ASTM D543-21

(Practice)Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents

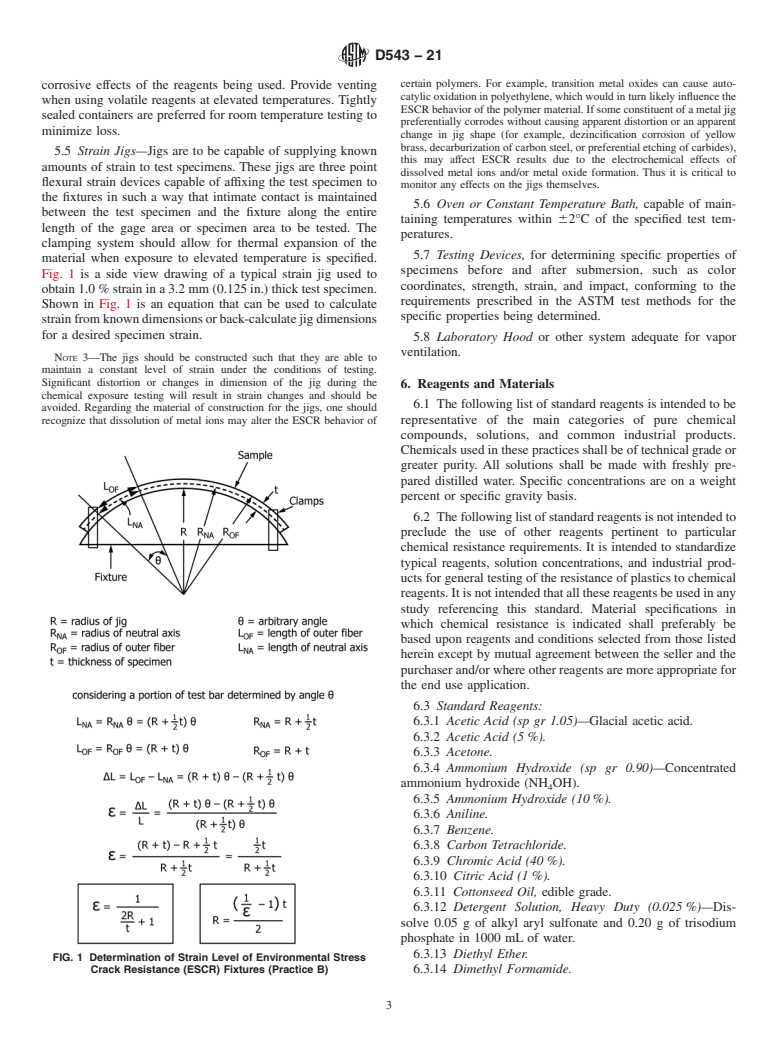

Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents

SIGNIFICANCE AND USE

4.1 There are limitations of the results obtained from these practices. The choice of types and concentrations of reagents, duration of immersion or stress, or both, level of stress, temperature of the test, and properties to be reported are necessarily arbitrary. The specification of these conditions provides a basis for standardization and serves as a guide to investigators wishing to compare the relative resistance of various plastics to chemical reagents.

4.2 Correlation of test results with the actual performance or serviceability of plastics is necessarily dependent upon the similarity between the testing and the end-use conditions. For applications involving continuous immersion, the data obtained in short-time tests are of interest only in eliminating the most unsuitable materials or indicating a probable relative order of resistance to chemical reagents.

4.3 Evaluation of plastics for special applications involving corrosive conditions shall be based upon the particular reagents and concentrations to be encountered. Base the selection of test conditions on the manner and duration of contact with reagents, the temperature of the system, applied stress, and other performance factors involved in the particular application.

4.4 The practices present general guidelines without covering specifics on all the varied applications of plastics, such as use in automobiles and exposure to various automotive fluids, or use in hospital environments with exposure to disinfectants and cleaning fluids. These practices can be extended to such applications with specifics on the study conducted noted in the report.

4.5 The use of appropriate controls is critical to evaluate the utility of the information generated by these practices. Particular attention should be given to the variability in the data generated, especially for the baseline controls, and issues in data generation reported to mitigate misuse of information.

SCOPE

1.1 These practices cover the evaluation of all plastic materials including cast, hot-molded, cold-molded, laminated resinous products, and sheet materials for resistance to chemical reagents.

1.2 Three procedures are presented, two under practice A (Immersion Test), and one under practice B (Mechanical Stress and Reagent Exposure under Standardized Conditions of Applied Strain). These practices include provisions for reporting changes in weight, dimensions, appearance, color, strength, and other mechanical properties. Standard reagents are specified to establish results on a comparable basis without precluding the use of other chemical reagents pertinent to specific chemical resistance requirements. Provisions are made for various exposure times, stress conditions, and exposure to reagents at elevated temperatures. The type of conditioning (immersion or wet patch/wipe method) depends upon the end-use of the material. If the material is used as a container or transfer line, immersion of the specimens is used. If the material will only see short exposures or will be used in proximity and reagent will splash or spill on the material, the wet patch or wipe method of applying reagent to the material is used.

Note 1: Practice B for evaluating environmental stress cracking resistance differs from Practice D7474, which seeks to measure residual stresses in molded sulfone plastic parts with the use of calibrated chemical reagents. Practice B differs from Test Method D1693, which seeks to quantify the susceptibility of ethylene plastics to environmental stress-cracking subjected to specific conditions, by measuring the proportion of specimens that crack in a given time.

1.3 The effect of chemical reagents on properties shall be determined by making measurements on standard specimens for such tests before and after immersion or stress, or both, if so tested.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for infor...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D543 − 21

Standard Practices for

Evaluating the Resistance of Plastics to Chemical

1

Reagents

This standard is issued under the fixed designation D543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

1.1 These practices cover the evaluation of all plastic

only.

materials including cast, hot-molded, cold-molded, laminated

1.5 This standard does not purport to address all of the

resinous products, and sheet materials for resistance to chemi-

safety concerns, if any, associated with its use. It is the

cal reagents.

responsibility of the user of this standard to establish appro-

1.2 Three procedures are presented, two under practice A

priate safety, health, and environmental practices and deter-

(ImmersionTest), and one under practice B (Mechanical Stress

mine the applicability of regulatory limitations prior to use.

and Reagent Exposure under Standardized Conditions of

Specific hazards statements are given in Section 7.

Applied Strain). These practices include provisions for report-

NOTE 2—ISO 175 and ISO 22088 Part 3 address the same subject

ingchangesinweight,dimensions,appearance,color,strength,

matter as PracticesAand B of this standard, but differ in technical content

and other mechanical properties. Standard reagents are speci-

and the results cannot be directly compared.

fied to establish results on a comparable basis without preclud-

1.6 This international standard was developed in accor-

ing the use of other chemical reagents pertinent to specific

dance with internationally recognized principles on standard-

chemical resistance requirements. Provisions are made for

ization established in the Decision on Principles for the

various exposure times, stress conditions, and exposure to

Development of International Standards, Guides and Recom-

reagents at elevated temperatures. The type of conditioning

mendations issued by the World Trade Organization Technical

(immersion or wet patch/wipe method) depends upon the

Barriers to Trade (TBT) Committee.

end-use of the material. If the material is used as a container or

transfer line, immersion of the specimens is used. If the

2. Referenced Documents

material will only see short exposures or will be used in 2

2.1 ASTM Standards:

proximity and reagent will splash or spill on the material, the

D13 Specification for Spirits of Turpentine

wet patch or wipe method of applying reagent to the material

D396 Specification for Fuel Oils

is used.

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

NOTE 1—Practice B for evaluating environmental stress cracking

resistance differs from Practice D7474, which seeks to measure residual D1040 Specification for Uninhibited Mineral Insulating Oil

stressesinmoldedsulfoneplasticpartswiththeuseofcalibratedchemical

for Use in Transformers and in Oil Circuit Breakers

3

reagents. Practice B differs from Test Method D1693, which seeks to

(Withdrawn 1980)

quantify the susceptibility of ethylene plastics to environmental stress-

D1693 Test Method for Environmental Stress-Cracking of

cracking subjected to specific conditions, by measuring the proportion of

Ethylene Plastics

specimens that crack in a given time.

D2244 Practice for Calculation of Color Tolerances and

1.3 The effect of chemical reagents on properties shall be

Color Differences from Instrumentally Measured Color

determined by making measurements on standard specimens

Coordinates

for such tests before and after immersion or stress, or both, if

D5947 Test Methods for Physical Dimensions of Solid

so tested.

Plastics Specimens

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

These practices are under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and are the direct responsibility of Subcommittee D20.50 on Durability of Plastics. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2021. Published December 2021. Originally the ASTM website.

3

approved in 1939. Last previous edition approved in 2020 as D543 - 20. DOI: The last approved version of this historical standard is referenced on

10.1520/D0543-21. www

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D543 − 20 D543 − 21

Standard Practices for

Evaluating the Resistance of Plastics to Chemical

1

Reagents

This standard is issued under the fixed designation D543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 These practices cover the evaluation of all plastic materials including cast, hot-molded, cold-molded, laminated resinous

products, and sheet materials for resistance to chemical reagents.

1.2 Three procedures are presented, two under practice A (Immersion Test), and one under practice B (Mechanical Stress and

Reagent Exposure under Standardized Conditions of Applied Strain). These practices include provisions for reporting changes in

weight, dimensions, appearance, color, strength, and other mechanical properties. Standard reagents are specified to establish

results on a comparable basis without precluding the use of other chemical reagents pertinent to specific chemical resistance

requirements. Provisions are made for various exposure times, stress conditions, and exposure to reagents at elevated temperatures.

The type of conditioning (immersion or wet patch) patch/wipe method) depends upon the end-use of the material. If the material

is used as a container or transfer line, immersion of the specimens is used. If the material will only see short exposures or will be

used in proximity and reagent will splash or spill on the material, the wet patch or wipe method of applying reagent to the material

is used.

NOTE 1—Practice B for evaluating environmental stress cracking resistance differs from Practice D7474, which seeks to measure residual stresses in

molded sulfone plastic parts with the use of calibrated chemical reagents. Practice B differs from Test Method D1693, which seeks to quantify the

susceptibility of ethylene plastics to environmental stress-cracking subjected to specific conditions, by measuring the proportion of specimens that crack

in a given time.

1.3 The effect of chemical reagents on properties shall be determined by making measurements on standard specimens for such

tests before and after immersion or stress, or both, if so tested.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific hazards statements are given in Section 7.

NOTE 2—ISO 175 and ISO 22088 Part 3 address the same subject matter as Practices A and B of this standard, but differ in technical content and the results

cannot be directly compared.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

These practices are under the jurisdiction of ASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.50 on Durability of Plastics.

Current edition approved Feb. 1, 2020Dec. 1, 2021. Published March 2020December 2021. Originally approved in 1939. Last previous edition approved in 20142020 as

D543 - 14.D543 - 20. DOI: 10.1520/D0543-20.10.1520/D0543-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D543 − 21

2. Referenced Documents

2

2.1 ASTM Standards:

D13 Specification for Spirits of Turpentine

D396 Specification for Fuel Oils

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1040 Specification for Uninhibited Mineral Insulating Oil for Use in Transformers and in Oil Circuit Breakers (Withdrawn

3

1980)

D1693 Test Method for Environmental Stress-Cracking of Ethylene Plastics

D2244 Practice for Calculation of Color Tolerances and Color Diffe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.