ASTM D7579-09

(Test Method)Standard Test Method for Pyrolysis Solids Content in Pyrolysis Liquids by Filtration of Solids in Methanol

Standard Test Method for Pyrolysis Solids Content in Pyrolysis Liquids by Filtration of Solids in Methanol

SIGNIFICANCE AND USE

Pyrolysis liquid can be produced to various char concentrations. Increasing pyrolysis solids content can affect the pyrolysis liquid biofuel handling, atomization and storage stability in a negative manner.

SCOPE

1.1 This test method describes a filtration procedure for determining the pyrolysis solids content of pyrolysis liquid. It is intended for the analysis of pyrolysis liquid with all ranges of pyrolysis solids concentrations.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage. For specific warning statements, see 7.2, 7.3, and 7.4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7579 − 09

StandardTest Method for

Pyrolysis Solids Content in Pyrolysis Liquids by Filtration

of Solids in Methanol

This standard is issued under the fixed designation D7579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions:

1.1 This test method describes a filtration procedure for

3.1.1 See also Terminology D4175.

determining the pyrolysis solids content of pyrolysis liquid. It

3.1.2 char, n—fine carbonaceous powder that is separated

is intended for the analysis of pyrolysis liquid with all ranges

from the vapors of biomass during pyrolysis.

of pyrolysis solids concentrations.

3.1.2.1 Discussion—Pyrolysis liquid biofuel contains uni-

1.2 The values stated in SI units are to be regarded as

formly suspended char at varying concentrations.

standard. No other units of measurement are included in this

3.1.3 pyrolysis, n—chemical decomposition of organic ma-

standard.

terials by heating in the absence of oxygen.

1.3 This standard does not purport to address all of the

3.1.4 pyrolysis liquid biofuel, n—liquid product from the

safety concerns, if any, associated with its use. It is the

pyrolysis of biomass.

responsibility of the user of this standard to establish appro-

3.1.4.1 Discussion—Pyrolysisliquidbiofueliscomprisedof

priate safety and health practices and determine the applica-

a complex mixture of the decomposition products of ligno-

bility of regulatory limitations prior to use. Material Safety

cellulosic biomass including highly oxygenated organic com-

Data Sheets are available for reagents and materials. Review

pounds. It is produced from the pyrolysis of biomass, followed

them for hazards prior to usage. For specific warning by the rapid condensation of its vapors.

statements, see 7.2, 7.3, and 7.4.

3.1.5 pyrolysis solids, n—solid particles contained within

the pyrolysis liquid biofuel.

2. Referenced Documents

3.1.5.1 Discussion—Pyrolysis solids consists of ash and

char.

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and

4. Summary of Test Method

Petroleum Products

4.1 Apyrolysis liquid sample is dissolved in a methanol and

D4175 Terminology Relating to Petroleum, Petroleum

dichloromethane solution (1:1), which is then filtered through

Products, and Lubricants

a vacuum filter system. After filtering, the filtrand is washed

D4177 Practice for Automatic Sampling of Petroleum and

with the solvent until the filtrate is clear. The filter is removed,

Petroleum Products

dried and weighed. The pyrolysis solids content is calculated

2.2 Other Standards:

based on the original pyrolysis liquid sample.

ESPOO 2001 A guide to physical property characterisation

5. Significance and Use

of biomass-derived fast pyrolysis liquids

5.1 Pyrolysis liquid can be produced to various char con-

centrations. Increasing pyrolysis solids content can affect the

pyrolysis liquid biofuel handling, atomization and storage

This test method is under the jurisdiction of ASTM Committee D02 on

stability in a negative manner.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.06 on Analysis of Lubricants.

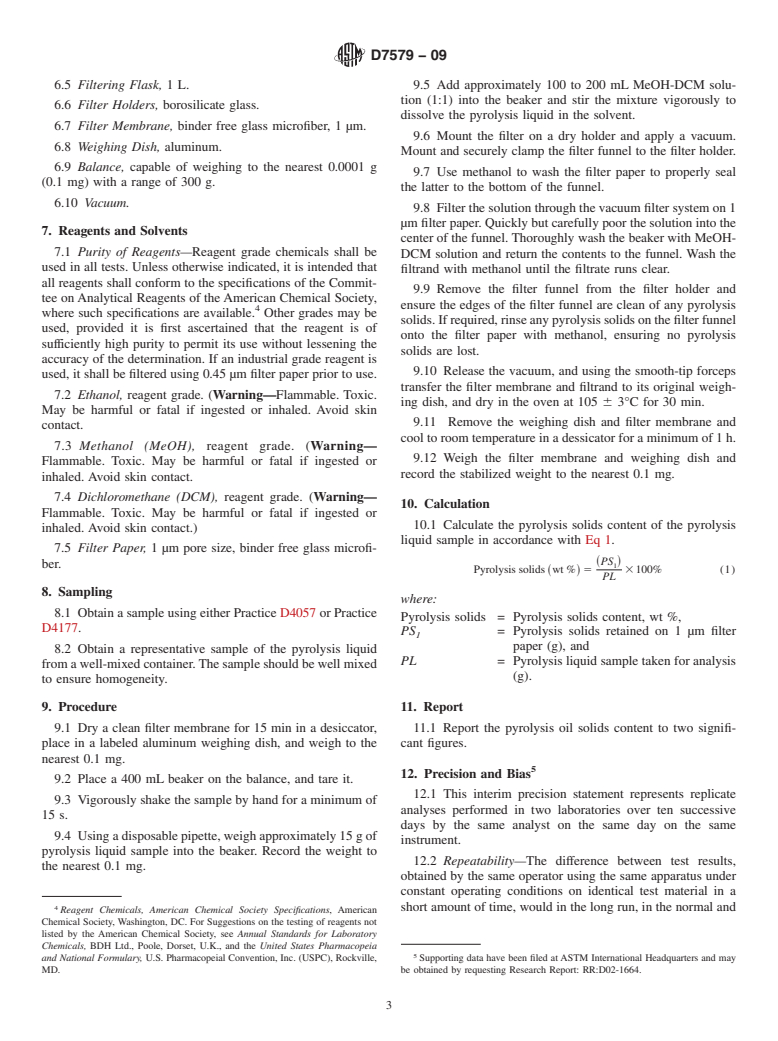

6. Apparatus (see Fig. 1)

Current edition approved Oct. 1, 2009. Published October 2009. DOI: 10.1520/

D7579-09.

6.1 Smooth-tip Forceps.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 Beaker, 400 mL.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.3 Glass Stirring Rod.

AvailablefromVTTEnergy,NewEnergyTechnologies,Biologinkuja3–5,P.O.

6.4 Oven, explosion-proof, capable of maintaining a tem-

Box 1601, FIN-02044 VTT, Finland. http://www.vtt.fi/inf/pdf/publications/2001/

P450.pdf perature of 105 6 3°C.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7579 − 09

FIG. 1 Paper Filtration Apparatus

D7579 − 09

6.5 Filtering Flask,1L. 9.5 Add approximately 100 to 200 mL MeOH-DCM solu-

tion (1:1) into the beaker and stir the mixture vigorously to

6.6 Filter Holders, borosilicate glass.

dissolve the pyrolysis liquid in the solvent.

6.7 Filter Membrane, binder free glass microfiber, 1 µm.

9.6 Mount the filter on a dry holder and apply a vacuum.

6.8 Weighing Dish, aluminum.

Mount and securely clamp the filter funnel to the filter holder.

6.9 Balance, capable of weighing to the nearest 0.0001 g

9.7 Use methanol to wash the filter paper to properly seal

(0.1 mg) with a range of 300 g.

the latter to the bottom of the funnel.

6.10 Vacuum.

9.8 Filter the solution through the vacuum filter system on 1

µm filter paper. Quickly but carefully poor the solution into the

7. Reagents and Solvents

center of the funnel. Thoroughly wash the beaker with MeOH-

7.1 Purity of Reagents—Reagent grade chemicals shall be

DCM solution and return the contents to the funnel. Wash the

used in all tests. Unless otherwise indicated, it is intended that

filtrand with methanol until the filtrate runs clear.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.