ASTM D1693-05

(Test Method)Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics

Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics

SCOPE

1.1 This test method covers the determination of the susceptibility of ethylene plastics, as defined in Terminology D 883, to environmental stress-cracking when subjected to the conditions herein specified. Under certain conditions of stress and in the presence of environments such as soaps, wetting agents, oils, or detergents, ethylene plastics may exhibit mechanical failure by cracking.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 1693–05

Standard Test Method for

1

Environmental Stress-Cracking of Ethylene Plastics

This standard is issued under the fixed designation D 1693; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

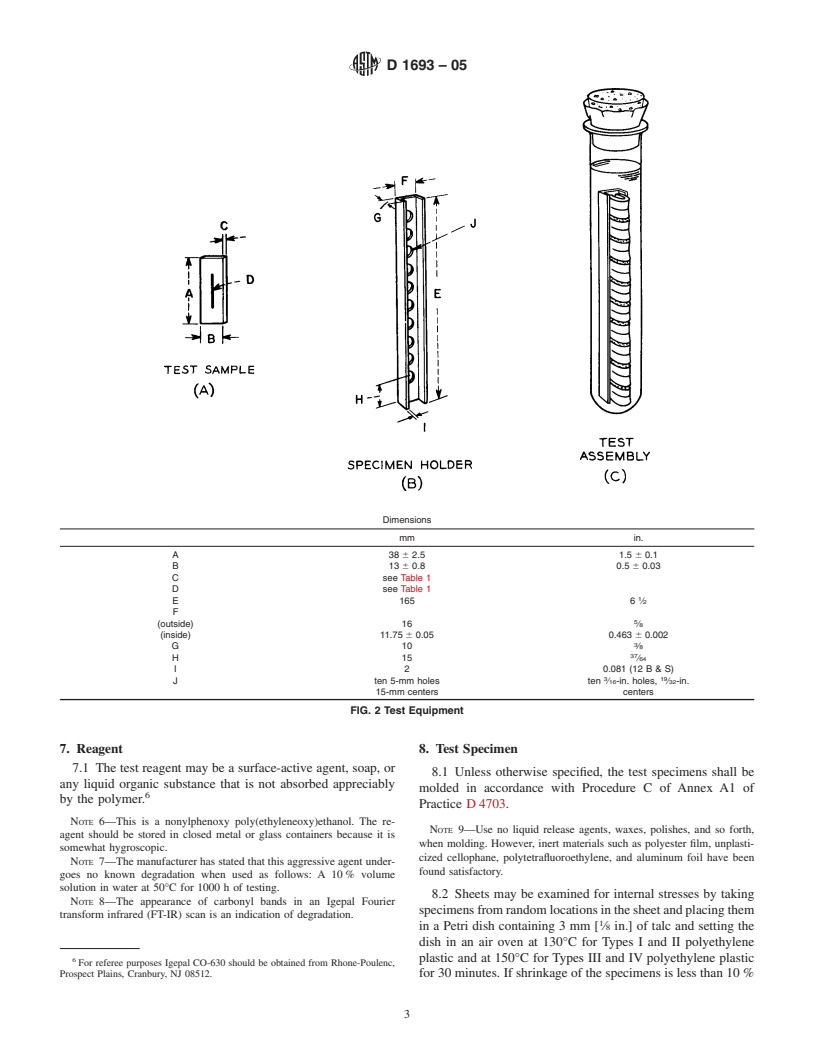

1. Scope* 2.2 ASTM Adjuncts:

3

Apparatus Drawings and Blueprints

1.1 This test method covers the determination of the sus-

ceptibility of ethylene plastics, as defined in Terminology

3. Terminology

D 883, to environmental stress-cracking when subjected to the

3.1 Definitions:

conditions herein specified. Under certain conditions of stress

3.1.1 stress-crack, n—an external or internal rupture in a

and in the presence of environments such as soaps, wetting

plastic caused by tensile stresses less than its short-time

agents, oils, or detergents, ethylene plastics may exhibit

mechanical strength.

mechanical failure by cracking.

3.1.1.1 Discussion—The development of such cracks is

1.2 The values stated in SI units are to be regarded as

frequently accelerated by the environment to which the plastic

standard.

is exposed. The stresses which cause cracking may be present

1.3 This standard does not purport to address all of the

internally or externally, or may be a combination of these

safety concerns, if any, associated with its use. It is the

stresses. The appearance of a network of fine cracks is called

responsibility of the user of this standard to establish appro-

crazing.

priate safety and health practices and determine the applica-

3.1.2 stress-crack failure, n—for purposes of this test

bility of regulatory limitations prior to use.

method, any crack visible to an observer with normal eyesight

4

NOTE 1—There is no similar or equivalent ISO standard.

shall be interpreted as a failure of the entire specimen (1).

Extension of the controlled imperfection shall not be construed

2. Referenced Documents

as a failure. The appearance of more than one crack in a single

2

2.1 ASTM Standards:

specimen shall be construed as a single failure.

D 618 Practice for Conditioning Plastics for Testing

3.1.2.1 Discussion—Cracks generally develop at the con-

D 883 Terminology Relating to Plastics

trolled imperfection and run to the outer edge of the specimen

D 1204 Test Method for Linear Dimensional Changes of

approximately at right angles to it (2). The cracks need not

Nonrigid Thermoplastic Sheeting or Film at Elevated

extend completely through the specimen to constitute failure.

Temperature

Cracks sometimes develop under the polymer surface, mani-

D 1248 SpecificationforPolyethylenePlasticsMoldingand

festing themselves as depressions on the surface. The time

Extrusion Materials

when this occurs should be noted, and if the depression later

D 3350 Specification for Polyethylene Plastics Pipe and

develops into a crack, the time of dimpling should be consid-

Fittings Materials

ered as the failure time.

D 4703 Practice for Compression Molded Thermoplastic

Materials into Test Specimens, Plaques, or Sheets 4. Summary of Test Method

D 4976 SpecificationforPolyethylenePlasticsMoldingand

4.1 Bent specimens of the plastic, each having a controlled

Extrusion Materials

imperfection on one surface, are exposed to the action of a

E 691 Practice for Conducting an Interlaboratory Study to

surface-active agent. The proportion of the total number of

Determine the Precision of a Test Method

specimens that crack in a given time is observed.

5. Significance and Use

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

5.1 This test method may be used for routine inspection

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi-

als. purposes by subjecting a required number of specimens to the

Current edition approved August 15, 2005. Published August 2005. Originally

approved in 1959. Last previous edition approved in 2001 as D 1693 - 01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Detail drawings of the apparatus are available from ASTM Headquarters.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Request ADJD169301, ADJD169302, ADJD169303, and ADJD169304.

4

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this test method.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.