ASTM B657-05

(Test Method)Guide for Metallographic Identification of Microstructure in Cemented Carbides

Guide for Metallographic Identification of Microstructure in Cemented Carbides

SIGNIFICANCE AND USE

The microstructure of a cemented carbide affects the material’mechanical and physical properties. This guide is not intended to be used as a specification for carbide grades. Producers and users may use the microstructural information as a guide in developing their own specifications.

SCOPE

1.1 This test method covers apparatus and procedures for the metallographic determination of microstructures in cemented tungsten carbides.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Precautions applying to use of hazardous laboratory chemicals should be observed for chemicals specified in Table 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B657 – 05

Standard Guide for

Metallographic Identification of Microstructure in Cemented

1

Carbides

This standard is issued under the fixed designation B657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* not intended to be used as a specification for carbide grades.

Producersandusersmayusethemicrostructuralinformationas

1.1 This guide covers apparatus and procedures for the

a guide in developing their own specifications.

metallographic identification of microstructures in cemented

carbides.

5. Apparatus

1.2 This standard does not purport to address all of the

5.1 Metallographic Microscope capable of magnifications

safety concerns, if any, associated with its use. It is the

up to 1500 times.

responsibility of the user of this standard to establish appro-

5.2 Ordinary metallurgical laboratory equipment.

priate safety and health practices and determine the applica-

5.3 Equipment for specimen preparation as outlined in

bility of regulatory limitations prior to use. Precautions apply-

Guide B665.

ing to use of hazardous laboratory chemicals should be

observed for chemicals specified in Table 1.

6. Specimen Preparation

6.1 A suitable procedure is described in Guide B665.

2. Referenced Documents

2

2.1 ASTM Standards:

7. Procedure

B665 Guide for Metallographic Sample Preparation of Ce-

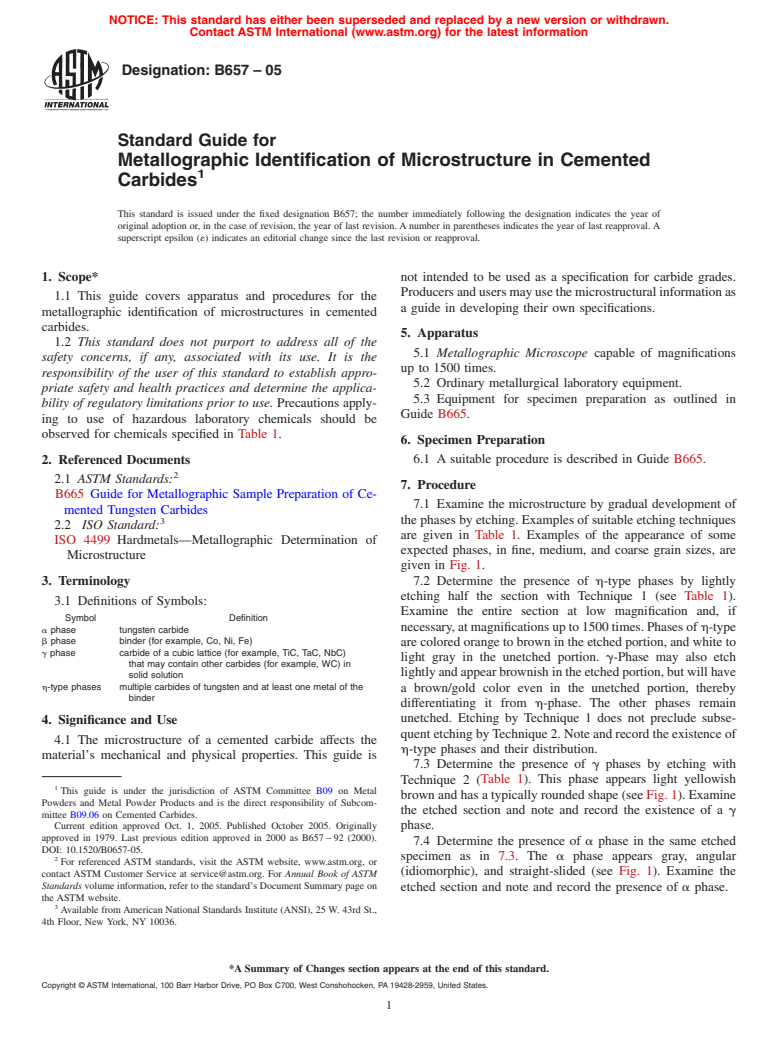

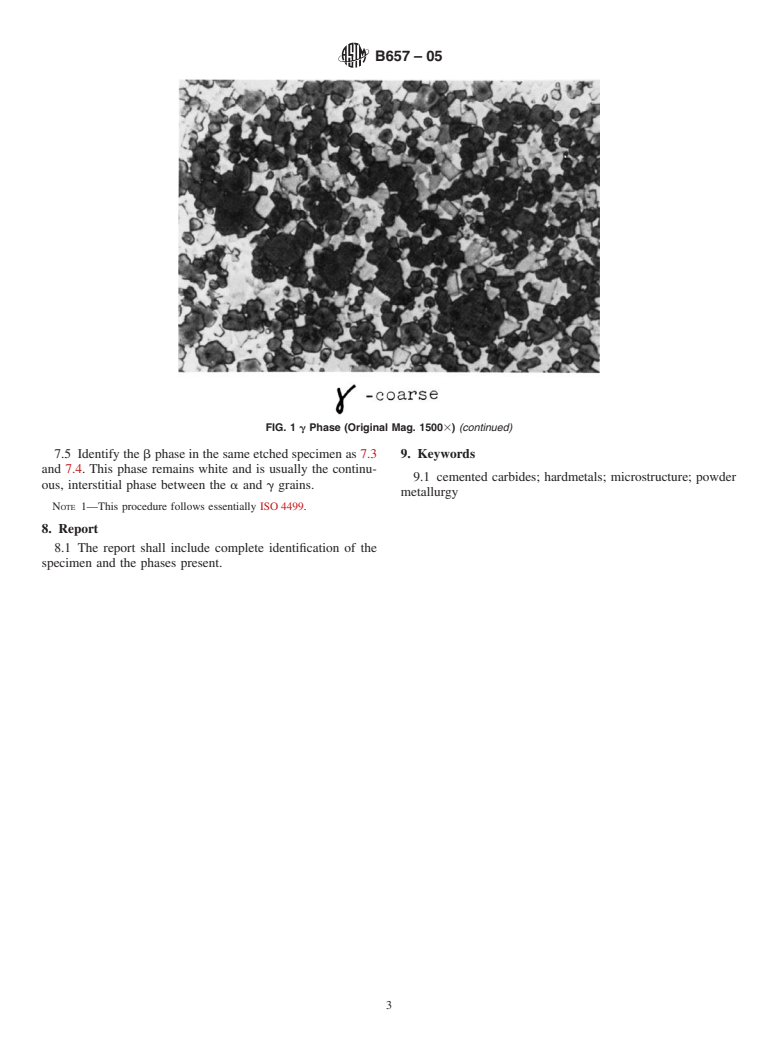

7.1 Examine the microstructure by gradual development of

mented Tungsten Carbides

3 the phases by etching. Examples of suitable etching techniques

2.2 ISO Standard:

are given in Table 1. Examples of the appearance of some

ISO 4499 Hardmetals—Metallographic Determination of

expected phases, in fine, medium, and coarse grain sizes, are

Microstructure

given in Fig. 1.

3. Terminology 7.2 Determine the presence of h-type phases by lightly

etching half the section with Technique 1 (see Table 1).

3.1 Definitions of Symbols:

Examine the entire section at low magnification and, if

Symbol Definition

necessary, at magnifications up to 1500 times. Phases of h-type

a phase tungsten carbide

b phase binder (for example, Co, Ni, Fe)

are colored orange to brown in the etched portion, and white to

g phase carbide of a cubic lattice (for example, TiC, TaC, NbC)

light gray in the unetched portion. g-Phase may also etch

that may contain other carbides (for example, WC) in

lightlyandappearbrownishintheetchedportion,butwillhave

solid solution

h-type phases multiple carbides of tungsten and at least one metal of the

a brown/gold color even in the unetched portion, thereby

binder

differentiating it from h-phase. The other phases remain

unetched. Etching by Technique 1 does not preclude subse-

4. Significance and Use

quent etching byTechnique 2. Note and record the existence of

4.1 The microstructure of a cemented carbide affects the

h-type phases and their distribution.

material’s mechanical and physical properties. This guide is

7.3 Determine the presence of g phases by etching with

Technique 2 (Table 1). This phase appears light yellowish

1

This guide is under the jurisdiction of ASTM Committee B09 on Metal

brown and has a typically rounded shape (see Fig. 1). Examine

Powders and Metal Powder Products and is the direct responsibility of Subcom-

the etched section and note and record the existence of a g

mittee B09.06 on Cemented Carbides.

Current edition approved Oct. 1, 2005. Published October 2005. Originally phase.

approved in 1979. Last previous edition approved in 2000 as B657 – 92 (2000).

7.4 Determine the presence of a phase in the same etched

DOI: 10.1520/B0657-05.

specimen as in 7.3. The a phase appears gray, angular

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(idiomorphic), and straight-slided (see Fig. 1). Examine the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

etched section and note and record the presence of a phase.

the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B657 – 05

TABLE 1 Etching Techniques

NOTE 1—The separate solutions of potassium hexacyanoferrate (III) and potassium or sodium hydroxide may be stored for a long time, but must be

freshly mixed each day when used.

Etching

Objective

Tech- Composition of Etchants Conditions of Etching

of Etching

nique

1 Fres

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.