ASTM D6512-07

(Practice)Standard Practice for Interlaboratory Quantitation Estimate

Standard Practice for Interlaboratory Quantitation Estimate

SIGNIFICANCE AND USE

Appropriate application of this practice should result in an IQE achievable by most laboratories properly using the test method studied. That is, most laboratories should be capable of measuring concentrations greater than IQEZ % with RSD = Z % or less. The IQE provides the basis for any prospective use of the test method by qualified laboratories for reliable quantitation of low-level concentrations of the same analyte as the one studied in this practice, and same media (matrix).

The IQE values may be used to compare the quantitation capability of different methods for analysis of the same analyte in the same matrix. The IQE is not an indicator of individual laboratory performance.

The IQE procedure should be used to establish the interlaboratory quantitation capability for any application of a method where interlaboratory quantitation is important to data use. The intent of the IQE is not to set reporting limits.

SCOPE

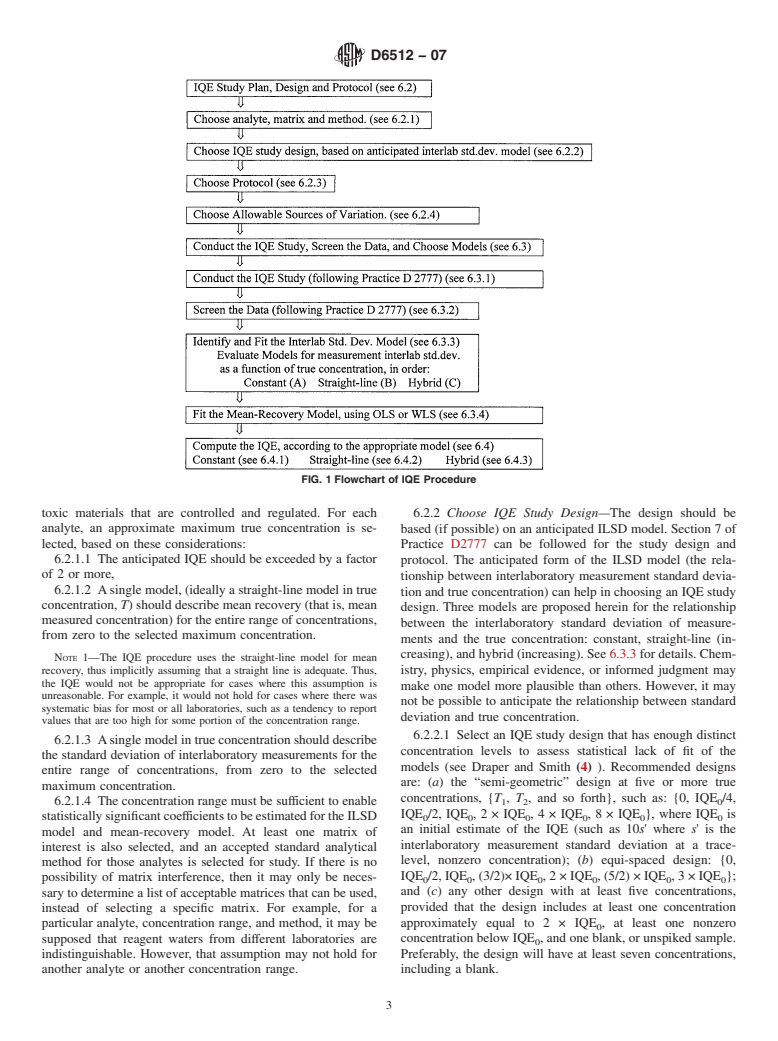

1.1 This practice establishes a uniform standard for computing the interlaboratory quantitation estimate associated with Z % relative standard deviation (referred to herein as IQEZ %), and provides guidance concerning the appropriate use and application. The calculations involved in this practice can be performed with DQCALC, Microsoft Excel-based software available from ASTM.

1.2 IQEZ % is computed to be the lowest concentration for which a single measurement from a laboratory selected from the population of qualified laboratories represented in an interlaboratory study will have an estimated Z % relative standard deviation (Z % RSD, based on interlaboratory standard deviation), where Z is typically an integer multiple of 10, such as 10, 20, or 30, but Z can be less than 10. The IQE10 % is consistent with the quantitation approaches of Currie (1) and Oppenheimer, et al (2).

1.3 The fundamental assumption of the collaborative study is that the media tested, the concentrations tested, and the protocol followed in the study provide a representative and fair evaluation of the scope and applicability of the test method as written. Properly applied, the IQE procedure ensures that the IQE has the following properties:

1.3.1 Routinely Achievable IQE Value—Most laboratories are able to attain the IQE quantitation performance in routine analyses, using a standard measurement system, at reasonable cost. This property is needed for a quantitation limit to be feasible in practical situations. Representative laboratories must be included in the data to calculate the IQE.

1.3.2 Accounting for Routine Sources of Error—The IQE should realistically include sources of bias and variation that are common to the measurement process. These sources include, but are not limited to: intrinsic instrument noise, some "typical" amount of carryover error; plus differences in laboratories, analysts, sample preparation, and instruments.

1.3.3 Avoidable Sources of Error Excluded—The IQE should realistically exclude avoidable sources of bias and variation; that is, those sources that can reasonably be avoided in routine field measurements. Avoidable sources would include, but are not limited to: modifications to the sample; modifications to the measurement procedure; modifications to the measurement equipment of the validated method, and gross and easily discernible transcription errors, provided there was a way to detect and either correct or eliminate them.

1.4 The IQE applies to measurement methods for which calibration error is minor relative to other sources, such as when the dominant source of variation is one of the following:

1.4.1 Sample Preparation, and calibration standards do not have to go through sample preparation.

1.4.2 Differences in Analysts, and analysts have little opportunity to affect calibration results (as is the case with automated calibration).

1.4.3 Differences in Laboratories (for whatever reasons), perhaps difficult to identify and eliminate.

1.4.4 Differences in I...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6512 − 07 AnAmerican National Standard

Standard Practice for

1

Interlaboratory Quantitation Estimate

This standard is issued under the fixed designation D6512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope “typical” amount of carryover error; plus differences in

laboratories, analysts, sample preparation, and instruments.

1.1 This practice establishes a uniform standard for com-

1.3.3 Avoidable Sources of Error Excluded—The IQE

putingtheinterlaboratoryquantitationestimateassociatedwith

should realistically exclude avoidable sources of bias and

Z% relative standard deviation (referred to herein as IQE ),

Z%

variation; that is, those sources that can reasonably be avoided

and provides guidance concerning the appropriate use and

in routine field measurements. Avoidable sources would

application. The calculations involved in this practice can be

include, but are not limited to: modifications to the sample;

performed with DQCALC, Microsoft Excel-based software

2 modifications to the measurement procedure; modifications to

available from ASTM.

themeasurementequipmentofthevalidatedmethod,andgross

1.2 IQE is computed to be the lowest concentration for

Z%

and easily discernible transcription errors, provided there was

which a single measurement from a laboratory selected from

a way to detect and either correct or eliminate them.

the population of qualified laboratories represented in an

1.4 The IQE applies to measurement methods for which

interlaboratory study will have an estimated Z% relative

calibration error is minor relative to other sources, such as

standard deviation (Z% RSD, based on interlaboratory stan-

when the dominant source of variation is one of the following:

dard deviation), where Z is typically an integer multiple of 10,

1.4.1 Sample Preparation, and calibration standards do not

such as 10, 20, or 30, but Z can be less than 10. The IQE

10%

3 have to go through sample preparation.

is consistent with the quantitation approaches of Currie (1)

1.4.2 Differences in Analysts,andanalystshavelittleoppor-

and Oppenheimer, et al (2).

tunitytoaffectcalibrationresults(asisthecasewithautomated

1.3 The fundamental assumption of the collaborative study

calibration).

is that the media tested, the concentrations tested, and the

1.4.3 Differences in Laboratories (for whatever reasons),

protocolfollowedinthestudyprovidearepresentativeandfair

perhaps difficult to identify and eliminate.

evaluation of the scope and applicability of the test method as

1.4.4 Differences in Instruments (measurement equipment),

written. Properly applied, the IQE procedure ensures that the

such as differences in manufacturer, model, hardware,

IQE has the following properties:

electronics, sampling rate, chemical processing rate, integra-

1.3.1 Routinely Achievable IQE Value—Most laboratories

tion time, software algorithms, internal signal processing and

are able to attain the IQE quantitation performance in routine

thresholds, effective sample volume, and contamination level.

analyses, using a standard measurement system, at reasonable

1.5 Data Quality Objectives—Typically, one would com-

cost. This property is needed for a quantitation limit to be

pute the lowest % RSD possible for any given dataset for a

feasible in practical situations. Representative laboratories

particular method. Thus, if possible, IQE would be com-

10%

must be included in the data to calculate the IQE.

puted. If the data indicated that the method was too noisy, one

1.3.2 Accounting for Routine Sources of Error—The IQE

might have to compute instead IQE , or possibly IQE .

20% 30%

should realistically include sources of bias and variation that

In any case, an IQE with a higher % RSD level (such as

are common to the measurement process. These sources

IQE ) would not be considered, though an IQE with RSD

50%

include,butarenotlimitedto:intrinsicinstrumentnoise,some

<10% (such as IQE ) would be acceptable.The appropriate

1%

level of % RSD may depend on the intended use of the IQE.

1

This practice is under the jurisdiction of ASTM Committee D19 onWater and

2. Referenced Documents

is the direct responsibility of Subcommittee D19.02 on Quality Systems,

4

Specification, and Statistics.

2.1 ASTM Standards:

Current edition approved March 1, 2007. Published April 2007. Originally

approved in 2000. Last previous edition approved in 2003 as D6512–03. DOI:

10.1520/D6512-07.

2 4

AvailablefromASTMInternationalHeadquarters.OrderAdjunctNo.ADJDQ- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CALC. Original adjunct produced in 2007. conta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.