ASTM D6361-98(2004)e1

(Guide)Standard Guide for Selecting Cleaning Agents and Processes

Standard Guide for Selecting Cleaning Agents and Processes

SIGNIFICANCE AND USE

This guide is to be used by anyone developing cleaning requirements for specifications for manufacturing, maintenance, or overhaul. This guide has been designed to be application specific for each cleaning task and to assure the design engineer that the process selected by the industrial or manufacturing engineer will be compatible with both the part material and the subsequent process(es). This guide allows the industrial or manufacturing engineer to customize the selection of the cleaning product based on the materials of the part being cleaned; the cleanliness required for the subsequent process(es); and the environmental, cost, and health and safety concerns.

SCOPE

1.1 This guide is intended to assist design engineers, manufacturing/industrial engineers, and production managers in selecting the best fit cleaning agent and process. This guide takes into account environmental pollution prevention factors in a selection process.

1.2 This guide is not to be considered as a database of acceptable materials. It will guide the engineers and managers through the cleaning material selection process, calling for engineers to customize their selection based on the cleaning requirements for the cleaning tasks at hand. If a part can be cleaned, and kept clean, it can be cycled through several process steps that have cleaning requirements. This eliminates extra cleaning process steps during the total process. A total life cycle cost analysis or performance/cost of ownership study is recommended to compare the methods available.

1.3 This guide is for general industry manufacturing, equipment maintenance and remanufacturing operations, and to some extent precision cleaning of mechanical parts and assemblies. It is not intended to be used for optical, medical, or electronics applications, nor is it intended for dry-cleaning or super-critical fluid cleaning.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6361–98(Reapproved2004)

Standard Guide for

Selecting Cleaning Agents and Processes

This standard is issued under the fixed designation D6361; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout in May 2004.

1. Scope D3167 Test Method for Floating Roller Peel Resistance of

Adhesives

1.1 This guide is intended to assist design engineers,

D3278 Test Methods for Flash Point of Liquids by Small

manufacturing/industrial engineers, and production managers

Scale Closed-Cup Apparatus

in selecting the best fit cleaning agent and process. This guide

D3519 Test Method for Foam in Aqueous Media (Blender

takes into account environmental pollution prevention factors

Test)

in a selection process.

D3601 Test Method for Foam In Aqueous Media (Bottle

1.2 This guide is not to be considered as a database of

Test)

acceptable materials. It will guide the engineers and managers

D3707 Test Method for Storage Stability of Water-in-Oil

through the cleaning material selection process, calling for

Emulsions by the Oven Test Method

engineers to customize their selection based on the cleaning

D3709 Test Method for Stability of Water-in-Oil Emulsions

requirements for the cleaning tasks at hand. If a part can be

Under Low to Ambient Temperature Cycling Conditions

cleaned, and kept clean, it can be cycled through several

D3762 Test Method forAdhesive-Bonded Surface Durabil-

process steps that have cleaning requirements. This eliminates

ity of Aluminum (Wedge Test)

extracleaningprocessstepsduringthetotalprocess.Atotallife

E70 Test Method for pH of Aqueous Solutions With the

cycle cost analysis or performance/cost of ownership study is

Glass Electrode

recommended to compare the methods available.

E1720 Test Method for Determining Ready, Ultimate, Bio-

1.3 This guide is for general industry manufacturing, equip-

degradabilityofOrganicChemicalsinaSealedVesselCO

ment maintenance and remanufacturing operations, and to

Production Test

some extent precision cleaning of mechanical parts and assem-

F483 Practice for Total Immersion Corrosion Test for Air-

blies. It is not intended to be used for optical, medical, or

craft Maintenance Chemicals

electronics applications, nor is it intended for dry-cleaning or

F484 Test Method for Stress Crazing of Acrylic Plastics in

super-critical fluid cleaning.

Contact with Liquid or Semi-Liquid Compounds

2. Referenced Documents

F485 Practice for Effects of Cleaners on UnpaintedAircraft

Surfaces

2.1 ASTM Standards:

F502 Test Method for Effects of Cleaning and Chemical

D56 Test Method for Flash Point by Tag Closed Cup Tester

Maintenance Materials on Painted Aircraft Surfaces

D92 Test Method for Flash and Fire Points by Cleveland

F519 Test Method for Mechanical Hydrogen Embrittlement

Open Cup Tester

Evaluation of Plating/Coating Processes and Service Envi-

D93 Test Methods for Flash Point by Pensky-Martens

ronments

Closed Cup Tester

F945 Test Method for Stress-Corrosion of Titanium Alloys

D2240 Test Method for Rubber Property—Durometer

by Aircraft Engine Cleaning Materials

Hardness

F1104 Test Method for Preparing Aircraft Cleaning Com-

pounds, Liquid Type, Water Base, for Storage Stability

This guide is under the jurisdiction of ASTM Committee D26 on Halogenated

Testing

Organic Solvents and Fire Extinguishing Agents and is the direct responsibility of

F1110 Test Method for Sandwich Corrosion Test

Subcommittee D26.03 on Cold Cleaning.

F1111 Test Method for Corrosion of Low-Embrittling Cad-

Current edition approved May 1, 2004. Published June 2004. Originally

approved in 1998. Last previous edition approved in 1998 as D6361-98. DOI:

mium Plate by Aircraft Maintenance Chemicals

10.1520/D6361-98R04E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6361–98 (2004)

G44 Practice for Exposure of Metals and Alloys by Alter- 5. Significance and Use

nate Immersion in Neutral 3.5 % Sodium Chloride Solu-

5.1 This guide is to be used by anyone developing cleaning

tion

requirements for specifications for manufacturing, mainte-

G121 Practice for Preparation of Contaminated Test Cou-

nance, or overhaul. This guide has been designed to be

pons for the Evaluation of Cleaning Agents

application specific for each cleaning task and to assure the

G122 Test Method for Evaluating the Effectiveness of

design engineer that the process selected by the industrial or

Cleaning Agents

manufacturing engineer will be compatible with both the part

2.2 Other Documents:

material and the subsequent process(es). This guide allows the

Aerospace Material Specification (AMS) 3204/AMS 3209

industrial or manufacturing engineer to customize the selection

Test for Rubber Compatibility

of the cleaning product based on the materials of the part being

ARP 1795 StockLoss Corrosion

cleaned; the cleanliness required for the subsequent pro-

FAA Technical Bulletin

cess(es); and the environmental, cost, and health and safety

2.3 Military Standards:

concerns.

MIL-S-8802

MIL-S-81722

6. Procedure

MIL-W-81381/11-20

6.1 Step 1—Define the Requirements of the Facility—The

first step taken in selecting a replacement cleaner is to

3. Terminology

determine which cleaners or classes of cleaners are acceptable

3.1 Definitions of Terms Specific to This Standard:

to the requirements of the facility. These requirements include

3.1.1 cleaning effıciency, n—the measure of how well a

environmental, safety, and health requirements and the physi-

cleaning agent is able to clean a substrate.

cal and chemical properties of the cleaner itself.

3.1.2 level of cleanliness, n—the degree to which a part

6.1.1 Environmental, Safety, and Health Requirements—

must be cleaned in order to perform successfully in subsequent

Table2presentssomeofthemorecommonconcernsregarding

manufacturing or maintenance procedures, or to perform ad-

cleaning agents and their effects on the environment, and

equately in its final application.

worker safety and health. To use Table 2, the engineer should

3.1.3 pre-cleaning, n—the initial cleaning step to remove

find their concerns on the left-hand column and ensure that the

gross contaminants prior to a precision cleaning process.

cleaner meets the requirements listed in the right-hand column.

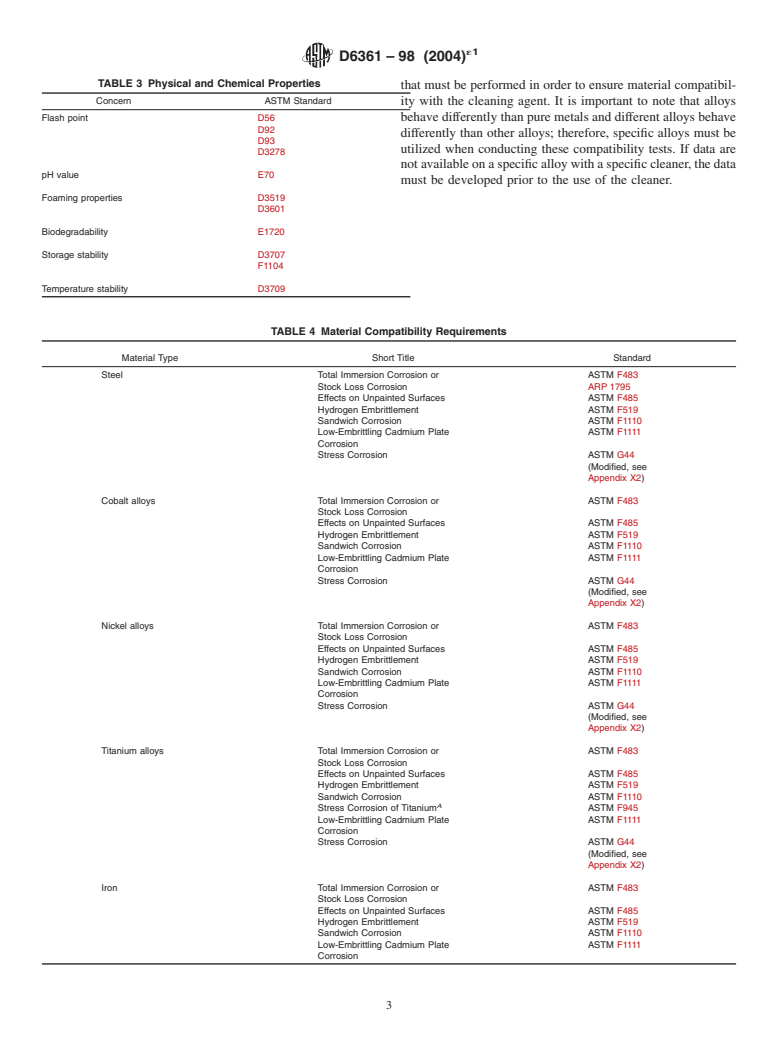

6.1.2 Physical and Chemical Properties—Table 3 presents

4. Summary of Guide

some of the more common concerns regarding cleaning agents

4.1 Thefollowingisasummaryofthefivestepapproachfor

andtheirphysicalandchemicalproperties,andthecorrespond-

selecting general cleaning agents and processes for use in

ing tests required to evaluate those properties. To use Table 3,

manufacturing, overhaul, and maintenance in industrial opera-

the engineer should find their concern(s) on the left-hand

tion. For each step, the user of the guide will provide specific

column and require the data from evaluations of the specifica-

information on a particular aspect of their process. Then, the

tions listed in the remainder of the row. Please note that this

user should consult the guide, which will provide appropriate

guide does not provide values for the inspection results. These

guidanceonevaluationcriteriathatshouldbefollowedinorder

values are to be determined by the engineer based on the

to evaluate the potential cleaning agents. Table 1 provides a

specific requirements of the operation.

summary of the user-defined requirements information and the

6.2 Step 2—Determine Materials of the Parts Being

procedures to be provided by this guide. The order of the steps

Cleaned to Ascertain Material Compatibility Test

presented in Table 1 is suggested, but not crucial to the

Requirements—The second step in using this guide is to

successful use of this guide. Section 6 will provide greater

determine the material, or materials of the parts, being cleaned.

details on both the user input and the guidance provided.

The information will provide the engineer with the material

compatibility test data required to ensure the cleaner will not

damage the parts being cleaned. Table 4 presents a table to be

TABLE 1 Summary of Guide

used to determine the required material compatibility tests. To

Step Defined User Requirements Procedure

useTable 4, select the material type from the left-hand column.

1 Define the ESH, physical and Physical and Chemical Properties

The remaining information in the corresponding row provides

chemical requirements of the Test—Verify that the prospective

the short title and the specification number for each of the tests

facility agent is acceptable.

2 Define the material(s) to be Material Compatibility Test(s)—

cleaned Verify that the prospective agent

will not harm the component(s)

TABLE 2 Environmental, Safety, and Health Requirements

being cleaned.

3 Determine shape of part (part Applicable processes and Concern Requirement

geometry) equipment Environment Compliance with all federal, state, and local laws

4 Define the reason for cleaning Performance Testing—Verify that and regulations concerning the procurement, use,

the prospective agent and and disposal of the cleaning agent and associated

process will perform to the materials.

desired level of cleanliness for the Worker safety and health Compliance with OSHA regulations, provide

particular cleaning application. sufficient personal protective equipment to ensure

5 Select cleaner Validate environment, cost, and the health and safety risks of using the cleaning

worker health and safety. agent are minimized.

´1

D6361–98 (2004)

TABLE 3 Physical and Chemical Properties

that must be performed in order to ensure material compatibil-

Concern ASTM Standard ity with the cleaning agent. It is important to note that alloys

behave differently than pure metals and different alloys behave

Flash point D56

D92

differently than other alloys; therefore, specific alloys must be

D93

utilized when conducting these compatibility tests. If data are

D3278

notavailableonaspecificalloywithaspecificcleaner,thedata

pH value E70

must be developed prior to the use of the cleaner.

Foaming properties D3519

D3601

Biodegradability E1720

Storage stability D3707

F1104

Temperature stability D3709

TABLE 4 Material Compatibility Requirements

Material Type Short Title Standard

Steel Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion ARP 1795

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Cobalt alloys Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Nickel alloys Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Titanium alloys Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

A

Stress Corrosion of Titanium ASTM F945

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Iron Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

´1

D6361–98 (2004)

TABLE 4 Continued

Material Type Short Title Standard

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Aluminum Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Sandwich Corrosion ASTM F1110

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Magnesium Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Sandwich Corrosion ASTM F1110

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Brass and bronze Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Sandwich Corrosion ASTM F1110

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Copper and alloys Total Immersion Corrosion or ASTM F483

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Sandwich Corrosion ASTM F1110

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Epoxy matrix with Total Immersion Corrosion or ASTM F483

metals

Stock Loss Corrosion

Effects on Unpainted Surfaces ASTM F485

Hydrogen Embrittlement ASTM F519

Sandwich Corrosion ASTM F1110

Low-Embrittling Cadmium Plate ASTM F1111

Corrosion

Stress Corrosion ASTM G44

(Modified, see

Appendix X2)

Rubber compounds Effects on Unpainted Surfaces ASTM F485

Rubber Compatibility AMS 3204/3209

Rubber Property—Durometer ASTM D2240

Thermoset plastics Stress Crazing of Acrylic Plastics ASTM F484

Rubber Property—Durometer ASTM D2240

Thermo plastics Stress Crazing of Acrylic Plastics ASTM F484

Rubber Propery—Durometer ASTM D2240

Acrylics Stress Crazing of Acrylic Plastics ASTM F484

Polycarbonates Stress Crazing of Acrylic Plastics ASTM F484

Optics Stress Crazing of Acrylic Plastics ASTM F484

Rubber Property—Durometer ASTM D2240

Wiring (insulation) Effects on Unpainted Surfaces ASTM F485

Effect on Polymide Insulated Wire Appendix X1

Rubber Compatibility AMS 3204/3209

Rubber Propery—Durometer ASTM D2240

Leather and fabrics Effects on Unpainted Surfaces ASTM F485

´1

D6361–98 (2004)

TABLE 4 Continued

Material Type Short Title Standard

Painted surfaces Effects on Painted Surfaces ASTM F502 (with

primers and paints

that are being

cleaned)

Appendix X3

Polysulfide sealants Effects on Polysulfide Sealants

A

Only applicable when dealing with engine parts exceeding 500°F.

TABLE 6 Inspection Type and Performance Requirements

6.3 Step 3—Analyze Part Geometry to Determine Accept-

able Cleaning Processes and Equipment—Once the engineer Reason for Cleaning Inspection Type Performance Requirement

has determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.