ASTM D4689-99

(Specification)Standard Specification for Adhesive, Casein-Type

Standard Specification for Adhesive, Casein-Type

SCOPE

1.1 This specification covers casein and other protein-blend adhesives for use adhering wood to wood. The adhesive type covered by this specification is a dry powder or granular product comprising a mixture of casein, or casein and other protein source, with the necessary dry chemicals to effect solution when the mixture is added to water. Note 1-Although the term casein adhesive is used throughout this specification, historically, the adhesive subclass described in 1.1 has been known as casein glue. See Terminology D907, adhesive types .

1.2 Limitations -Cooked casein adhesives are not covered by this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Sections 8 through 16, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4689 – 99

Standard Specification for

Adhesive, Casein-Type

This standard is issued under the fixed designation D 4689; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 5266 Practice for Estimating the Percentage of Wood

Failure in Adhesive Bonded Joints

1.1 This specification covers casein and other protein-blend

E 104 Practice for Maintaining Constant Relative Humidity

adhesives for use adhering wood to wood. The adhesive type

by Means of Aqueous Solutions

covered by this specification is a dry powder or granular

2.2 Other Standards:

product comprising a mixture of casein, or casein and other

MIL-STD-129—Marking for Shipment and Storage

protein source, with the necessary dry chemicals to effect

FED-STD-123—Marking for Shipment

solution when the mixture is added to water.

PPP-C-96—Cans, Metal, 28 Gage and Lighter

NOTE 1—Although the term casein adhesive is used throughout this

PPP-D-723—Drums, Fiber

specification, historically, the adhesive subclass described in 1.1 has been

PPP-D-729—Drums, Shipping and Storage, Steel, 55 Gal

known as casein glue. See Terminology D 907, adhesive types.

(208 L)

1.2 Limitations—Cooked casein adhesives are not covered

3. Terminology

by this specification.

1.3 The values stated in inch-pound units are to be regarded

3.1 Definitions—Many terms in this specification are de-

as the standard.

fined in Terminology D 907.

1.4 The following safety hazards caveat pertains only to the

3.2 Definitions of Terms Specific to This Standard:

test method portion, Sections 8 through 16, of this specifica-

3.2.1 adhesive designation, n—an adhesive that is manufac-

tion: This standard does not purport to address all of the safety

tured by a unique combination of raw materials and manufac-

concerns, if any, associated with its use. It is the responsibility

turing process that conforms to a given set of physical and

of the user of this standard to establish appropriate safety and

performance properties and is identified by a specific name,

health practices and determine the applicability of regulatory

number, or alphanumeric designation.

limitations prior to use.

3.2.2 lot, n—adhesive manufactured at one place from the

same batch or blends of raw materials subjected to the same

2. Referenced Documents

operation and conditions.

2.1 ASTM Standards:

NOTE 2—In this specification, the maple block lamination in Test

D 899 Test Method for Applied Weight per Unit Area of

Method D 905 and the birch plywood construction in Test Method D 906

Liquid Adhesive

are described as assemblies.

D 905 Test Method for Strength Properties of Adhesive

Bonds in Shear by Compression Loading

4. Significance and Use

D 906 Test Method for Strength Properties of Adhesives in

4.1 Thisspecificationprovidestestingproceduresandspeci-

Plywood Type Construction in Shear by Tension Loading

fies requirements to differentiate the physical, adhesive, and

D 907 Terminology of Adhesives

durability properties of commercially available casein and

D 1084 Test Methods for Viscosity of Adhesives

casein-protein adhesives. The two classes are defined by water

D 2556 Test Method for Apparent Viscosity of Adhesives

resistance. Selection of class is left to the choice of the product

Having Shear-Rate-Dependent Flow Properties

manufacturer and the consumer, based on measures used by

each to protect the bond line from moisture degradation.

NOTE 3—Because of strict EPA requirements as to disposal of waste

This specification is under the jurisdiction of ASTM Committee D-14 on

Adhesives and is the direct responsibility of Subcommittee D 14.30 on Wood

Adhesives.

Current edition approved April 10, 1999. Published June 1999. Originally Annual Book of ASTM Standards, Vol 11.03.

published as D 4689 – 87. Last previous edition D 4689 – 95a. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 15.06. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4689–99

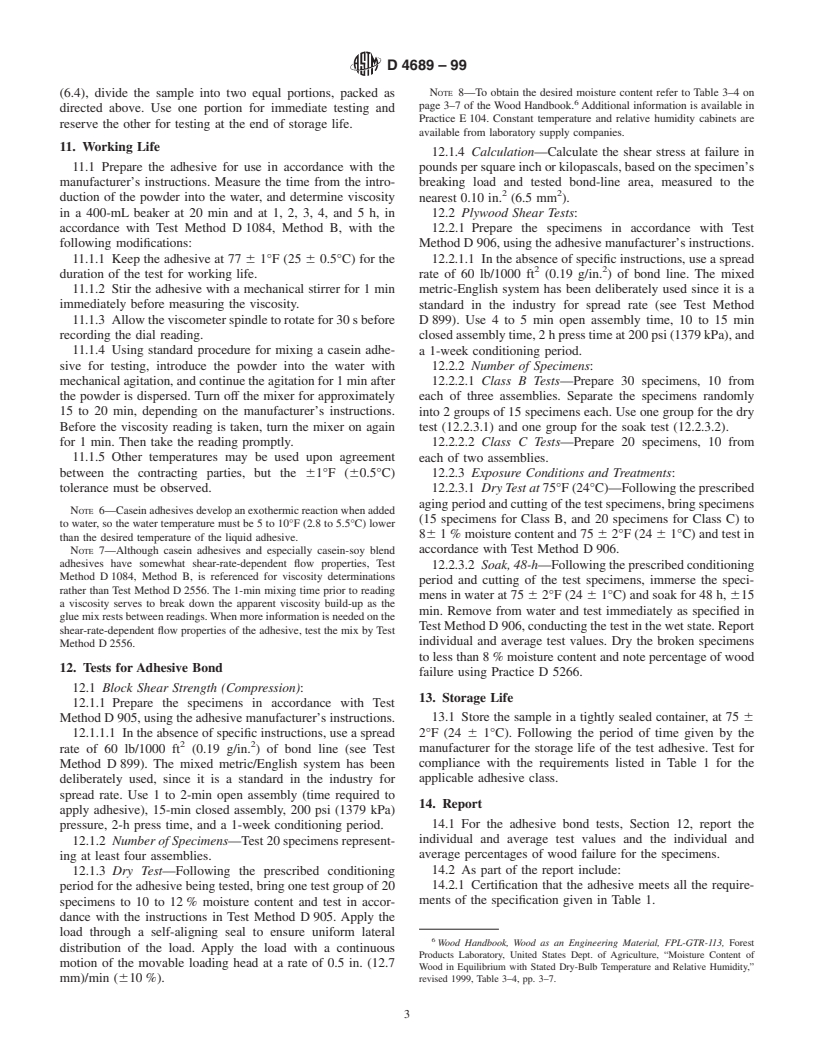

TABLE 1 Test Requirements

Minimum Test Test Required

Test Section Number

Requirement

Class B Class C

Working life 6.1 5 h yes yes

Viscosity at 77 6 0.5°F 6.1 3000 to 15 000 cp yes yes

(256 0.25°C)

Block shear (compression)

Dry at 1 and 4 h 12.1 2800 psi (19 306 kPa) yes yes

Plywood (tension) 12.2 340 psi (2344 kPa) yes yes

A

Dryat1and4h 12.2.3.1

A

Soak, 48-h at 1 and 4 h 12.2.3.2 140 psi (965 kPa) yes no

B

Storage life 14. yes yes

A

One and four hours refers to age of adhesive after mix. See 6.2.1.

B

A lot of the designated adhesive shall be tested for all the required tests after aging for the desired storage life time. The longest shelf life tested which passes all the

minimum requirements shall be the storage life certified by the manufacturer.

from manufacturing and production facilities, it has become necessary for

6.2.1 Two sets of adhesive bond tests are required, one to be

more than a decade to remove biocides from casein adhesives. Paint,

initiated 1 h after mixing the adhesive with water, and one 4 h

varnish, and restrictive exposure conditions are protective measures

after mixing.

commonly employed to protect the bond line against degradation due to

6.3 To meet the storage-life requirements, an initial lot of

mold and moisture.

the adhesive shall be tested following the manufacturer’s

4.2 The stress calculated by this specification should not be

certified storage life, and shall pass all test requirements for the

used to predict failure, nor should it be used directly for design

applicable adhesive classification. Following this initial test,

stress in joints with different geometry or with loading direc-

certification for this requirement shall be based on submission

tion different from the test geometry.

from the manufacturer.

5. Classification

7. Retest and Rejection

5.1 For purposes of this specification, adhesives are classi-

7.1 When a specimen fails at a load less than that specified

fied on the basis of water resistance at two performance levels:

and the wood failure is at least 50 %, that specimen shall be

5.1.1 Class B, Water Resistant—An adhesive passing Class

disregardedincomputingtheaverage.Ifmorethanonethirdof

B test requirements, as listed in Table 1, is capable of

the test specimens for any one test condition are discarded for

producing sufficient adhesive-joint strength and durability and

this reason, the test shall be repeated.

has sufficient water resistance to make the bonded products

7.2 If the results of any initial test do not conform to the

serviceable under conditions in which there will be occasional

requirements prescribed in this specification, that test shall be

intermittent exposure to wet conditions or high humidity.

repeated on an additional set of specimens made from the same

5.1.2 Class C, Dry Use—An adhesive passing Class C test

lot of adhesive, each of which shall conform to the require-

requirements, as listed in Table 1, has sufficient adhesive-joint

ments specified. If this set of specimens fails to meet the

strengthanddurabilityundernormalinteriorserviceconditions

requirements, the lot shall be rejected.

where the relative humidity is not high and does not fluctuate

TEST METHODS

between wide limits.

8. Significance and Use

6. Test Requirements

8.1 This specification provides testing procedures to differ-

6.1 The test adhesives, when tested in accordance with

entiate the physical, adhesive, and durability properties of

Section 11, shall remain in the viscosity range of 3000 to

commercially available casein and casein-protein adhesives.

15 000 cP for a working life of at least 5 h, minimum.

9. Apparatus

NOTE 4—The viscosity requirement covers a 5-h span, although the

“end-of-working-life” adhesive bond strength test is run at 4 h. This

9.1 Mechanical Stirrer or Mixer, capable of speed in air of

apparent conflict is necessary in order to assure that the mixed casein

5000 r/min for the preparation of the adhesive mix.

adhesive is not in a rapidly rising viscosity pattern at the end of the

9.2 Other apparatus required to conduct tests are covered in

working life.

Test Methods D 899, D 905, D 906, D 1084 and D 2556.

6.1.1 The working life shall be timed from the addition of

10. Sampling

the adhesive powder to the water.

6.1.2 The viscosity requirements shall not apply until the

10.1 Take a 5-lb (2.3-kg) representative sample of the

casein has dissolved and the adhesive is ready for use.

adhesive from the lot to be tested. Store samples in airtight

containers and seal. For the initial testing of storage life only

NOTE 5—Unless the manufacturer instructs otherwise, 20 min is the

typical time period required, after the adhesive powder is added to the

water, before the adhesive is ready for use.

Satisfactory mixing may be obtained using the intermediate speed of the

Thomas Three-Speed Stirrer No. 8585-M10 used with the stirring shaft, AHT No.

6.2 To meet the adhesive bond requirements of the specifi-

8633-T10, 9 in. (23 cm) long, and 1.5-in. (38-mm) diameter, four-blade propeller.

cation, the test adhesive shall be subjected to the tests de-

Available from Thomas Scientific, Swedesboro, NJ 08085-0099, and other loca-

scribed in Section 12 and shall meet the requirements listed on

tions. Many other laboratory supply houses can provide this same mixer or its

Table 1. equivalent.

D4689–99

NOTE 8—To obtain the desired moisture content refer to Table 3–4 on

(6.4), divide the sample into two equal portions, packed as

page 3–7 of the Wood Handbook. Additional information is available in

directed above. Use one portion for immediate testing and

Practice E 104. Constant temperature and relative humidity cabinets are

reserve the other for testing at the end of storage life.

available from laboratory supply companies.

11. Working Life

12.1.4 Calculation—Calculate the shear stress at failure in

11.1 Prepare the adhesive for use in accordance with the pounds per square inch or kilopascals, based on the specimen’s

m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.