ASTM D7452-08

(Test Method)Standard Test Method for Evaluation of the Load Carrying Properties of Lubricants Used for Final Drive Axles, Under Conditions of High Speed and Shock Loading

Standard Test Method for Evaluation of the Load Carrying Properties of Lubricants Used for Final Drive Axles, Under Conditions of High Speed and Shock Loading

SIGNIFICANCE AND USE

Final drive axles are often subjected to severe service where they encounter high speed shock load conditions, characterized by sudden accelerations and decelerations. This severe service can lead to scoring distress on the ring gear and pinion surface. This test method measures anti-scoring properties of final drive lubricants.

This test method is used or referred to in the following documents:

American Petroleum Institute (API) Publication 1560.

SAE J308 and SAE J2360.

SCOPE

1.1 This test method covers the determination of the anti-scoring properties of final drive axle lubricating oils when subjected to high-speed and shock conditions. This test method is commonly referred to as the L-42 test.

1.2 The values stated in foot-pound units are to be regarded as standard. For example, torque is stated in foot-pound units, the values for temperature are stated in degrees Fahrenheit, and the test lubricant sample volume is stated in pints. The values given in parentheses are mathematical conversions to SI units that are provided for information purposes only, and are not considered standard. SI units are provided for all parameters except where there is no direct equivalent such as the units for screw threads, national pipe threads/diameters, and tubing size.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning information is given in Sections 4 and 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7452–08

Standard Test Method for

Evaluation of the Load Carrying Properties of Lubricants

Used for Final Drive Axles, Under Conditions of High Speed

and Shock Loading

This standard is issued under the fixed designation D7452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Society of Automotive Engineers Standards:

SAE J308 Information Report on Axle and Manual Trans-

1.1 This test method covers the determination of the anti-

mission Lubricants

scoring properties of final drive axle lubricating oils when

SAE J2360 Lubricating Oil, Gear Multipurpose (Metric)

subjectedtohigh-speedandshockconditions.Thistestmethod

Military Use

is commonly referred to as the L-42 test.

1.2 The values stated in foot-pound units are to be regarded

3. Terminology

as standard. For example, torque is stated in foot-pound units,

3.1 Definitions of Terms Specific to This Standard:

thevaluesfortemperaturearestatedindegreesFahrenheit,and

3.1.1 coast side, n—the convex side of the pinion and the

the test lubricant sample volume is stated in pints. The values

concave side of the ring gear which are in contact during

given in parentheses are mathematical conversions to SI units

deceleration in a forward gear. CRC Manual 21

that are provided for information purposes only, and are not

3.1.2 drive side, n—the concave side of the pinion and the

considered standard. SI units are provided for all parameters

convex side of the ring gear which are in contact during

except where there is no direct equivalent such as the units for

acceleration in a forward gear. CRC Manual 21

screwthreads,nationalpipethreads/diameters,andtubingsize.

3.1.3 scoring, n—on the ring and the pinion gear teeth, the

1.3 This standard does not purport to address all of the

displacement of metal by local momentary welding from the

safety concerns, if any, associated with its use. It is the

gear tooth, resulting in the development of a matt, or frosted

responsibility of the user of this standard to establish appro-

dull surface. CRC Manual 21

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific warning

4. Summary of Test Method

information is given in Sections 4 and 7.

4.1 Charge a specially prepared light duty hypoid rear axle

2. Referenced Documents (Dana Model 44 ASTM Part No. 044AA100-1) with the

3 lubricant sample to be tested (see 10.1). Mount the axle

2.1 ASTM Standards:

between two load absorbing dynamometers which are driven

D235 Specification for Mineral Spirits (Petroleum Spirits)

with a V-8 gasoline engine through a manual transmission.

(Hydrocarbon Dry Cleaning Solvent)

4.2 Condition the test axle with light loads at different

E29 Practice for Using Significant Digits in Test Data to

speed, torque and temperature conditions on both the drive and

Determine Conformance with Specifications

coast sides of the gears. (Warning—High-speed rotating

equipment, electrical shock, high-temperature surfaces.) After

conditioning, subject the test axle to high speed and shock

This test method is under the jurisdiction of ASTM Committee D02 on

loadings at higher temperatures.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4.3 Ratethedriveandcoastsideofthepinionandringgears

D02.B0.03 on Automotive Gear Lubricants & Fluids.

Current edition approved May 1, 2008. Published June 2008. DOI: 10.1520/ at the end of test (EOT) for scoring distress.

D7452-08.

Until the next revision of this test method, the ASTM Test Monitoring Center

5. Significance and Use

(TMC) will update changes in this test method by means of information letters.

5.1 Final drive axles are often subjected to severe service

Information letters may be obtained from the ASTM Test Monitoring Center, 6555

Penn Avenue, Pittsburgh, PA 15206, Attention: Administrator. The TMC is also a

where they encounter high speed shock load conditions,

source of reference oils.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Standards volume information, refer to the standard’s Document Summary page on Dr., Warrendale, PA 15096-0001, http://www.sae.org.

the ASTM website. CRC Rating Manual, No. 21, Coordinating Research Council, Atlanta, GA.

Parts and Model 44 Maintenance Manual available from Dana Corporation,

P.O. Box 2424, Fort Wayne, IN 46801.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D7452–08

characterized by sudden accelerations and decelerations. This 6.6.4.2 Use a single control valve to control the cooling

severe service can lead to scoring distress on the ring gear and water supply. The control shall be a ⁄2 in. (12.7 mm) two-way,

pinion surface. This test method measures anti-scoring prop- C linear trim, air to close, Research Control valve. Use a single

erties of final drive lubricants. PID loop to maintain the axle lubricant temperature control for

5.2 This test method is used or referred to in the following both the Standard and Canadian version test. A separate PID

documents: loop control for each version is not permitted. See Annex A1.

3 1

5.2.1 American Petroleum Institute (API) Publication 6.6.4.3 Use only ⁄8 or ⁄2 in. line material to the spray

1560. nozzles.

5.2.2 SAE J308 and SAE J2360. 6.6.4.4 Use a minimum supply water pressure of 25 psig

(172 kPa) to the control valve.

6. Apparatus

6.6.4.5 Use an axle containment box as shown in Fig.

6.1 This test method provides a description of essential A2.10. The purpose is to contain water.

6.6.4.6 Use a locating pin or stop block as an indexing

apparatus features, including mandatory equipment type and

performance specifications where established. device to ensure that all subsequent axle installations are

consistently installed perpendicular with the axle housing

6.2 Test Axle—The test unit consists of a Dana model 44

cover to engine and transmission drive-shaft centerline.

rear axle, 45 to 11 (4.09) ratio, and uncoated gears. (Dana

6.7 Torque Meter—Include in the test equipment a torque

ASTM part number 044AA100-1. See 10.1.)

meter installed in the drive shaft (see Figs. A2.3-A2.5)to

6.3 CoverPlate—Modifytherearcoverplateofthetestunit

measure the torque applied to the pinion. Install a Himmelstein

to provide an inspection port and thermocouple fitting. Locate

inline torque meter Model numbers MCRT28061T(1-4) or

the thermocouple fitting by using the locating fixture shown in

9,10

MCRT2661TN(1-4) without a foot mount and a range of

Fig.A2.1.An optional ⁄4 in. NPT(National PipeThread) drain

10 000 lb-in. (1130 N-m) shall be installed to measure pinion

fitting may be added.

torque. Additional suffix letters only indicate allowable op-

6.4 Axle Shaft Assemble—Use a Ford Axle shaft assembly,

tions.

(Dana Part No. 26762-14X ) or equivalent with this test

6.8 Signal Conditioning—Use a Himmelstein Models 701

method.

or 711 strain gage conditioner for signal conditioning. Set the

6.5 Hinge Plate StandAssembly—Mountandsecurethetest

unit in place on the hinge plate assembly, see Figs.A2.6-A2.9. low pass cut-off frequency at 10 Hz.

6.9 Digital Data Acquisition System—System requires ca-

6.6 Temperature Control System—The temperature control

apparatus consists of a thermocouple, a temperature recording pability of measuring a minimum of five channels at sampling

frequencies outlined in Section 10.

system,temperaturecontrollerandacoolingsystemthatisable

to maintain lubricant temperature at specified conditions. 6.9.1 Do not use hardware or software filtering for the

pinion torque channel during data acquisition periods of the

6.6.1 Thermocouple—Installthethermocouplesuchthatthe

thermocoupletipisflushwiththecoverplatelipbyplacingthe test.

6.10 Dynamometers—Two axle dynamometers (Midwest

cover plate face on a flat surface and inserting the thermo-

,

9 11

Dynamatic, Model 3232) with suitable control equipment

couple into the cover plate until the thermocouple tip is flush

capable of maintaining specified test conditions.

with the flat surface. For recording and control of the test

6.11 Engine Speed Control—System requires a device to

lubricant temperature, use a ⁄8-in. (3.2-mm) diameter J or K

maintain steady state conditions and also provide adjustable

type closed tip style thermocouple.

throttle acceleration and deceleration rates to attain specified

6.6.2 Temperature Recording System—Throughout the test,

shock loading torques.

ensure the temperature recording system records the tempera-

6.11.1 Throttle Controller System—Use a Foxboro/Jordan

ture of the test oil at a minimum frequency of 1 Hz.

9,12

Controller, Model AD7530. Use a power transformer from

6.6.3 Temperature Controller—Proportional-Integral-

Acme Electric Corp. PN T-1-81058 or equivalent, primary

Derivative (PID) type; percent output adjustable.

volts 120X240, secondary volts 16/32 center tap, 0.500 kVAin

6.6.4 Axle Cooling—Use three spray nozzles to distribute

conjunction with the Foxboro/Jordan Controller.

water over the cover plate and axle housing as shown in Fig.

A2.2. Actuate the water control valve by the temperature PID 6.12 Connecting Shafts—Use connecting shafts of equal

length 6 1 in. (25.4 mm) and less than 30 in. (762 mm) long

control system.

6.6.4.1 Depending on how the system is plumbed, use spray from flange face to flange face. Use a tubing diameter of 3.5 6

0.2 in. (88.9 6 5.1 mm) OD, with a wall thickness of 0.095 6

nozzles in any combination of the following part numbers:

Straight Male NPT (Part No. 3/8GG-SS22), 90° Male NPT

(Part No. 3/8GGA-SS22), Straight Female NPT (Part No.

,

8 9 If you are aware of alternative suppliers, please provide this information to

3/8G-SS22), and 90° Female NPT (Part No. 3/8GA-SS22).

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee, which you may attend.

The sole source supply of the apparatus known to the committee at this time

API Publication 1560, Lubricant Service Designations for Automotive Manual is S. Himmelstein and Company, 2490 Pembroke Avenue, Hoffman Estates, IL

Transmissions, Manual Transaxles, and Axles, American Petroleum Institute, 60195.

Washington, DC. Available from Dyne Systems, P.O. Box 18 W209 N17391 Industrial Drive,

The sole source supply of the apparatus known to the committee at this time is Jackson, WI 53037.

Spray Systems Company, and can be purchased through E. I. Pfaff Company, 3443 Available from Fox/Jordan, Inc., 5607 West DouglasAvenue, Milwaukee, WI

Edwards Road, Suite D, Cincinnati, OH 45208. 53218.

D7452–08

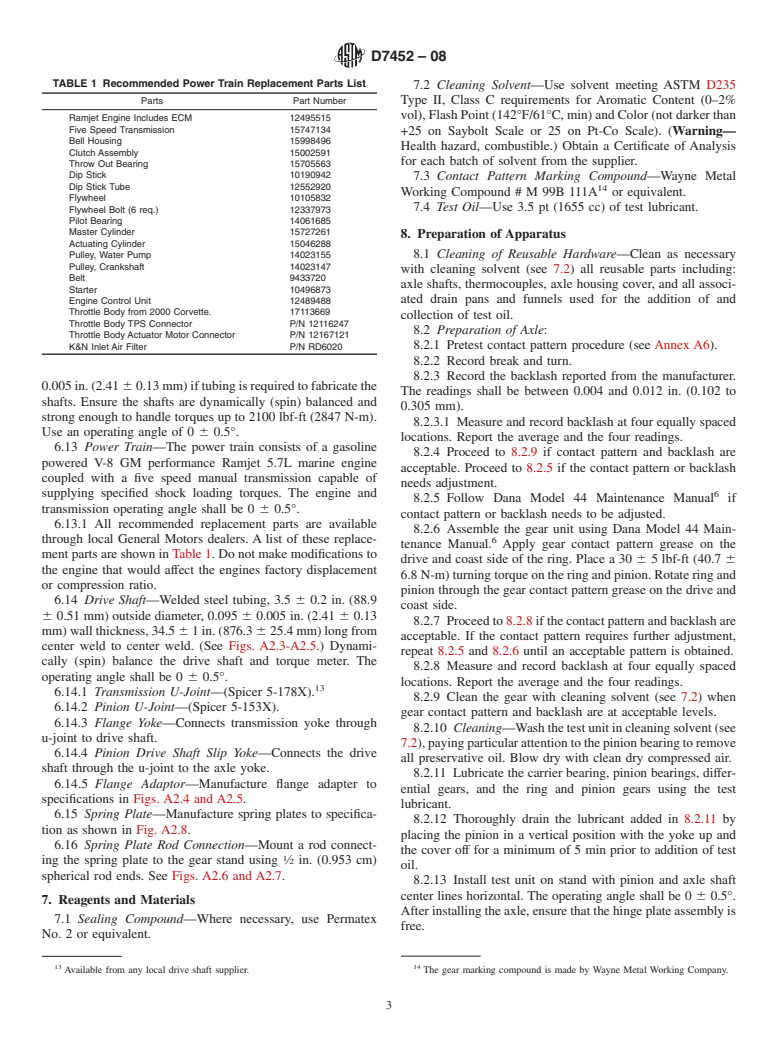

TABLE 1 Recommended Power Train Replacement Parts List

7.2 Cleaning Solvent—Use solvent meeting ASTM D235

Parts Part Number Type II, Class C requirements for Aromatic Content (0–2%

vol), Flash Point (142°F/61°C, min) and Color (not darker than

Ramjet Engine Includes ECM 12495515

Five Speed Transmission 15747134

+25 on Saybolt Scale or 25 on Pt-Co Scale). (Warning—

Bell Housing 15998496

Health hazard, combustible.) Obtain a Certificate of Analysis

ClutchAssembly 15002591

for each batch of solvent from the supplier.

Throw Out Bearing 15705563

Dip Stick 10190942

7.3 Contact Pattern Marking Compound—Wayne Metal

Dip Stick Tube 12552920

Working Compound # M 99B 111A or equivalent.

Flywheel 10105832

7.4 Test Oil—Use 3.5 pt (1655 cc) of test lubricant.

Flywheel Bolt (6 req.) 12337973

Pilot Bearing 14061685

Master Cylinder 15727261

8. Preparation of Apparatus

Actuating Cylinder 15046288

8.1 Cleaning of Reusable Hardware—Clean as necessary

Pulley, Water Pump 14023155

Pulley, Crankshaft 14023147

with cleaning solvent (see 7.2) all reusable parts including:

Belt 9433720

axle shafts, thermocouples, axle housing cover, and all associ-

Starter 10496873

ated drain pans and funnels used for the addition of and

Engine Control Unit 12489488

Throttle Body from 2000 Corvette. 17113669

collection of test oil.

Throttle Body TPS Connector P/N 12116247

8.2 Preparation of Axle:

Throttle BodyActuator Motor Connector P/N 12167121

K&N InletAir Filter P/N RD6020 8.2.1 Pretest contact pattern procedure (see Annex A6).

8.2.2 Record break and turn.

8.2.3 Record the backlash reported from the manufacturer.

0.005in.(2.41 60.13mm)iftubingisrequiredtofabricatethe

The readings shall be between 0.004 and 0.012 in. (0.102 to

shafts. Ensure the shafts are dynamically (spin) balanced and

0.305 mm).

strong enough to handle torques up to 2100 lbf-ft (2847 N-m).

8.2.3.1 Measure and record backlash at four equally spaced

Use an operating angle of 0 6 0.5°.

locations. Report the average and the four readings.

6.13 Power Train—The power train consists of a gasoline

8.2.4 Proceed to 8.2.9 if contact pattern and backlash are

powered V-8 GM performance Ramjet 5.7L marine engine

acceptable. Proceed to 8.2.5 if the contact pattern or backlash

coupled with a five speed manual transmission capable of

needs adjustment.

supplying specified shock loading torques. The engine and 6

8.2.5 Follow Dana Model 44 Maintenance Manual if

transmission operating angle shall be 0 6 0.5°.

contact pattern or backlash needs to be adjusted.

6.13.1 All recommended replacement parts are available

8.2.6 Assemble the gear unit using Dana Model 44 Main-

through local General Motors dealers. A list of these replace- 6

tenance Manual. Apply gear contact pattern grease on the

ment parts are shown inTable 1. Do not make modifications to

drive and coast side of the ring. Place a 30 6 5 lbf-ft (40.7 6

the engine that would affect the engines factory displacement

6.8 N-m)turningtorqueontheringandpinion.Rotateringand

or compression ratio.

pinion through the gear contact pattern grease on the drive and

6.14 Drive Shaft—Welded steel tubing, 3.5 6 0.2 in. (88.9

coast side.

6 0.51 mm) outside diameter, 0.095 6 0.005 in. (2.41 6 0.13

8.2.7 Proceedto8.2.8ifthecontactpatternandbacklashare

mm)wallthickness,34.5 61in.(876.3 625.4mm)longfrom

acceptable. If the contact pattern requires further adjustment,

center weld to center weld. (See Figs. A2.3-A2.5.) Dynami-

repeat 8.2.5 and 8.2.6 until an acceptable pattern is obtained.

cally (spin) balance the drive shaft and torque meter. The

8.2.8 Measure and record backlash at four equally spaced

operating angle shall be 0 6 0.5°.

locations. Report the average and the four readings.

6.14.1 Tra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.