ASTM A125-96

(Specification)Standard Specification for Steel Springs, Helical, Heat-Treated

Standard Specification for Steel Springs, Helical, Heat-Treated

SCOPE

1.1 This specification covers hot-coiled, heat-treated helical compression springs with tapered, closed, squared and ground ends made of hot-wrought round steel bars 3/8 in. (9.5 mm) and larger in diameter.

1.2 This specification also serves to inform the user of practical manufacturing limits, mechanical tests, and inspection requirements applicable to the type of spring described in 1.1.

1.3 Supplementary Requirements S1 to S8 inclusive of an optional nature are provided. They shall apply only when specified by the purchaser. Details of these supplementary requirements shall be agreed upon by the manufacturer and purchaser.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 125 – 96 An American National Standard

Standard Specification for

Steel Springs, Helical, Heat-Treated

This standard is issued under the fixed designation A 125; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraph 4.4.1 was added and the year date changed in January 1996.

1. Scope 3.1.3 A drawing or list showing required dimensions and

loads, and part number,

1.1 This specification covers hot-coiled, heat-treated helical

3.1.4 Packaging, marking and loading, and

compression springs with tapered, closed, squared and ground

3.1.5 End use.

ends made of hot-wrought round steel bars ⁄8 in. (9.5 mm) and

larger in diameter.

NOTE 1—A typical ordering description is: 500 springs Drawing 3303

1.2 This specification also serves to inform the user of

Rev. A. to ASTM A 125, 1095 steel, for cyclical machine operation.

Palletize, maximum weight 4000 lb.

practical manufacturing limits, mechanical tests, and inspec-

tion requirements applicable to the type of spring described in

4. Materials and Manufacture

1.1.

4.1 Material:

1.3 Supplementary Requirements S1 to S8 inclusive of an

4.1.1 Unless otherwise specified, the springs shall be made

optional nature are provided. They shall apply only when

of carbon steel bars conforming to the requirements of Speci-

specified by the purchaser. Details of these supplementary

fication A 689. Due to hardenability limitations of carbon steel,

requirements shall be agreed upon by the manufacturer and

it is suggested that the bar diameter be limited to 1 ⁄8 in. (41.8

purchaser.

mm) max in order to withstand the maximum test stress

1.4 The values stated in inch-pound units are to be regarded

requirements of this specification.

as the standard. The values given in parentheses are for

4.1.2 If alloy steel is specified, the springs shall be made

information only).

from alloy steel bars conforming to Specification A 689. Any

2. Referenced Documents

of the alloy steel grades referred to may be used at the option

of the spring manufacturer, providing that a minimum as-

2.1 ASTM Standards:

quenched hardness of Rockwell HRC-50 will be achieved at

A 29/A 29M Specification for Steel Bars, Carbon and Alloy,

the center of the bar section representing the spring when

Hot-Wrought and Cold-Finished, General Requirements

quenched in the same media and manner as the spring.

for

4.1.3 Springs Made from Bars Over 2 in. (50.8 mm)—Note

A 689 Specification for Carbon and Alloy Steel Bars for

that the bias tolerance (reference A29/A 29M, Table A1.1 on

Springs

Permissible Variations in Cross Section for Hot-Wrought

E 10 Test Method for Brinell Hardness of Metallic Materi-

Round, Square, and Round-Cornered Square Bars of Steel) of

als

the bar diameter shall be taken into consideration when

E 112 Test Methods for Determining Average Grain Size

designing and calculating the solid height, spring rate, solid

E 709 Guide for Magnetic Particle Examination

stress, and solid capacity.

3. Ordering Information

4.2 Hardness:

4.2.1 The springs must be quenched and tempered to a

3.1 Orders for springs under this specification shall include

sufficiently high hardness (strength) to withstand the stresses

the following information:

developed in testing the finished spring. The maximum hard-

3.1.1 Quantity,

ness shall not exceed 477 Brinell numbers (2.80 mm indenta-

3.1.2 Name of material,

tion diameter).

4.2.2 When hardness limits are specified, the total range or

1 spread may not be less than 0.15 mm difference in indentation

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee diameters. The specified or indicated minimum hardness must

A01.15on Bars.

be sufficient to develop the required strength to withstand the

Current edition approved Jan. 25, 1996. Published February 1996. Originally

solid stresses of the spring design involved.

published as A 125 – 29 T. Last previous edition A 125 – 95.

4.2.3 Hardness shall be read on a prepared flat surface in an

Annual Book of ASTM Standards, Vol 01.05.

Annual Book of ASTM Standards, Vol 03.01.

area not detrimental to the life of the spring at a full section

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 125

TABLE 2 Brinell Hardness

after removal of the decarburized layer. A tungsten-carbide

10-mm ball shall be applied under a 3000-kg load and the

Indentation Diameter, mm Brinell Hardness Numbers

indentation diameter converted to Brinell numbers by using

2.75 495

Table 1. The values for Table 1 have been taken from

2.80 477

Specification E 10.

2.85 461

4.3 Metallurgical Requirements:

2.90 444

2.95 429

4.3.1 The total depth of decarburization, partial plus com-

3.00 415

plete as measured on the finished spring in the quenched and

3.05 401

tempered condition, shall not exceed 0.006 in. (0.15 mm) plus

3.10 388

3.15 375

1 % of the bar diameter. The decarburization shall be examined

at 1003 on a test specimen suitably etched and cut from a full

cross section of the test spring showing at least one lineal inch

of original bar circumference. 4.4.2 Springs with ground ends having a free height-to-

mean diameter ratio of not less than 1 or more than 5 shall not

4.3.2 The structure of the finished spring shall have an

average ASTM Grain Size No. 5 or finer as determined by the deviate from the perpendicular more than the number of

degrees prescribed in Table 3, as determined by standing the

latest revision of Test Methods E 112.

4.4 End Construction: spring on its end and measuring the angular deviation of a

straightedge along the outer helix from a perpendicular to the

4.4.1 End Construction-Tapered Squared and Ground—

The end bearing surfaces of the spring shall be ground to plate on which the spring is standing.

produce a firm bearing. The end bearing surfaces shall have a 4.4.3 The ends of springs shall be parallel within a tolerance

of twice that specified for the squareness of ends as determined

minimum bearing surface of two thirds of the mean coil

circumference and a minimum width of two thirds of the by standing the spring on its end and measuring the maximum

angular deviation of the other end from a plane parellel to the

hot-tapered surface of the bar. The tip ends of the bar shall be

in approximate contact with the adjacent coil, and shall not plate on which the spring is standing.

protrude beyond the maximum permissible outside diameters

5. Physical Requirements

of the spring as established by Table 2.

4.4.1.1 End Construction Coil Blunt Squared and Ground 5.1 Measurements:

(Optional)—The end bearing surfaces of the spring shall be 5.1.1 Solid Height—The solid height is the perpendicular

ground to produce a firm bearing. The end bearing surfaces distance between the plates of the testing machine when the

shall have a minimum ground bearing surface of two thirds of spring is compressed solid with the load specified in 7.3. The

the mean coil circumference and a minimum width of two solid height thus measured may be less, but shall not exceed

thirds of the bar diameter. The tip ends of the bar shall be in the specified nominal solid height by more than the limits given

approximate contact with the adjacent coil and shall not in Table 4.

protrude beyond the maximum permissible outside diameters 5.1.2 Free Height—The free height is the height of the

of the spring as established by Table 2. spring after the load specified in 7.3 has been released, and is

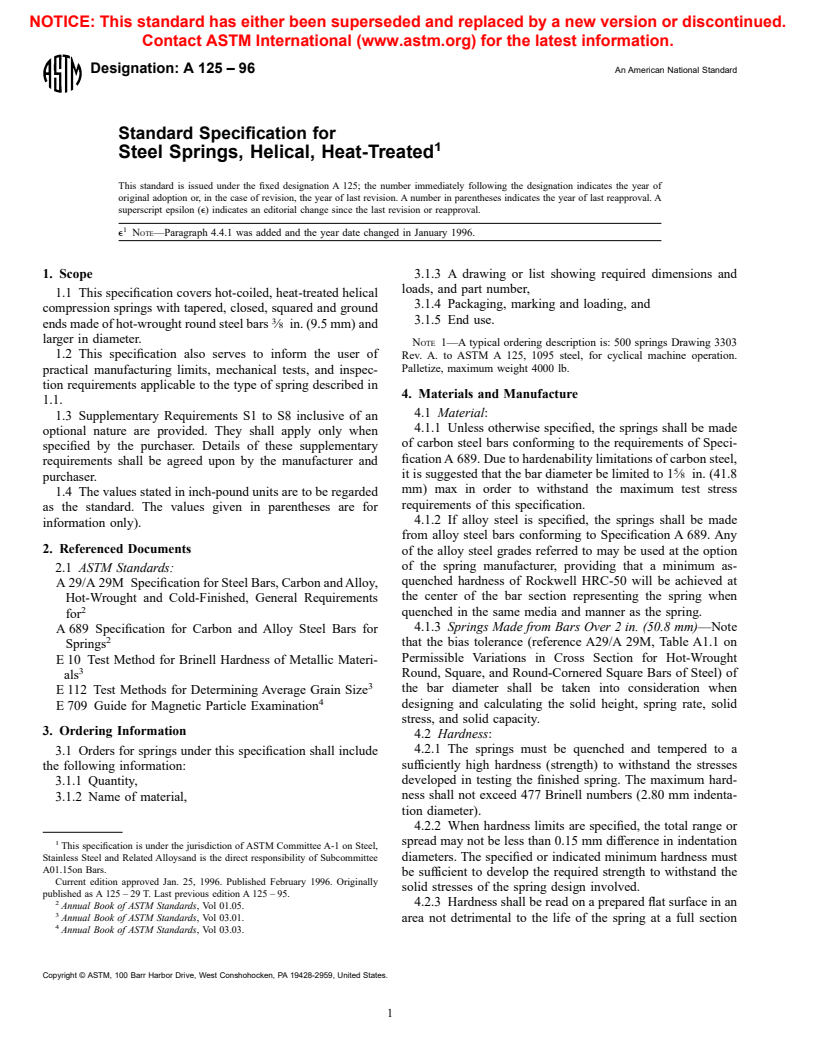

TABLE 1 Permissible Out-of-Squareness, Springs with Ground Ends

Total Travel, in. (mm) Mean Diameter, in. (mm)

2 (51) Over 2 Over 4 Over 6 Over 8 Over 10 Over 12 Over 14 Over 16 Over 18

and to 4 to 6 to 8 to 10 to 12 to 14 to 16 to 18 to 20

under (51 to (102 to (152 to (203 to (254 to (305 to (356 to (406 to (457 to

102), incl 152), incl 203), incl 254), incl 305), incl 356), incl 406), incl 457), incl 508), incl

Degree

1 1

2 (51) and under 1 ⁄4 1 ⁄4 1111 . . . .

3 1 1 1

Over 2 to 4 (51 to 102), incl 1 ⁄4 1 ⁄2 1 ⁄4 1 ⁄4 1 1 1 . . .

1 3 1 1 1

Over 4 to 6 (102 to 152), incl 2 ⁄4 1 ⁄4 1 ⁄2 1 ⁄4 1 ⁄4 1 1 . . .

1 1 3 1 1 1

Over 6 to 8 (152 to 203), incl 2 ⁄2 2 ⁄4 1 ⁄4 1 ⁄2 1 ⁄4 1 ⁄4 1 1 . .

3 1 1 1 1 1

Over 8 to 10 (203 to 254), incl 2 ⁄4 2 ⁄2 21 ⁄2 1 ⁄2 1 ⁄4 1 ⁄4 1 . .

3 1 3 1 1 1 1

Over 10 to 12 (254 to 305), incl 3 2 ⁄4 2 ⁄4 1 ⁄4 1 ⁄2 1 ⁄2 1 ⁄4 1 ⁄4 1 .

1 3 3 1 1 1 1

Over 12 to 14 (305 to 356), incl . . . 3 2 ⁄2 21 ⁄4 1 ⁄4 1 ⁄2 1 ⁄2 1 ⁄4 1 ⁄4

3 1 3 3 1 1

Over 14 to 16 (356 to 406), incl . . . . . . 2 ⁄4 2 ⁄4 22 1 ⁄4 1 ⁄4 1 ⁄2 1 ⁄2

1 1 3 3 1

Over 16 to 18 (406 to 457), incl . . . . . . 3 2 ⁄2 2 ⁄4 22 1 ⁄4 1 ⁄4 1 ⁄2

3 1 1 1 3

Over 18 to 20 (457 to 508), incl . . . . . . 3 2 ⁄4 2 ⁄2 2 ⁄4 2 ⁄4 22 1 ⁄4

3 1 1 3

Over 20 to 22 (508 to 559), incl . . . . . . . . . 3 2 ⁄4 2 ⁄4 2 ⁄4 22 1 ⁄4

1 1 3

Over 22 to 24 (559 to 610), incl . . . . . . . . . . . . 3 2 ⁄4 2 ⁄4 22 1 ⁄4

1 1 1 1

Over 24 to 26 (610 to 660), incl . . . . . . . . . . . . . . . 2 ⁄2 2 ⁄2 2 ⁄4 2 ⁄4 2

1 1 1 1

Over 26 to 28 (660 to 701), incl . . . . . . . . . . . . . . . 2 ⁄2 2 ⁄2 2 ⁄4 2 ⁄4 2

3 1 1 1

Over 28 to 30 (702 to 762), incl . . . . . . . . . . . . . . . 2 ⁄4 2 ⁄2 2 ⁄4 2 ⁄4 2

3 3 1 1

Over 30 to 32 (762 to 813), incl . . . . . . . . . . . . . . . 2 ⁄4 2 ⁄4 2 ⁄2 2 ⁄2 .

3 3 1 1

Over 32 to 34 (813 to 864), incl . . . . . . . . . . . . . . . 2 ⁄4 2 ⁄4 2 ⁄2 2 ⁄2 .

3 3 3

Over 34 to 38 (864 to 914), incl . . . . . . . . . . . . . . . 3 2 ⁄4 2 ⁄4 2 ⁄4 .

3 3

Over 36 to 38 (914 to 965), incl . . . . . . . . . . . . . . . . . . 3 2 ⁄4 2 ⁄4 .

Over 38 to 42 (965 to 1016), incl . . . . . . . . . . . . . . . . . . . . . 3 3 . . .

A 125

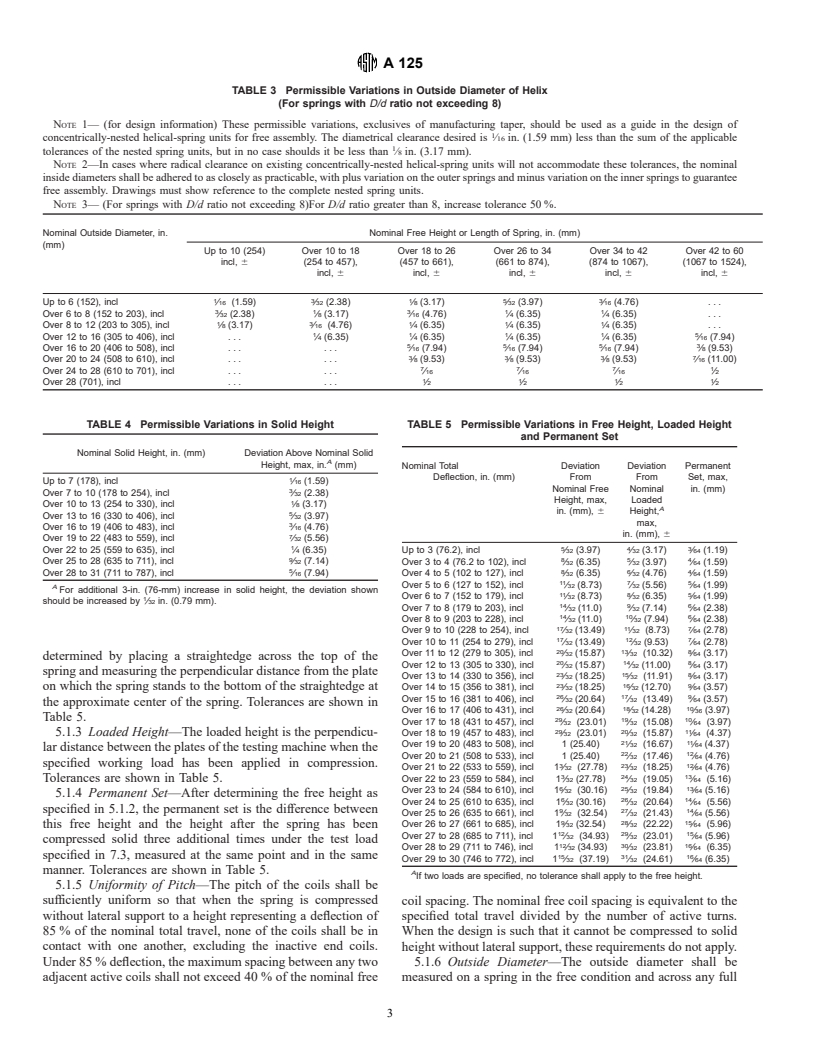

TABLE 3 Permissible Variations in Outside Diameter of Helix

(For springs with D/d ratio not exceeding 8)

NOTE 1— (for design information) These permissible variations, exclusives of manufacturing taper, should be used as a guide in the design of

concentrically-nested helical-spring units for free assembly. The diametrical clearance desired is ⁄16 in. (1.59 mm) less than the sum of the applicable

tolerances of the nested spring units, but in no case shoulds it be less than ⁄8 in. (3.17 mm).

NOTE 2—In cases where radical clearance on existing concentrically-nested helical-spring units will not accommodate these tolerances, the nominal

inside diameters shall be adhered to as closely as practicable, with plus variation on the outer springs and minus variation on the inner springs to guarantee

free assembly. Drawings must show reference to the complete nested spring units.

NOTE 3— (For springs with D/d ratio not exceeding 8)For D/d ratio greater than 8, increase tolerance 50 %.

Nominal Outside Diameter, in. Nominal Free Height or Length of Spring, in. (mm)

(mm)

Up to 10 (254) Over 10 to 18 Over 18 to 26 Over 26 to 34 Over 34 to 42 Over 42 to 60

incl, 6 (254 to 457), (457 to 661), (661 to 874), (874 to 1067), (1067 to 1524),

incl, 6 incl, 6 incl, 6 incl, 6 incl, 6

1 3 1 5 3

Up to 6 (152), incl ⁄16 (1.59) ⁄32 (2.38) ⁄8 (3.17) ⁄32 (3.97) ⁄16 (4.76) . . .

3 1 3 1 1

Over 6 to 8 (152 to 203), incl ⁄32 (2.38) ⁄8 (3.17) ⁄16 (4.76) ⁄4 (6.35) ⁄4 (6.35) . . .

1 3 1 1 1

Over 8 to 12 (203 to 305), incl ⁄8 (3.17) ⁄16 (4.76) ⁄4 (6.35) ⁄4 (6.35) ⁄4 (6.35) . . .

1 1 1 1 5

Over 12 to 16 (305 to 406), incl . . . ⁄4 (6.35) ⁄4 (6.35) ⁄4 (6.35) ⁄4 (6.35) ⁄16 (7.94)

5 5 5 3

Over 16 to 20 (406 to 508), incl . . . . . . ⁄16 (7.94) ⁄16 (7.94) ⁄16 (7.94) ⁄8 (9.53)

3 3 3 7

Over 20 to 24 (508 to 610), incl . . . . . . ⁄8 (9.53) ⁄8 (9.53) ⁄8 (9.53) ⁄16 (11.00)

7 7 7 1

Over 24 to 28 (610 to 701), incl . . . . . . ⁄16 ⁄16 ⁄16 ⁄2

1 1 1 1

Over 28 (701), incl . . . . . . ⁄2 ⁄2 ⁄2 ⁄2

TABLE 4 Permissible Variations in Solid Height TABLE 5 Permissible Variations in Free Height, Loaded Height

and Permanent Set

Nominal Solid Height, in. (mm) Deviation Above Nominal Solid

A

Height, max, in. (mm)

Nominal Total Deviation Deviation Permanent

Deflection, in. (mm) From From Set, max,

Up to 7 (178), incl ⁄16 (1.59)

Nominal Free Nominal in. (mm)

Over 7 to 10 (178 to 254), incl ⁄32 (2.38)

Height, max, Loaded

Over 10 to 13 (254 to 330), incl ⁄8 (3.17)

A

in. (mm), 6 Height,

Over 13 to 16 (330 to 406), incl ⁄32 (3.97)

max,

Over 16 to 19 (406 to 483), incl ⁄16 (4.76)

in. (mm), 6

Over 19 to 22 (483 to 559), incl ⁄32 (5.56)

5 4 3

Over 22 to 25 (559 to 635), incl ⁄4 (6.35)

Up to 3 (76.2), incl ⁄32 (3.97) ⁄32 (3.17) ⁄64 (1.19)

9 8 5 4

Over 25 to 28 (635 to 711), incl ⁄32 (7.14) Over 3 to 4 (76.2 to 102), incl ⁄32 (6.35) ⁄32 (3.97) ⁄64 (1.59)

8 6 4

Over 28 to 31 (711 to 787), incl ⁄16 (7.94)

Over 4 to 5 (102 to 127), incl ⁄32 (6.35) ⁄32 (4.76) ⁄64 (1.59)

11 7 5

Over 5 to 6 (127 to 152), incl ⁄32 (8.73) ⁄32 (5.56) ⁄64 (1.99)

A

For additional 3-in. (76-mm) increase in solid height, the deviation shown

11 8 5

Over 6 to 7 (152 to 179), incl ⁄32 (8.73) ⁄32 (6.35) ⁄64 (1.99)

should be increased by ⁄32 in. (0.79 mm).

14 9 6

Over 7 to 8 (179 to 203), incl ⁄32 (11.0) ⁄32 (7.14) ⁄64 (2.38)

14 10 6

Over 8 to 9 (203 to 228), incl ⁄32 (11.0) ⁄32 (7.94) ⁄64 (2.38)

17 11 7

Over 9 to 10 (228 to 254), incl ⁄32 (13.49) ⁄32 (8.73) ⁄64 (2.78)

17 12 7

Over 10 to 11 (254 to 279), incl ⁄32 (13.49) ⁄32 (9.53) ⁄64 (2.78)

20 13 8

Over 11 to 12 (279 to 305), incl ⁄32 (15.87) ⁄32 (10.32) ⁄64 (3.17)

determined by placing a straightedge across the top of the

20 14 8

Over 12 to 13 (305 to 330), incl ⁄32 (15.87) ⁄32 (11.00) ⁄64 (3.17)

spring and measuring the perpendicular distance from the plate

23 15 8

Over 13 to 14 (330 to 356), incl ⁄32 (18.25) ⁄32 (11.91) ⁄64 (3.17)

23 16 9

on which the spring stands to the bottom of the straightedge at Over 14 to 15 (356 to 381), incl ⁄32 (18.25) ⁄32 (12.70) ⁄64 (3.57)

26 17 9

Over 15 to 16 (381 to 406), incl ⁄32 (20.64) ⁄32 (13.49) ⁄64 (3.57)

the approximate center of the spring. Tolerances are shown in

26 18 10

Over 16 to 17 (406 to 431), incl ⁄32 (20.64) ⁄32 (14.28) ⁄36 (3.97)

Table 5.

29 19 10

Over 17 to 18 (431 to 457), incl ⁄32 (23.01) ⁄32 (15.08) ⁄64 (3.97)

29 20 11

5.1.3 Loaded Height—The loaded height is the perpendicu- Over 18 to 19 (457 to 483), incl ⁄32 (23.01) ⁄32 (15.87) ⁄64 (4.37)

21 11

Over 19 to 20 (483 to 508), incl 1 (25.40) ⁄32 (16.67) ⁄64 (4.37)

lar distance between the plates of the testing machine when the

22 12

Over 20 to 21 (508 to 533), incl 1 (25.40) ⁄32 (17.46) ⁄64 (4.76)

specified working load has been applied in compression. 3 23 12

Over 21 to 22 (533 to 559), incl 1 ⁄32 (27.78) ⁄32 (18.25) ⁄64

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.