ASTM D1304-99

(Test Method)Standard Test Methods for Adhesives Relative to Their Use as Electrical Insulation

Standard Test Methods for Adhesives Relative to Their Use as Electrical Insulation

SCOPE

1.1 These test methods cover procedures for testing adhesives in liquid, highly viscous, solid, or set states, that are intended to be cured by electronic heating, or that are intended to provide electrical insulation, or that are intended for use in electrical apparatus.

1.2 The procedures appear in the following order: (1) Procedure for Testing Adhesives Before Use: Section Power Factor and Dielectric Constant of Liquid Adhesives 7 Direct-Current Conductivity 8 Extract Conductivity 9 Acidity and Alkalinity 10 pH Value 11 Section Power Factor and Dielectric Constant of a Dried or Cured Adhesive Film 12 Dielectric Strength 13 Volume and Surface Resistivity 14 Arc Resistance 15

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use . For a specific hazard statement, see 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1304–99

Standard Test Methods for

Adhesives Relative to Their Use as Electrical Insulation

This standard is issued under the fixed designation D 1304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Arc Resistance of Solid Electrical Insulation

D 897 Test Method for Tensile Properties of Adhesive

1.1 These test methods cover procedures for testing adhe-

Bonds

sives in liquid, highly viscous, solid, or set states, that are

D 907 Terminology of Adhesives

intended to be cured by electronic heating, or that are intended

to provide electrical insulation, or that are intended for use in

3. Terminology

electrical apparatus.

3.1 Definitions—Many terms in these test methods are

1.2 The procedures appear in the following order:

defined in Terminology D 907.

(1) Procedure for Testing Adhesives Before Use:

Section

4. Significance and Use

Power Factor and Dielectric Constant of Liquid Adhesives 7

Direct-Current Conductivity 8

4.1 Insulatingmaterialsareusedtoisolatecomponentsofan

Extract Conductivity 9

electrical system from each other and from ground, as well as

Acidity and Alkalinity 10

to provide mechanical support for the components. For this

pH Value 11

purpose, it is generally desirable to have the insulation resis-

(2) Procedures for Testing Properties of Adhesives As Used:

tance as high as possible, consistent with acceptable mechani-

Section

cal, chemical, and heat-resisting properties. Since insulation

Power Factor and Dielectric Constant of a Dried or Cured Adhesive

resistance or conductance combines both volume and surface

Film 12

Dielectric Strength 13

resistance or conductance, its measured value is most useful

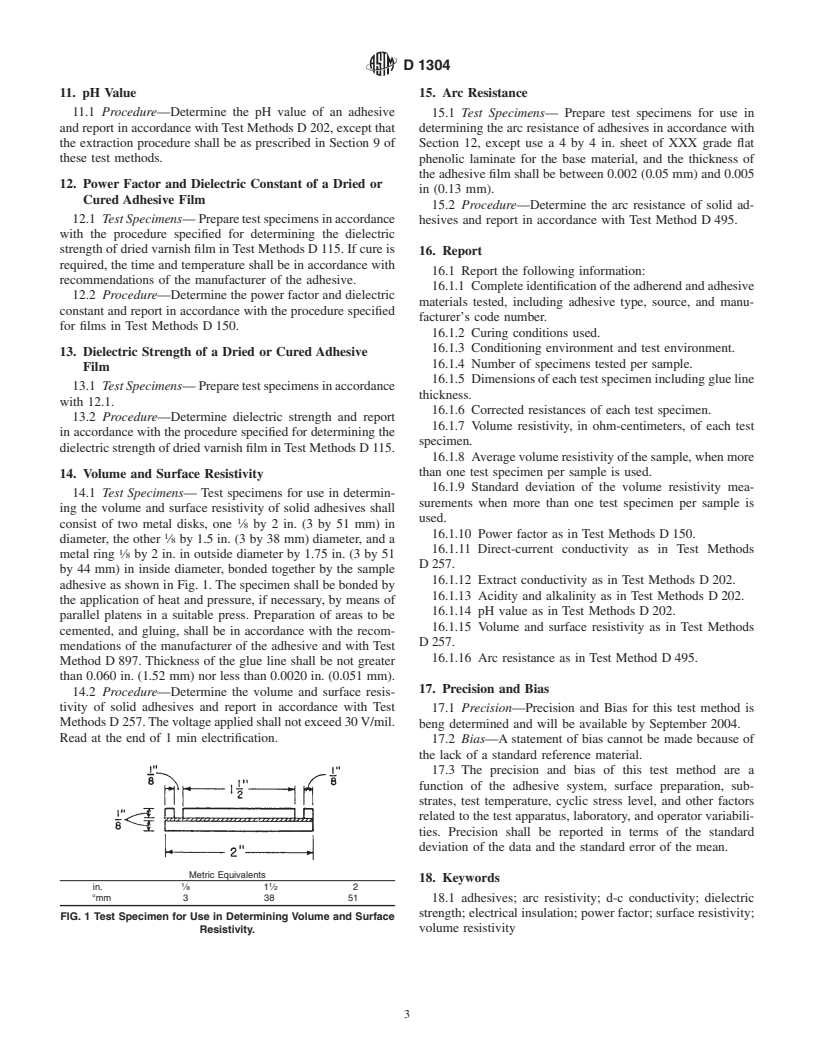

Volume and Surface Resistivity 14

when the test specimen and electrodes have the same form as

Arc Resistance 15

is required in actual use. Surface resistance or conductance

1.3 This standard does not purport to address all of the

changes rapidly with humidity, while volume resistance or

safety concerns, if any, associated with its use. It is the

conductance changes slowly although the final change may

responsibility of the user of this standard to establish appro-

eventually be greater.

priate safety and health practices and determine the applica-

4.2 Resistivity or conductivity is used to predict, indirectly,

bility of regulatory limitations prior to use. For a specific

the low-frequency dielectric breakdown and dissipation factor

hazard statement, see 8.2.

properties of some materials. Resistivity or conductivity is

often used as an indirect measure of moisture content, degree

2. Referenced Documents

of cure, mechanical continuity, and deterioration of various

2.1 ASTM Standards:

types. The usefulness of these indirect measurements is depen-

D 115 Test Methods for Testing Solvent Containing Var-

dent on the degree of correlation established by supporting

nishes Used for Electrical Insulation

theoretical or experimental investigations. A decrease of sur-

D 150 Test Methods for AC Loss Characteristics and Per-

face resistance will result either in an increase of the dielectric

mittivity (Dielectric Constant) of Solid Electrical Insula-

breakdown voltage because the electric field intensity is

tion

reduced, or a decrease of the dielectric breakdown voltage

D 202 Test Methods for Sampling and Testing Untreated

because the area under stress is increased.

Paper Used for Electrical Insulation

4.3 All the dielectric resistances or conductances depend on

D 257 Test Methods for DC Resistance or Conductance of

the length of time of electrification and on the value of applied

Insulating Materials

voltage (in addition to the usual environmental variables).

D 495 Test Method for High-Voltage, Low-Current, Dry

Thesemustbeknowntomakethemeasuredvalueofresistance

or conductance meaningful.

4.4 Volume resistivity or conductivity is used as an aid in

These test methods are under the jurisdiction of ASTM Committee D-14 and

designing an insulator for a specific application. The change of

are the direct responsibility of Subcommittee D14.80 on Metal Bonding Adhesives

Current edition approved May 10, 1999. Published August 1999. Originally

published as D 1304 – 54. Last previous edition D 1304 – 93.

2 3

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 15.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1304

resistivity or conductivity with temperature and humidity may 8.2 Pour approximately 10 g of the sample into a low-form

be great, and must be known when designing for operating weighing bottle, cover, and weigh. After removing the cover

conditions. Volume resistivity or conductivity determinations

apply heat at 70°C until the sample reaches constant weight

are often used in checking the uniformity of an insulating

(see Note 1). Then cool the sample in a desiccator and weigh.

material, either with regard to processing or to detect conduc-

NOTE 1—Caution—Care should be exercised when volatile materials

tive impurities that affect the quality of the material and that

are of such a nature as to constitute toxic, fire, or explosive hazard.

may not be readily detectable by other methods.

21 19

4.5 Volume resistivities above 10 V·cm (10 V·m), ob-

8.3 Calculations— Calculate the percentage of total solids

tained on specimens under usual laboratory conditions, are of

as follows:

doubtful validity, considering the limitations of commonly

Total solids, percent 5 wt of residue/wt of sample 3 100 (1)

used measuring equipment.

4.6 Surface resistance or conductance cannot be measured 8.4 Stirthedriedadhesiveintothesolventwithacleanglass

accurately,onlyapproximated,becausesomedegreeofvolume

rod until all the adhesive is dissolved. Return the cell to the

resistance or conductance is always involved in the measure-

solution and raise and lower it in the solution several times.

ment. The measured value is also affected by the surface

Determine volume resistivity of the solution r and calculate

contamination. Surface contamination, and its rate of accumu-

conductivity, s, as follows:

lation, is affected by many factors including electrostatic

s~ micromho cm! 5 1/r 2 1/r

0 1

charging and interfacial tension. These, in turn, may affect the

(2)

surface resistivity. Surface resistivity or conductivity can be

considered to be related to material properties when contami-

9. Extract Conductivity

nation is involved but is not a material property in the usual

sense.

9.1 Procedure—Determine the extract conductivity of an

adhesive and report in accordance with the procedure specified

5. General Considerations

for Aqueous Extract Conductivity in Test Methods D 202,

5.1 Definitions, theory, and measuring equipment pertaining except use a 5-g sample of adhesive in a solid state, or

to this method shall be in accordance with test methods already sufficient sample to be equivalent to5gof solids based on

established for the property under consideration.

determining percentage total solids in accordance with 4.2. For

adhesivessolubleinasolvent(notwater)addasuitablereagent

6. Test Specimens

grade solvent as selected or agreed upon by the manufacturer

6.1 For tests that are to be performed upon the adhesive and user, or as specified in the specification or purchase order,

itself, the specimens shall consist of an adequate representative

until the total volume is 100 ml. Stir and warm gently until the

sample which, until required, shall be kept at room temperature

sample is completely dissolved or diluted. To the solution add

in a nearly filled, tightly sealed container to avoid contamina-

slowly with constant stirring 100 ml of boiling distilled water.

tion or escape of solvents.

Gentlywarmwithconstantstirringonanelectrichotplateuntil

6.2 For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.