ASTM C770-98(2003)

(Test Method)Standard Test Method for Measurement of Glass Stress—Optical Coefficient

Standard Test Method for Measurement of Glass Stress—Optical Coefficient

SIGNIFICANCE AND USE

Stress-optical coefficients are used in the determination of stress in glass. They are particularly useful in determining the magnitude of thermal residual stresses for annealing or pre-stressing (tempering) glass. As such, they can be important in specification acceptance.

SCOPE

1.1 This test method covers procedures for determining the stress-optical coefficient of glass, which is used in photoelastic analyses. In Procedure A the optical retardation is determined for a glass fiber subjected to uniaxial tension. In Procedure B the optical retardation is determined for a beam of glass of rectangular cross section when subjected to four-point bending. In Procedure C, the optical retardation is measured for a beam of glass of rectangular cross-section when subjected to uniaxial compression.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 770–98 (Reapproved 2003)

Standard Test Method for

Measurement of Glass Stress—Optical Coefficient

This standard is issued under the fixed designation C 770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope scribed in Test Method F218. The quarter-wave plate shall be

designed for the wavelength of the light being used. The

1.1 This test method covers procedures for determining the

polarizing axes of the polarizer and analyzer shall be set at

stress-optical coefficient of glass, which is used in photoelastic

right angles to each other with each being located at an angle

analyses. In Procedure A the optical retardation is determined

of 45° with the horizontal and vertical.The analyzer, however,

for a glass fiber subjected to uniaxial tension. In Procedure B

shallbemountedinarotatablemounthavingascalegraduated

the optical retardation is determined for a beam of glass of

on either side from 0 to 180°. The quarter-wave plate shall be

rectangularcrosssectionwhensubjectedtofour-pointbending.

fixed to give maximum extinction when the polarizer and

In Procedure C, the optical retardation is measured for a beam

analyzer are crossed at right angles; that is, when its polarizing

ofglassofrectangularcross-sectionwhensubjectedtouniaxial

axes are set at 45° and 135° to the horizontal and vertical. In

compression.

place of the immersion cell E, a means of supporting and

1.2 This standard does not purport to address all of the

loading a glass specimen shall be provided, either in air (Fig.

safety concerns, if any, associated with its use. It is the

3(a)) or in an immersion liquid (Fig. 3(b)). In this arrangement

responsibility of the user of this standard to establish appro-

the optical elements of the polarimeter between light source

priate safety and health practices and determine the applica-

andtelescopehavebeenreversedandalargescalegraduatedin

bility of regulatory limitations prior to use.

2-nm divisions is employed with the rotatable analyzer I.

2. Referenced Documents

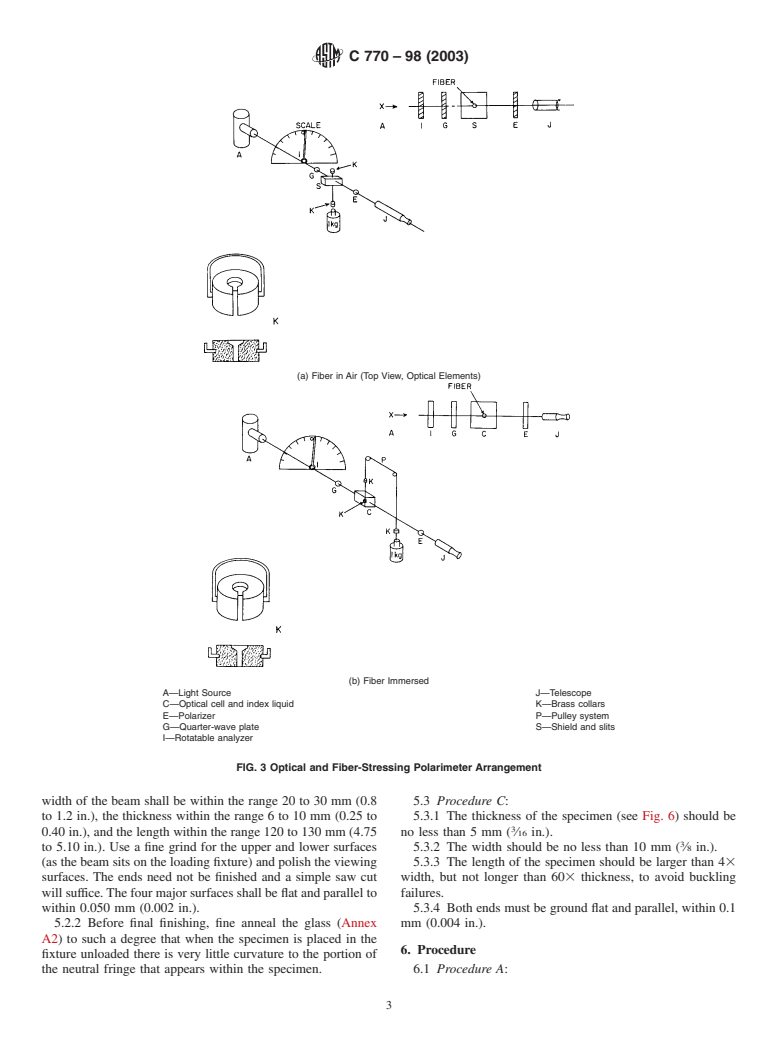

4.1.1.1 Fig. 3 illustrates the fiber-stressing and optical

arrangement used in Procedure A. Figure 3(a) shows the fiber

2.1 ASTM Standards:

mounted vertically, positioned, and supported by two brass

C336 Test Method forAnnealing Point and Strain Point of

collarswithswivelhandlessothatthekilogramweightmaybe

Glass by Fiber Elongation

appliedtoloadthefiber.Alightshieldhavingentranceandexit

C598 Test Method forAnnealing Point and Strain Point of

slitssurroundsthefiberprovidingadegreeofcollimationtothe

Glass by Beam Bending

light passing through the fiber and also helping to eliminate

F218 Test Method for Analyzing Stress in Glass

stray light.

3. Significance and Use

4.1.1.2 In Fig. 3(b) the fiber is stressed while immersed in a

liquid which matches the refractive index of the fiber. This

3.1 Stress-optical coefficients are used in the determination

arrangement provides more satisfactory viewing of the fiber.

of stress in glass. They are particularly useful in determining

4.1.2 Procedure B:

the magnitude of thermal residual stresses for annealing or

4.1.2.1 The apparatus for the beam-bending procedure is

pre-stressing (tempering) glass.As such, they can be important

shown in Fig. 4(a). Radiation from a white-light source passes

in specification acceptance.

through the following components and in this sequence: a

4. Apparatus

diffusingplate,anadjustableaperture,apolarizerwhoseaxisis

at 45° to the vertical, the glass specimen, a Babinet compen-

4.1 Stressing Equipment and Polarimeter:

sator, a polarizer whose axis is at 90° to that of the first

4.1.1 Procedure A— Figs. 1 and 2 illustrate a polarimeter

polarizer, and a telescope of modest power.

employing a quarter-wave plate and rotatable analyzer, de-

4.1.2.2 The loading scheme is shown in Fig. 4(b). Metal

fixtures shall be provided to subject the specimen to four-point

This test method is under the jurisdiction of ASTM Committee C14 on Glass

bending. A support span of 115 mm and a moment arm, a, of

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

45 mm are recommended. Dimensions within 5% of these

Physical and Mechanical Properties.

Current edition approved April 10, 2003. Published January 1999. Originally values are acceptable. Symmetrical loading is essential, and

approved in 1973. Last previous edition approved in 1995 as C770–95.

requirescarefulcenteringoftheupperloadingblock.Theknife

Annual Book of ASTM Standards, Vol 15.02.

edgesshallbefinishedtoapproximately5-mmradius.Loading

Goranson andAdams, “Measurement of Optical Path Differences,” Journal of

canbeaccomplishedthroughayoke,whichrestsinaV-groove

Franklin Institute, Vol 216, 1933, p. 475.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 770–98 (2003)

FIG. 1 Polarimeter

FIG. 2 Orientation of Polarimeter in Standard Position

in the upper loading block, and a weight pan as shown. c) Swivel-mounted loading blocks, offering at least two

However, any convenient loading scheme at the center of the degrees of swivel freedom, to avoid the loading on the edge.

upper block may be used. 4.2 Micrometer Caliper, for measuring specimen dimen-

4.1.2.3 A Babinet compensator is positioned so as to pro- sions to 0.0025 mm (0.0001 in.).

duce vertical fringes (Fig. 4(c)). The neutral fringe must fall 4.3 Weights that are known to an accuracy of 61%.

near the center of the support span. Recommended fringe

5. Test Specimen

spacing is 1000 6 200 nm of retardation per centimeter. In

actual practice the compensator is placed very close to the 5.1 Procedure A:

specimen inside the loading yoke. 5.1.1 Select a mass of the glass to be tested that has good

4.1.2.4 Atelescope is mounted in a rotating collar equipped optical quality with no heavy cords or striae. By conventional

with an angular scale which can be read to 0.1° by a vernier. lamp-working methods, draw 0.6 to 0.9 m (2 to 3 ft) of fiber

The cross hairs in the eyepiece are used to measure the tilt from the glass, sufficient to provide five specimens 76 to 102

angle of the neutral fringe as shown in Fig. 4(c). An 80-mm mm(3to4in.)longwithtaper(variationindiameteralongthe

objective lens and 103 eyepiece are adequate components for length) less than 0.025 mm (0.001 in.) and diameters in the

the telescope. range 0.635 mm (0.025 in.) to 0.760 mm (0.030 in.). The

4.1.2.5 The adjustable aperture is set at the smallest diam- difference in mutually perpendicular diameters at any point

eter that permits suitable viewing.As with the fiber apparatus, along the specimen length shall be less than 0.0076 mm

this provides some collimation and helps to eliminate stray (0.0003 in.).

light. 5.1.2 Bead both ends of each specimen by holding the end

4.1.3 Procedure C: in a flame with the fiber vertical until a bead of two to three

4.1.3.1 Polarimeter as described in Test Method F218. fiber diameters forms.

4.1.3.2 Force application frame, shown in Fig. 5 must 5.1.3 Anneal the specimens together so as to remove most

include: of the lamp-working stress (Annex A2).

a) Astrain-gage load cell and load cell indicator, capable of 5.2 Procedure B:

measuring the force applied within 1% accuracy. 5.2.1 Selectamassofglasstobetestedthathasgoodoptical

b) Hydraulic or mechanical means of applying constant qualitywithnoheavycordsorstriae.Byconventionalgrinding

force and maintaining the force during the measuring time. methods, prepare a beam of rectangular cross section. The

C 770–98 (2003)

(a) Fiber in Air (Top View, Optical Elements)

(b) Fiber Immersed

A—Light Source J—Telescope

C—Optical cell and index liquid K—Brass collars

E—Polarizer P—Pulley system

G—Quarter-wave plate S—Shield and slits

I—Rotatable analyzer

FIG. 3 Optical and Fiber-Stressing Polarimeter Arrangement

width of the beam shall be within the range 20 to 30 mm (0.8 5.3 Procedure C:

to 1.2 in.), the thickness within the range 6 to 10 mm (0.25 to 5.3.1 The thickness of the specimen (see Fig. 6) should be

0.40 in.), and the length within the range 120 to 130 mm (4.75 no less than 5 mm ( ⁄16 in.).

to 5.10 in.). Use a fine grind for the upper and lower surfaces 5.3.2 The width should be no less than 10 mm ( ⁄8 in.).

(as the beam sits on the loading fixture) and polish the viewing 5.3.3 The length of the specimen should be larger than 43

surfaces. The ends need not be finished and a simple saw cut width, but not longer than 603 thickness, to avoid buckling

willsuffice.Thefourmajorsurfacesshallbeflatandparallelto failures.

within 0.050 mm (0.002 in.). 5.3.4 Both ends must be ground flat and parallel, within 0.1

5.2.2 Before final finishing, fine anneal the glass (Annex mm (0.004 in.).

A2) to such a degree that when the specimen is placed in the

6. Procedure

fixture unloaded there is very little curvature to the portion of

the neutral fringe that appears within the specimen. 6.1 Procedure A:

C 770–98 (2003)

(a) Beam Stressing and Polarimeter Arrangement

(b) Beam Loading Scheme (c) V

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.