexural strength and modulus of elasticity of chemical-resistant mortars, grouts, monolithic surfacing, and polymer concretes; test method for determining the static coefficient of friction of ceramic tile and other like surfaces by horizontal dynamometer pull-meter method.

SCOPE

1.1 This specification covers the requirements for aggregate-filled, resin-based, monolithic surfacings for use over concrete floors in areas where chemical resistance and the protection of concrete are required.

1.2 The application methods for these floor surfacings include troweled, broadcast, slurry broadcast, self-leveling, sprayed, and reinforced. The resin chemistries include epoxy, urethane, polyester, and vinyl ester.

1.3 Floor surfacings used as vessel linings are excluded from this specification.

1.4 The values stated in SI units are to be regarded as the standard. The values in parenthesis are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C722 − 18 (Reapproved 2023)

Standard Specification for

Chemical-Resistant Monolithic Floor Surfacings

This standard is issued under the fixed designation C722; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C413 Test Method for Absorption of Chemical-Resistant

Mortars, Grouts, Monolithic Surfacings, and Polymer

1.1 This specification covers the requirements for

Concretes

aggregate-filled, resin-based, monolithic surfacings for use

C531 Test Method for Linear Shrinkage and Coefficient of

over concrete floors in areas where chemical resistance and the

Thermal Expansion of Chemical-Resistant Mortars,

protection of concrete are required.

Grouts, Monolithic Surfacings, and Polymer Concretes

1.2 The application methods for these floor surfacings

C579 Test Methods for Compressive Strength of Chemical-

include troweled, broadcast, slurry broadcast, self-leveling,

Resistant Mortars, Grouts, Monolithic Surfacings, and

sprayed, and reinforced. The resin chemistries include epoxy,

Polymer Concretes

urethane, polyester, and vinyl ester.

C580 Test Method for Flexural Strength and Modulus of

1.3 Floor surfacings used as vessel linings are excluded Elasticity of Chemical-Resistant Mortars, Grouts, Mono-

lithic Surfacings, and Polymer Concretes

from this specification.

C904 Terminology Relating to Chemical-Resistant Nonme-

1.4 The values stated in SI units are to be regarded as the

tallic Materials

standard. The values in parenthesis are provided for informa-

C1486 Practice for Testing Chemical-Resistant Broadcast

tion only.

and Slurry-Broadcast Resin Monolithic Floor Surfacings

1.5 This standard does not purport to address all of the

D638 Test Method for Tensile Properties of Plastics

safety concerns, if any, associated with its use. It is the

D790 Test Methods for Flexural Properties of Unreinforced

responsibility of the user of this standard to establish appro-

and Reinforced Plastics and Electrical Insulating Materi-

priate safety, health, and environmental practices and deter-

als

mine the applicability of regulatory limitations prior to use.

D1308 Test Method for Effect of Household Chemicals on

1.6 This international standard was developed in accor-

Clear and Pigmented Coating Systems

dance with internationally recognized principles on standard-

D2047 Test Method for Static Coefficient of Friction of

ization established in the Decision on Principles for the

Polish-Coated Flooring Surfaces as Measured by the

Development of International Standards, Guides and Recom-

James Machine

mendations issued by the World Trade Organization Technical

D6132 Test Method for Nondestructive Measurement of Dry

Barriers to Trade (TBT) Committee.

Film Thickness of Applied Organic Coatings Using an

Ultrasonic Coating Thickness Gage

2. Referenced Documents

F2508 Practice for Validation, Calibration, and Certification

2.1 ASTM Standards: of Walkway Tribometers Using Reference Surfaces

C267 Test Methods for Chemical Resistance of Mortars,

2.2 ANSI/ESD Association Standard:

Grouts, and Monolithic Surfacings and Polymer Concretes ANSI/ESD-STM7.1 ESD Association Standard Test Method

C307 Test Method for Tensile Strength of Chemical-

for Protection of Electrostatic Discharge Susceptible

Resistant Mortar, Grouts, and Monolithic Surfacings Items—Floor Materials—Resistive Characterization of

Materials

2.3 ANSI/ASSE American Society of Safety Engineers Stan-

1 dards:

This specification is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of ANSI/ASSE A1264.2 Provision of Slip Resistance on

Subcommittee D01.46 on Industrial Protective Coatings.

Walking/Working Surfaces

Current edition approved June 1, 2023. Published June 2023. Originally

ANSI/NFSI B101.3 Test Method for Measuring Wet DCOF

approved in 1972. Last previous edition approved in 2018 as C722 – 18. DOI:

of Common Hard-Surface Floor Materials

10.1520/C0722-18R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C722 − 18 (2023)

2.4 NACE/SSPC Joint Standard: 6.5 Reinforcing materials used with these flooring systems

NACE#6/SSPC-SP13 Surface Preparation of Concrete must themselves be chemical resistant. Such materials include

synthetic, carbon or fiberglass materials in mats, strands or

3. Terminology rovings.

6.6 The surfacing materials for TR, SL and SP systems are

3.1 Definitions—For definitions of terms used in this

usually installed by mixing the resin with the setting agent,

standard, see Terminology C904.

blending in the aggregate component until uniform and

homogenous, and then placing and finishing the mixture onto a

4. Significance and Use

properly prepared concrete substrate in accordance with

4.1 This standard specification covers the requirements for

NACE#6/SSPC-SP13.

floor surfacing products. When specifying surfacing over

6.7 The surfacing materials for BC systems are usually

concrete according to this standard, the floor surfacing shall be

installed by mixing the resin with the setting agent (called

classified by the application method, resin chemistry, aggregate

liquids here), and then spreading onto a properly prepared

type, and applied thickness.

concrete substrate. This is followed by broadcasting the aggre-

4.2 The specifier must consider service conditions such as

gate to excess into the wet film. The application is allowed to

chemical exposure, traffic, and temperature conditions in se-

harden. The excess aggregate is removed. The surface is then

lecting the flooring system.

topcoated with the same liquids or the application process is

4.3 Other items that are not specified in this standard but are repeated until the desired thickness is reached, and then the

surface is topcoated.

important to the performance of the floor surfacing include

condition of the concrete, concrete surface preparation, surfac-

6.8 In a SBC system, the resin, setting agent and aggregate

ing installation, and finished floor slope and surface texture.

are blended and applied on a properly prepared concrete

substrate. More aggregate is then broadcast into this slurry and

4.4 Additional items that may be required for specific

allowed to harden. The excess aggregate is removed and the

applications but are not specified in this standard include floor

system is then topcoated.

surfacing flammability, electrical conductivity, spark genera-

tion properties, and flatness and levelness.

6.9 RF systems are usually applied as the TR, SL or SP

systems. The reinforcement is usually embedded in this layer

5. Classification

and then the reinforcement is saturated with liquids. A second

TR, SL, or SP layer is then applied.

5.1 Classification by application method includes: troweled

(TR), broadcast (BC), slurry broadcast (SBC), self-leveling

6.10 The components of the floor surfacing systems are

(SL), spray (SP), and reinforced (RF). usually formulated to perform optimally at specified mixing

ratios. They are usually either packaged by the manufacturer in

5.2 Classification by resin chemistry includes epoxy (EP),

the required proportions (weight or volume) or mixing instruc-

urethane (UR), polyester (PE), and vinyl ester (VE).

tions include guidelines for mixing proportions.

6.11 Any of these systems may be topcoated. At the

6. Materials

recommendation of the manufacturer of the system, this

6.1 Most of these systems include three components: a

topcoat may be mandatory for optimal appearance and perfor-

resinous liquid, a liquid setting agent, and an aggregate

mance.

component.

6.12 Many floor surfacings include some type of finish

6.2 The resinous liquid shall be epoxy, urethane (polyol),

texture or profile incorporated into the design of the surface

polyester or vinyl ester.

that can range from relatively smooth to extremely aggressive.

6.3 The setting agents for these materials are usually amines TR systems without a sealing topcoat, BC and SBC systems

(for epoxies), isocyanates (for urethanes), and peroxides (for inherently produce surfaces with a texture. SL systems usually

polyesters and vinyl esters). produce a smooth surface. Other common methods for incor-

porating texture include: broadcasting an aggregate into a

6.4 The aggregates or fillers are usually siliceous or carbo-

topcoat (and optionally, resealing); or mixing an aggregate

naceous materials. These materials are selected to have ad-

directly into the topcoat before application.

equate resistance to the chemicals that are in the area where

6.13 Occasionally, floor surfacings are required to have

they are installed and are properly sized to provide ease of

specific conductive or static dissipative electrical properties for

application.

personnel or product protection. Specific requirements for

6.4.1 Other aggregates and/or filler components are fre-

electrical resistance are not covered in this standard. Refer to

quently used to obtain specific properties. Aluminum oxide and

ESD-S7.1 for test methods to determine this property.

silicon carbide are used to provide increased abrasion and/or

slip resistance properties in the flooring system.

6.14 In areas where flammable materials are present, it may

be required that floor surfacings be non-sparking when im-

pacted with metallic or other hard materials. Specific require-

ments for non-sparking properties are not covered in this

Available from NACE International (NACE), 15835 Park Ten Pl., Houston, TX

77084, http://www.nace.org. standard.

C722 − 18 (2023)

7. Physical Properties, Chemical Resistance and C579 Test Method for Compressive Strength of Chemical-

Performance Requirements Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer

Concretes

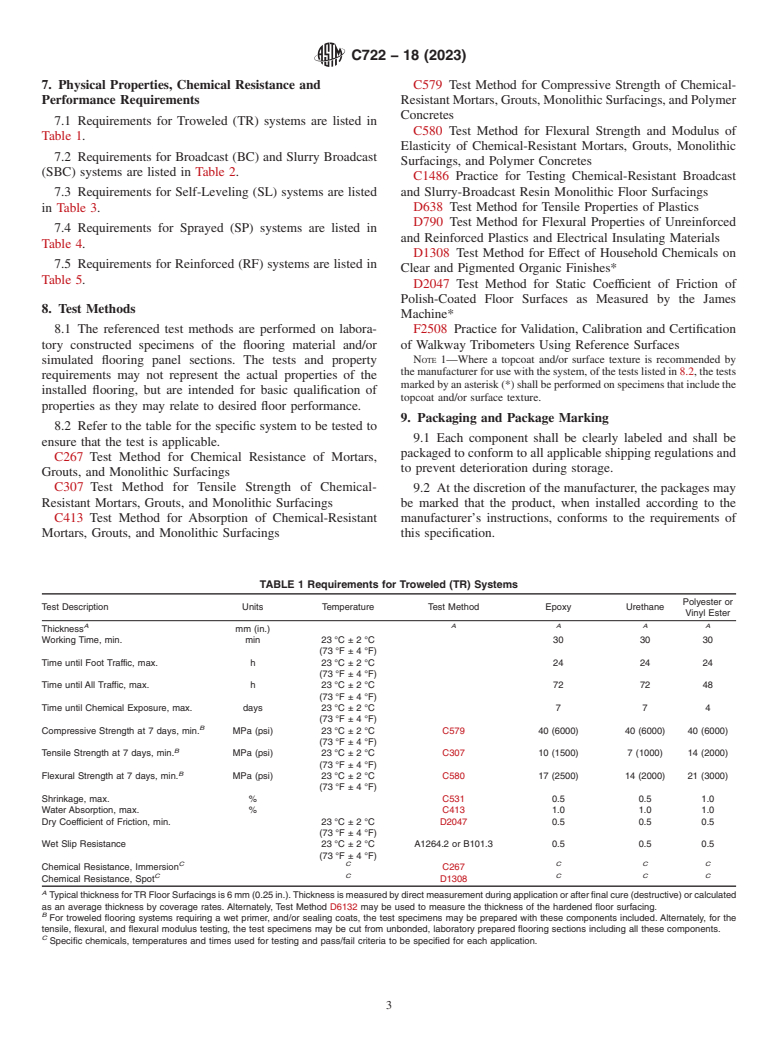

7.1 Requirements for Troweled (TR) systems are listed in

C580 Test Method for Flexural Strength and Modulus of

Table 1.

Elasticity of Chemical-Resistant Mortars, Grouts, Monolithic

7.2 Requirements for Broadcast (BC) and Slurry Broadcast

Surfacings, and Polymer Concretes

(SBC) systems are listed in Table 2.

C1486 Practice for Testing Chemical-Resistant Broadcast

7.3 Requirements for Self-Leveling (SL) systems are listed and Slurry-Broadcast Resin Monolithic Floor Surfacings

D638 Test Method for Tensile Properties of Plastics

in Table 3.

D790 Test Method for Flexural Properties of Unreinforced

7.4 Requirements for Sprayed (SP) systems are listed in

and Reinforced Plastics and Electrical Insulating Materials

Table 4.

D1308 Test Method for Effect of Household Chemicals on

7.5 Requirements for Reinforced (RF) systems are listed in

Clear and Pigmented Organic Finishes*

Table 5.

D2047 Test Method for Static Coefficient of Friction of

Polish-Coated Floor Surfaces as Measured by the James

8. Test Methods

Machine*

8.1 The referenced test methods are performed on labora- F2508 Practice for Validation, Calibration and Certification

tory constructed specimens of the flooring material and/or of Walkway Tribometers Using Reference Surfaces

NOTE 1—Where a topcoat and/or surface texture is recommended by

simulated flooring panel sections. The tests and property

the manufacturer for use with the system, of the tests listed in 8.2, the tests

requirements may not represent the actual properties of the

marked by an asterisk (*) shall be performed on specimens that include the

installed flooring, but are intended for basic qualification of

topcoat and/or surface texture.

properties as they may relate to desired floor performance.

9. Packaging and Package Marking

8.2 Refer to the table for the specific system to be tested to

9.1 Each component shall be clearly labeled and shall be

ensure that the test is applicable.

packaged to conform to all applicable shipping regulations and

C267 Test Method for Chemical Resistance of Mortars,

to prevent deterioration during storage.

Grouts, and Monolithic Surfacings

C307 Test Method for Tensile Strength of Chemical- 9.2 At the discretion of the manufacturer, the packages may

Resistant Mortars, Grouts, and Monolithic Surfacings be marked that the product, when installed according to the

C413 Test Method for Absorption of Chemical-Resistant manufacturer’s instructions, conforms to the requirements of

Mortars, Grouts, and Monolithic Surfacings this specification.

TABLE 1 Requirements for Troweled (TR) Systems

Polyester or

Test Description Units Temperature Test Method Epoxy Urethane

Vinyl Ester

A A A A A

Thickness mm (in.)

Working Time, min. min 23 °C ± 2 °C 30 30 30

(73 °F ± 4 °F)

Time until Foot Traffic, max. h 23 °C ± 2 °C 24 24 24

(73 °F ± 4 °F)

Time until All Traffic, max. h 23 °C ± 2 °C 72 72 48

(73 °F ± 4 °F)

Time until Chemical Exposure, max. days 23 °C ± 2 °C 7 7 4

(73 °F ± 4 °F)

B

Compressive Strength at 7 days, min. MPa (psi) 23 °C ± 2 °C C579 40 (6000) 40 (6000) 40 (6000)

(73 °F ± 4 °F)

B

Tensile Strength at 7 days, min. MPa (psi) 23 °C ± 2 °C C307 10 (1500) 7 (1000) 14 (2000)

(73 °F ± 4 °F)

B

Flexural Strength at 7 days, min. MPa (psi) 23 °C ± 2 °C C580 17 (2500) 14 (2000) 21 (3000)

(73 °F ± 4 °F)

Shrinkage, max. % C531 0.5 0.5 1.0

Water Absorption, max. % C413 1.0 1.0 1.0

Dry Coefficient of Friction, min. 23 °C ± 2 °C D2047 0.5 0.5 0.5

(73 °F ± 4 °F)

Wet Slip Resistance 23 °C ± 2 °C A1264.2 or B101.3 0.5 0.5 0.5

(73 °F ± 4 °F)

C C C C C

Chemical Resistance, Immersion C267

C C C C C

Chemical Resistance, Spot D1308

A

Typical thickness for TR Floor Surfacings is 6 mm (0.25 in.). Thickness is measured by direct measurement during application or after final cure (destructive) or calculated

as an average thickness by coverage rates. Alternately, Test Method D6132 may be used to measure the thickness of the hardened floor surfacing.

B

For troweled flooring systems requiring a wet primer, and/or sealing coats, the test specimens may be prepared with these components included. Alternately, for the

tensile, flexural, and flexural modulus testing, the test specimens may be cut from unbonded, laboratory prepared flooring sections including all these components.

C

Spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.