ASTM D3261-03

(Specification)Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

ABSTRACT

This specification covers polyethylene (PE) butt fusion fittings for use with polyethylene pipe (IPS and ISO) and tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure. Pressure strength test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers polyethylene (PE) butt fusion fittings for use with polyethylene pipe (IPS and ISO) and tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure.

1.2 The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D3261 – 03

Standard Specification for

Butt Heat Fusion Polyethylene (PE) Plastic Fittings for

1

Polyethylene (PE) Plastic Pipe and Tubing

This standard is issued under the fixed designation D3261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

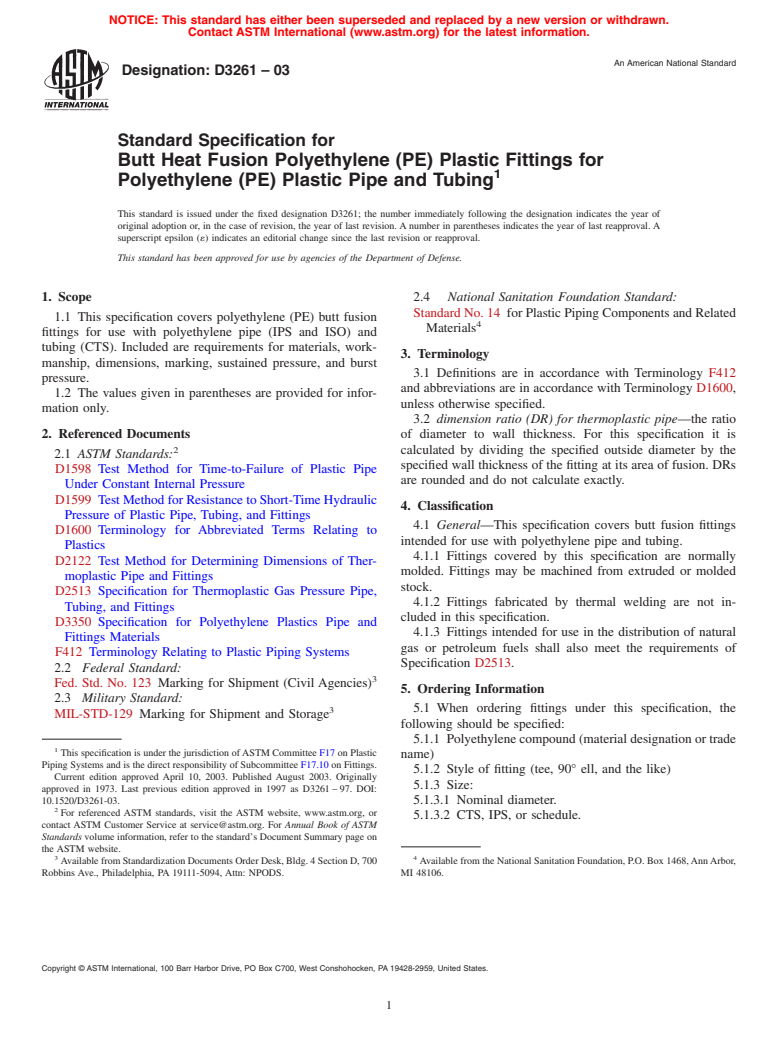

1. Scope 2.4 National Sanitation Foundation Standard:

Standard No. 14 for Plastic Piping Components and Related

1.1 This specification covers polyethylene (PE) butt fusion

4

Materials

fittings for use with polyethylene pipe (IPS and ISO) and

tubing (CTS). Included are requirements for materials, work-

3. Terminology

manship, dimensions, marking, sustained pressure, and burst

3.1 Definitions are in accordance with Terminology F412

pressure.

and abbreviations are in accordance with Terminology D1600,

1.2 The values given in parentheses are provided for infor-

unless otherwise specified.

mation only.

3.2 dimension ratio (DR) for thermoplastic pipe—the ratio

2. Referenced Documents of diameter to wall thickness. For this specification it is

2

calculated by dividing the specified outside diameter by the

2.1 ASTM Standards:

specified wall thickness of the fitting at its area of fusion. DRs

D1598 Test Method for Time-to-Failure of Plastic Pipe

are rounded and do not calculate exactly.

Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic

4. Classification

Pressure of Plastic Pipe, Tubing, and Fittings

4.1 General—This specification covers butt fusion fittings

D1600 Terminology for Abbreviated Terms Relating to

intended for use with polyethylene pipe and tubing.

Plastics

4.1.1 Fittings covered by this specification are normally

D2122 Test Method for Determining Dimensions of Ther-

molded. Fittings may be machined from extruded or molded

moplastic Pipe and Fittings

stock.

D2513 Specification for Thermoplastic Gas Pressure Pipe,

4.1.2 Fittings fabricated by thermal welding are not in-

Tubing, and Fittings

cluded in this specification.

D3350 Specification for Polyethylene Plastics Pipe and

4.1.3 Fittings intended for use in the distribution of natural

Fittings Materials

gas or petroleum fuels shall also meet the requirements of

F412 Terminology Relating to Plastic Piping Systems

Specification D2513.

2.2 Federal Standard:

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

5. Ordering Information

2.3 Military Standard:

5.1 When ordering fittings under this specification, the

3

MIL-STD-129 Marking for Shipment and Storage

following should be specified:

5.1.1 Polyethylene compound (material designation or trade

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

name)

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

5.1.2 Style of fitting (tee, 90° ell, and the like)

Current edition approved April 10, 2003. Published August 2003. Originally

5.1.3 Size:

approved in 1973. Last previous edition approved in 1997 as D3261 – 97. DOI:

10.1520/D3261-03. 5.1.3.1 Nominal diameter.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.3.2 CTS, IPS, or schedule.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

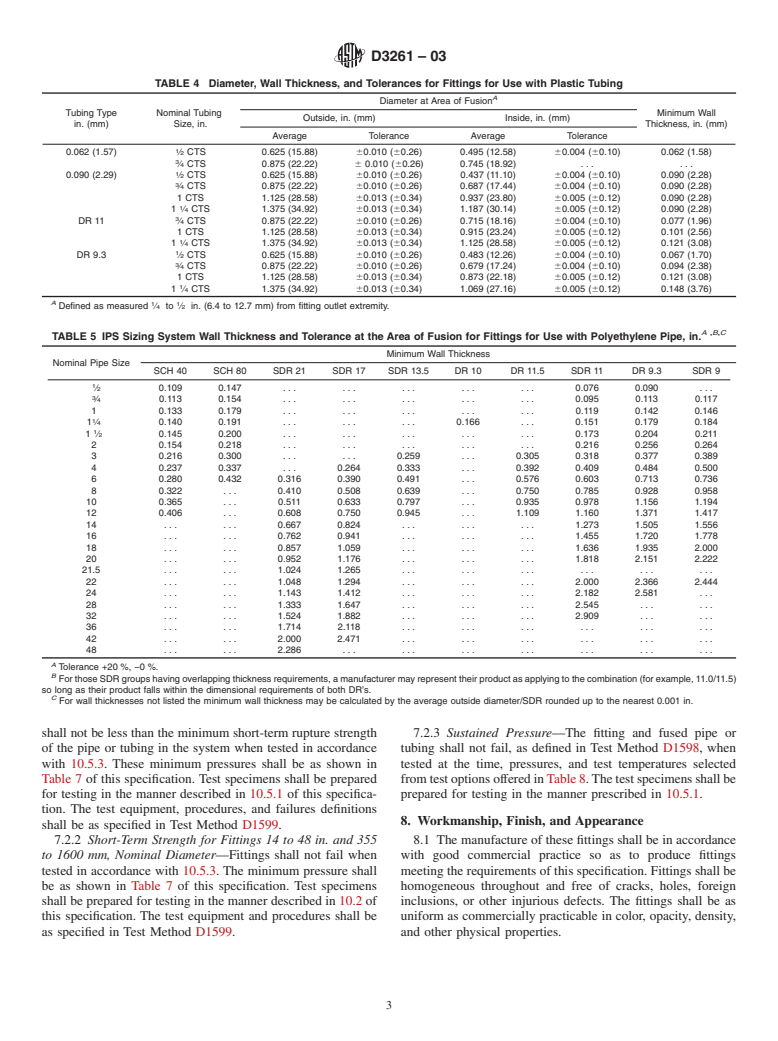

D3261 – 03

TABLE 1 Specification D3350 Classification of Polyethylene TABLE 2 IPS Sizing System Outside Diameters and Tolerances

Fittings Materials for Fittings for Use with Polyethylene Pipe, in.

For HDB of 1250 psi 1600 psi Average Outside

Nominal Pipe

(8.6 MPa) (11 MPa) Diameter at Area of Tolerance

Size

A

Fusion

Physical Properties and Cell Classification Limits are:

1

⁄2 0.840 60.008

Density (base resin) 2 3

3

⁄4 1.050 60.008

Melt Index 3 or 4 3 or 4

1 1.315 60.010

Flexural Modulus 4 to 5 4 or 5 or 6

1

1 ⁄4 1.660 60.010

Tensile Strength 3 or 4 3 or 4 or 6

1

1 ⁄2 1.900 60.010

A

SCG Resistance 4or6 4or6

2 2.375 60.010

HDB 3 4

3 3.500 60.012

Color and UV Stabilizer C or E C or E

4 4.500 60.015

A

6 6.625 60.018

In accordance with the requirements of Specification D2513a6isrequired

when fittings are intended for use in the distribution of natural gas or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.